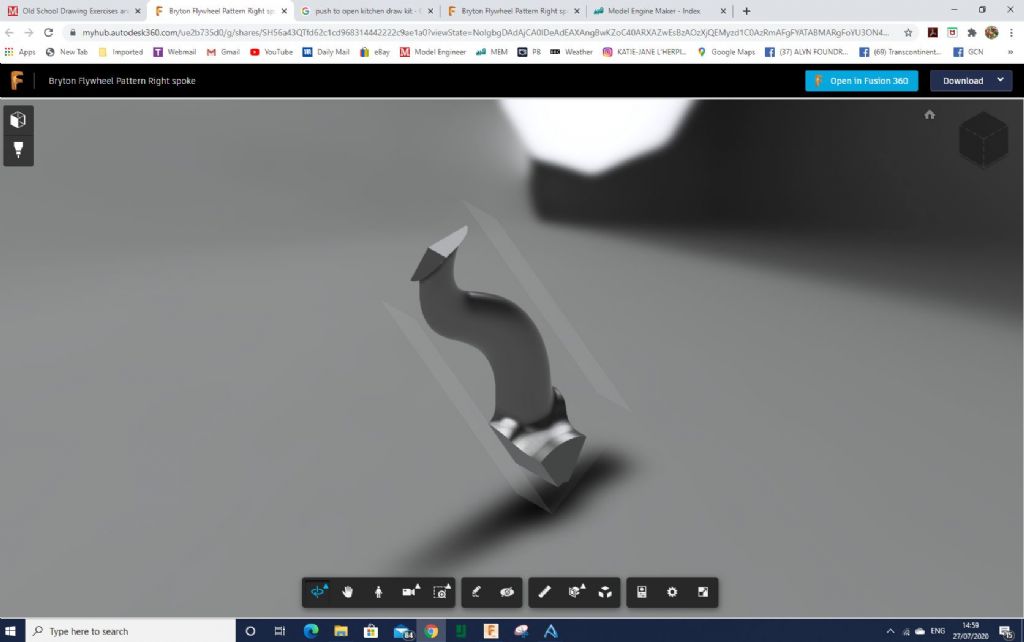

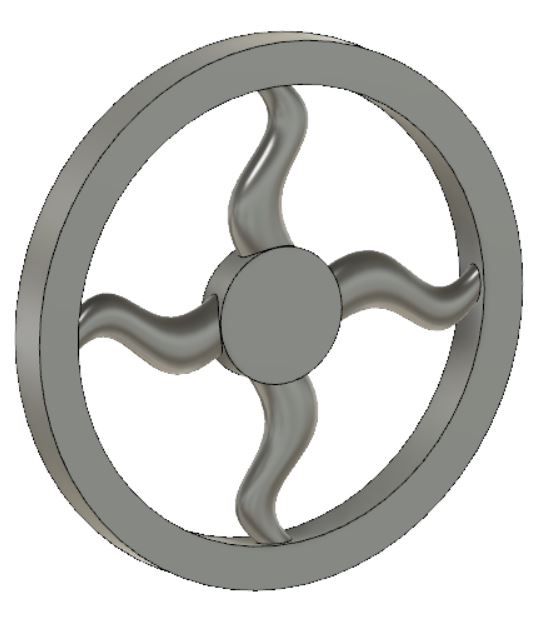

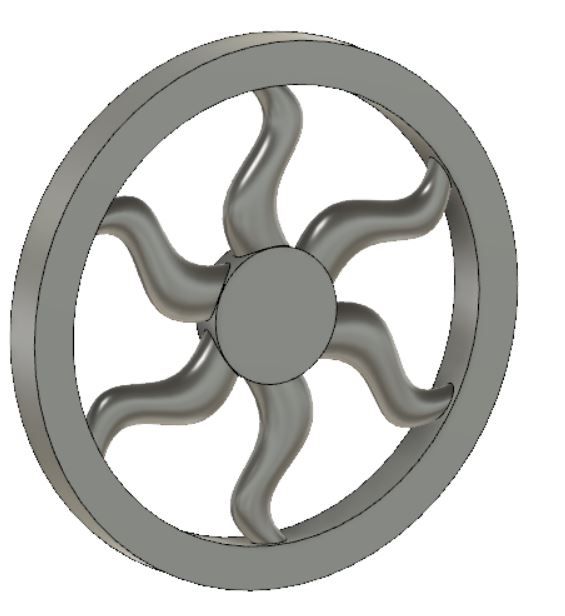

There are some wonderful puzzles and geometry exercises in this thread, such as the multiple Ying-Yang shapes and that lovely sun-spoked flywheel!

.

Everyone else here has learnt alone to be a very skilled creator of 3C CAD models in order to make things from their projected drawings – by conventional or CAM methods.

I have learnt TurboCAD to a basic but useful level; but not touched it for some months now, nor indeed tried to re-assemble my prematurely-dismantled drawing-board.

Learning's diminishing-returns law means I can identify my natural limit for CAD as essentially just accelerating my drawing on paper, but least CAD doesn't cover the place in eraser "swarf".

I failed with Fusion 360, Alibre and SolidEdge CE; but have up-dated my copy of TurboCAD, which has three advantages for me:

– 1) Honest, single purchase, very reasonable up-front price; no sneaky "subscriptions" months later.

– 2) A CD-mounted, pdf. introductory manual, not a wretched video of a professional user showing off.

– 3) Direct 2D/3D option switch – with a very important proviso that you cannot switch in mid-drawing.

(Apparently that option does catch beginners, because it is horribly easy to switch mode by mistake, producing irreversible difficulties.)

Its main disadvantage is an appallingly weak, incoherent, on-line "Help" manual with no real index, very hard to search for what turn out at best, only prompts for expert users.

'

My main project, a 4-inch scale steam-wagon I should have completed years ago, has no drawings. I have only some photocopies of 1908-dated advertising material with photos of the prototypes, of which no two were exactly alike. I wanted CAD to help me design the remaining parts; but unable to use it to its best, I use it less and less often; and then orthographically because my 3D attempts are of no practical use.

It is easier to use the vehicle itself as its own "drawing" – measuring the metalwork so far, to make rough pencil sketches of the next bits; but still keep having to modify or replace parts made months – even years- previously!

.

I still admire the skills of those able to draw to the standard illustrated on this thread, or published in the magazines' construction series – I just wish I could do it too!

Alyn Foundry.

![20200726_132503[1].jpg 20200726_132503[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/871889.jpg)

![20200727_122720[1].jpg 20200727_122720[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/872026.jpg)