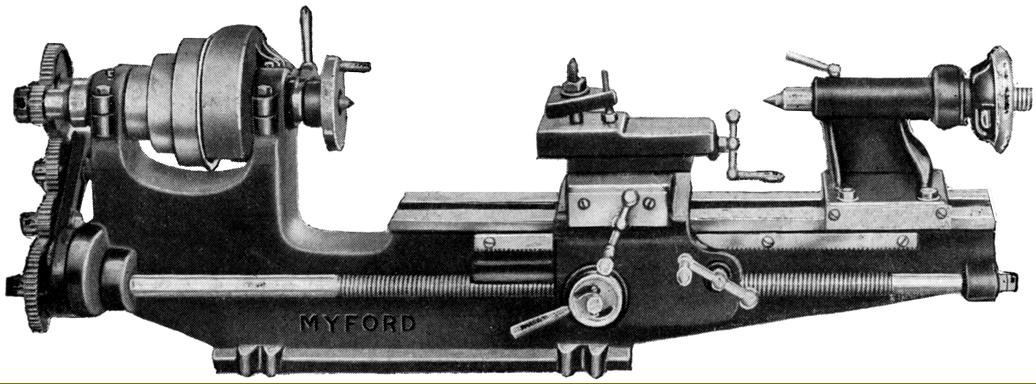

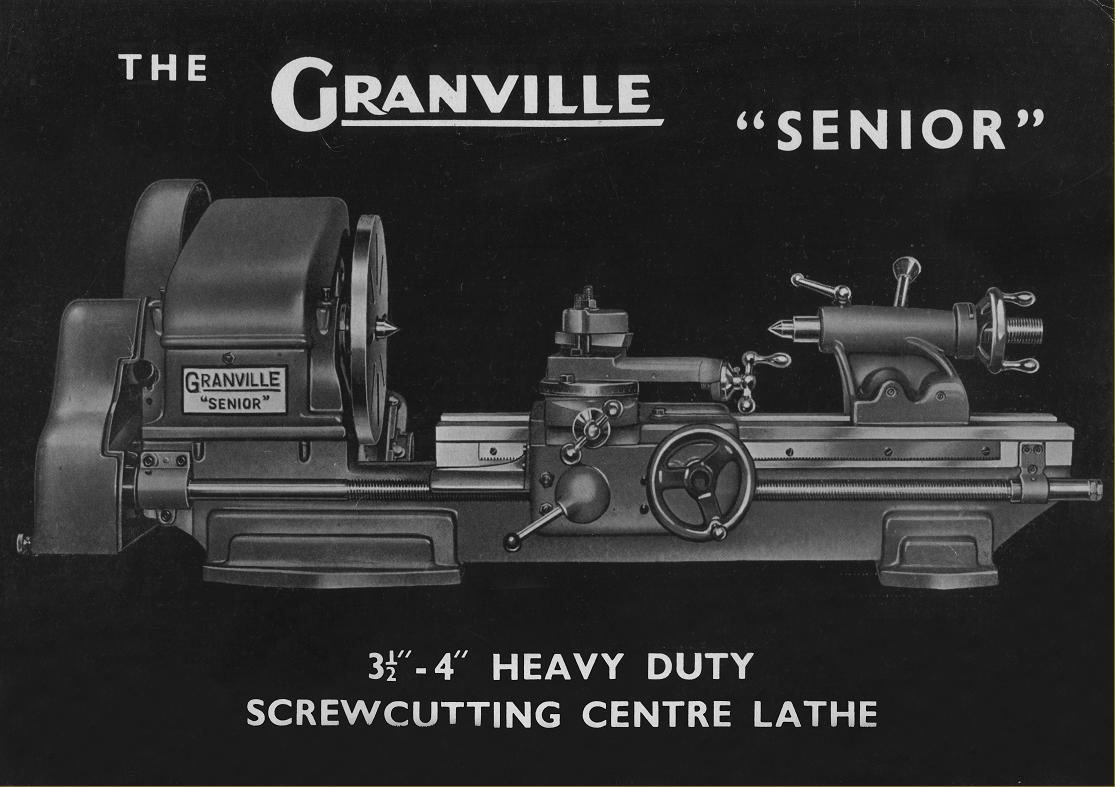

Don't recognise the lathe, so can be of limited help.

If the lathe is British and 70 -80 years old, everything is likely to be Imperial, so metric dimensions will bbe non integer. Better to measure in Inches.

The threads are very likely to be BSW and BSF, possibly with BA used for the gib strip adjusters.

