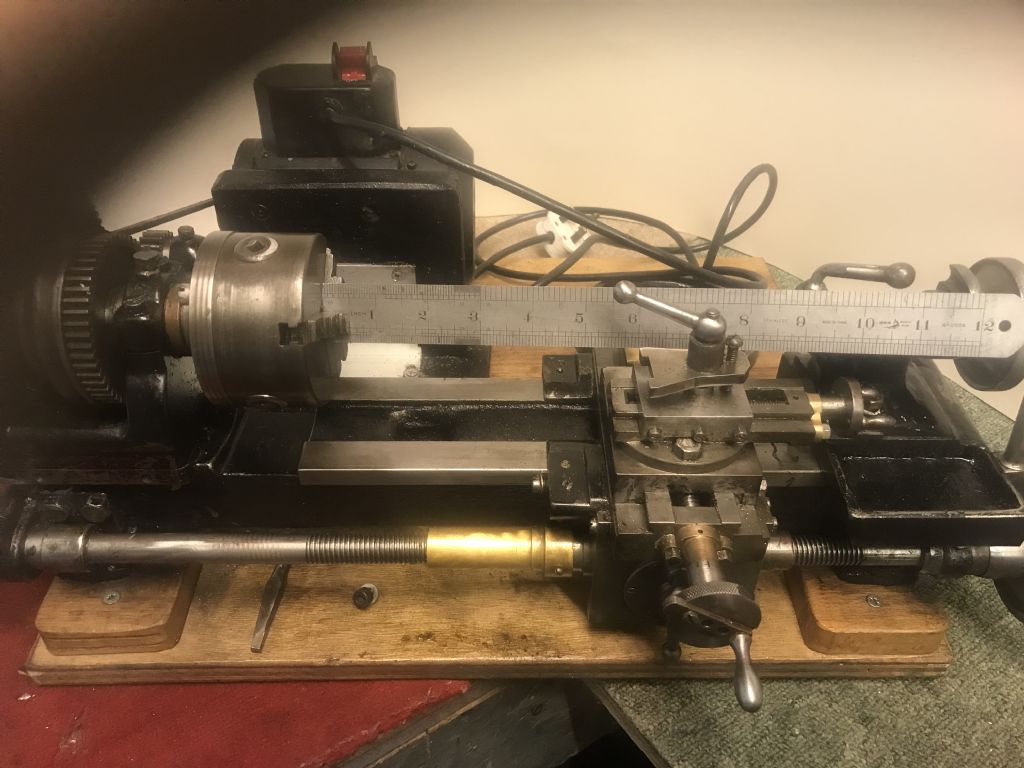

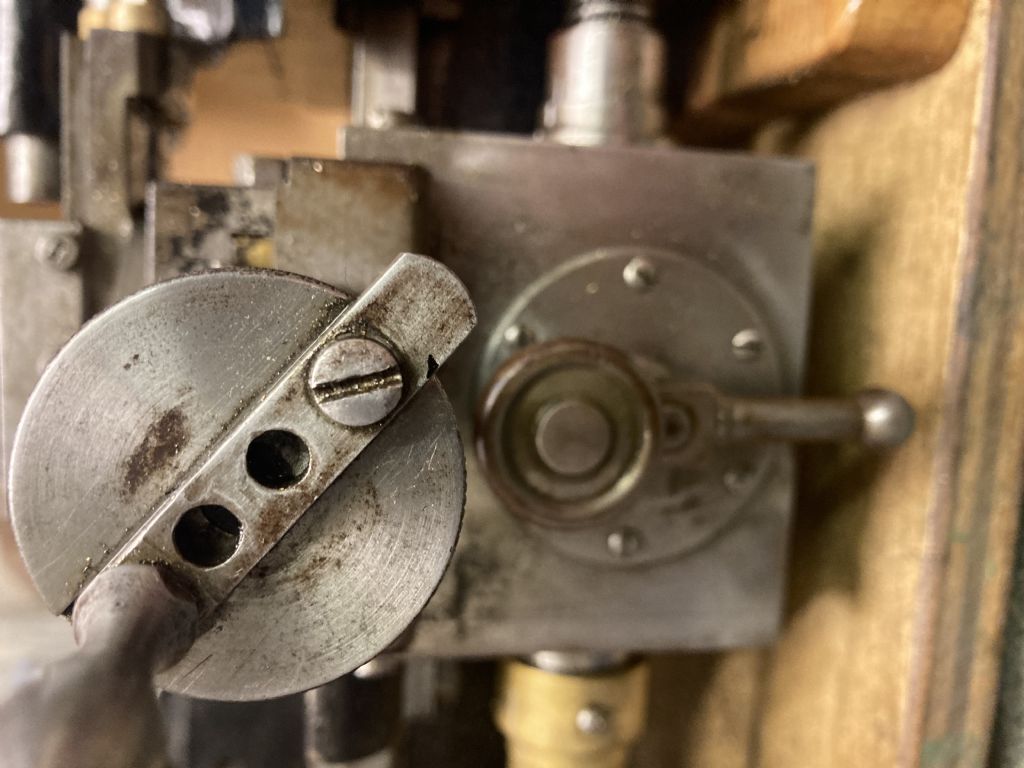

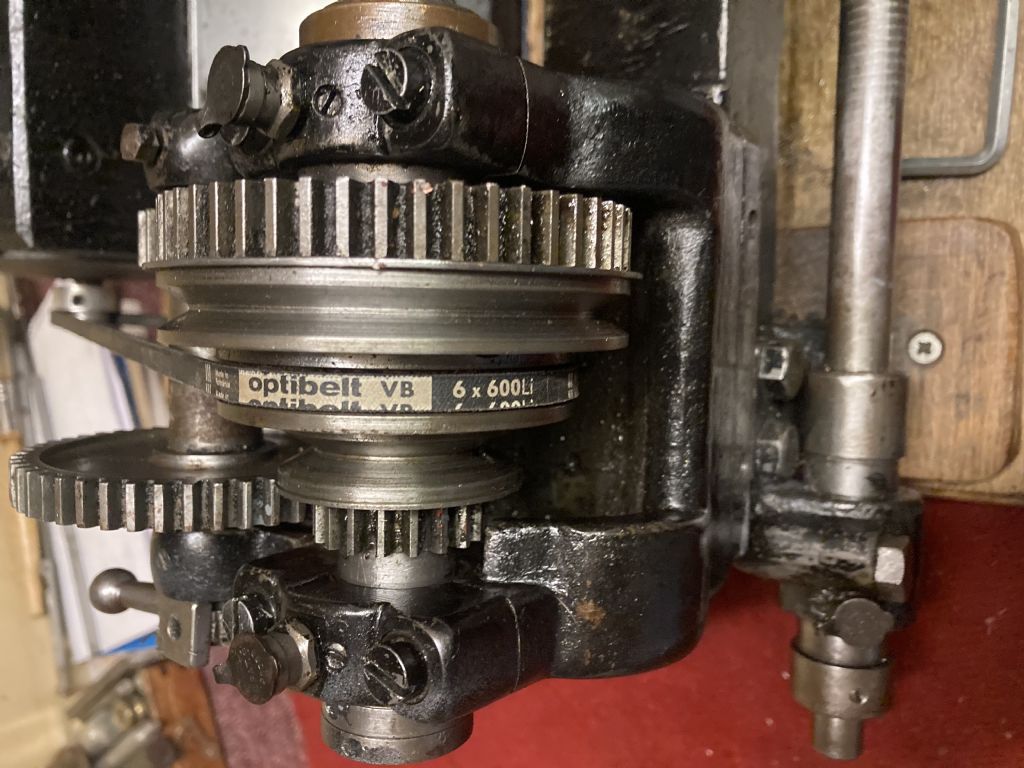

