Hiya!

Last set of photos:-

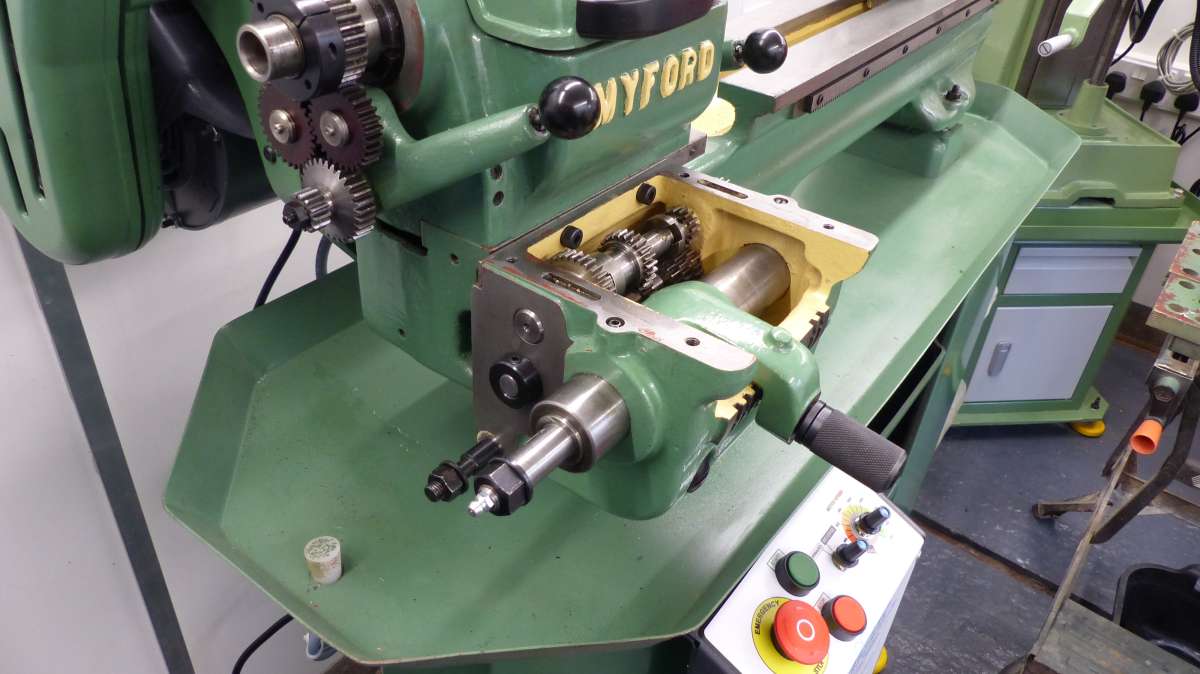

The Carriage refitted with updated locking lever. Gearbox end cover left loose on leadscrew while drive gear secured,then bolted in place.

inner drive guard refitted,stud at bottom will have nut and washer fitted before locking stud into gearbox casing with grubscrew.

