Posted by John Smith 47 on 05/10/2021 22:22:03:

…

The more research I do, the clearer it becomes …

Not from where I'm sat! In software jargon, I fear you've become entangled in anti-patterns. Candidates are: Analysis Paralysis, Bicycle Shed, Over-engineering, Scope Creep, Accidental Complexity, Golden Hammer, Silver Bullet, and Wishful Thinking.

I short I see John has requirement conflicts that cannot be satisfied.

- Small Size

- Low Cost

- High Capability

- General Purpose

- Hobby versus Commercial

I suggest the problem isn't selecting tools, it's sorting out the requirement conflict. Requirements are important. Most obviously in this example, there isn't a small, cheap, high capability milling machine available. High-capability machines tend to hold their prices unless worn-out or damaged, in which case they aren't high-capability. Small, affordable mills are aimed squarely at genteel modelling – HO railways and so forth.

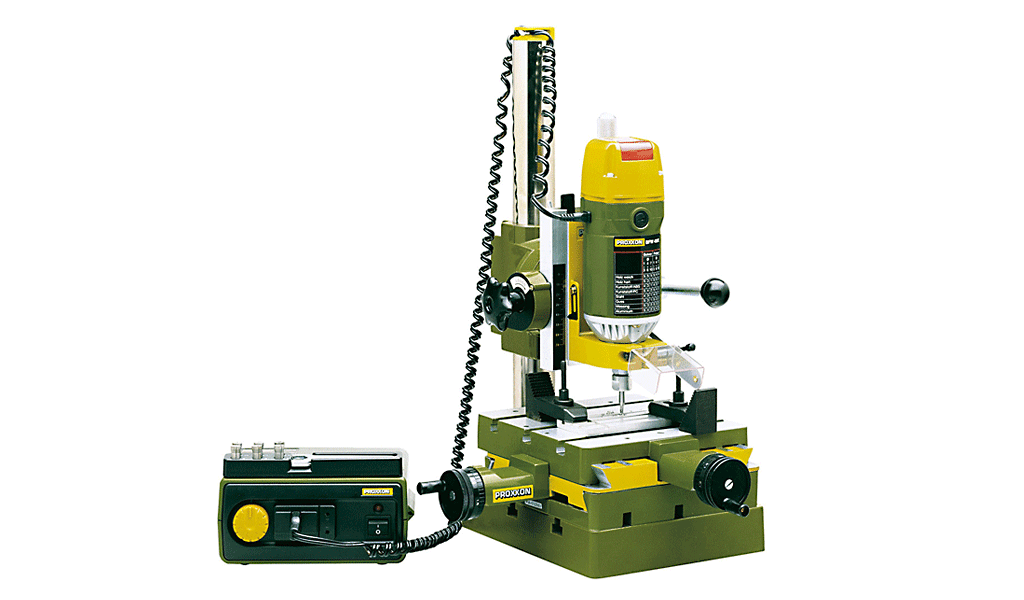

I suggest the most suspicious requirement is 'high-capability'. Stop looking for a Golden Hammer! Dump that, and a number of small machines become acceptable. Chinese, Proxxon, whatever, they will all do the job provided they're operated within their shortcomings. The user gets the job done by applying skill and patience rather than relying on the machine.

Compromise is almost universal on the forum. I don't know of any hobbyist rich enough to buy the best possible equipment: our budgets limit us to Far Eastern hobby machines and older second-hand gear, mostly manual. Even though they do all we need and much more, no hobbyist owns an 11-axis machine centre.

The Hobby versus Commercial issue also needs attention. If the goal is a commercial product, it's worth investing in. Development is a team game: lone inventors rarely succeed. Take advice. Pay someone else to make prototype parts: you do the design, they make it. Or raise the money to buy or hire the equipment and space needed. If the goal is commercial, different rules apply. Time is of the essence because someone else may be working on the same idea: first one to patent it wins. (Have you checked the idea isn't already patented?) Sell the car, mortgage the house, sell shares in the City, find a partner, put daughters on the street etc.

And once the item is in production marketing is even more a team sport than manufacture. James Watt found this: not enough to be a technical genius – his success only came after partnering with Matthew Boulton who knew how to organise, finance, and sell stuff.

Is the object to buy the best possible small mill at the lowest price for future fun, or is it to make a prototype? If the latter, compromise on the requirements or raise the cash. Be ruthless if the goal is a commercial product. Strict intellectual honesty is necessary because emotion badly fogs the issues. Worth writing a Business Case if not done already: working out how to make stuff is only one factor, and it's often the least difficult. Forcing oneself to think through all the risks and issues is always valuable, especially when setting priorities.

Metalwork for business is much harder than metalwork for fun. Don't assume they're the same!

Dave

John Smith 47.

>**LINK**

>**LINK**