New Toy

New Toy

- This topic has 20 replies, 12 voices, and was last updated 16 July 2020 at 13:25 by

Phil H1.

Viewing 21 posts - 1 through 21 (of 21 total)

Viewing 21 posts - 1 through 21 (of 21 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

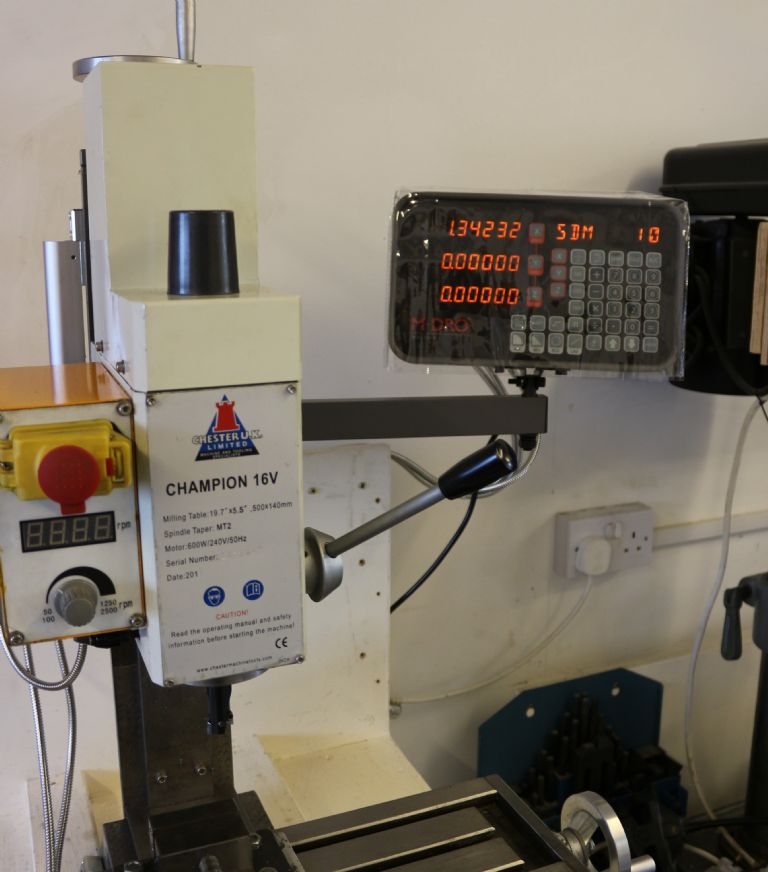

but it definitely states 0.001" on all the dials and it was sold as an Imperial machine. However, perhaps all the Imperial machines are in fact metric but with very poorly executed handwheel conversions? If you look closely at the front plate (it is a bit small on the picture) – even the table has inch sizes rather than metric.

but it definitely states 0.001" on all the dials and it was sold as an Imperial machine. However, perhaps all the Imperial machines are in fact metric but with very poorly executed handwheel conversions? If you look closely at the front plate (it is a bit small on the picture) – even the table has inch sizes rather than metric.