New technology in Model Engineers Workshop

New technology in Model Engineers Workshop

Home › Forums › Model Engineer & Workshop › New technology in Model Engineers Workshop

- This topic has 152 replies, 43 voices, and was last updated 14 February 2015 at 04:50 by

John McNamara.

-

AuthorPosts

-

7 June 2011 at 11:24 #69867

John Haine

Participant@johnhaine32865Try a boat building materials supplier for West Systems epoxy – used to seal & reinforce wooden boats.

7 June 2011 at 12:10 #69870Terryd

Participant@terryd72465Posted by John Haine on 07/06/2011 11:24:33:

Try a boat building materials supplier for West Systems epoxy – used to seal & reinforce wooden boats.Hi John,

Thanks for the suggestion but it appears to be even more expensive than pouring epoxy from a builders supply house. Nowhere near the sort of price John McNamara quoted in Australia for his Megapoxy H,Best regardsTerry7 June 2011 at 12:47 #69875John McNamara

Participant@johnmcnamara74883Hi AllHi John HaineWest system is used by some US machine builders. it is rather expensive. they specialise in boats. With the interest in boating in the UK there must be stiff competition for epoxy suppliers. A little research should find a competitive supplier.Hi TerrydGreat to hear you are interested…..

I found a list of distributors in Europe by doing a Google search for Megapoxy

Then I found this page for Distributors.I believe Megapoxy was developed by Vivacity Engineering an Australian company.There are not that many kinds of epoxy on the market, many companies’ market similar products. I chose Megapoxy H because it was reasonably priced and the company was helpful when I made enquiries, I will stick with them in Australia.In Australia (found today on the net) one supplier quoted 4 litres of Megapoxy H about $96.00 ex GST (VAT in the UK)

One litre packs of anything tend to be expensive. in OZ it is sold by the litre, not weight as many of the suppliers I Googled in the UK tonight showed on their price lists.The main thing is to get an epoxy that does not have added solvents. And has a reasonably slow setting time to give you time to place the mix.

I tried the following four word Google search and came up with a number potential of contacts.

Buy epoxy resin EnglandWith the membership behind MEW I guess there will be a number members who know local suppliers.

CheersJohn8 June 2011 at 16:50 #69944John McNamara

Participant@johnmcnamara74883Hi All

The mechanical design has almost been completed, all the motions and table locking now work properly. A good example where CAD excels being able to see how parts relate to each other before you build.

I used the cam method for table rise and fall, clamped by the lever on the right and a substantial friction disk; you can see it on the right in the front view.

The table angle is directly indicated.

I would appreciate a little help; I do not have any plans for the Worden; in order for the many accessories that have been designed it would help if I knew the position and size of the arc and centre point locations and dimensions. I will amend the plan. That way the accessories should fit

The position of the Motor, should it be movable laterally or rotatable? There is plenty of room to make it so. Will it make the machine more versatile?

The drawings are all AutoCAD files. If any non commercial user would like them I will be pleased to oblige PM me if you would like a copy.

Once the machine is tested I will produce a set of PDF drawings.

Cheers

John9 June 2011 at 14:45 #70031dcosta

Participant@dcostaHello Terry.

“I have searched for a while trying to find Megapoxy H over here in the UK as I would like to try the technology you have proposed. However, I cannot find a source and the nearest equivalent I can find locally is almost £30 sterling (46 Aud) for 1 litre. This seems a bit pricey. “

Being curious about Megapoxy H (and possibly interested in trying it), I made a search for the product here in Portugal. I found a distributor and I was told the price for a 4 litre is around €80,20 (£70,82). Around £17,50 per litre. A little cheaper than in England.

However, suspecting of the existence here in Portugal of other makers offering similar products, I phoned to some telling I’m looking for some product to replace Megapoxy H (explaining the intended use) and Sika answered to me saying its product called Icosit KC 220 N has identical characteristics.

I could find a price in some distributor here in Portugal and it goes at around €126,00 (£111,00) for a 5 litres can. Around £22,00 per litre.

Than, a simple search with Google showed the following address:

http://www.epms-supplies.co.uk/p-Icosit-KC-330/10-%28179%29.aspx

I don’t know the price of this product in England but I think it may be an alternative deserving to be explored…

Best regardsDias CostaEdited By Dias Costa on 09/06/2011 14:46:19

9 June 2011 at 15:38 #70035John McNamara

Participant@johnmcnamara74883Hi Terry and CostaI found the following link.By Googling “Buy epoxy resin UKI do not know the company but the pricing looked a little more reasonable.If you decide to call them make sure the epoxy has no added solvents.Sifting through the pages there were a number of other company websites that quoted pricing for comparison.CheersJohnEdited By John McNamara on 09/06/2011 15:44:15

Edited By John McNamara on 09/06/2011 15:46:42

9 June 2011 at 17:10 #70042Gordon W

Participant@gordonwI don’t know much about resins, but a few years ago I bought quite a lot for a job, and found a company selling re-made (?) resin, considerably cheaper than new, might well do for this sort of job. Can’t remember the co. tho.12 June 2011 at 17:14 #70198John McNamara