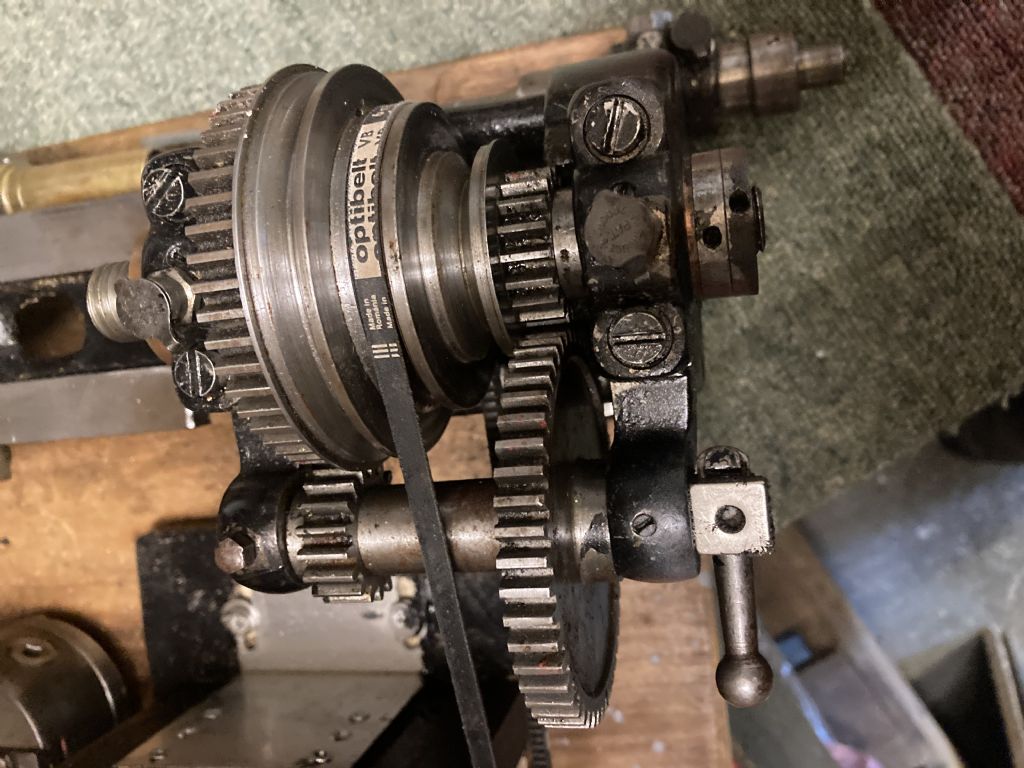

Can anyone help me to identify this lathe please.

