Welcome to the forum Martyn.

The machine you have is good for indoor model railway sized work rather than clocks or traction engines. It's probably quiet enough to be used inside the house rather than needing a shed or workshop to to contain the racket and mess.

The motor is small, so although it will turn, drill and mill mild-steel, it will be happier on Aluminium and Brass. Don't expect it to plough through metal in seconds! I like to drive my machines so the motor can be heard to be straining slightly, but not struggling. Patience is essential on a machine with a 250W motor, but they can do good work.

Best to buy metal described as machineable or free-cutting rather than trust random scrap; quite a lot of scrap and DIY store metal doesn't machine well and small lathes are less able to deal with awkward metal than big powerful ones. My entry into the hobby was almost derailed because my collection of scrap was all rubbish!

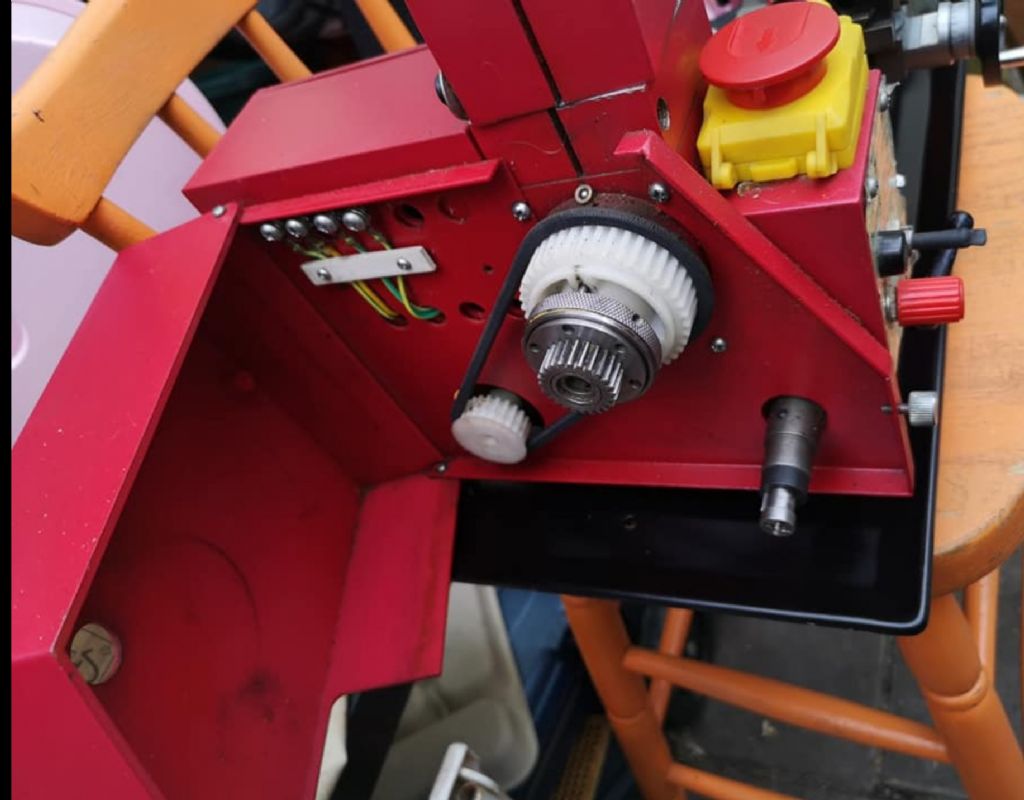

The missing change gears are annoying but not the end of the world. Most small threads are cut in the lathe by tap and die. Change wheels are only really needed for large diameter threads. A problem may be the lead-screw moving the saddle too quickly to be used as an automatic fine-feed; again annoying rather than fatal – you just have to develop a steady hand.

Any idea what you want to make yet? If not, people often build skills by making simple tools and whatnots before moving on to a model or real-world object.

Dave

Steven Corston.