Participant@johnmcnamara74883Hi AllUpdate on the Epoxy WordenThe endplates are finished… see attached photos.A nice set of photos and yes it all worked…..However all wrong! Well the method was.It is easy to fall into the trap of thinking traditionally when you should be thinking “how can I improve the process using new technology.In this case I cast the part and then machined it in the same old way as I would have with cast iron.I then separately bored the right and left table pivot holes first, they are different one 25mm the other 20mm; as I wanted to bore all the other holes together that created an alignment problem. In the end I made a stepped locating dowel to align those holes while boring. So after setting out, then jigging up on the mill to hold them precisely, I was ready to bore. In the end I used a drill to open up the holes meaning that the location of the holes will not be exact. Jig boring the holes one by one would have been more accurate while taking a lot more time. However the error is small. Drilling them together does guarantee the holes are precisely located opposite each other a primary requirement. I ran very slowly at 75rpm with a feed of .0025” the holes did not wander, I takes a while so I set the auto stop. so I did not have to watch.To align the Y axis rails I clamped them to two cylindrical squares, self made from 50mm x 5mm tube the large hole in the centre allows plenty of latitude when positioning ….Very handy .So what is wrong with all that…… the time taken.A far quicker method would have been to make up a small plate for the base of the mould using a small piece of light steel or aluminium for accuracy. All that was needed was to mark precisely drill and attach four accurately turned locating pins; and then pace the inserts pre bored on the lathe over the locating pins. There is no need to allow for shrinkage there is none with epoxy.No further machining would have been needed the holes would be exactly positioned.A lesson learntNext job is the 4 shafts and the four rail mounting blocks.CheersJohnY axis aligned level with bed Zero both ends in indicator (Also transversely)Main pivot bearing BoredSet up to be gang drilledY axis bearing aligned to cylindrical squares.Stepped dowel to align main bearing13 June 2011 at 13:35 #70253Richard Parsons

Participant@richardparsons61721John – This is a very interesting and useful series of posts. I have no plans (as yet) to try the technique yet.

However long ago I used to make chess sets from materials supplied by Strand Glass – Brentford (Usual disclaimer) with French chalk as filler. One trick I learned was to cool the resins down in the ‘fridge (in fact I cooled everything). This slowed down the setting time and helped to get more air out of the moulds and the mix.

Subsequently I have had a thought about vacuum de-gassing. I used to have some ‘space bags’. You put your stuff into them and sucked out the air with a Vacuum Cleaner. Blankets, duvets etc went as solid as a rock and about half the size. The problems, as usual over here, are the Hungarians. They will overlord/overfill/over stress anything! To open them they do not undo the seal they just cut it open! –More forints up your shirt- Also I need to rebuild my vacuum cleaners, Hungarians again they can burn a new vacuum cleaner out in 30 minutes by chattering to each other with their hands over the suction pipe to stop any air getting in and cooling the motor.

If you combine the cold mixing method and put the filled mould into a ‘space bag’ –with some guards to stop the bag flexing down onto the mould-. You then suck out the air and leave it to set, it should do the trick.

20 June 2011 at 16:16 #70593John McNamara

Participant@johnmcnamara74883Thank You Richard Parsons for your words of supportI did not have any problem with setting times or exothermic heat with this project With 15% only of epoxy Megapoxy H has a fairly slow cure the balance being aggregate and sand, the mass of the fillers was sufficient to absorb the heat. From reading other people’s papers however you are correct it can be a problem particularly with larger castings, the Worden castings are thin sections able to dissipate the heat. If I make a bigger object it will be done in layers firmly tamping each as the filling progresses.Interesting how you mention space bags; If you look around you tube… from memory for carbon fibre processing; you will find a number of videos showing glass fibre matting being placed between two permeable sheets that are then placed in what are effectively your space bags and evacuated to high vacuum They are supported by a mould. Once the air has been removed epoxy resin is introduced into one side of the permeable membrane, it flows through the mould (The matting) and some is lost out the other side. After closing and heat curing the mould the bags and membranes are stripped away leaving the part. They were making parts for commercial aircraft.When you mention Hungarian I think of reverse polish notation…Bar humbug!The biggest problem for the method developed so far is the stiffness of the mix more than air bubbles. However as I am a firm believer in paint the blemishes have been patched. They have not affected the structural integrity.CheersJohn20 June 2011 at 16:18 #70594John McNamara