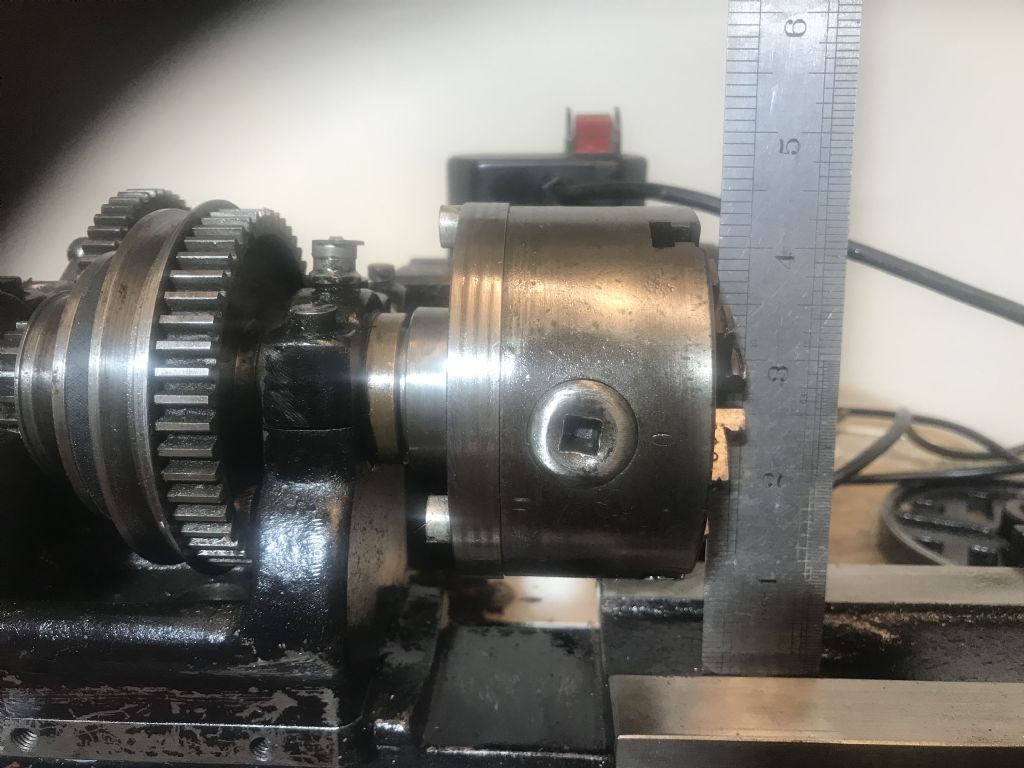

Probably British made, 60/70 years old. I’m told it

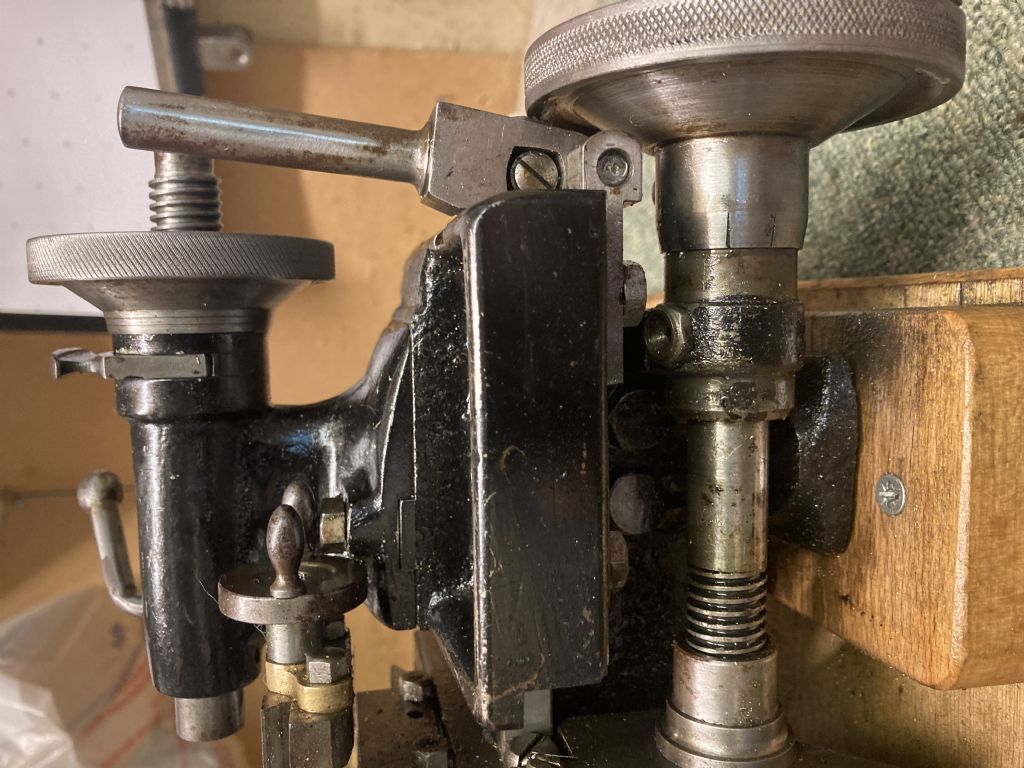

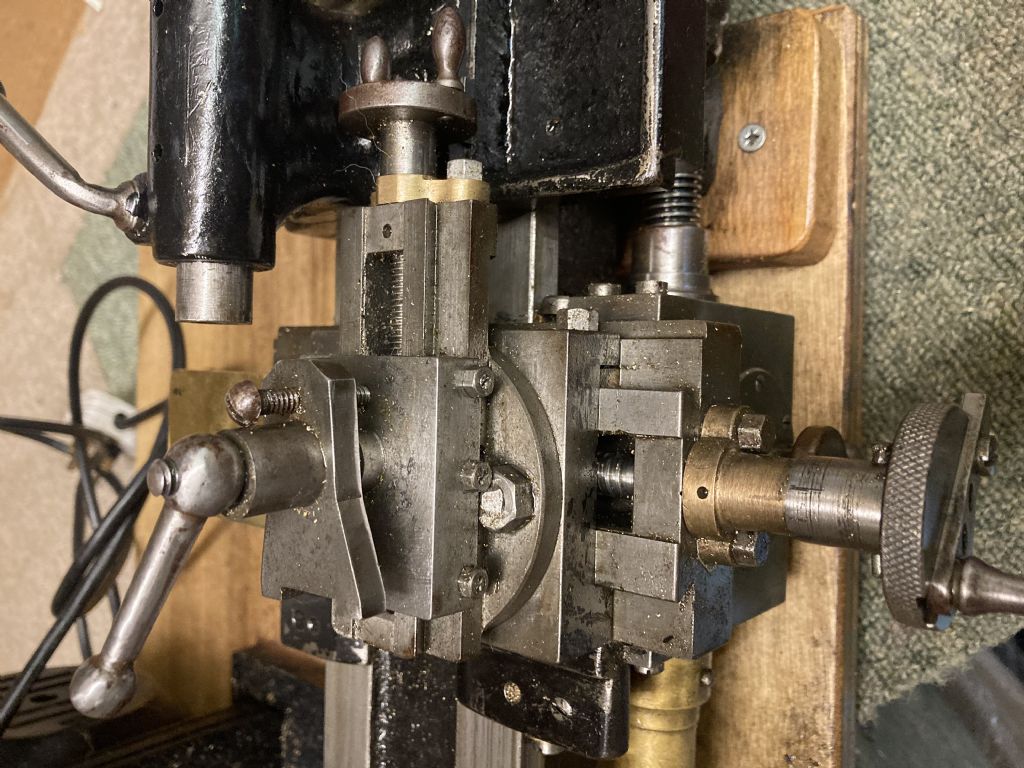

had a power feed which has been removed. I’m having issues with the tail stock. The widest apertureon the tail stock measures a tad under 10mm. It’s a taper and the only way I could think of measuring it was to either buy a few tools of various sizes to see which fits, I haven’t done this yet, or to place various size drill bits in the aperture. It will not take a 10mm bit, the 9.5mm goes 10mm into it, the

9.00mm bit 20mm in, the 8.5mm bit 30mm in,

the 8.0mm bit 35mm in, 7.5mm 120mm in, the

7.00m bit passes right through the whole 140mm

length.

They’re no makers marks at all on the lathe.

If there other questions that need answering, or

different photo angles required then please shout and

I will do my best.

Ian from ACE Euro Trade who was very helpful

suggested I solicit your assistance.

Many thanks for taking the time to read this post.

Regards

Mick

Howard Lewis.