Posted by Brian John on 17/10/2015 15:39:15:

I could not wait until later so I have tried adjusting 232, 234 and 220 ; nothing makes any difference. 234 in particular does not seem to affect anything. Maybe it should but it doesn't ! The only way to remove the excess play is to tighten up the gib screws to the point where it is hard to turn the wheel. Even backing them off by 1/16 turn introduces too much play…very frustrating as it did not have this problem last week. I do not know what has changed.

Brian,

Where EXACTLY is this excess play you speak of?

1. The gib screws should be adjusted to eliminate play (sideways, twisting) between the cross slide and the saddle only, but allow the cross slide to freely move along the saddle dovetail.

2. the screws 232 and 220 should be tightened as per above (temporarily leave 234 loose) to fix the nut 213 firmly to the cross slide.

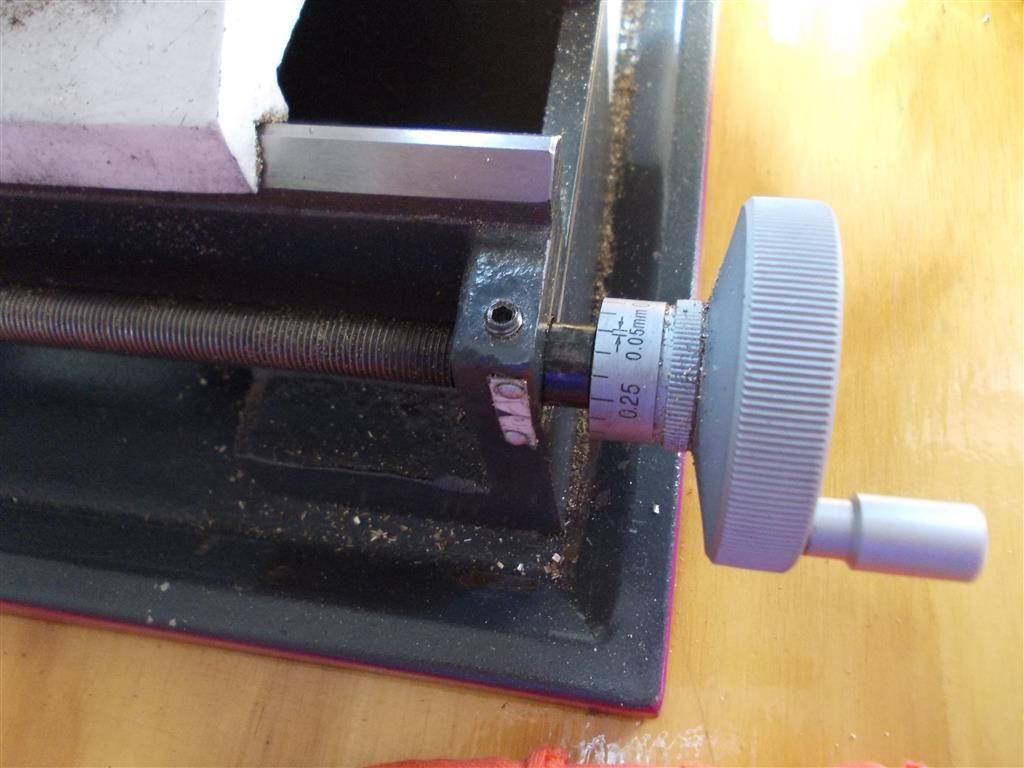

3. the cross slide feed screw dial should be mounted on the cross slide screw to minimise the end play between the screw and the cross slide, but there should still be some clearance (end play) there (this is OK, necessary for lubrication and free rotation of the screw)

4. the cross slide feed screw should rotate freely in the nut 213, but screw 234 can then be screwed down to an extent that the rotational end play in the cross slide feed screw is reduced (this is the backlash adjustment). Some end play (which shows up as rotational backlash) is still desirable here for the reasons stated in previous posts.

Items 3 and 4 above will show up as front to back slop (backlash) in the cross slide movement on the saddle, but this is not important compared to any movement left from item 1, as cutting forces should automatically take up this front to back movement. The only place where this backlash may become important is when the cross slide dial feed direction is reversed (winding the cross slide back out from the workpiece), and this should be accounted for by winding the cross slide out further and then winding back in to your setting taking out the backlash. This is normal for nearly every lathe.

Hope this is helping, and not muddying the issue.

Andrew

marko veic.