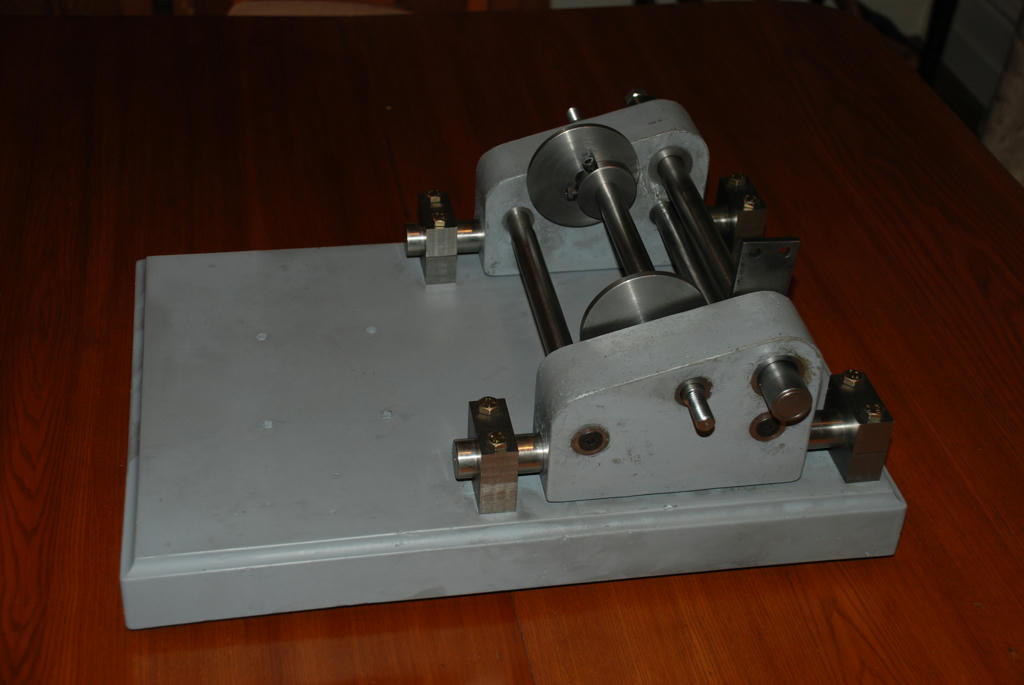

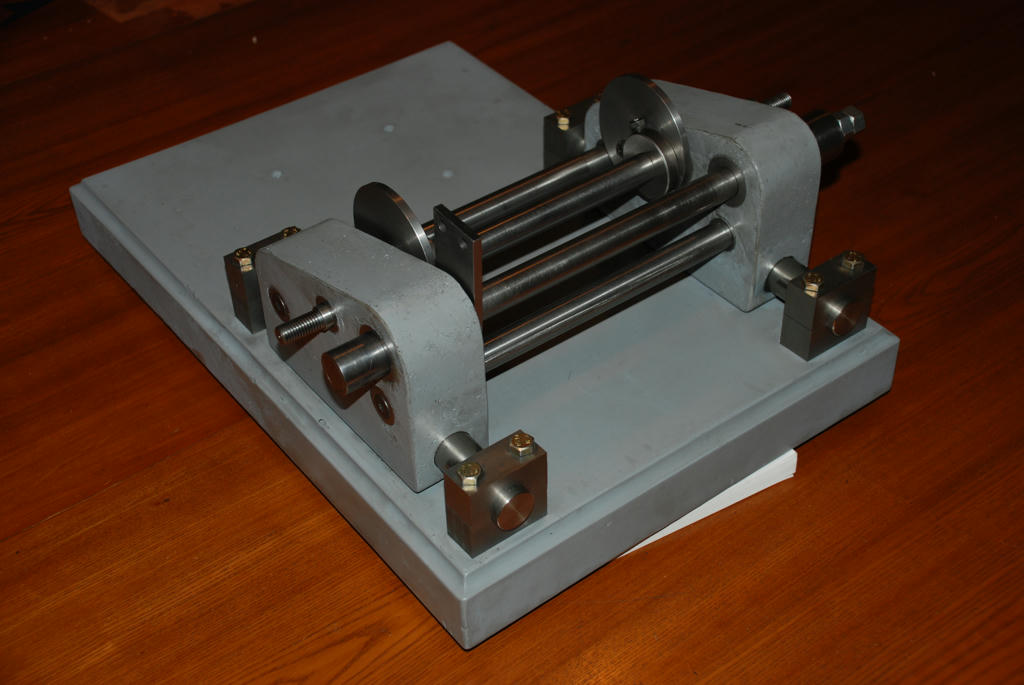

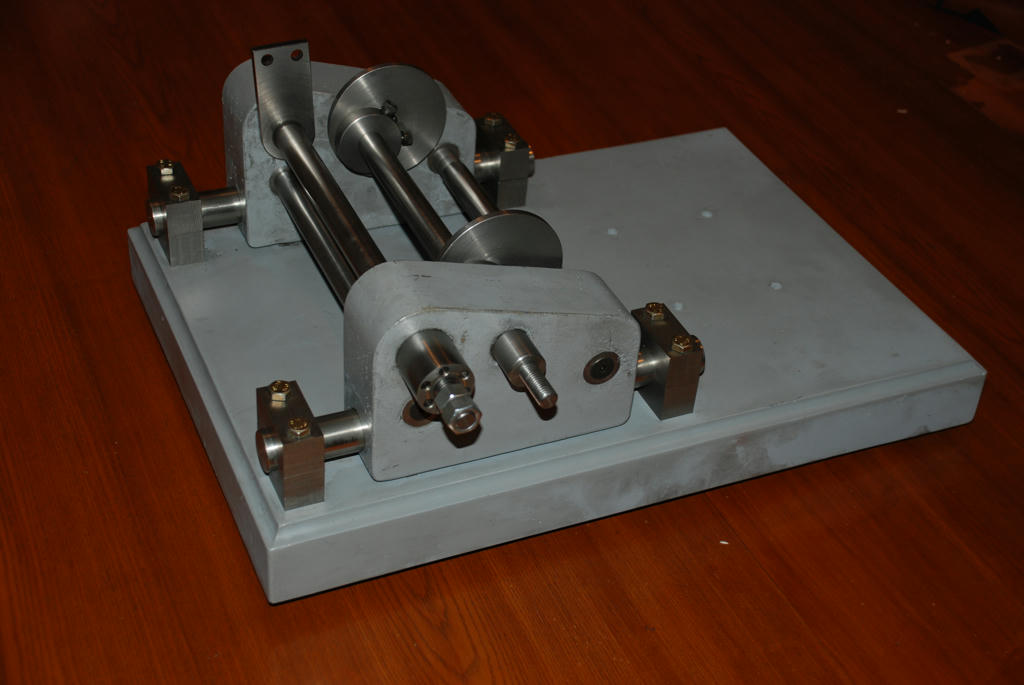

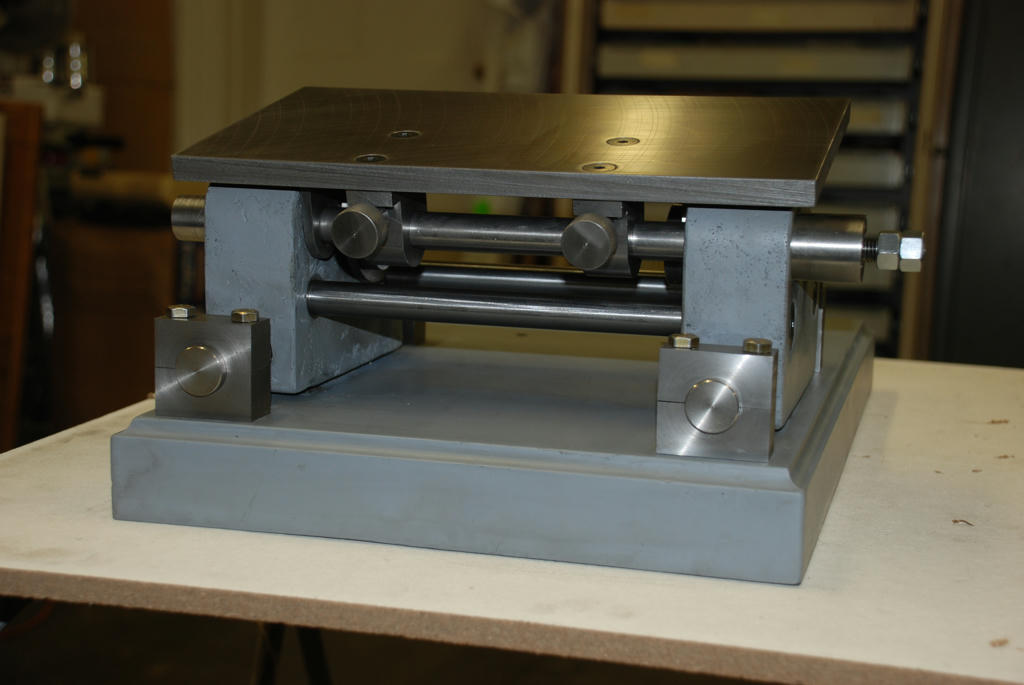

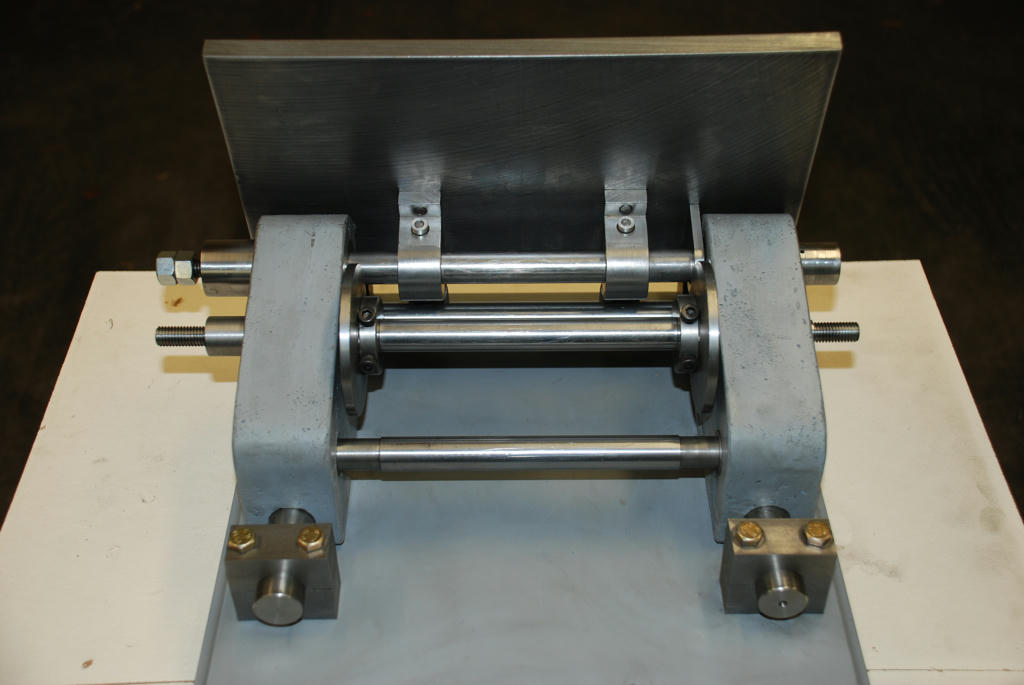

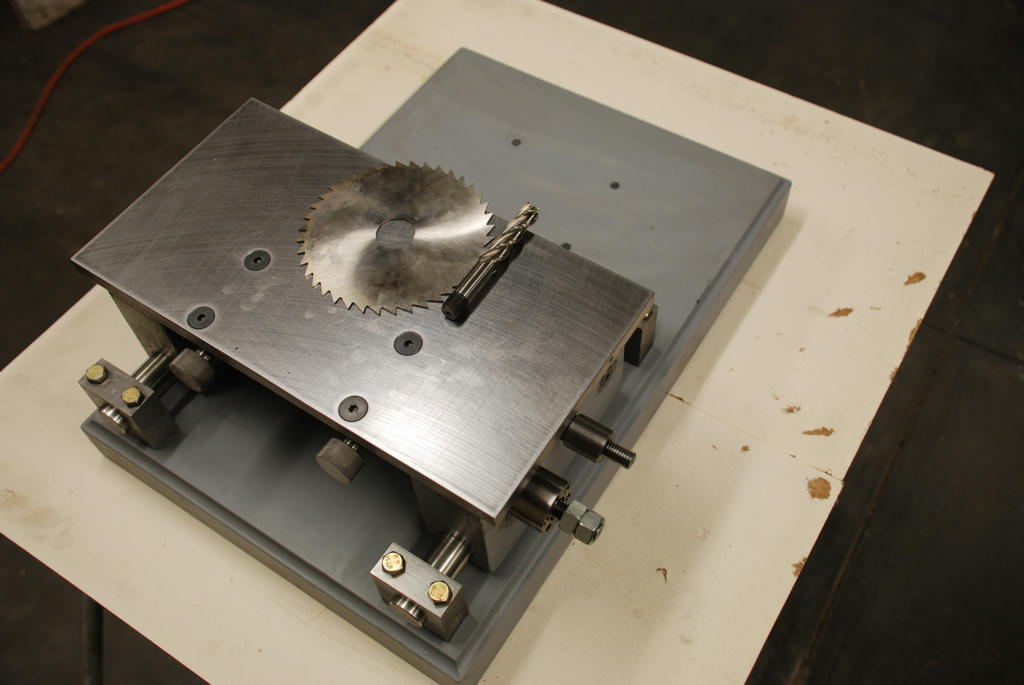

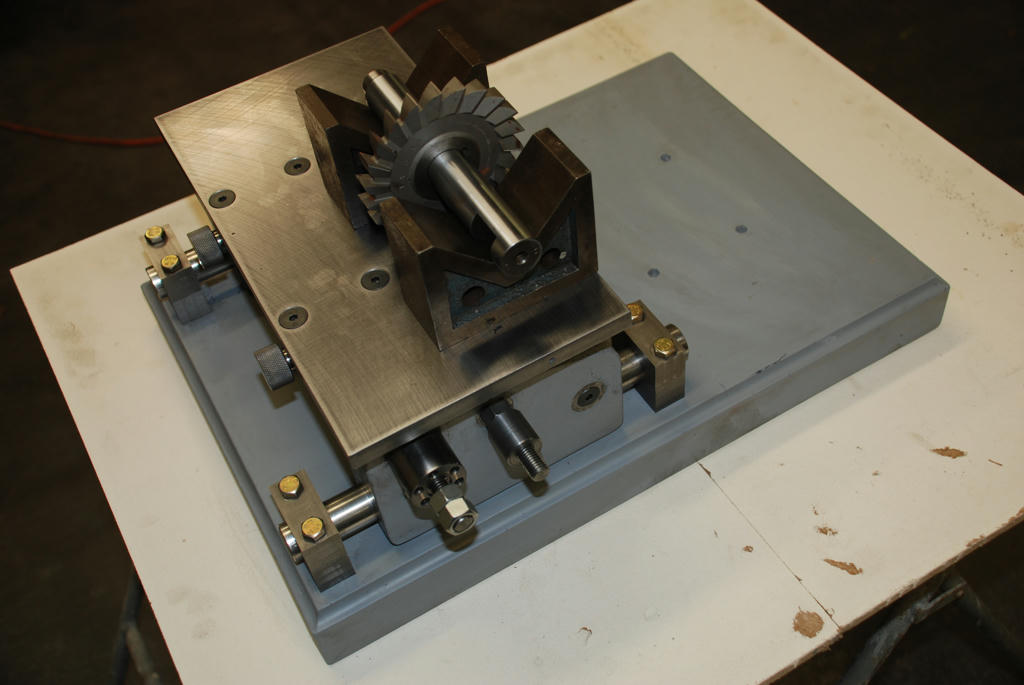

Participant@johnmcnamara74883Hi AllIt’s been a while since I updated the Mineral Casting method Worden tool and cutter grinder. The good news it has proven without doubt the kind of rigidity you can expect from this method of construction. The movement of the table carriage feels more like a lathe saddle than a grinder there is no perceptible movement. When the tool is finished I will document it formally.The bill of materials: So far all from the scrap bin except for a Litre and a bit of epoxy, Cost about 30 dollars and a bag of aggregate and a bag of sand; total cost $14 from a garden supply. It looks like the only steel to be purchased will be the Table piece but I am still rummaging, also some M8 hex cap screws to replace the machine screws currently holding the bearing rail blocks.To this point The x axis table movement is complete; it is not obvious from the photos but the front top bar that will carry the table pivot brackets can move laterally a distance of 25mm left or right a total of 50mm. The table itself can also move independently upon releasing the two lock nuts (See previous photos). At the opposite end the shaft is bored for a long spring to preload the feed screw. Similar to the way the Quorn feed