Posted by noel shelley on 08/05/2023 10:49:17:

A close inspection would seem to show the start windings are tapped from the run windings – this being so then reversal in simple terms is not possible. But it appears to be only 1/4 Hp ? …

I agree reversing this motor is likely much more trouble that it's worth.

Only three terminals in the box and a diagram showing the start winding is tapped into the run winding mean this design isn't simple to reverse! Unlucky: it's more usual for the both ends of the start winding to be brought out to terminals, and these are easy to reverse once the terminals are identified.

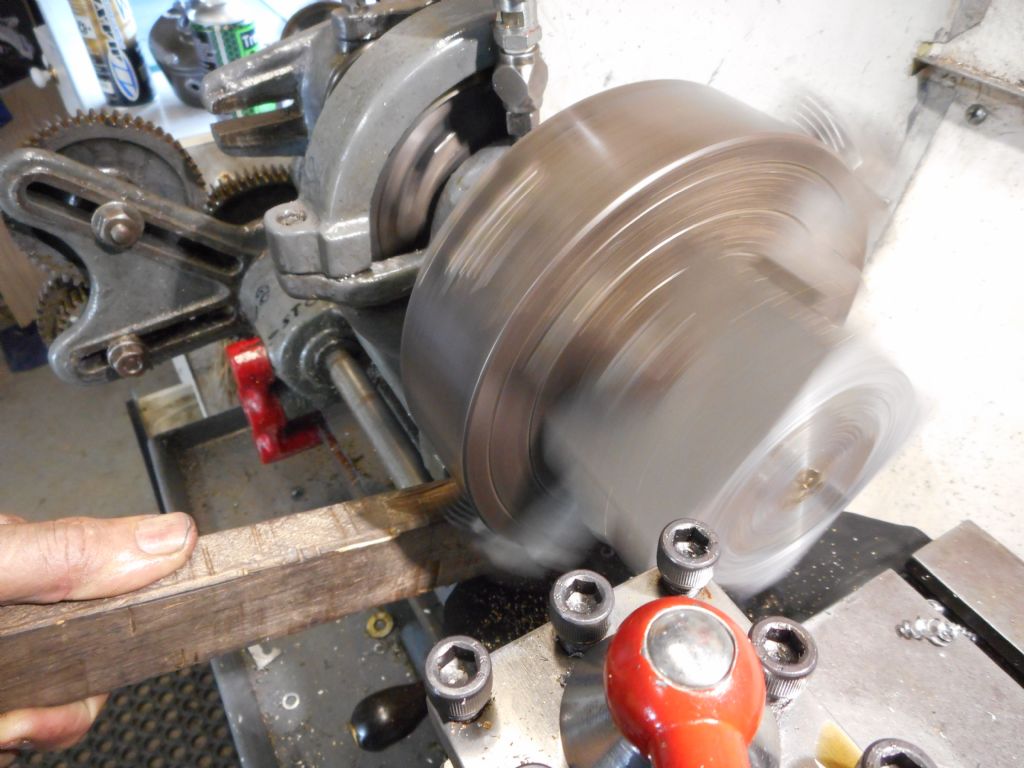

The photo is blurred, but as Bazlye says, ¼HP is the bare minimum power for a lathe of this size. ½HP or ¾HP is more usual. 1HP is a shade too much poke, and more than 1HP unwise because of the high wear rate and risk of damage when the lathe is crashed.

That a Super 7 won't run in reverse isn't a huge problem, and many owners with reverse avoid doing so because it risks unscrewing the chuck. Lathes with bolt-on or cam-lock chucks do forward and reverse equally well, which is very useful at times, but not essential.

The machine will work plugged into an ordinary mains socket, but this is bad practice today. It's usual to fit a combined Emergency Stop / No Volt Release switch. Various, styles such as:

The big red emergency stop button is wonderful if the operator gets caught in the works, especially if wifey has to rush in and cut the power. NVR stops the lathe restarting unexpectedly after a power cut – a common cause of accidents. Look for NVR on the internet – widely available from Amazon and others.

Dave

SillyOldDuffer.