Did this originally on my ML7. made taking out the twist SO much easier. Made up a kit for a friend with a CLM 500., using 25mm x 25mm box section, M8 nuts and studding.

My BL12 -24 does not have a cabinet, but rests on six 1/2 UNF setscrews, and nuts, bolted to three 2.5" x 2.5 " transverse angles, with 1.5" x 1.5" angle welded on each end. These angle sit on the beams of some ex warehouse staging. The end frames carry three pairs of beams, two pairs for shelving, the middle pair carrying the 300 Kg lathe. The original idea was to level by using M10 setscrews, bearing on 2.5 x 2.5" angle iron on the floor. tapped through the 2.5" x 2.5" angle on which the end frames sat.. The frame was so rigid that adjusting one screw, lifted the end frame wholesale. Given that the racking is supposed to carry upto 2 tons on each shelf, not surprising.

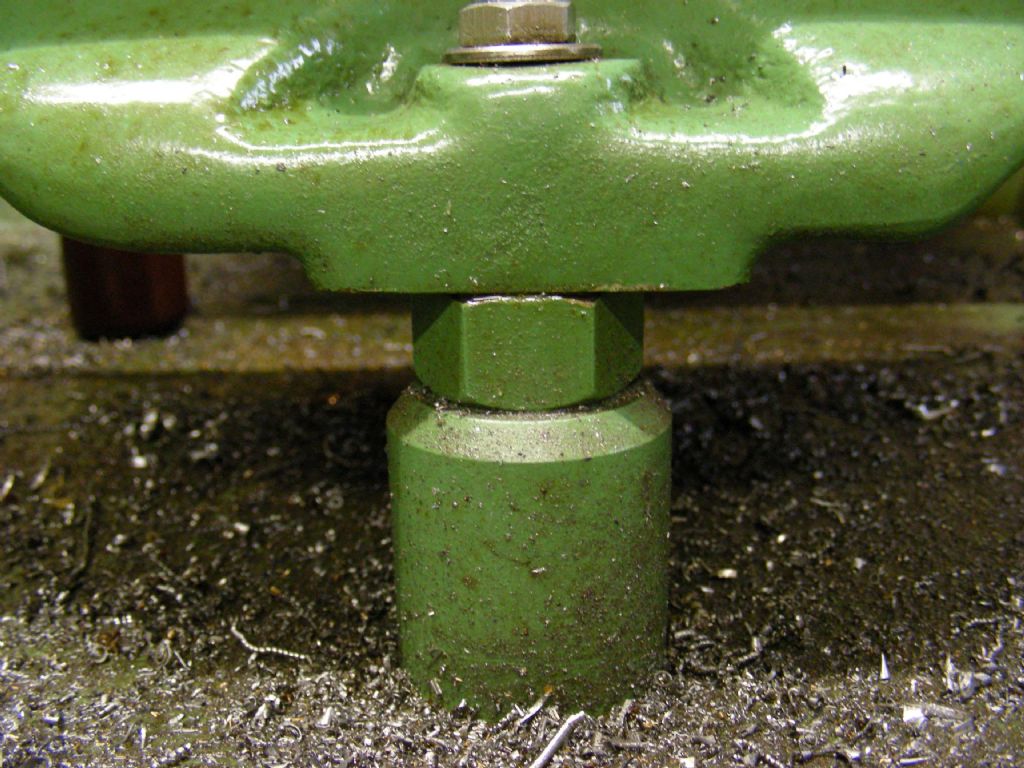

Adjusting the nuts above and below each foot, provides a fine adjustment to remove any twist from the bed, and to produce a gradient between Headstock and Tailstock, if required for coolant flow.

It has been in use for the last fifteen years, without any obvious signs of trouble.

Howard

Mike Joseph.