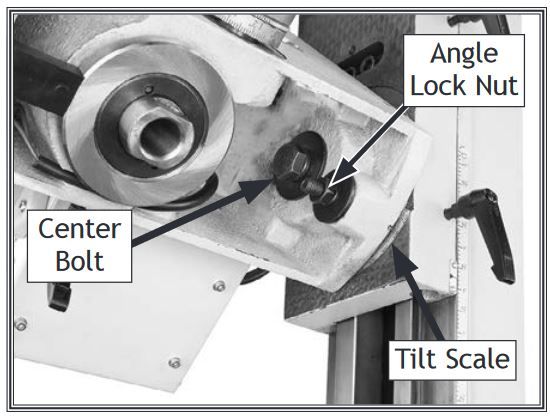

Not sure why the head should stick at 45 degrees. Some photos would be good. My similar mill has two bolts controlling head angle, and the pull knob disengages a detent to stop it flopping over when the nuts are are slackened. (Pic from a Grizzly Manual; they're often better than ours, even if they can't spell centre!)

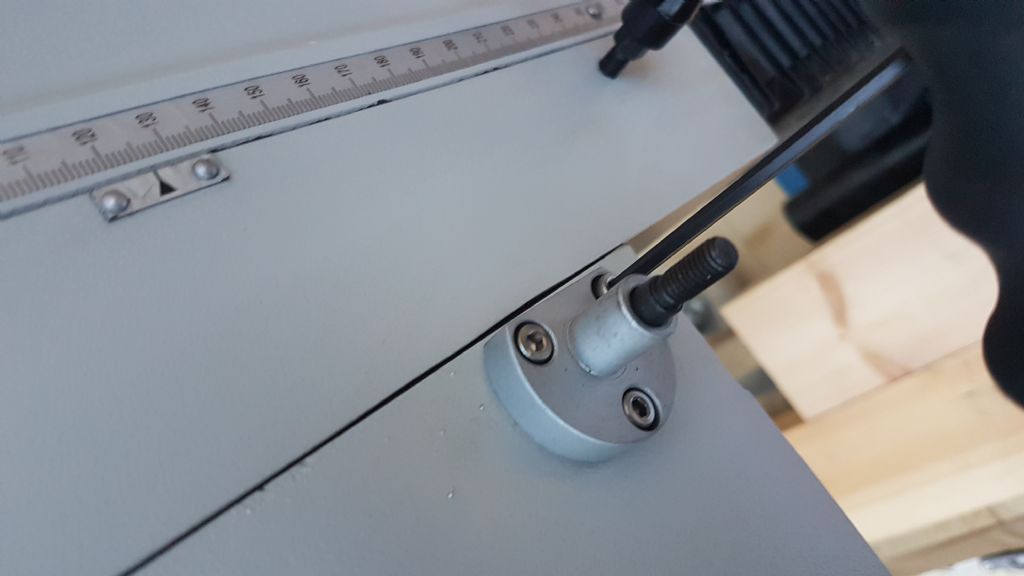

The top bolt is the axle, the lower nut is to lock the head at the wanted angle. Normally both are done up tight. To move the head, the top bolt is slackened slightly then the lower – not much, just enough to allow movement. Once those two are slackened pulling the knob allows the head to swivel. It's heavy – be careful to keep it under control.

Good news is the mechanism is simple – there's not much to go wrong. How loose is the head? Possibly it's tilted forward on the axle and wedged. It may need to be lifted and pushed backwards while the nuts are retightened. Perhaps a two man job, one lifting while the other removes excess slack on the nuts.

Wish you'd asked on the Forum before mioving the head. We'd have advisedyou not to touch it without good cause! The reason is 99% of the time, a milling head should be vertical to the best possible accuracy, 'tramming'. Not done roughly with a scale or a set-square, a DTI is used to get it right within about 0.007%. Keeping the head spot on and whilst nipping up the locks is 'fun'. On these simple machines it's usually better to angle the work than to tilt the head.

Sorry if this is unwelcome advice, but I recommend not taking new machines apart and inspecting them. It can cause a lot of bother unless one is familiar with machines already. Better and safer to test machines by cutting metal and judging the results. Cutting errors are more revealing than eyeballing the machine or attempting precision measurements. Dismantling and measuring to isolate and fix actual issues is one thing, accidently making trouble whilst exploring is to be avoided!

Dave

Iain Downs.