John,

I consider myself to be fairly new to CAD, also, having been dabbling with Alibre Atom for “only” a couple of years.

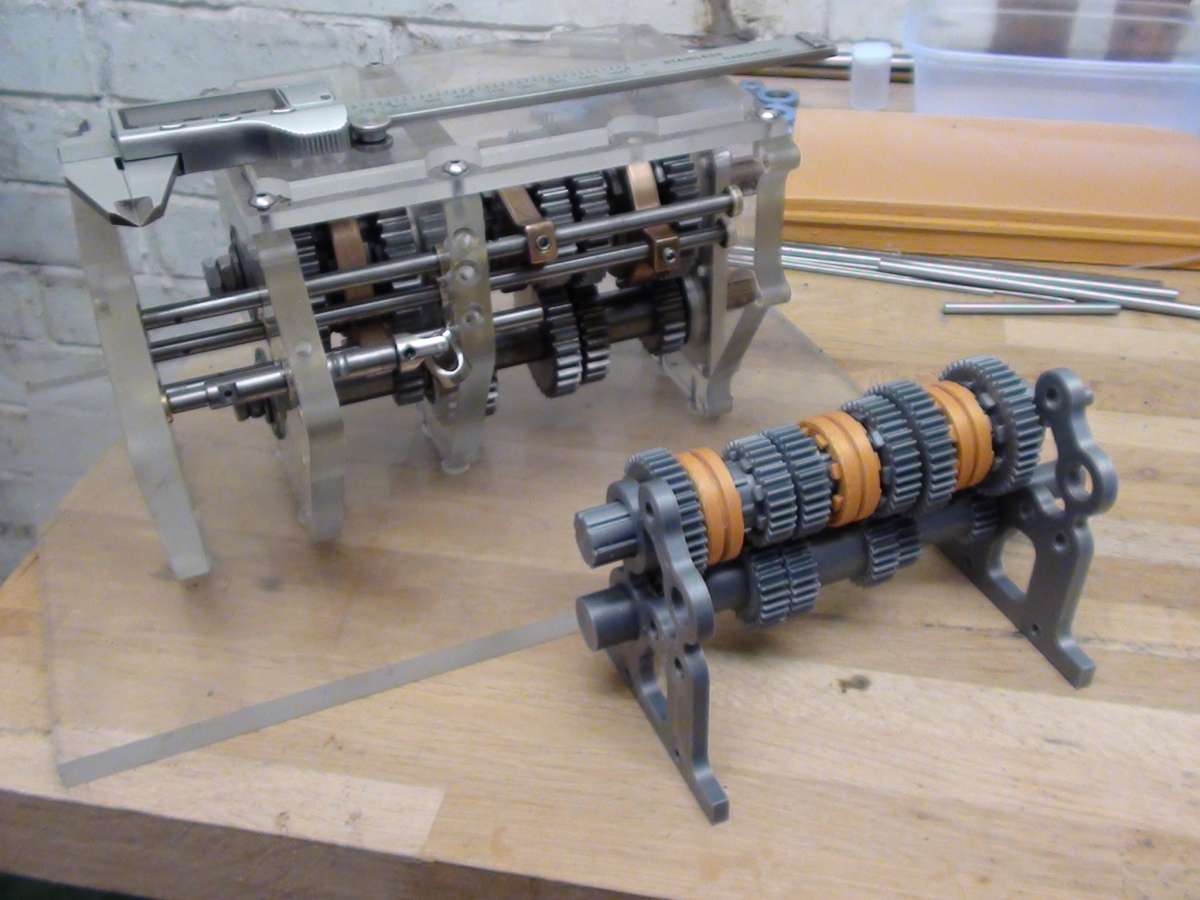

The thought process that you describe above is pretty much the same methodology that I use. In this case I downloaded maintenance manuals for a number of Hewland gearboxes and studied them quite thoroughly. Originally, I drew up my version of a 5-speed, non-sequential gearbox and made CAD drawings of that, eventually making a model in metal, mounted on transparent perspex for display purposes as seen below in a size comparison with the current project :

