Gents,

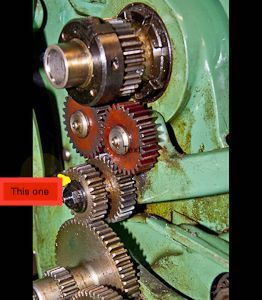

After reading Brian Woods book on the 33t and 34T threading possibilities for the Myford S7 I made the drop arm required to lower the banjo slightly and set up to cut a thread. Work piece was supported by a half dead center.

I had a go at an M10 x 1.5 and the results were terrible, I couldn't even call it a thread. More like a train wreck. This is what I did. Please let me know if my thinking is on the right track here.

Half nuts left engaged the whole time. I used the "jog" function I have and took a first pass which conformed 1.5mm pitch. I then reversed the machine and dragged the tool over the first thread. This buggered everything up. Was this because of backlash in the gear train? Should I have retracted the tool first, then reversed everything, moved the tool back in and only then taken another pass?

Am I right in assuming that you can't just reverse a gear train set up and expect the tool to pass over the exact same scratches you just made?

Sorry for the silly question, all help is much appreciated,

Mark

Mark Gould 1.