Well, the fun has begun. We got Brian's little lathe up on the bench this afternoon/evening. Overall it does not look too disastrously bad but needs a bit of "fine tuning", as far as can be done in the home workshop without specialist scraped templates etc.

Here is what a preliminary inspection/play around found:

The carriage is indeed a loose fit at the tailstock end and gets tight when pushing it by hand to the headstock end. The carriage indeed has quite a bit of what Brian has described as "wobble" when at the loose end of the bed. The wobble is such that you can rotate the carriage back and forth when viewed from above by about .004".

So it seems the lower bed ways are not parallel to the top ways, being further apart ("thicker" ) at the headstock end. Simple measurement with a mic revealed a .oo4" (0.10mm) variation on the rear ways and about half that much on the front ways.

A second test using a small DTI gauge mounted to the carriage with the pointer running on the under way confirmed these measurements.

This runout is over a 12" (300mm) distance along the bed. To give an idea how far out this is, for a full-sized toolroom lathe, the standard traditional spec for this lower carriage gib way is a maximum of .0007" over a 48" length. IE, pretty much a zero-zero reading over a 12" distance.

The machining quality on the lower ways on Brian's lathe is OK for the purpose. It looks to have been end-milled and is reasonably smooth to the touch, not ground or scraped at all. As this is a non-bearing surface under most circumstances super-fine finish is not required. (Although on my old Drummond it is hand-scraped dead smooth. But many other lathes use a milled surface here.

So it's looking like one of the first steps will be to file/scrape a few though off those lower ways to smooth out carriage movement all along the bed.

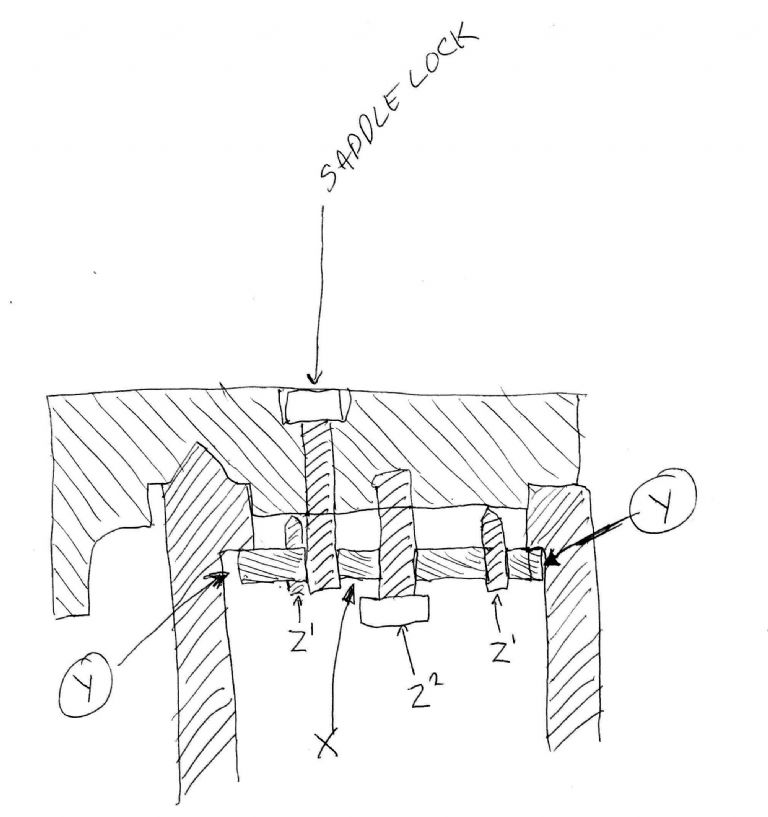

BUT, further points of interest popped up when we removed the lower gib plate (called the clamping plate in the manual and sometimes called the lift plate on English lathes.) Without it the carriage sits much more firmly on the major inverted V way and the rotational slop there (we could fit a .004" feeler in the gap on the V way) is gone.

So it seems the set-up with the gib plate being a piece of cast iron almost as thick as the carriage, the four jacking grub screws on the outer edges of the plate exert an upward pressure on the little carriage while the clamping cap screws exert a downward pressure on the carriage and the force is sufficient to distort the carriage.

So final set-up is going to include remachining the gib plate truly flat (it has slight drop-offs on the critical edges) and scraping flat. And then either rounding the ends of those grub screws and setting it all up very carefully with miinimal pressure – which is leaving it open to slacken off under working conditions — or replace the jacking screws with somelarge squares of flat shim to sit the gib plate where we want it and so the force of the cap screws then is spread evenly across the carriage to minimise distortion.

On the good news side, the carriage sliding ways, both the inverted V front way and the flat rear way, are not too bad. They are roughishly machined, end mill for the flatway and maybe a shaper or planer for the V, but a bit of bearing blue on the bed ways showed reasonably good contact areas for unscraped ways on the carriage.

The upper bed ways are pretty nicely surface ground so it will not be too hard to scrape the carriage ways to match . I laid the blue on pretty thick for initial sightings and to show in the photos but still not too bad.

One end of the flat way is a bit light on in the centre area, but has some reading all along the edges, so I don't think the light spot is due to the rear way being not parallel to the front way. Checked the bed for level with my old Rabone precision level and it seems OK, but that was using the flat on the top of the inverted V as a reference point. I would rather check it to the cheeks of the V later in the week by making a little jig that rides two cylinders on the cheeks and a third on the flat way and then borrow my mate's fancy new digital super precision level to sit on that.. My money is on it confirming the old Rabone but it pays to be sure that top flat is ground parallel to the V cheeks. You never know with unknown machinists.

Will also check the carriage's V way for parallel to the flat way on the surface table with a round ground precision bar (aka endmill shank) laid in the V groove and a DTI ..

Tthe cross slide ways seem OK. Again, one set (on the slide) appear to be nicely ground and the others (on the carriage) have been milled but not too roughly and then the nominal scraper marks thrown in their general direction as seen in Brian's earlier pics. So again, the milled ways can be scraped to match the nicely ground ones. With one set of good ways we can fix the mating set. If both were bad, there is not much you can do without making special scraped straight edges, V templates and dovetail templates — more work than the lathe is worth for a one-off job!

So overall, nothing catastrophic but a series of small errors/faults/poor finishing adding up to a problem.

Will keep you posted as we progress.

Hopper

@hopper

Well I dont know why my last post went all skinny columns and stuff. Maybe a mod can fix it?

marko veic.