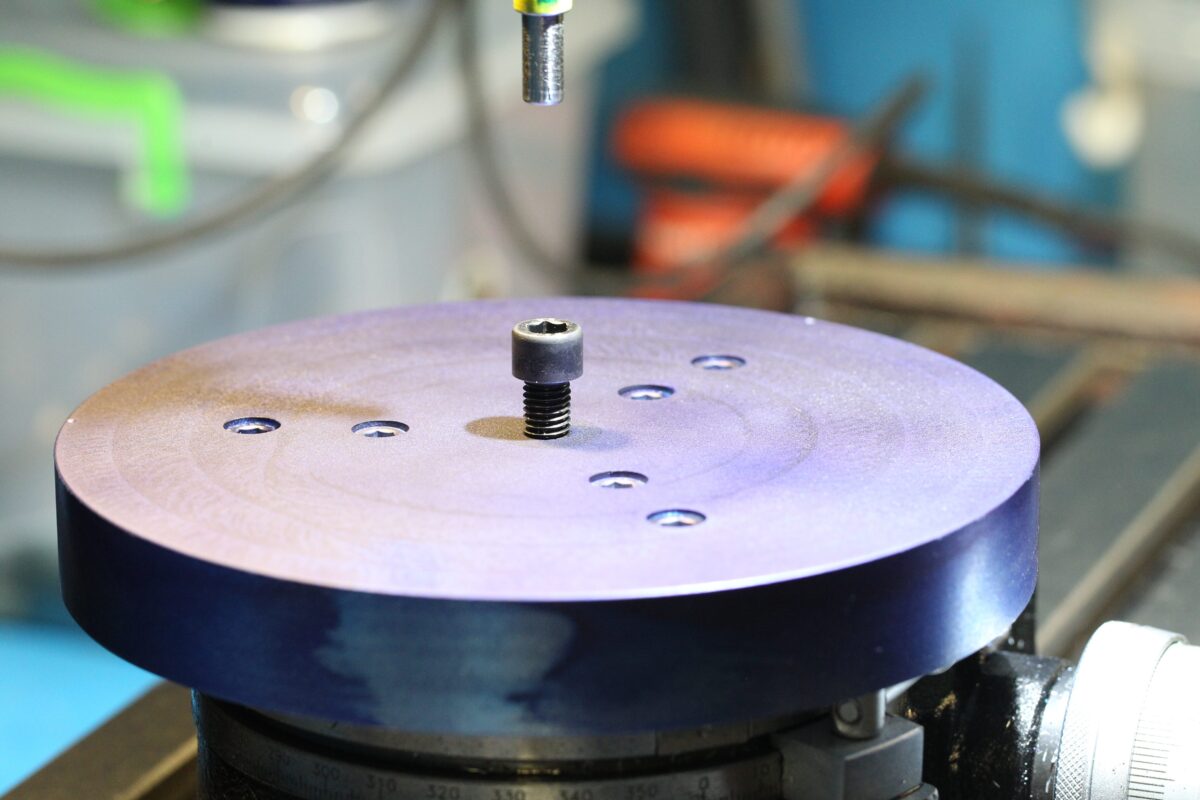

My HV6 is most often used for gear cutting, so Division Plates are always used.

Personally. I have nevr bothered about lining up a slot withe mill table.

If you do, and then disengage the worm from the wormwheel, the table can “freewheel” so that the ooriginal 0 – 0 -0 settings no longer apply.

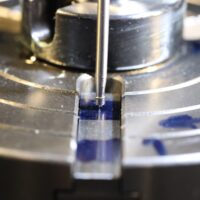

If, with the worm engaged properly, the table is set, accurately to Zero, the graduated ring on the handwheel can be repositioned, so the Zero coincides with the Zero on the Vernier scale.

Basic checks should show :

Startying with everything set at Zero, 40 complete turns with the handwheel and Zero marks aligned, the table should read 90.

Again from all Zeros, 90 complete turns should result in everything returning to Zero.

So from 0-0-0, 40 turns should produce 0 – 0 – 90; 90 turns from 0 – 0 – 0 should result in readings of

0 – 0 – 0 again.

Have you found this?

Howard

Chris Mate.