Hi George,

You're quite right. It is a problem, it's a long time since I had to go through what you dscribe.

I've had the machine since I was eleven, and I'm now in my mid forties! Granted it spent a long time as parts in a box, but it seems to have stood the test of time. I learned to turn on that machine, I got ten years use out of it.

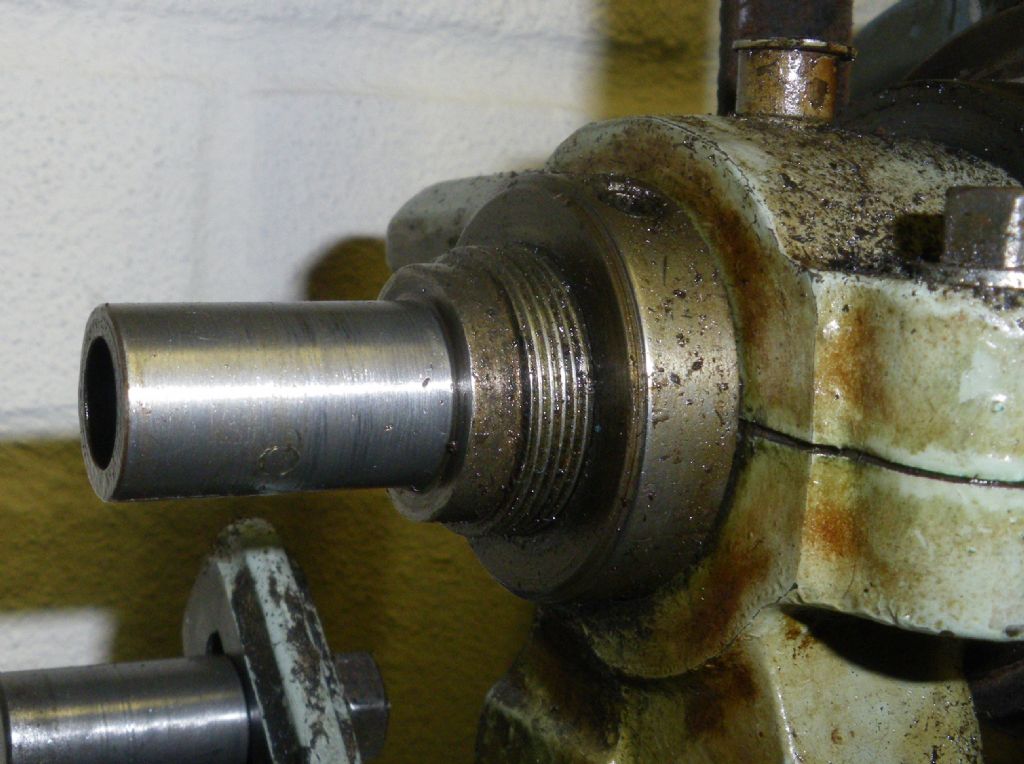

I'd forgotten that I had to drift the spindle out with a hardwood block and a 'mer. The bearings are original, and it is still fine, so I guess I was careful enough.

I think this stirred a braincell or two actually.

