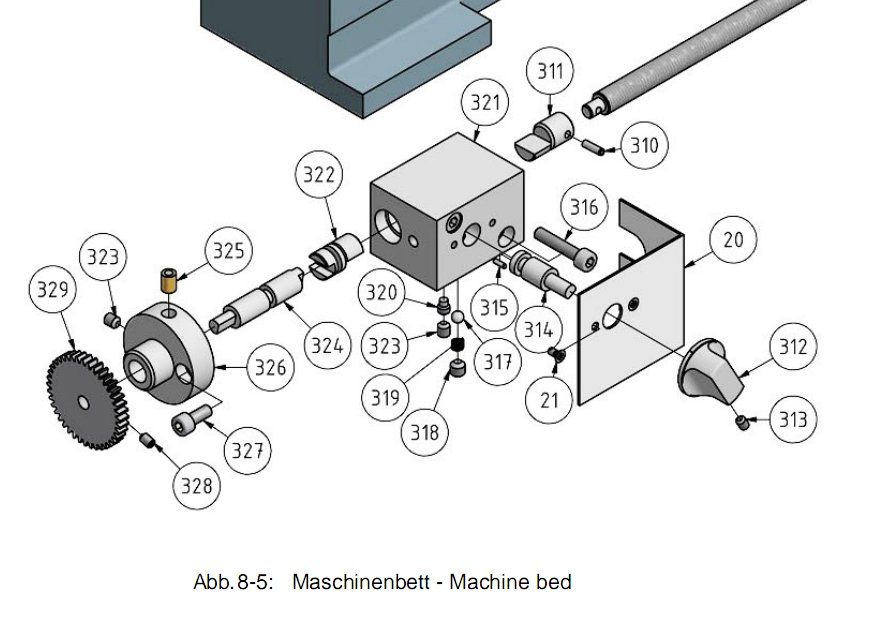

I'm pretty sure Brian has pulled the knob out so given that everything else is ok should be able to push it back in as all that holds it in is the detent – 317,319,318.. It look like 320 hold 324 in place and 323 locks 320 otherwise the set up wouldn't work.

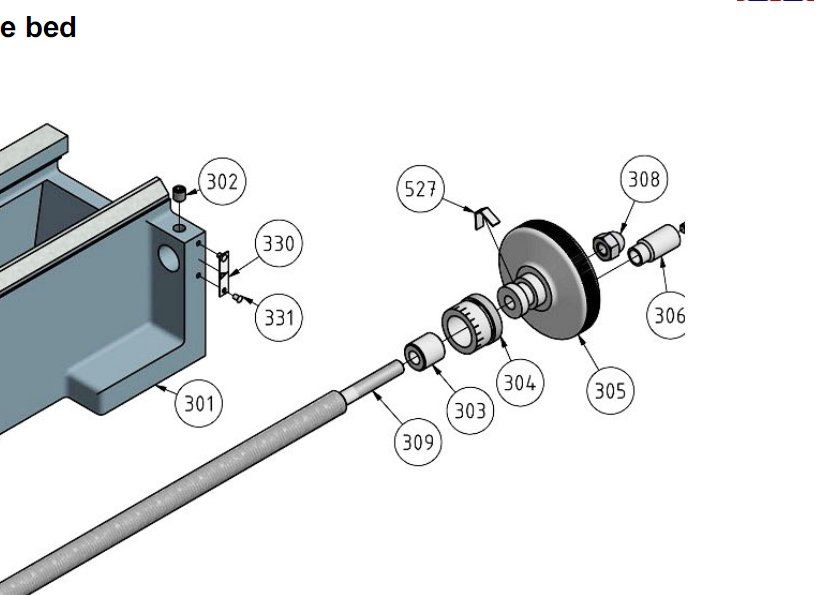

What I think has happened is that the bush by the handle has come out so that needs a fix. What I would suggest first is to loosen 302 right off, push the bush 303 in with a clean surface up towards the screw that holds it in place. Tighten the screw which will mark the bush, remove a file a groove in it to suit the end of the screw. This will mean pushing the lead screw back in place. It will have to be rotated so that parts 311 and 322 mesh with each other. I'd guess that the bush has a little sticking out of the casting at each end when it's in the correct place.

The set up reminds me of a Hobbymat so there may be another problem if the feed didn't engage easily and became stiff. The tongue on 324 and the mating slot in 322 burr over. These aught to be hardened but aren't as supplied on a Hobbymat. The fix is to dismantle and see what is fouling and clean it up with a file. Not using too much force on the knob can help prevent the problem – these parts wont mate until they line up. Also engaging and disengaging smartly.

In order to get the knob and shaft 314 back in place 318 may have to be slackened off or even removed. Make sure the ball and spring aren't lost. The peg on the end of it will locate in the slot in part 322 so it should be possible to see the orientation needed when it is pushed back in. Adjust 318 until the detent works nicely.

There should be no need to touch 323 which locks the 320 screw in place.

John

–

marko veic.

All to save a rack, gear and handle plus a clasp nut but I suppose it is cheaper.

All to save a rack, gear and handle plus a clasp nut but I suppose it is cheaper.