So I have a cottage in a wild and windy place with an en-suite. I have built a heat recovery system for it which seems to work. My problem is that for 23.5 hours of the day, heat is escaping from it. So it is always cold to start off with and so I thought I need a way of sealing the air ducts when not in use.

I have built a prototype which is a geared down induction motor (as used in washing machine timers etc.) driving a flap that moves through 90* to open or seal the 4" air duct.

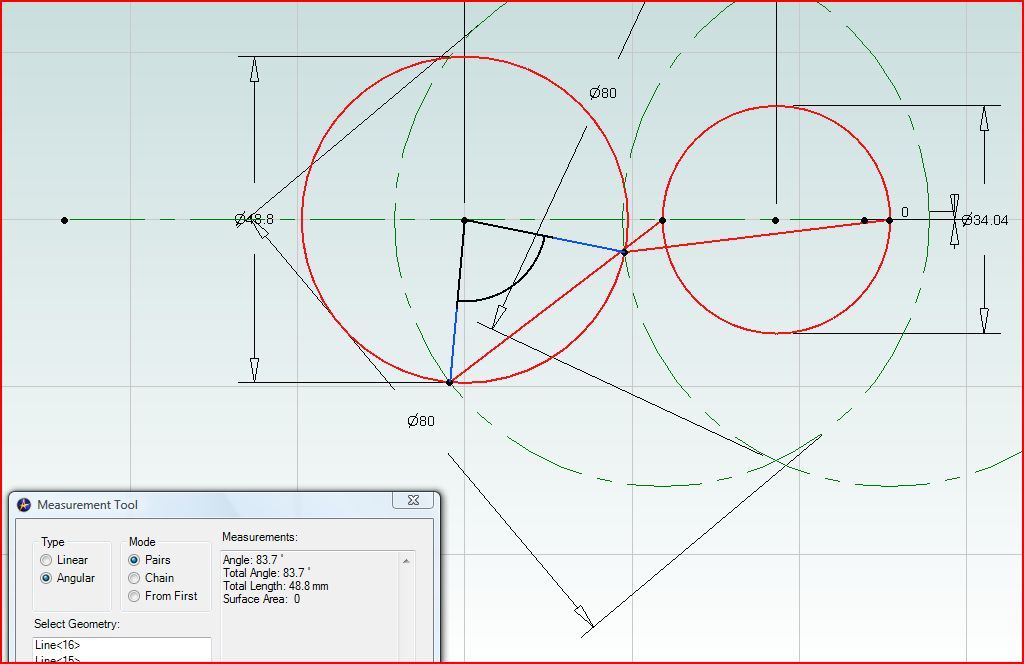

The motor which only starts and stop and runs in one direction is 46.6mm from the hinge pin of the flap. At a distance of 17.02mm from the centre of the motor shaft is a bearing onto a connecting rod of 40mm centres. The connecting rod then connects on to a disc ,24.4mm from the centre of the flaps hinge.

I have mounted microswitches on the other side of the flap so the motor only stops when the flap is open or closed. The whole thing works beautifully, with a change over light switch the flap opens an closes.

There is no slop to speak of in the con rod bearings, but I am worried that when I proceed to invest in stainless steel shafts etc, that the whole thing will jam up. So I thought I would do maths on the various bits and pieces to prove to myself it can work. But I can't seem to even get started.

So has anyone seen a con rod mechanism working on unequal swing arms and its mathematical proof?

Frank

JasonB.

JasonB.