is arranged although the Quorn does not have a bored shaft the screw bears against the shaft.I am considering adding stops and a lever for quick action on saws and cutters. In particular the draw full inch bore milling cutters I have not been able to sharpen. I plan to sit them on the table in the horisontal position on a locating arbor, and index them against a spring stop finger as is the norm. A lever action would speed the process. There should be no chatter the machine is rock solid.The y axis in feed not yet built will make precise adjustment of the depth of cut very easy. This is where this design is quite different from the original the entire table can be precisely located in the X and y plane. Attachments can be simplified in some cases avoiding the need for a feed mechanism.The turned boss bolted to the right hand casting with a projecting screw is the x axis control. The screw itself is fixed within the boss, the movement being obtained by an M12 threaded hole in the end of the shaft that engaged the threaded shaft. This keeps the mechanism completely internal and away from grinding dust.The arm pointing upwards from the top shaft abutting the left hand casting is to transfer the angle of the table to the table angle pointer that will be fitted to the outside of the left casting…You can see it in the photos of the earlier posts. This part is not finished the two holes and a section of it will be cut off. It is just a convenient piece of scrap that was to hand. Because this piece needs to be exactly in line with the top of the table support brackets I will not trim it until the brackets are done.The table lift cams are complete as well as a secure brake to hold them in position. The plain turned M12 nut in the photo will have a lever with a bored hole that can clamp on the turned nut. This will provide adjustment of the clamped position.Engaging that nut pulls the cam bar to the right, the cam itself sits against a shoulder to stop it sliding along the bar the other side of the cam is forced against a 45mm hollowed out disk attached to the casting, effectively forming a small disk brake. A half turn on the M12 nut and I was unable to move the cams.The next step is the table and brackets. As no one has posted the dimensions of a warden table I will just make it as is if anyone builds the machine by this method they will have to adapt any attachments they may build to fit this table as the position of the radius clamping Arc and the centre point is unlikely to fit.The motor mount is still a work in progress; I think it should be possible to rotate the motor. Even as much as 90 degrees? Any comments would be welcome.There was some discussion re Epoxy a few posts ago, Has anyone found a reasonably priced source of supply for the UK?There are a few photos below the captions should be fairly self explanatory.CheersJohnNicking the two halves of the bearing blocks in the centre to start the hole in the centreStarter drilling the 25mm holesContinued next post20 June 2011 at 16:37 #70595John McNamara

