Hi Everyone!

Hi Everyone!

Sorry that it has been a while since I posted on this thread, I did not start back at work full time until January, after recovering from an heart attack last summer,so I have been getting back in the swing of things!!

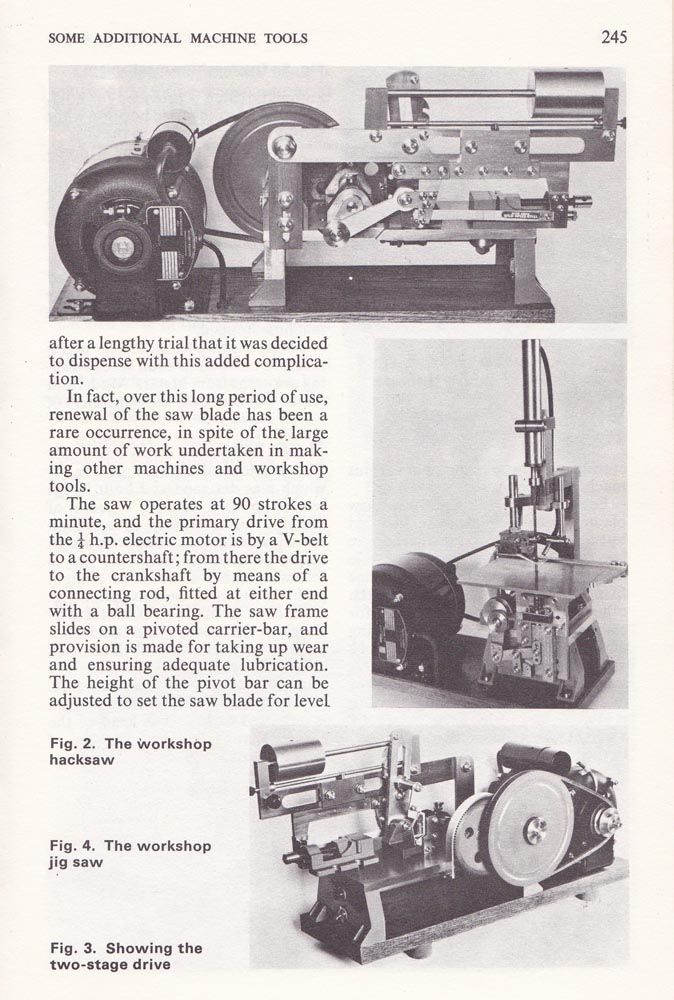

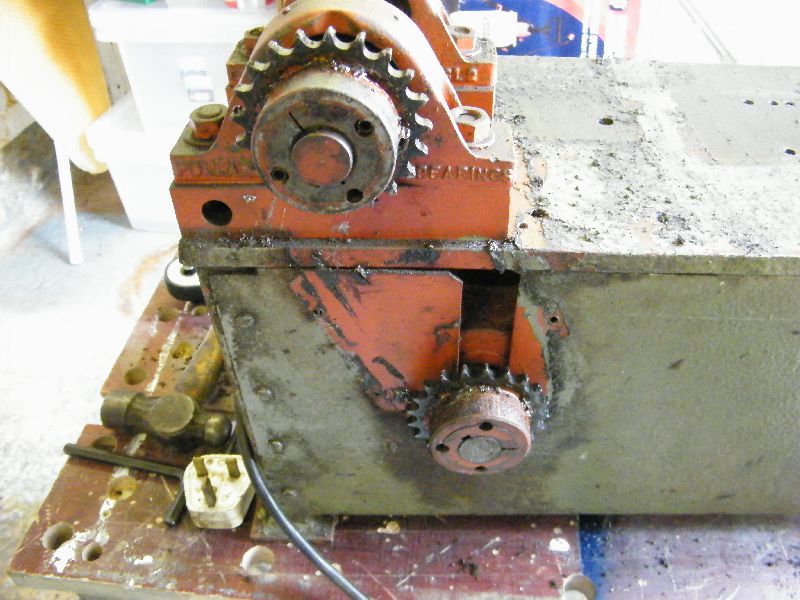

Having found Myself, like many more, with more time on My hands recentley, I thought it was about time to get on things, so I have finished tidying up My power hacksaw which I bought last year………

Sorry that the text is in the middle of the photos, i have not sussed out how to layout the posts yet!!

I just need to make an extension for the rear blade peg, I thought that it fit 10" blades,(which I have bought a good stock of…) but on trying to fit a blade, found out it was requires 9" blades??……..

The original builder must have shortened and re-drilled his blades to fit…….

Not a problem, saw is stored away for the workshop is finished.

Now, what to do when You are on lockdown?

Ah! I've got a Super 7 lathe that needs a good looking at! (as glimpsed in some of this photos)

Please take care Everyone, keep Yourselves and Your Families safe.

Thanks for looking in, Pete

Morty.