Brian

Quite possibly, yes …

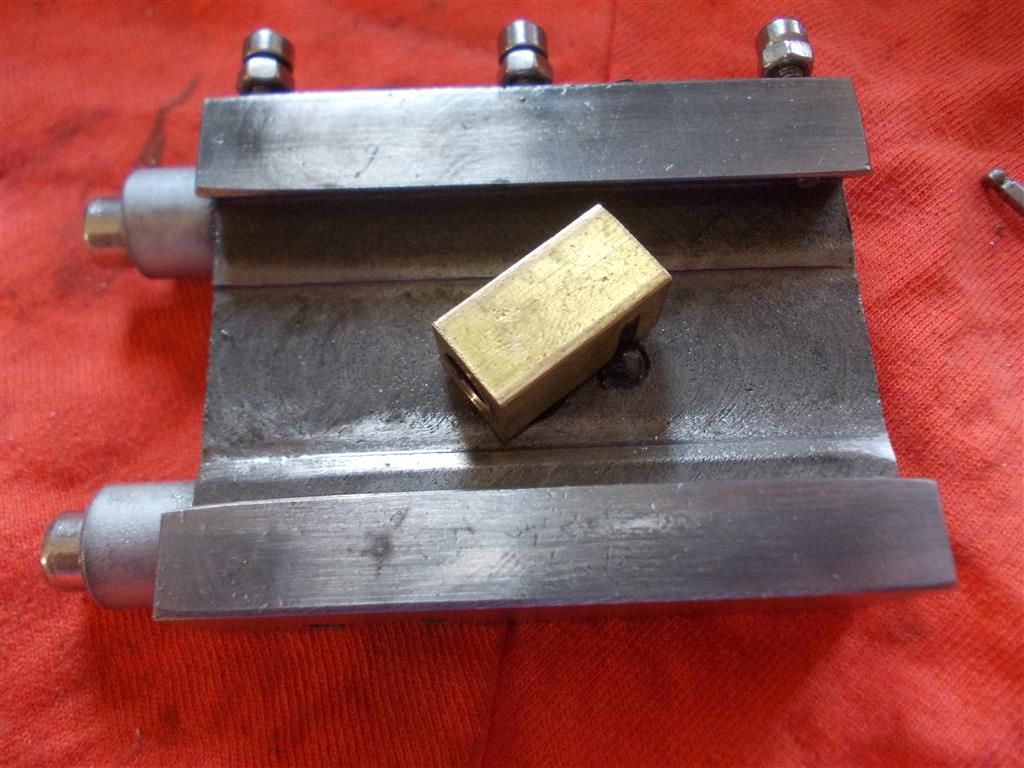

As others have mentioned, you first need to ensure that [where appropriate] corners are 'broken' so that the surfaces that are supposed to slide together actually do. … this is easily done with a decent quality file, and reasonable care.