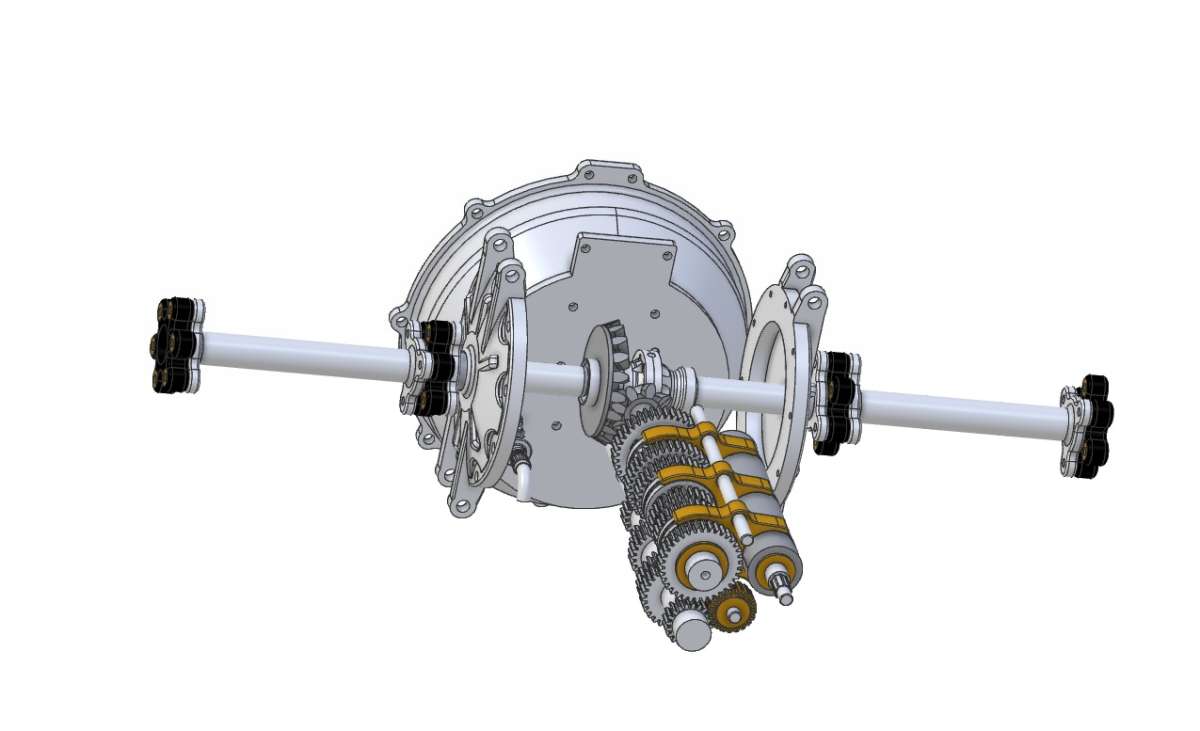

The 3D print is a scaled-down version of the “old” design, but with the added complication of the sequential gear selection mechanism. All the gears were made using the GearDFX program from ForestMoon. This is a costumisable program which will output gear forms in a multitude of formats, including DXF, SVG, STEP, STL and OBJ, so it should be suitable for any number of CAD programs or even straight into slicing software.

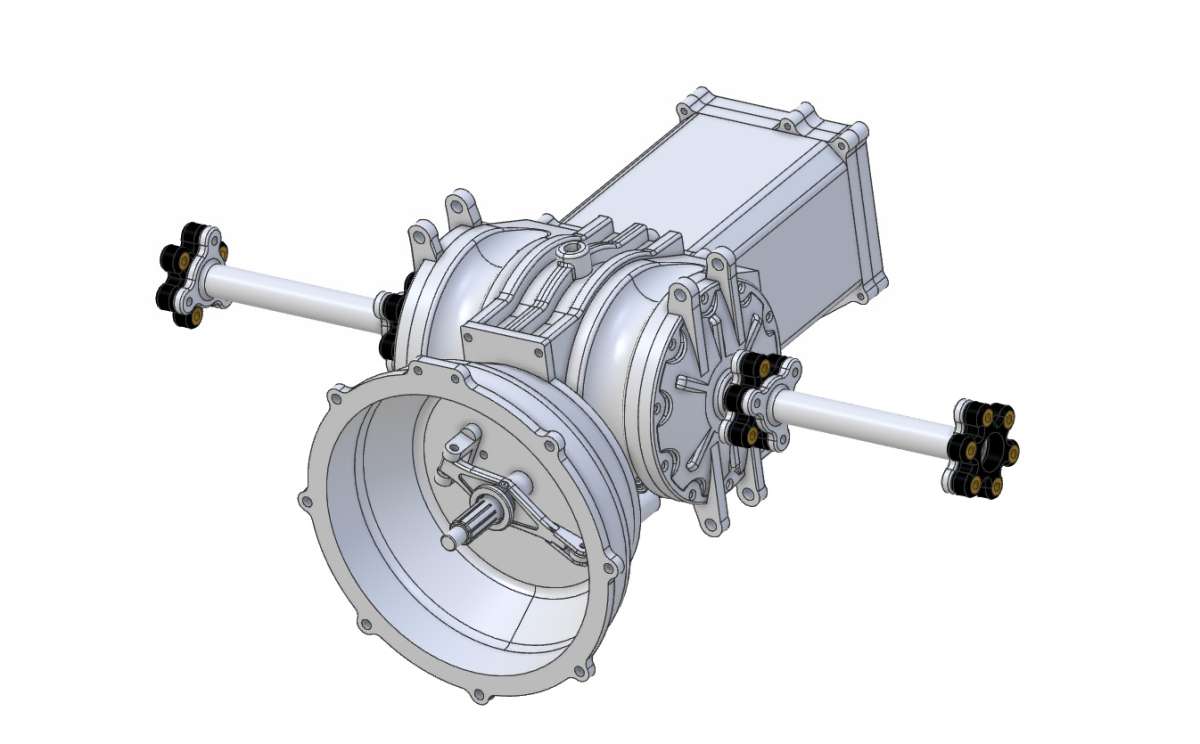

Once the gear clusters were sorted, I designed the differential. As I mentioned previously, the crown wheel and pinion were done in Fusion 360 and are straight bevel-toothed gears as per the full-size Hewland gearbox. Now that I had the innards, I drew the casings around them to give an aesthetically (to my eyes) look, adding the strengthening ribs and chassis mounting points, etc as it progressed. As you can imagine, this took a long time, a lot of trial and error and involved adding various new planes and axes along the way. It sounds more complicated than it is, really. It is a matter of taking it a step at a time and if it doesn’t look right, be prepared to press delete and start again. Once the casings were complete, I added a bellhousing and the clutch release fork and slave cylinder/pushrod as the design developed.

I am (almost) ashamed to say that there wasn’t lot of pre-planning involved, like Topsy, “it just grew”.

I hope that gives you a brief glimpse of my design philosophy and execution of this design. I’m happy to answer any specific questions, by PM if you prefer, but bear in mind I’m NOT qualified in any way in CAD, engineering, design or machining – just a keen self-taught amateur.

Regards,

John

John Hinkley.

John Hinkley.