Hi there, just wonder if any one can help with this one.

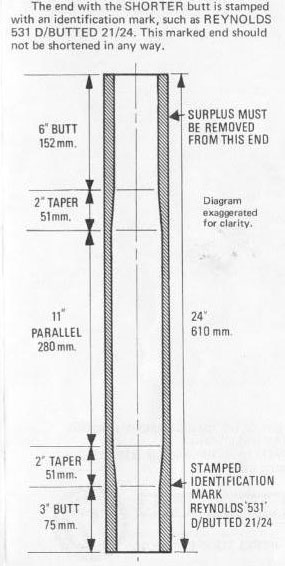

One of my hobbies is collecting and restoring vintage bicycles. I have a late 30's bicycle. A previous owner I assume has stuck a Reynolds 531 butted tubing on. Reynolds 531 was around then, as both plain and butted tube. But the hand built manufacturer does not list it for that model. So is it really Reynolds 531, or a heavier gauge tube.

The tubes we are looking at here are 1 1/8" to 1 1/4" od, 18-24 swg.

I have borrowed from work an ultrasonic tester with a stated lower thickness of 1.2 mm. On test samples this correctly measured a 1.2 mm wall tube, but on a 0.8 mm plate it measured 1.6 mm. Twice the thickness.

I have taken numerous measurements of the bicycle tube, and get figures from 1.1 to 2.0 mm. 1.1 mm could be correct for a heavy gauge tube. But 1.6 mm or higher is wrong. So do I divide by 2?

At the moment I am inclined to discount the measurements.

So is there a better way. I can only access down inside 1 tube about 20" long.

I have read about eddy current methods but not going to pay for the equipment for a one off.

Any suggestions while you have a cup of tea.

Neil Wyatt.

Neil Wyatt.