Hi Ian, just discovered your posts on the refurbishment of your Elliott Omnimill, spectacular job.

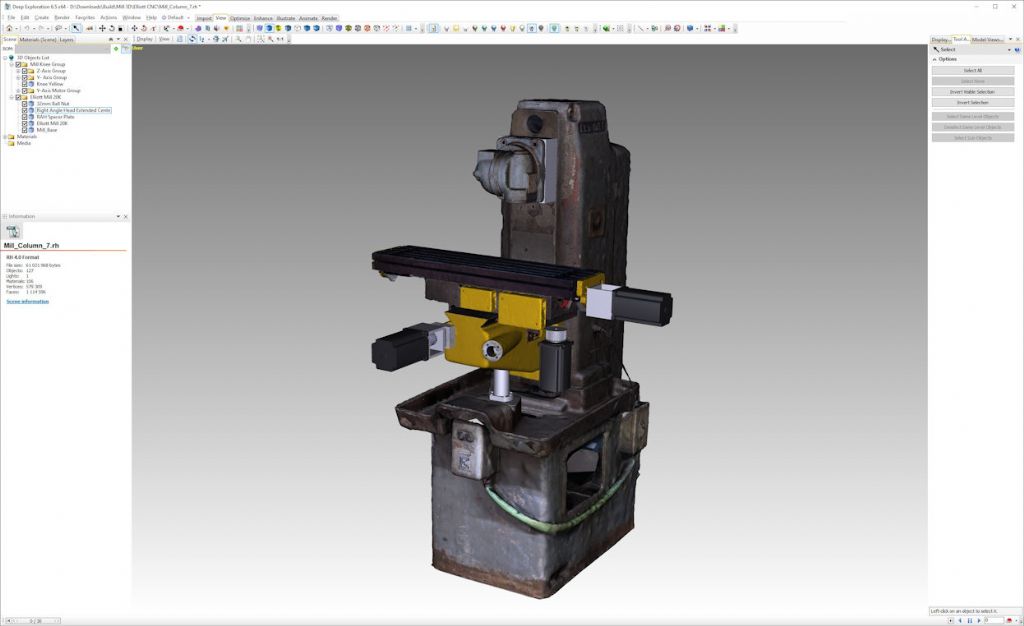

I picked up an Elliott 181 in need of restoration about a year ago and it is going through a full CNC conversion at the moment. I was lucky enough to pick this up with the "double swivel" vertical head.

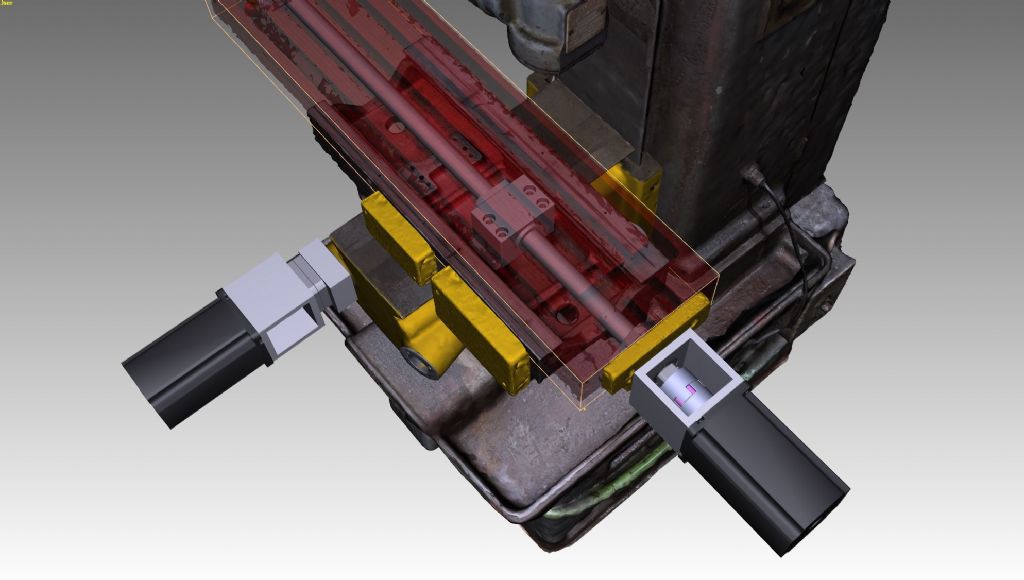

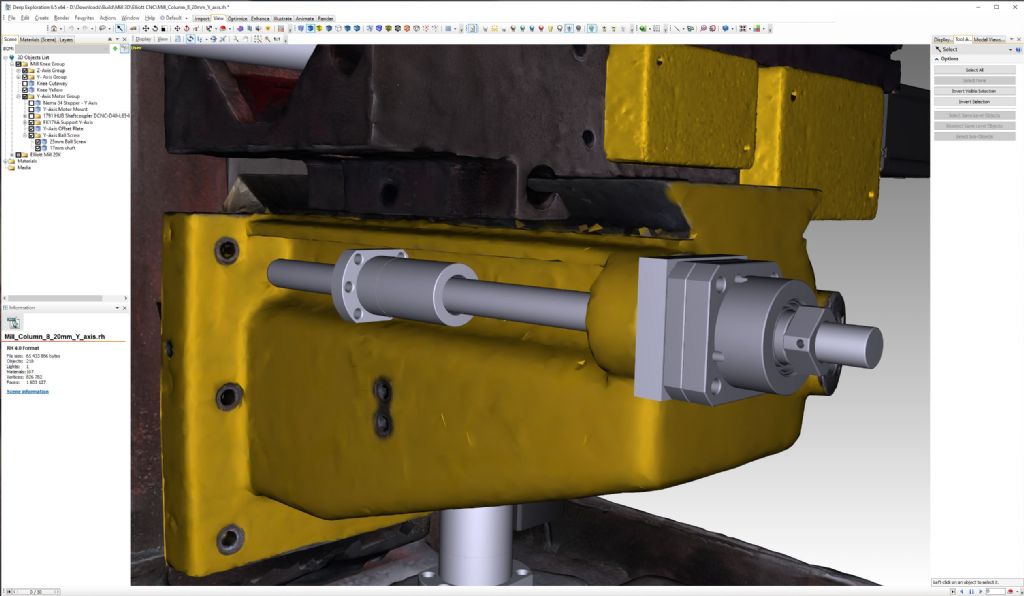

Ball-screws on all axes and stepper motors on all drives. Feed motor can now be deleted completely.

Control system is a Centroid Acorn.

Standard motor on this was a 1.5HP, 3Ph (460V). This will be replaced with a 1.5kW-3ph (220V) so I can run off a single phase supply with an inverter.

To make sure everything was going to fit I scanned (Photogrammetry) the whole mill into my computer and could then "trial" fit everything virtually.

Its still a while away from being finished but felt very inspired by your restoration and now will have to up my game

Wade Beatty.