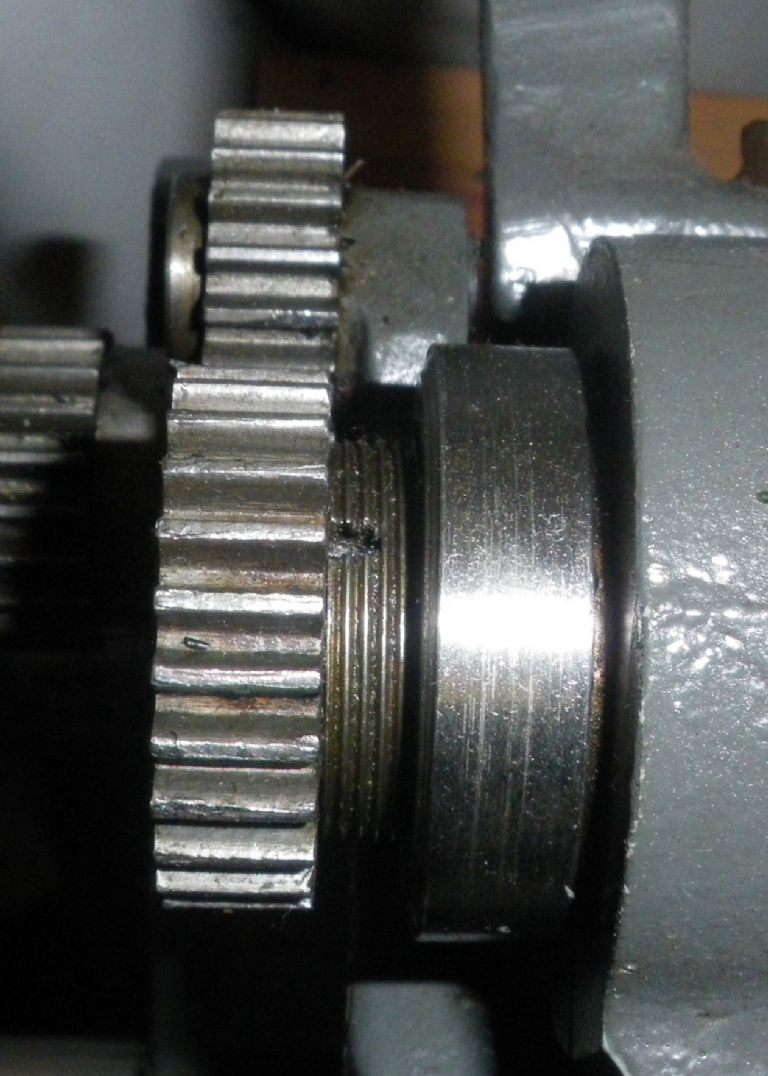

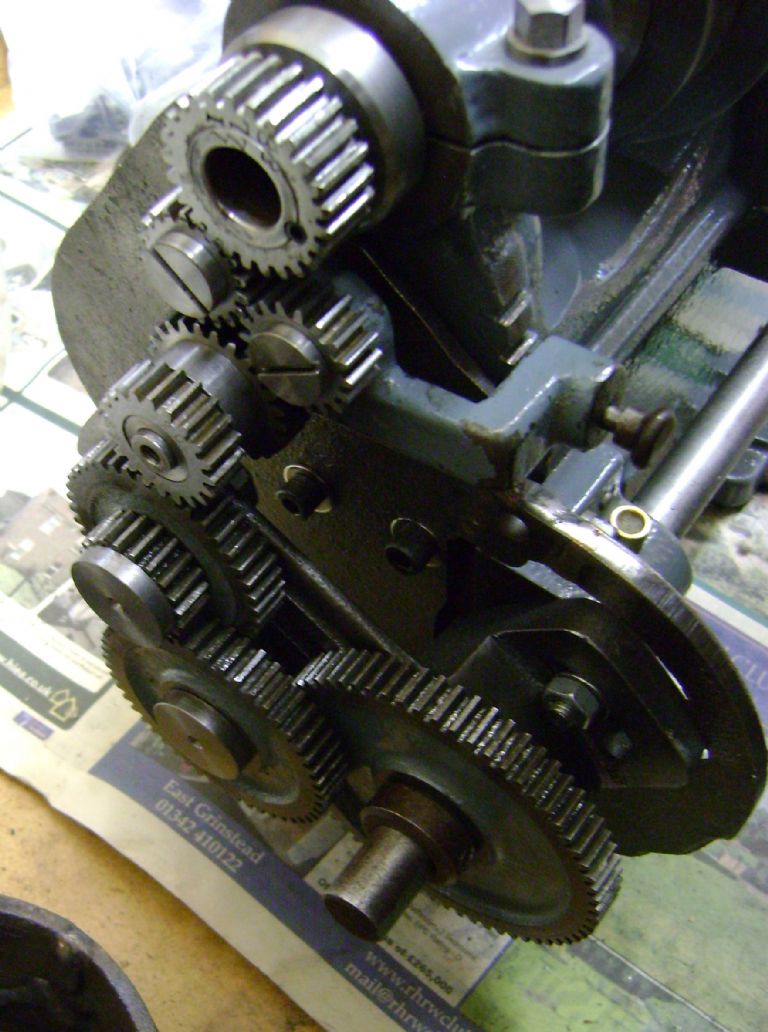

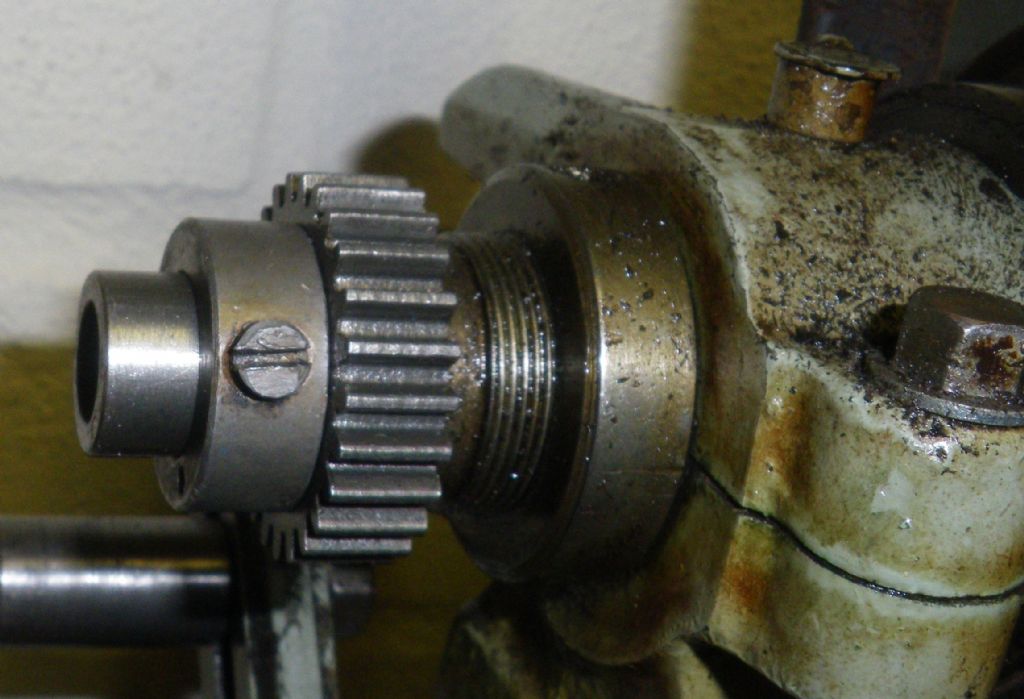

So, when you remove the spindle, it comes out through the bed end of the headstock. Also it is worth looking out for burrs raised by the grubscrew on the preload ring behind the 25T gear. Obviously that grub screw bears directly on the screw thread, and that's a little nasty. If a burr has been rised on the thread there, then it will be good if you can take the burr away with a stone, or a diamond file. The benefit is that you don't then drag the burr through the bronzes.

The same philosophy is true of the pulley grub screw that would need removing to engage the back-gear. Obviously you need to remove that to extract the spindle, but if it has not been properly withdrawn when the backgear was used, it will make a mess of the spindle, which can then damage the bronzes. I doubt you will be able to get at the damage unless you remove the spindle, but if you get the spindle out, you should certainly tidy it up with a stone.

I'm really not sure about the wisdom of the tumbler reverse anyhow. The machine should cut a right hand thread well enough, but the thrust race only copes with forces into the headstock. Any operation which requires resistance to a cutting force away from the headstock is not adequately managed by the design of the lathe. This includes turning operations away from the chuck and cutting left hand threads.

The preload ring does rest against a shoulder on the bronze headstock bearing, but there is no way it is as good as the thrust race on the nose end of the spindle. I guess it's woth being mindful of that, especially if you are a user of a vertical slide, and you use the side of a milling cutter often.

These old lathes are often quite limited, by comparison with newer machines, but you can still produce excellent work if you understand their limitations.

P.S. Mine has matching numbers on the bed, under the saddle and on the tailstock. It also has a small aluminium plate which I think indicates that it was owned by the Air Ministry. There is a number, and a small crown. There are letters around the crown, "P P" either side above, "A M" either side below the crown. I always wonder if mine actually shot down an ME109!

Edited By Andy Ash on 02/05/2016 11:06:31

Colin Spence.