Later machines uswed V belts rather than flat beltsDepending on it's age, the thread on the Mandrel could be 7/8 x 9 (Which is 7/8 BSW ) or 7/8 x 12 tpi.

I belive that some of the very last used 1 1/8" x 12 tpi, but without the 1 1/4" register of the 7 Series.

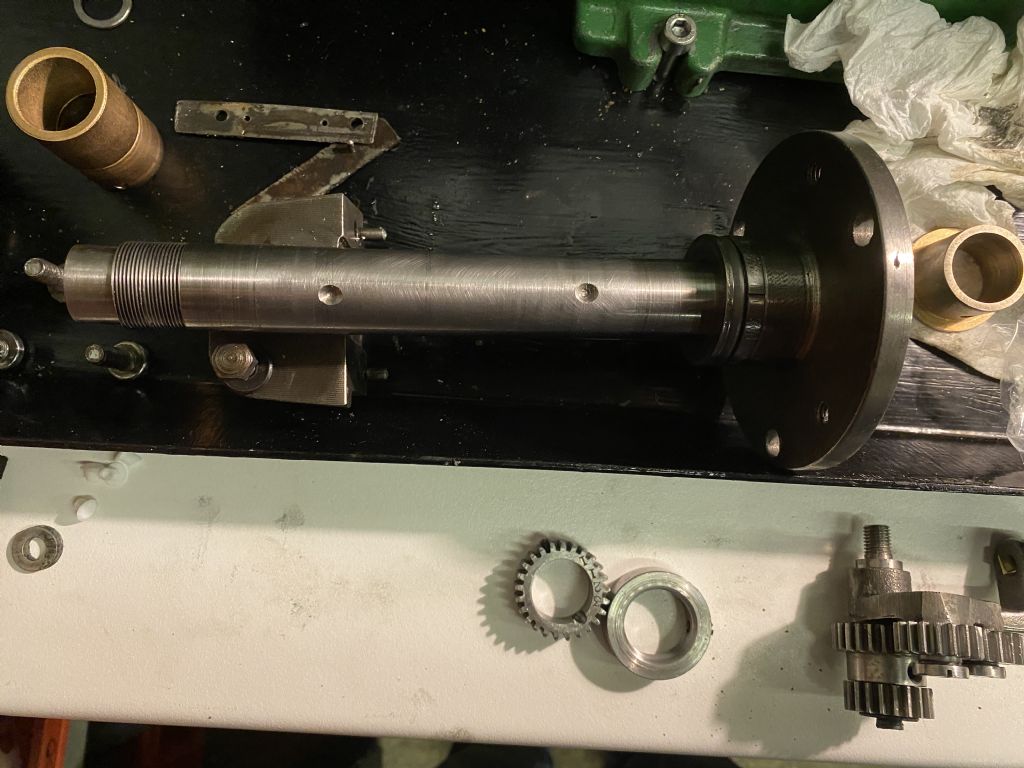

The lever with two gears on it, under the Spindle is the Tumbler Reverse. This allolws you to select in which direction the Leadscrew revolven when using it for power feed for sliding or screwcutting.

The damaged gears are the result of engaging Back Gear without releasing the grubscrew in the pulley that locks it to the Spindle. This is the abusive way of slackening a stuck chuck, but the gars suffer damage as a result!

You will already know that the fixings used are either BSF or BSW. (Possibly BA for the gib adjusters)

The changewheels are driven by Driving Collars, (These are secured to the shaft by 1/4 BSF grub or capscrews ), which drive the gear by a 3/32" diameter pin.

Usdsually the gear on the Mandrel will be 20T.

The gear that you fit ro the Leadscrew will also be driven by a Driving Collar and pin.

If you need to use a compounf gear in the drive between Spoindle and Leadscrew, they will have a 3/32" pin locating them to each other. The holes do not go all the way througjh, to ptrevent the pin falling out.

The Leadscre wis 8 tpi, so if screrwcutting you need to set up a suitable ration to achieve the thread pitch that you want.

If you can summon up enough gears you can set up a fine feed of about 0.004" / rev.

Driver 20 : 60/20 : 65/20 : 60 on the Leadscrew. You may need to fettle the Mandrel end of trhe slot in the bamjo, and possibly the lower end of the stud that fits into the slot, to be able to get proper mesh..

For this using two idlers, the Tumbler Reverse will need to be used to ensure that the Saddle moves twoards the Headstock for most work.

To set the mesh, run a piece of paper (About 0.003" thick ) betweem the Leadscrew gear and the Idler., adjusting the stud position to achieve this, when tightened into mplace. Repeat for the other Idler mesh, if there is one, and finally, swing the Banjo to run the paper through the idler / Driver mesh.and lock with the 1/4 BSF bolt.

The Cross Slide and Top Slide leadscrews are 12 tpi, and the dials have 80 divisions, so each division is not EXACTLY 0.001 (0.0010416666 a little more precisely )

The Tailstock barrel is prevented from rotating by a 1/4 BSF grubscrew with a key machined or filed on the bottom. This locates in a keyway bin the barrel. Ideally it is a snug fit. Adjustment is by trial and error. Screw it it until it will not engage in the keyway, and then back out, half a turn at a time until it just enters. Job done!

If you are short of gears, and cannot find any for the ML4, ML7 ones can be use. Thay are the same DP , PA and bore. but will need a 3/32 hol drilling for the driving pin, instead of the key used on 7 Series machines.

I used one of the genuine ML4 gears as a drill jig, by drilling right thriugh and locating this on a stud over the 7 Series gear. Keep away from the keyway!

Hope tnat some of this helps.

Howard

Colin Spence.