As a completer newbie, you need to buy and study some books, to learn the nomenclature of the parts..

"Basic Lathework" , by Stan Bray, "Lathework" by Harold Hall, "The Amateur's lathe" by L H Sparey, "Lathework" by Neil Wyatt, would all be contenders.

Ian Bradley's "The Amateur's Workshop" might be a useful book to have also.

You should find a set of Zeus Charts very useful (Still using mine from 1948! ).

As you progress, you will find "Model Engineer's handbook" by Tubal cain a useful reference book, since it cover many aspects.

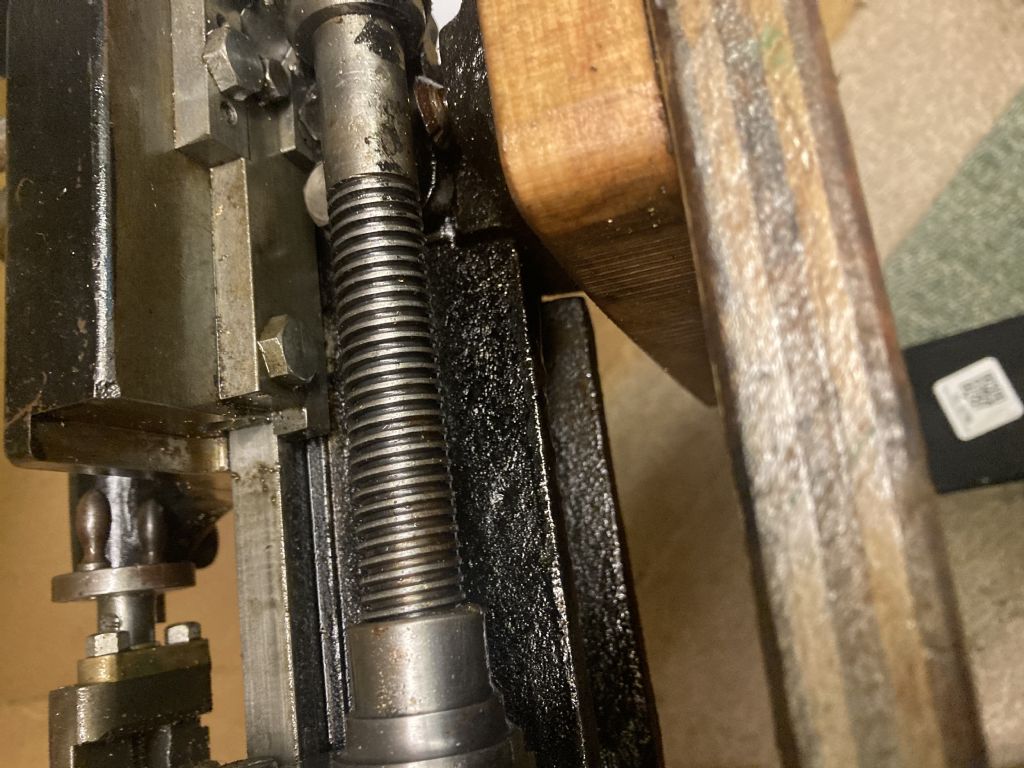

If you have a complete set of changewheels for the lathe, you would find "screwcutting in the lathe" by Martin Cleeve.

Many of these are in the Workshop Practice Series. (One place where you could buy them would be Arc EuroTrade, or some of the other model engineering suppliers )

If you can find a local Model Engineering Society, do joiun it. You will find folk there who can help ypou.

Where are you located?

Maybe someone near could give first hand advice and help. Hnads on denonstration and guidance will be invaluable.

Reading Model Engineering magazines will also help.

Here comes a shameless plug!

The March issue of Model Engineers' Workshop contains part 1 of "Notes for Newbies" which may help you.

(It includes a poor picture naming the variousn parts of a lathe )

Presumably April will contain part 2.

Do not rush. Become familiar with the lathe, and what you can do with it. Once you grasp the most basics, you can learn by just making swarf. Then, you progress to making small tools. Not only will you learn, but they will be useful in the future.

You will need to make extra purchases, such as a digital calliper (As your first piece of measuring equipment ) and a bench grinder to grind High Speed tools. (A lathe of that age will not really be suitable for carbide tools. )

Before too long you will need Drill, and then very probably Taps and Dies (There is a book in the W P S about using those )

You have a very useful and versatile machine. With it you can do MANY things, and you will have many bnhours, years, of pleasure.

H T H

Howard

Howard Lewis.