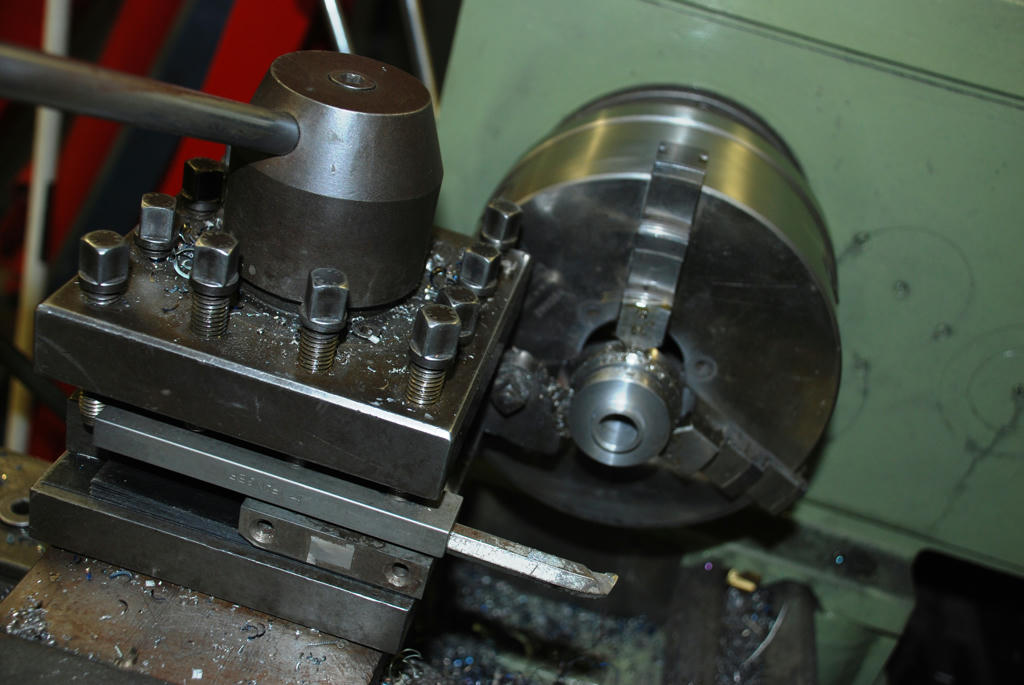

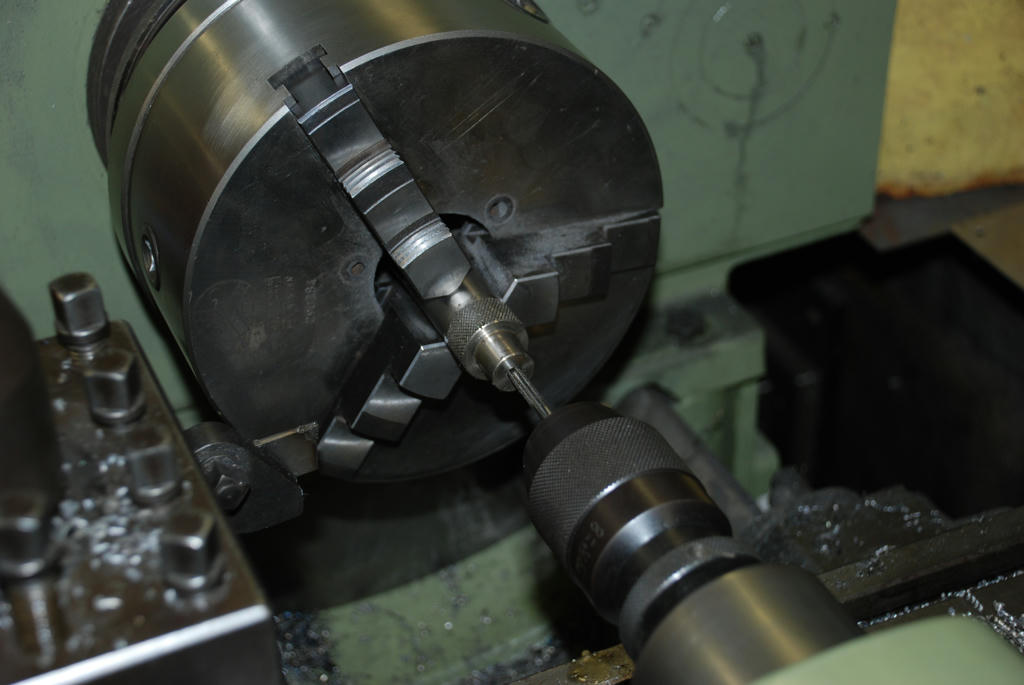

Participant@johnmcnamara74883Continued from previous postPaper inserted to create a gap for clamping.Gang Drilling table camsPrecision boring table camsBoring cam bossParting Cam BossMilling table angle arm on rotary tableContinued next postEdited By John McNamara on 20/06/2011 16:48:28

Edited By John McNamara on 20/06/2011 16:49:20

20 June 2011 at 16:52 #70599John McNamara

Participant@johnmcnamara74883Continued from previous postLeft rear viewLeft Front ViewRight front viewFeed and clamp shaft detail… Boss was bored straight through reducing collar silver brazed in then faced off in the lathe. The M3 set screws attach to the steel casting insertCheersJohn McNamaraEdited By John McNamara on 20/06/2011 16:59:47

26 June 2011 at 16:53 #70833John McNamara

Participant@johnmcnamara74883Hi All

A quick Update… The Table support brackets and table made…. Yes I found a nice bit of plate in the scrap pile. Rather happy it had been Blanchard ground, you can see the marks, After a bit of cutting it was ready, it is 13.5mm thick, a little thicker than the 12mm I had planned on using.The photos show the process I used.

The last two are exciting…. I just placed the cutters on the table for inspiration. The motor will have to be rotatable. This will be more versatile for working on various shapes of cutters.Next, the Y axis feed and the motor base after that. The plan is to do all other knobs and the graduations at the same time at the end.Cheers

JohnFirst milling cut table support brackets I squared them on the lathe in the 4 jawCutting the circular Arc on the table support bracketsThe part is centred by the bore hole for the support shaft, on a centre mounted

on the rotary table. Clamp is pressing down.Table slide locking knobs. In one chuck setting25mm shaft chuckedFacedThin section turned watch out for the SS swarf it cuts (the lathe was stopped but even clearing it away it got me.)Turn the area to be knurled taking a couple of thou of to get a true centering. and a clean start for ther rolls to bite inKnurled.. Heavy pressure .003 feed (Or the lowest feed you have) 3 passes (Do not go off the end just to the 3/4 point on the rolls) increase the pressure a little each feed.I got a very nice diamond knurl. the material was 304 stainless it work hardens so be patient.Drill 20mm hole and tap I started the tap in the tailstock to get a straight startPart off knob Dont dither with the tool rubbing, it will work harden, enough pressure to keep it cutting. If you want to stop pull well back. Lots of oilThe final step is to put the knob back in the chuck face off the parted end and do a small 45 degree chamfer on the edge.