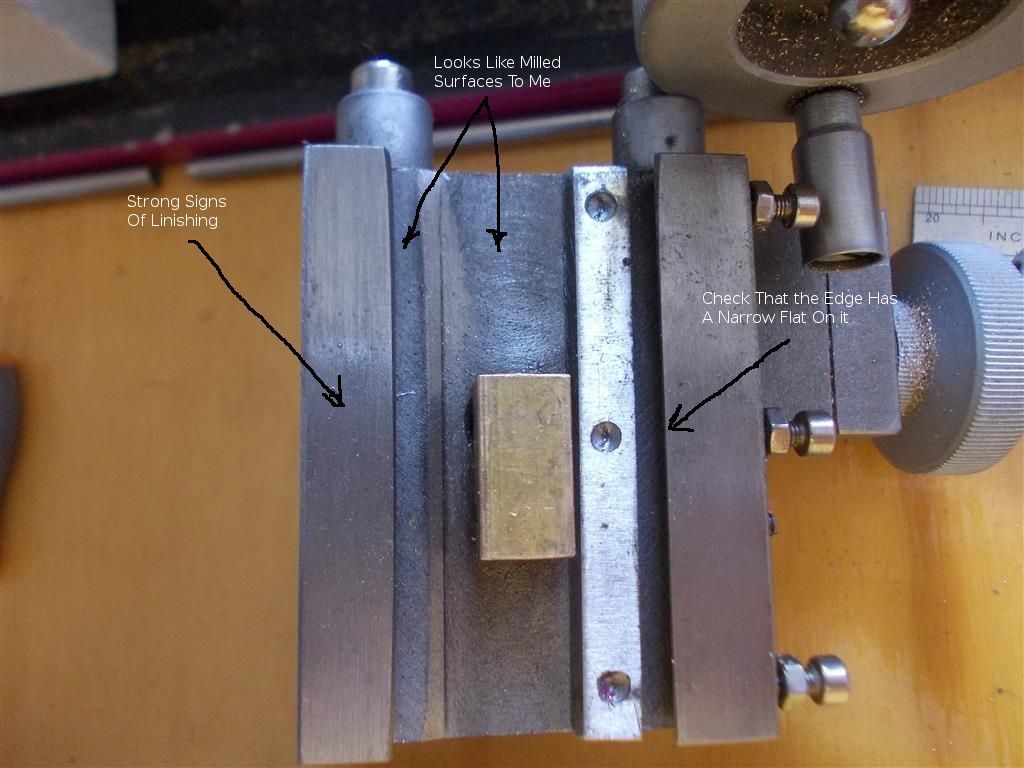

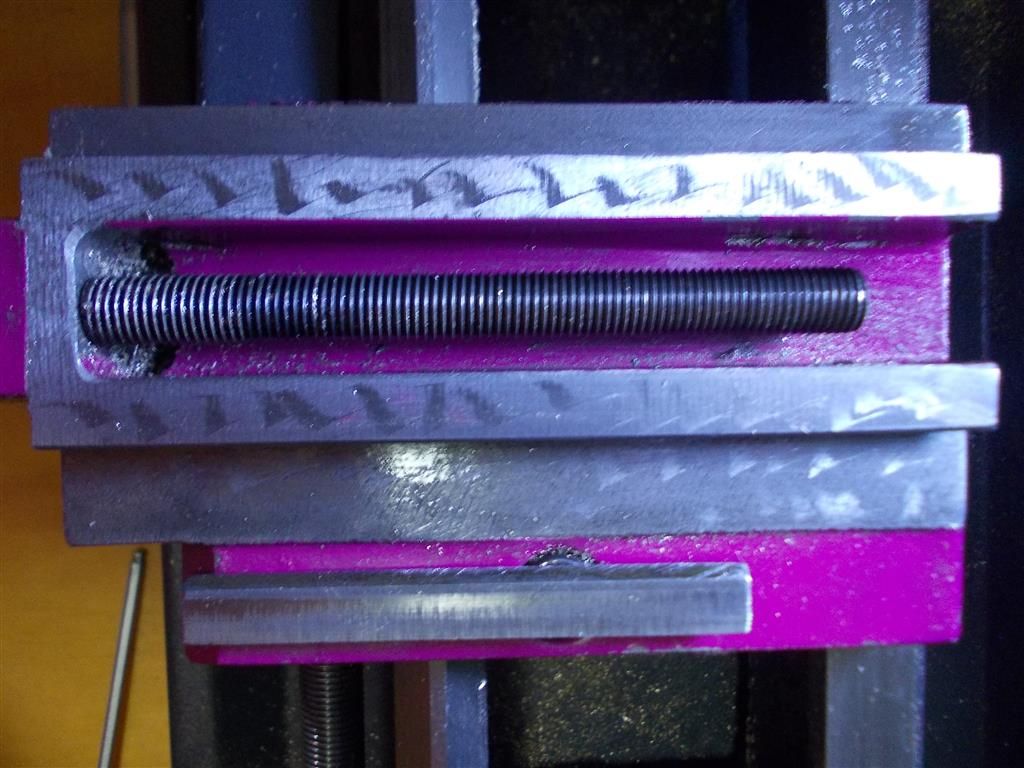

You might then consider improving the surface finish of the sliding surfaces … depending on how bad they are, gentle filing may be useful; but hopefully, lapping [as suggested by John W1] will bring a substantial improvement. … The really important dovetail is the one without the gib-strip, because that one aligns the slide with respect to the bed, and you need to maintain that alignment. … The gib adjustment will cover up a few sins on the other side!

