All sorted now, thanks to Roy I have now the Viper plans. As I expected, studying these brought up a couple of questions. Certainly there will be more when the work really starts!

But for now what has come to my attention.

In sheet 1, crankcase: what does the expression 0.005" witness mean in practical machining terms?

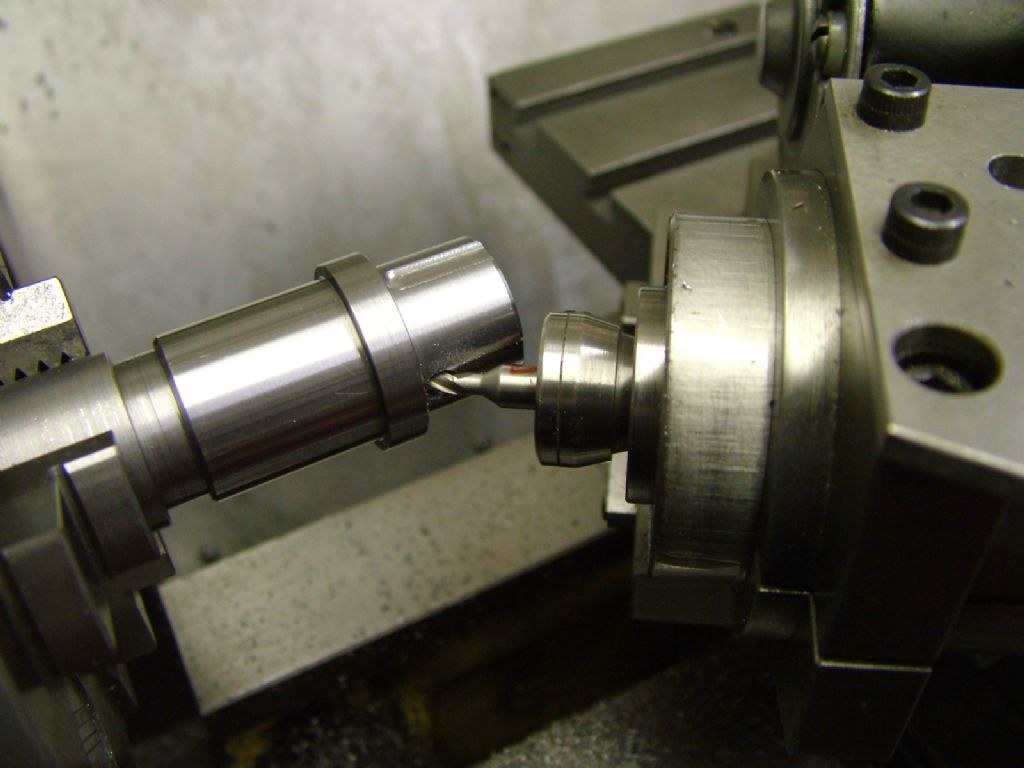

In sheet 2, crankshaft: how can the counterweight be machined (in the form as drawn) when the crank pin is in the way? Or is the pin pressed in, but not shown as such?

In sheet 4, cylinder: how is it possible to drill a #33 hole (2.9 mm ) at an angle of 25 °? Might be possible with a 3 mm slot mill, but that would be too large then? Or using 2.5 mm and then opening out a bit?

I started to read through the couple of Viper threads, including the long one from 2019 (what the Google search brings up). I saw a building report from someone, but that ended just when the cylinder machining would becoming interesting. I can't find that thread atm, lost again a couple of hours in searching.

Kind regards,

Hans

Ramon Wilson.

Ramon Wilson.