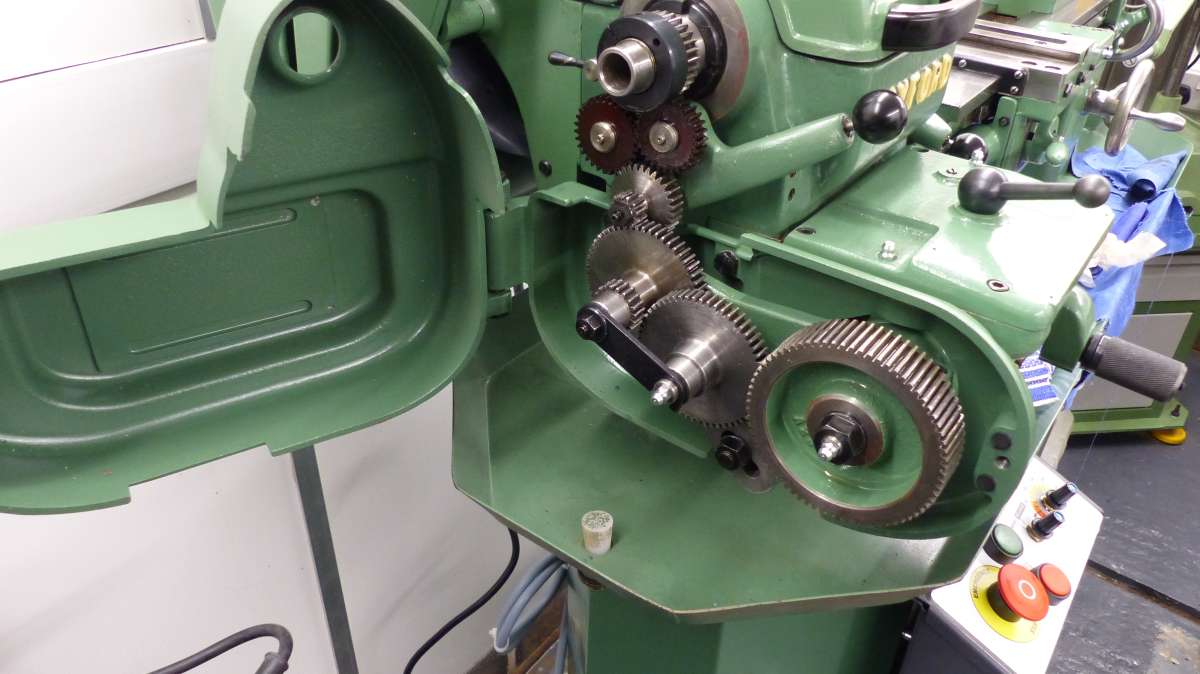

Outer guard re-hung on hinge pins,note rubber bumpers made from suitabe ‘O’ ring stock.

Carriage,saddle,cross slide and compound re-fitted, feed screws and nuts were all servicable. ball handles,retaining screws and micrometer dials were all beyond saving, so were replaced with new ones from Myford.

Saddle Handle will be replaced when I can get hold of one.

Note telescopic swarf guard on leadscrew, and Myford rear toolpost fitted.

I have sourced an original Dickson QC toolpost with a couple of tool holders but will need some more, has anybody tried fitting aftermarket (Chinese,Indian) ones, if so, do they fit the Dickson OK?

Job finished off with new dataplate on gearbox lid,the later boxes had the same plate, so I was able to get a replacement one.

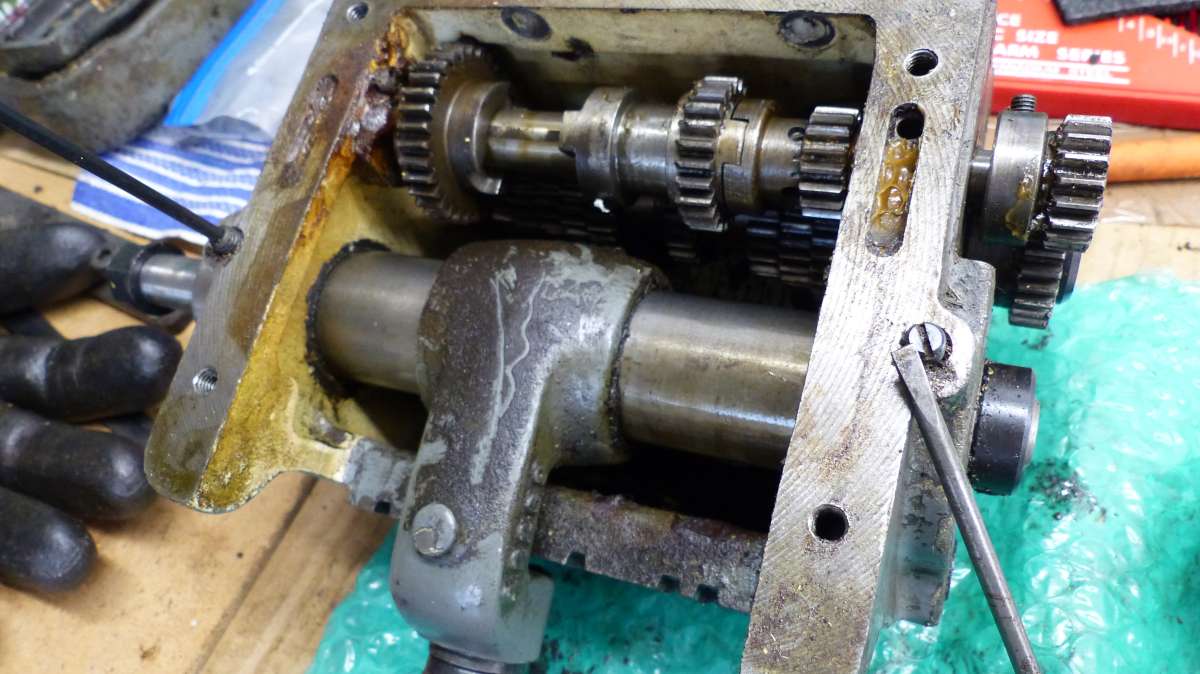

Last photo is a before refurbishment shot to show the work involved in bringing it back to life.

I have recently had surgery on My thumb for arthritis, so I am in plaster at the moment, but when i have recovered I will put down the floor tiles and fit a splashguard to the wall behind the chuck (which I have to clean up, 3 jaw and independant 4 jaw), and fit the nameplate to cabinet and pop the cork mats on the shelves.

I will put a new thread up detailing the workshop refit when it is complete.

Many thanks to everybody that has helped and followed Me along on this journey, I can only apologise for the length of time it has taken to get to this point, but as They say ‘Life has a way of getting in the way’!

Looking forward to making lots of swarf, and getting to grips with the Miller as well!!

Many,many thanks to All, Morty

Grindstone Cowboy.

Grindstone Cowboy.