I'll be interested to see if anyone else agrees, but I'd question the value of a clamping set. I have one, it is useful, but I don't use it very much. Instead, most of what I do is held in a vice, or a rotary table, or bolted direct to the table. Home-made T-nuts and studding to fit are used more than the clamping set, which is most used on the rare occasions I bolt something big, heavy &/or oddly shaped to the table.

I'd say an edge finder is essential, with a DTI a close second for tramming and setting the vice accurately. Not all edge finders are equally useful, and a set may be waste of money. My preferred edge finder is Type C on this page.

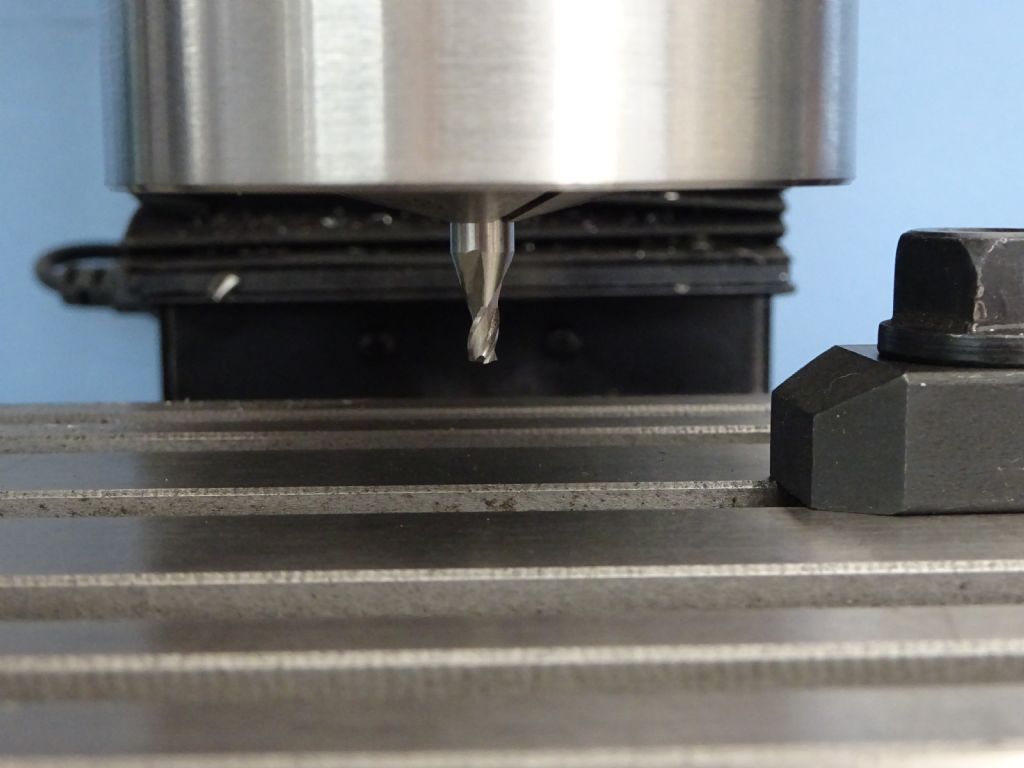

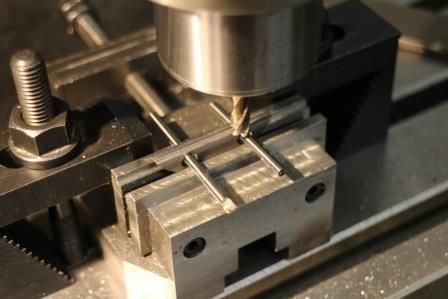

You probably need some 2-flute as well as 4-flute end-mills and a set of twist drills.

In the 'might be essential depending on what you do' class:

- A collet set with a wider range (2mm to 22mm) is good because it reduces tool changes, for example it takes most twist drills without having to stop and swap the collet chuck for a drill chuck and back again.

- Metric twist-drills in 0.1mm steps

- Boring head and boring bar (for making wide diameter and non-standard holes)

- Fly-cutter for flattening large areas.

- Rotary table ( I use mine about 30% of the time.)

Not essential, but highly desirable is a DRO on each scale. I fitted Warco's cheapest and most basic model to mine and it makes using the mill an order of magnitude easier to use than the dials. The problem with mechanical dials is remembering how far you've got, remembering which way you're going, and remembering to allow for backlash. And there are three of them on a mill!

In the 'most likely to be a waste of money' group, a flood cooling system (unless you are going to munch a lot of steel in every session). Also, for general purpose work angle vices not such a good idea because they're bendy and finicky to set up.

Dave

Ron Laden.

will be useful.

will be useful.