Post to explain how corrected gears can be cut using standard cutters to a reasonable accuracy**

Could be long and may need to be in two parts because of the length of it, so best go get a coffee and throw the cat out.

Bit of background first and some of this may be simple but as I don't know who's reading this I need to explain the whole.

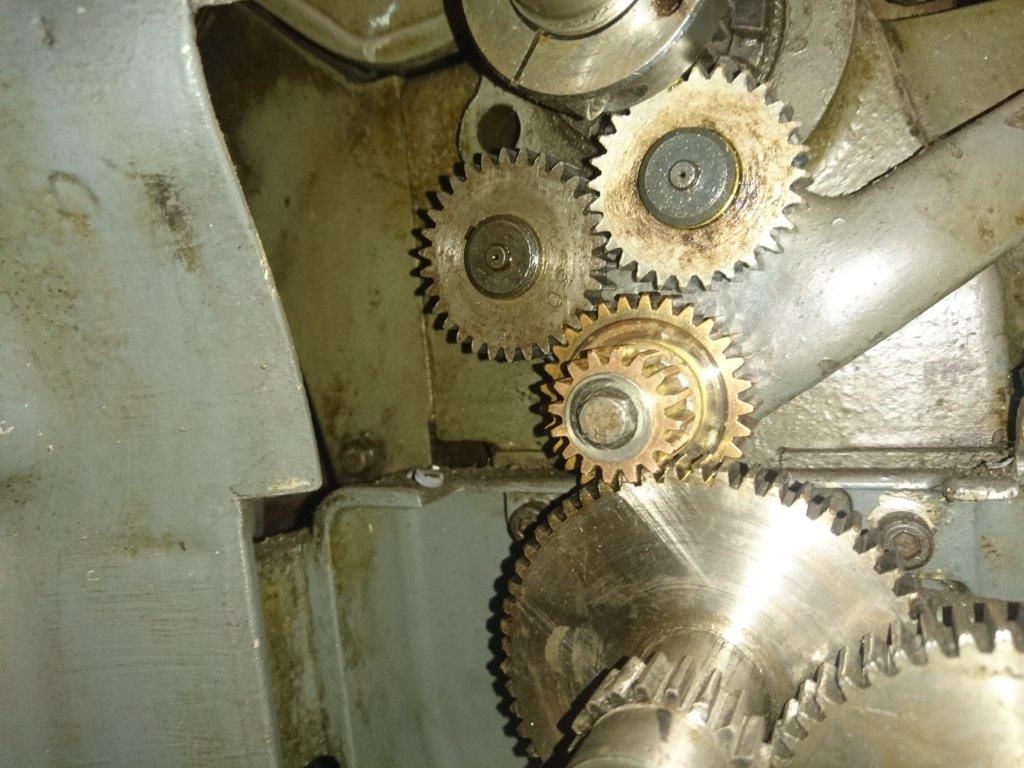

Making corrected gears is something that is done in industry all the while. Strip and measure any modern automobile gearbox and I'll bet none of the gears are standard, all modified for strength, quietness etc.

In production work it's easy to modify corrected gears as any manufacturing method that uses the GENERATING method like hobbing, shaping etc will form the corrected involute automatically.

Unfortunately the home shop method uses FORMING which is limited to the shape of the forming cutter.

As every gear as it increases in tooth number has a different shape then we need a different cutter for each shape, rather a tall order to have say 100 cutters and then you need a hundred in every pitch or DP ] you want to use.

So very early on Brown and Sharpe decided to 'band' these as the differences are very slight.

The bands were numbered 1 to 8 so only eight cutters were needed per set.

Cutter No 8 cuts from 12T to 13T

Cutter No 7 cuts from 14T to 16T

Cutter No 6 cuts from 17T to 20T

Cutter No 5 cuts from 21T to 25T

Cutter No 4 cuts from 26T to 34T

Cutter No 3 cuts from 35T to 54T

Cutter No 2 cuts from 55T to 134T

Cutter No 1 cuts from 135T to a rack.

As you can see the number of teeth in the lower range is limited by the differences in shape whereas as you get bigger the difference isn't so great as regards shape.

A Number 8 12T to 13T is very curved whereas a number 1 from 135 to a rack is virtually straight sided as a rack should be.

A note here to explain that the band of cutters is most accurate at the lowest number of teeth listed.

Now lets take Simon's 29T special gear.

Standard 30 T on the left, 29T on the right, both standard at 20DP and 14.5 pressure angle. There is virtually no difference in shape as these would have been cut with the same FORMED cutter but these shapes are GENERATED.

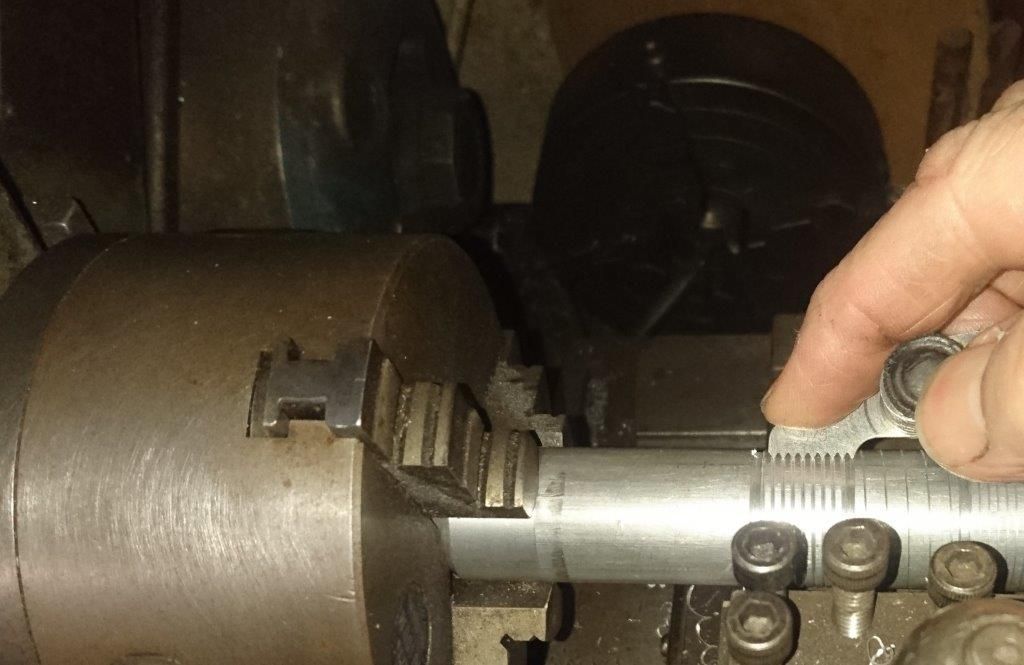

The important bit is the 30T has an OD of 1.600" and the 29 has an OD of 1.550" but Simon needs it to have an OD the same as the 30T so it meshes correctly.

So we correct the gear by moving the relationship of the Addendum and Dedendum [ top bit of the gear above the pitch line and bottom bit of the gear below the pitch line ] and we get this.

Now both OD's are the same but now look at the shape of the tooth. Because 29 teeth have been spread out where 30 should be they now have fatter stronger teeth but unfortunately you can't use the standard No 4 cutter or you just finish up with the same shape at the 30 T.

End of this post. I need a coffee and I reckon the cat is still outside.

More later.

Steviegtr.

Steviegtr.