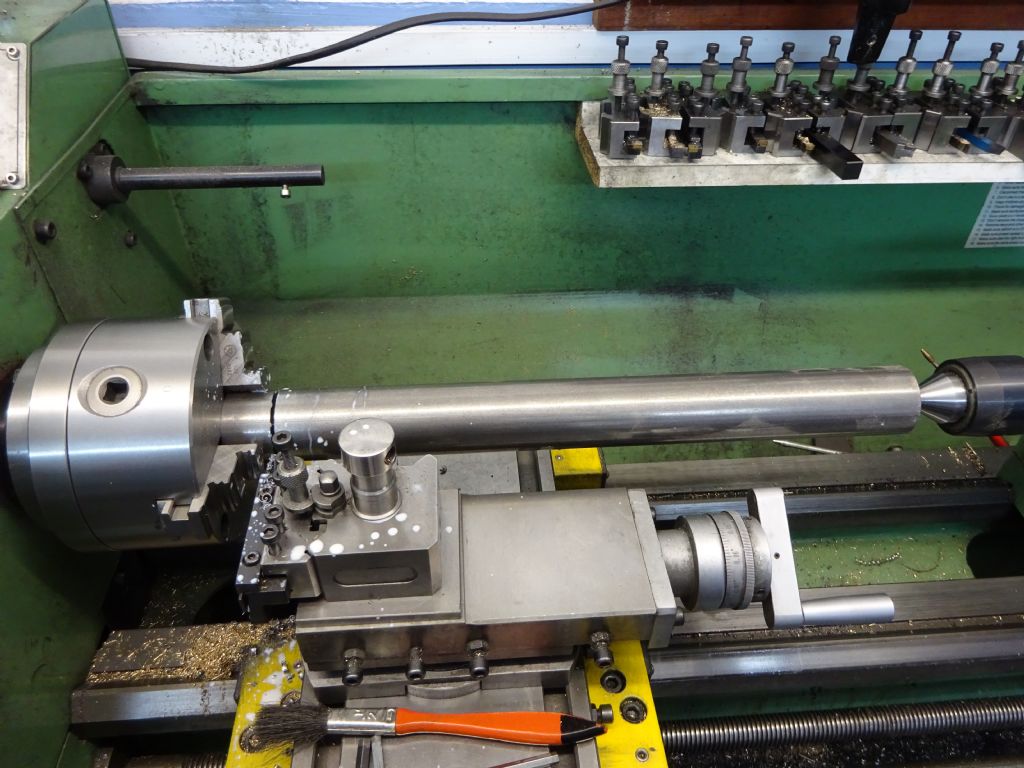

Hmmm, looks like you have the basic rough-machined casting kit one hears of.

The very edges of that rough machined "clamping plate" are what runs on the lathe ways at the bottom of the bed. That area really should be a) dead smooth, either scraped or ground, and b) much larger, hopefully there is room on the bed to make a wider plate.

What is the finish on the lower bed ways where that clamping plate runs? Is it rough machined like the plate, or smooth ground the like ways on the top of the bed?

It looks to me like the main top ways have been ground to a reasonable finish. This now needs to be used as the template to hand-scrape the sliding ways on the carriage to match it.

Then the bottom ways will need checking/scraping to make sure they are parallel to the top ways, so you dont get tight and loose spots.

Then the bottom clamping plate needs scraping to match the bottom ways so it bears on a large area that will not wear down quickly.

Then, hopefully either the cross slide ways on the carriage, or the ones on the cross slide itself, are well enough finished to be used as a template to scrape in the other half to match and get it all tightened up and straight etc.

Absolutely not something a beginner can tackle. When you bring it around we can give it a bit of attention and get it sorted properly though. Thankfully the machine is so small it will not take massive amounts of scraping to get it significantly better than it is now. (Bloody hell, an angle grinder could almost get it better than it is now!) In fact, a good seeing to with a millsaw file by an experienced hand will do that clamping plate the world of good and not take very long at all.

Edited By Hopper on 25/10/2015 08:39:34

marko veic.