The bearing suface of the gib-strip also looks like it could use some attention … ideally it should be a 'mirror' finish, and flat … I restored the one in my Myford, using a fine file, followed an Eze-Lap hone [the red one that I linked for you when we discussed sharpening Carbide tools]

If you can do some close-up photos of various surfaces, it would help 'the team' to advise you.

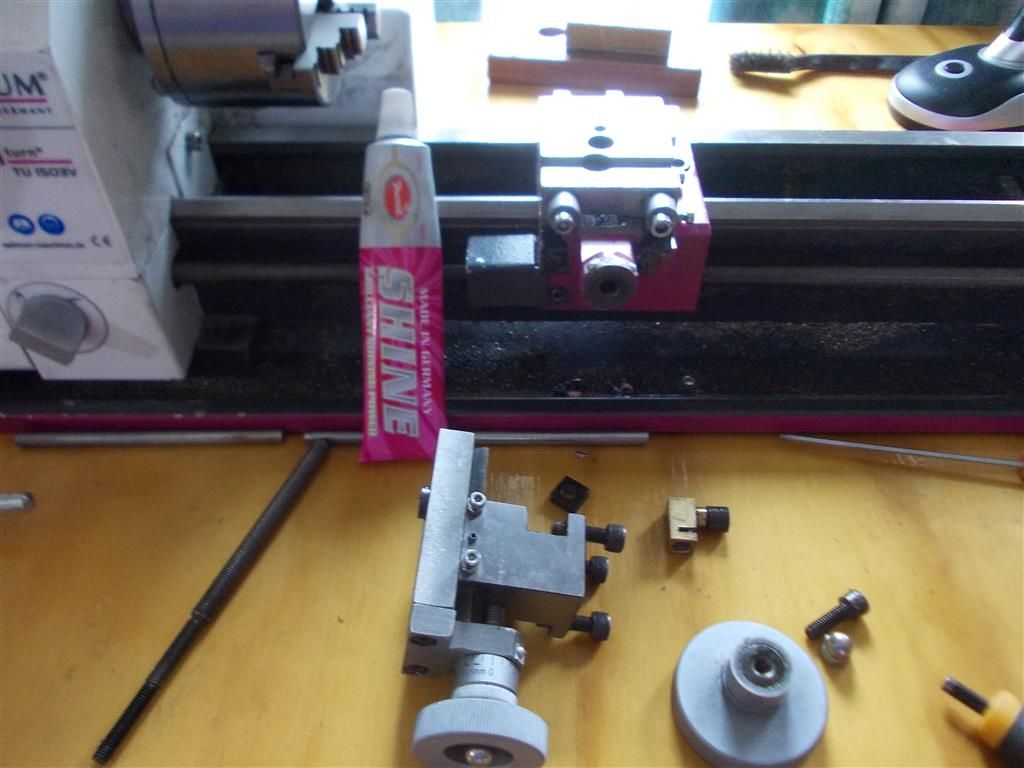

Note: All of this is 'to be expected' on a modestly priced 'Hobby' lathe, and it is why they have sometimes been described as a set of castings. … It would be easier if we could afford to buy a Schaublin or Levin <etc.>, but most of us cannot.

Take it steady, and look for the areas that you can improve by simpe 'fettling' … in the fullness of time, you will probably go several times round the block as your skills and tooling improve.

MichaelG.

marko veic.