When I was initially looking for metalworking capabilty at home (some 25 years ago), my first thoughts were to go for one of the Chester lathe mill combination machines that were advertised in the motorcycle magazines. Seeing one in the flesh at a classic bike show was a bit of an eye-opener – there was so much play in the various moving parts it felt worn out straight from the crate ! At the time, this was pretty well the only mainland Chinese machine available for the hobby market, with the other affordable (relatively !) small machines being Taiwanese or East German. My thoughts changed to a CT918 lathe – basically an Emco Compact 8 & still available until recently from Chester & Warco. – and the saving began.

My father had bought a Boxford CUD from one of his customers – he didn't particularly want a lathe, but the seller wanted rid of it and the pillar drill Dad really wanted in one transaction.. After it bit him (thou shalt not start the spindle with the chuck key still in the chuck …) it got no further use. When he passed away, I bought the lathe from my brother (who continued to run my father's business for a while & the machine was a company asset.).for a nominal amount.

A mid-'60s ex-school CUD that had ended up in a clothing manufacturer making press stud insertion dies, it was not in bad condition, but had been greased through all the oiling points. So it was completely stripped, cleaned, repainted & rebuilt. Over the course of a couple of years, I managed to get most of the missing change gears, a direct mount 6" 4 jaw chcuk, faceplate, QC toolpost, a boring table (the lathe was pre-tee slot cross slide) & a travelling steady – never did manage to find a fixed steady. This was pre-Ebay, so the bits came from dealers, Auttjumbles & ME exhibitions. It worked mostly quite well & was accurate, but the under drive was a pain. As the final drive belt has to pass through the swarf tray, it has to be a link type belt. The original that Boxfords used was of a canvas-type material & that worked OK-ish, but was in poor condition. The new types are made from a plastic material & slipped badly under load depite being bow-string tight.

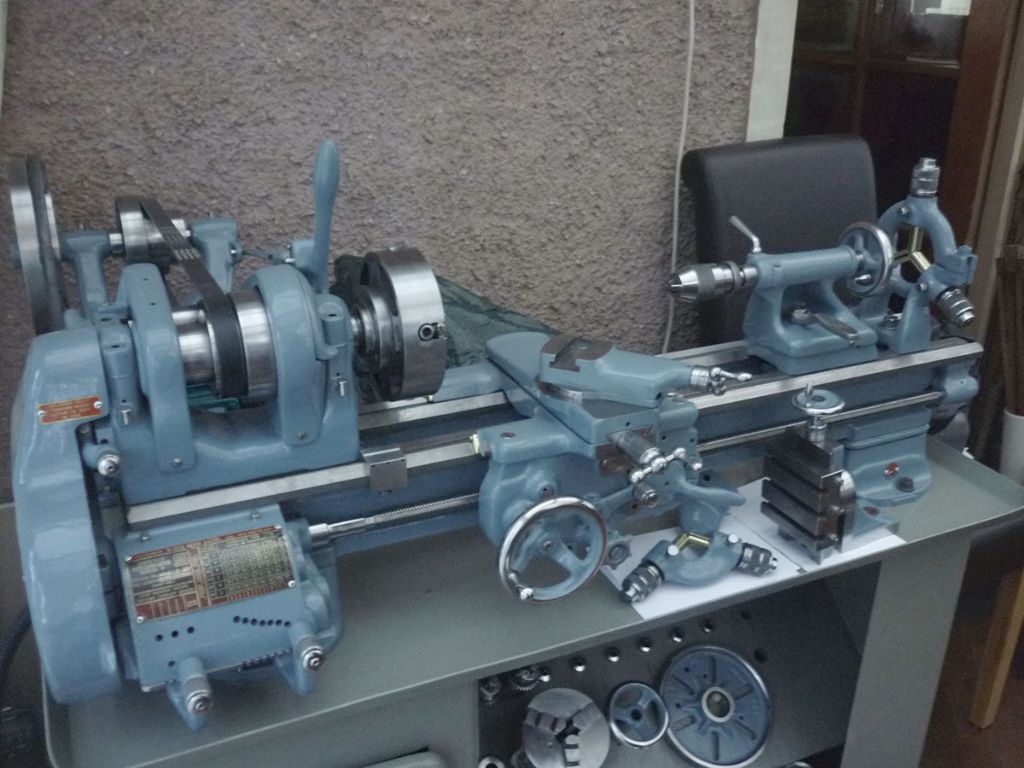

Skip forward a couple of years & I was on-site at a machine tool dealer fixing a machine that the company I worked for at at the time had retrofitted a replacement control to. They had a pretty clean, mid-'60s ex-school Myford Super 7 – direct mount 3 & 4 jaw chucks, faceplate, catchplate, taper turning attachment & 3 sets of change gears (there must have been 2 more lathes somewhere else gearless !). My milling machine fund was depleted to the tune of £825 & it came home with me a couple of days later. My thinking at the time was that I would get it cleaned up & use it, determine whether I prefered the Boxford or the Myford & sell the looser. The Boxford went. For what I wanted to do (and still do for that matter), the Myford was nicer & more convenient to use (speed range, ease of speed setting & the spindle clutch particluarly). Selling the Boxford & accessories raised far more than the Myford cost, so the milling machine fund was reinstated.

I found a fixed steady at an Autojumble a fortnight later (never did find a Boxford one) & a couple of years later bought another (poor condition & damaged) Super 7 B of similar vintage to get the feed gearbox. The gearbox was swapped to my lathe, parts that were beyond redemption on the "scrapper" were purchased new direct from Myford & fitted to my machine, with my good-but-slightly-worn bits intended to go into the other. A friend wanted this machine after I had done it up, but he died suddenly before I finished it & I lost interest after that. It went as parts on Ebay, raising more than it & the new parts had cost – effectively a free feedbox , leadscrews & nuts on my machine.

Used machines, as has been said, are a lottery & the quality of the Chinese competion has come on leaps & bounds since I looked at the Chester Multi-purpose machine 25 years or more ago (and shuddered !). The newest "original style" Boxford will be 30 + years old now & they were not made in the quantities that the Myford 7 Series machines were, so availability is not as good. Finding accessories at a reasonable price (or just finding them period) was a chore over 20 years ago & doesn't seem to have got better. Find a nice, fully equipped machine & it may be a better buy than a Myford or a new Warco etc., but if I were to start out again I would probably go the new route. Had I bought the new 918 I intended to had fate not intervened, I would most likely have made more "stuff" and spent less time rebuilding !

Nigel B

Hopper.