Continued next thread26 June 2011 at 17:00 #70834John McNamara

Participant@johnmcnamara7488328 June 2011 at 21:11 #70965Sub Mandrel

Participant@submandrelPhew this has been a bit of a marathon read. All fascinating, and I must say my interest is piqued in engineering epoxy.My ‘surface plate’ is a slab of epoxy granite worktop, about 18″x12″ and appears to be both accurate and durable. The price was just the cost of the cheap angle grinder I used to cut it off a larger piece. It cut easily with a diamond wheel, and I got a bit blase… until teh smoke started. Oh well, nice set of bevel wheels for future project!My ‘worden-a-like’ grinder is semi-finished but working. Its based around linear bearings from an old dot-matrix printer, and the workholder is made so it can swap with a mini-lathe topslide.The motor is a cheap grinder remounted on a length of alloy scaffold pole (found in the road) with a diamond wheel attached. The wheel adpator was turned in place with the existing centres on the grinder spindle between centres – you can’t see or feel any wobble in the diamond wheel stopped or spinning – cheap grinder, but decent bearings. It can be moved up and down or rotated, but not with any degree of fine feed. Most workholding is done using ER25 collets in a spindle.Wait for it.. the base is 1 1/4″ thick plywood and the table and itssupports are 3mm or 1/8″ mild steel plate found in the garage that became my workshop. The table moves on tworails made of angle iron! Cuts are applied by moving the table left/right on the printer slides (phosphor bronze bearings on hard steel rod) or advancing the work holder on a scombined swivel/dovetail slide base from cast iron.It all looks VERY agrcultural and the motor get hot if run more than about 20-30 minutes, but I’m quite happy with the results sharpening a range of endmills.I’ve since wondered about mounting a smallish grinding wheel on the X2 mill to make a surface grinder.Neil30 June 2011 at 15:48 #71102John McNamara

Participant@johnmcnamara74883Hi Stub Mandrel

Glad to hear you are piqued….Re Epoxy

Cheers

John30 June 2011 at 15:49 #71103John McNamara

Participant@johnmcnamara74883Hi AllI noticed a mention on another post in the MEW forum “Using the technology” of externally linked images compared to images posted on MEW

I am not sure if this site does but many sites cut the resolution down before storing the files to save space.

I use externally hosted file images stored at the full resolution of the camera (10.2 megapixels). In case you are not aware; if you double click the image you can zoom in to see more detail.

However the image is not full resolutionThe actual images are posted here:Cheers

JohnEdited By John McNamara on 30/06/2011 15:55:21

1 July 2011 at 18:03 #71194Richard Parsons

Participant@richardparsons61721John McNamaraThanks for your reverse polish notation – You’ve met them! I have PM-ed you so your ‘My Messages are ‘flashing’RegardsDick Parsons5 July 2011 at 12:58 #71347John McNamara

Participant@johnmcnamara74883Hi All

Just an update….

I am bogged down with the motor design. And feel a little guilty for not posting an update to the project.

The plan is to make the motor rotatable; the trouble with that is a standard frame size motor is too big to comfortably fit within the base of the machine. Making the motor rotatable means that a spindle is required in addition to the motor (the grinding wheels for this design being around 100mm in diameter) that is a lot smaller than a typical induction motor.

The spindle itself is not a problem and it gets over the problem of end play of the motor shaft. I know you can pack the motor bearings and get some sort of pre load. But conventional Conrad ball bearings as used in nearly every motor are not nearly as stiff as Angular contact bearings properly preloaded in a spindle.

Back to the motor…I came unstuck! the plan was to use a Universal motor (It is almost fully enclosed so dust will not be a problem) and I had one in stock. Well I thought I did. It is a FRAMCO (Fractional Horsepower Motors UK) 1/3 hp the right size and all it needed was a new bearing. So it was taken apart and the bearing replaced. I noticed the comutator was a little grooved, no problem…. into the lathe it went and after a light skim, the copper was shiny bright. After cleaning out the groves between the contacts it was ready to reassemble. No I did not check it for shorts, wrong move there…. having put it back together and powering it up you guessed it a little puff of smoke and a blown fuse; so much for that Idea. The comutator is shorted.

A new motor will have to be sourced. Hopefully this week so I can get on with finishing the project.

Cheers

John

Edited By John McNamara on 05/07/2011 12:59:21

6 July 2011 at 11:14 #71389Ian S C

Participant@ianscA few years ago (quite a few), I would have suggested a rebuild, But not today, I imagine its similar in the UK, you would buy two motors for the price of a rewound armature. Ian S C12 July 2011 at 13:10 #71711John McNamara

Participant@johnmcnamara74883Hi AllAn update

A new motor was ordered today, it arrives in a couple of days. Now I know the size it is back to work and the project can continue. Once it arrives (The supplier is in another state South Australia) and is tested; I will post the source. It is an induction motor 1/6 hp 120watt 2800rpm 120mm diameter 190mm long including the shaft Frame size 56 continuous running and IP56 fan cooled sealed construction.

Also today I spoke to the Megapoxy representative in Melbourne. He suggested that the best contact for them in Europe is:

Tassos Anastasopoulos

megapoxy@otenet.gr

As I understand it this is their main distribution hub.I would like to point out that I am only a customer of this company and have no other connection to them, having said that they have given excellent service.

