Roy, Steve,

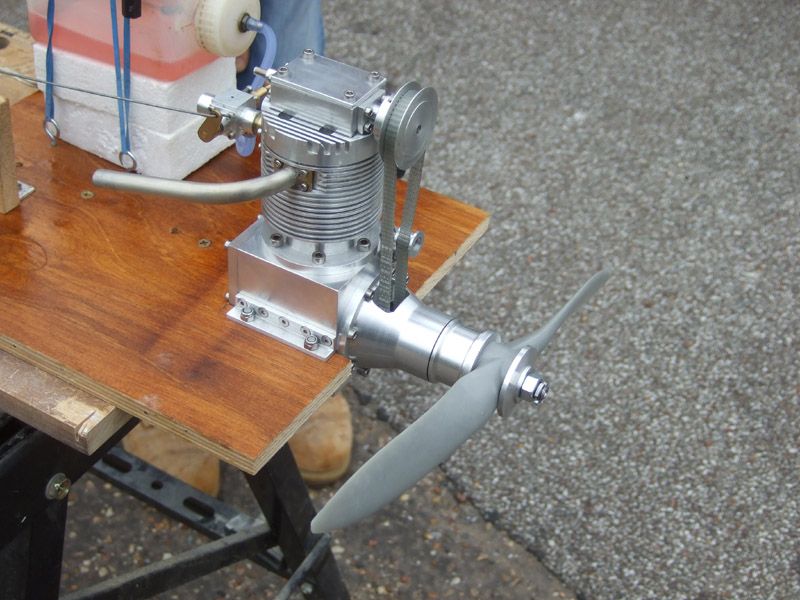

Speaking from personal experience a prop continually loosening or indeed spinning off all together is definitely not ideal

.

Personally I think the circlip idea to prevent total ‘loss’ is better than the split pin if for no other reason than asthetics though either could catch an unwary finger if run exposed. A split pin will have to be continually straightened for removal too. However niether will actually prevent the prop from loosening as it fires and kicks back which is the root of the problem.

Though I have no experience with them directly I know model four strokes have a far greater propensity to throw a prop than two strokes but it happens with these quite often too.

When flying/competing in C/L aerobatics there is only one minute allowed to start and

get airborne. A loose prop in that situation then is a definite no-no.

I found that introducing a paper ‘washer’ cut from 240/320 grit wet and dry between the driver and the back of the prop (grit toward the prop) virtually eliminated this problem both on wooden and ‘plastic’ props. On some aircraft there was the need to space the spinner backplate out from the prop driver to clear the fuselage and these spacers were made from nylon. Again wet and dry washers were used between all surfaces with total success.

It’s a simple tip but works well certainly worth trying to see if it will do the same in your situation.

Small, short, drive peg/pegs can also be incorporated into the driver to match a shallow hole/holes in the prop but a paper washer is much easier to produce

Like wise by drilling a radial hole in the prop driver to accomodate a ‘tommy’ bar when tightening the prop nut if you decide to use a nylok – though it’s hardly likely to cause an effect, by drilling two or three the balance remains and is more asthetic.

Hope this is of use/interest

regards – Ramon

Edited By Ramon Wilson on 05/09/2011 09:49:16

Emgee.

.

.