Re missing images:

The servers are being upgraded at Mediafire. See the following mesage I received.“”Thank you for contacting MediaFire. While our development team is performing maintenance on some of our image servers, image previews will be unavailable for some images. The images can still be downloaded and shared, but the web-based preview will not work until this maintenance is complete. Currently the time estimate I have been given is several days, although that is subject to change. We apologize for the inconvenience that this is causing to both you and your clients. “”Lets hope that is sooner rather than later.Cheers

John12 July 2011 at 13:28 #71712Ian S C

Participant@ianscJohn, are you sure that 120W is enough, I run my Super Adept on a 180W induction motor, and anything over an inch in dia takes a lot of patience to say the least. My small bench grinder is 380W, 2800rpm, running 5″ wheels, I’d have thought 300W might be nearer, but size is the thing. Ian S C13 July 2011 at 06:42 #71732John McNamara

Participant@johnmcnamara74883Hi Ian

Gee you got me thinking.

The local hardware has small 120watt bench grinders. However you may be right. Anyway I changed my order to a bigger frame size. .55kw I guess that will be overkill. If I cannot get the small size I wanted I might as well get plenty of power.The minus is it has added 55mm to the length of the motor, meaning a longer ball bearing wheel spindle will be required. The new design will include the ability to rotate the motor 90 degrees. This should make the design more flexible.

It might even be possible to use it as a cylindrical grinder within the 50mm table travel.

The motor was sourced here:

I have no connection with this company I found them on the net. However I received friendly and helpful service so am happy to recommend them. Ask for Sam.Cheers

John13 July 2011 at 11:22 #71738Ian S C

Participant@ianscMy little motor is a 1450rpm ie 4pole motor, so it has more torque than the 2800rpm motor. Its marked IBM, I think it came out of a cash register. Ian S CAuthorPosts- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Model Engineer & Workshop › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Starrett and other tool manufacturer wood boxes

Started by:

Ian Owen NZ in: Workshop Tools and Tooling

- 8

- 11

-

6 July 2025 at 10:24

SillyOldDuffer

-

Pragotron Slave Clock

Started by:

renardiere7 in: Clocks and Scientific Instruments

- 1

- 1

-

6 July 2025 at 10:10

renardiere7

-

Sanjay’s Banjo Engine

Started by:

JasonB

in: Stationary engines

JasonB

in: Stationary engines

- 3

- 7

-

6 July 2025 at 09:58

JasonB

JasonB

-

In memoriam: Peter Neal

Started by:

jamesn in: The Tea Room

- 1

- 1

-

6 July 2025 at 09:53

jamesn

-

Colchester Chipmaster Clutch question

Started by:

Peter_H in: Manual machine tools

- 4

- 6

-

6 July 2025 at 09:41

Ian Owen NZ

-

Wickseed power hacksaw 8” information

Started by:

simonkeeligan@me.com in: Beginners questions

- 2

- 2

-

6 July 2025 at 07:44

Nicholas Farr

Nicholas Farr

-

M type top slide conversion??

Started by:

jimmyjaffa in: Beginners questions

- 7

- 13

-

6 July 2025 at 06:55

JasonB

JasonB

-

Bentley BR2 Rotary Aero Engine

Started by:

notlobgp14 in: Miscellaneous models

- 4

- 8

-

5 July 2025 at 22:46

notlobgp14

-

New member

Started by:

nige1 in: Introduce Yourself – New members start here!

- 3

- 6

-

5 July 2025 at 22:41

notlobgp14

-

Starrett micrometer.

Started by:

Graeme Seed in: Workshop Tools and Tooling

- 7

- 14

-

5 July 2025 at 21:30

peak4

peak4

-

Twin Engineering’s heavy mill/drill quill removal

Started by:

Martin of Wick in: Manual machine tools

- 11

- 25

-

5 July 2025 at 21:10

Martin of Wick

-

Dial test indicator vs Dial indicator

Started by:

martian in: Workshop Tools and Tooling

- 17

- 25

-

5 July 2025 at 20:19

martian

-

Speed camera

1

2

3

Started by:

David George 1

in: The Tea Room

David George 1

in: The Tea Room

- 23

- 60

-

5 July 2025 at 19:40

John Haine

-

Any ideas how to repair this?

Started by:

Ian Parkin in: Related Hobbies including Vehicle Restoration

- 11

- 14

-

5 July 2025 at 15:36

Pete Rimmer

-

Chucking Money Away!

Started by:

Chris Crew in: The Tea Room

- 6

- 8

-

5 July 2025 at 12:55

Chris Crew

-

2 Machine lights

Started by:

modeng2000 in: Workshop Tools and Tooling

- 2

- 8

-

5 July 2025 at 11:58

Dalboy

-

Boxford lathe & vertical mill VFD conversion help with start stop

Started by:

Andrew Schofield in: Beginners questions

- 8

- 10

-

5 July 2025 at 11:39

Clive Brown 1

-

1965 Colchester Chipmaster

Started by:

andyplant in: Introduce Yourself – New members start here!

- 6

- 10

-

5 July 2025 at 11:09

Rod Renshaw

-

What Did You Do Today 2025

1

2

…

6

7

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 33

- 175

-

5 July 2025 at 09:26

Nick Wheeler

-

Amadeal AMABL210E Review – Any Requests?

1

2

Started by:

JasonB

in: Model Engineer & Workshop

JasonB

in: Model Engineer & Workshop

- 16

- 39

-

5 July 2025 at 05:49

Diogenes

-

ML10 backgear

Started by:

alexander1 in: Manual machine tools

- 3

- 5

-

5 July 2025 at 00:11

Bazyle

Bazyle

-

The Perpetual Demise of the Model engineer

Started by:

Luker in: Model engineering club news

- 13

- 25

-

4 July 2025 at 17:06

JasonB

JasonB

-

Advice moving 3x machines

Started by:

choochoo_baloo in: Workshop Techniques

- 5

- 5

-

4 July 2025 at 15:46

Bazyle

Bazyle

-

Black plastic to replicate Bakelite

Started by:

Craig Brown in: Materials

- 8

- 9

-

4 July 2025 at 15:35

nj111

nj111

-

Firth Valve Gear

Started by:

Andy Stopford in: Traction engines

- 10

- 22

-

4 July 2025 at 14:42

duncan webster 1

-

Starrett and other tool manufacturer wood boxes

-

Latest Issue

Newsletter Sign-up