Hi Everyone!

I hope everyone is well and keeping busy!

I could not believe it was so long since My last post until I checked, but the good news is the Myford is finished bar setting up, and the rest of the workshop is done,bar laying a floor covering, which will be inter-locking tiles.

I have been making use of ‘Beachcomber Bobs’ YouTube videos to guide Me through the process, including the early Gearbox, and highly recommend anybody undertaking a restoration to follow suit. Down to earth and clear explanations of the steps needed, I would only be repeating what He said if I gave a Blow by Blow account on here, Many thanks Bob!

I will post photos of My restoration, with notes where needed, and will split over about 3 posts due to the ammont of pics.

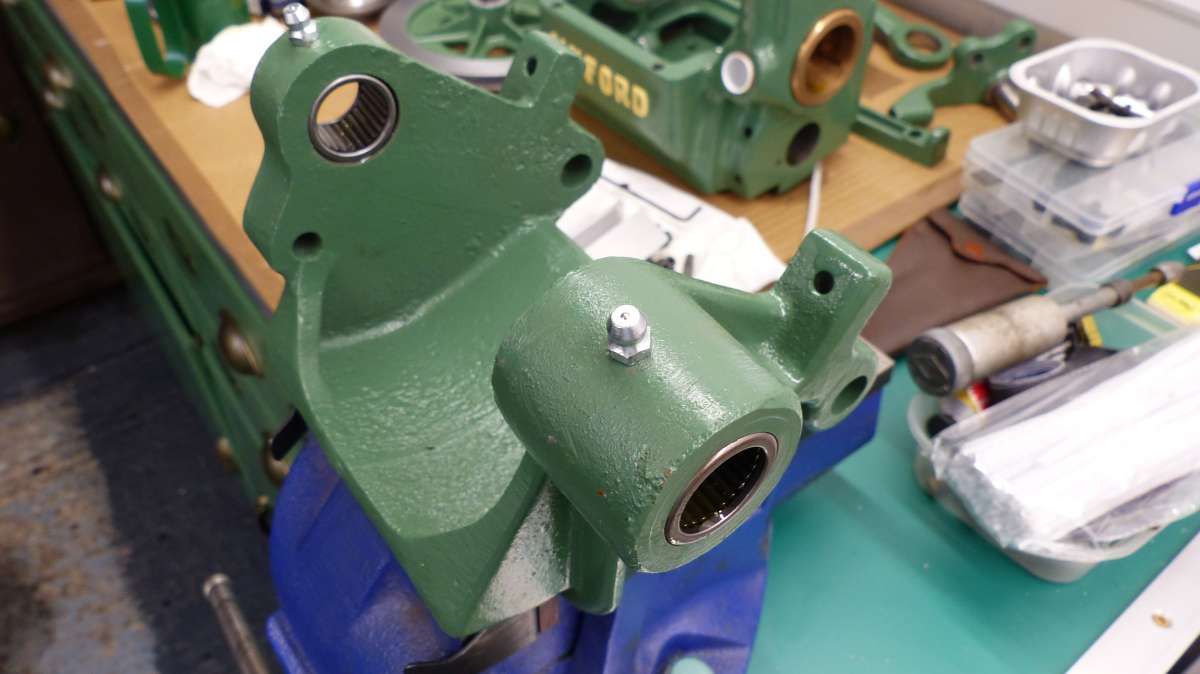

New needle bearings fitted to countershaft housing,use the type with a lube hole drilled where needed:-

(Holes are £5 extra by the way!!)

Clutch went back together fine and works OK,all bearings in clutch and headstock replaced while I had everything in bits.

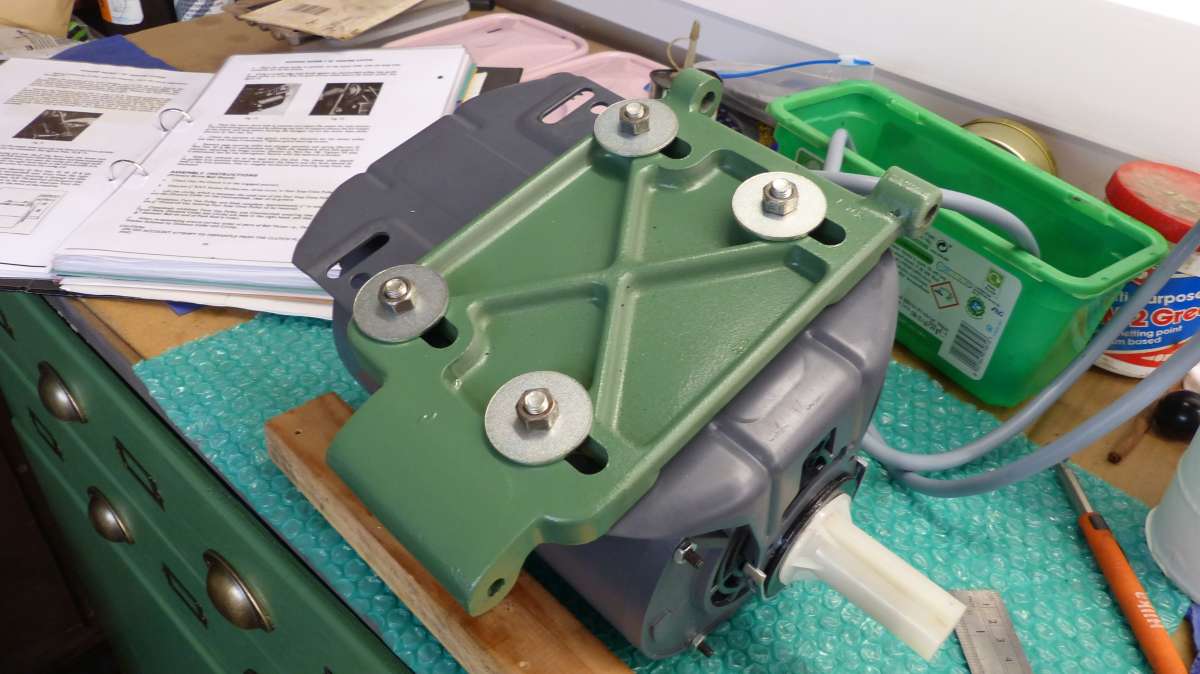

New motor and control unit from Newton Tesla fitted, very easy to fit and runs very smoothly, I will fit a revcounter to the rear of spindle in due course to make use of the variable speed.

Headstock set up in line with bed, using test bar to zero the tailstock.

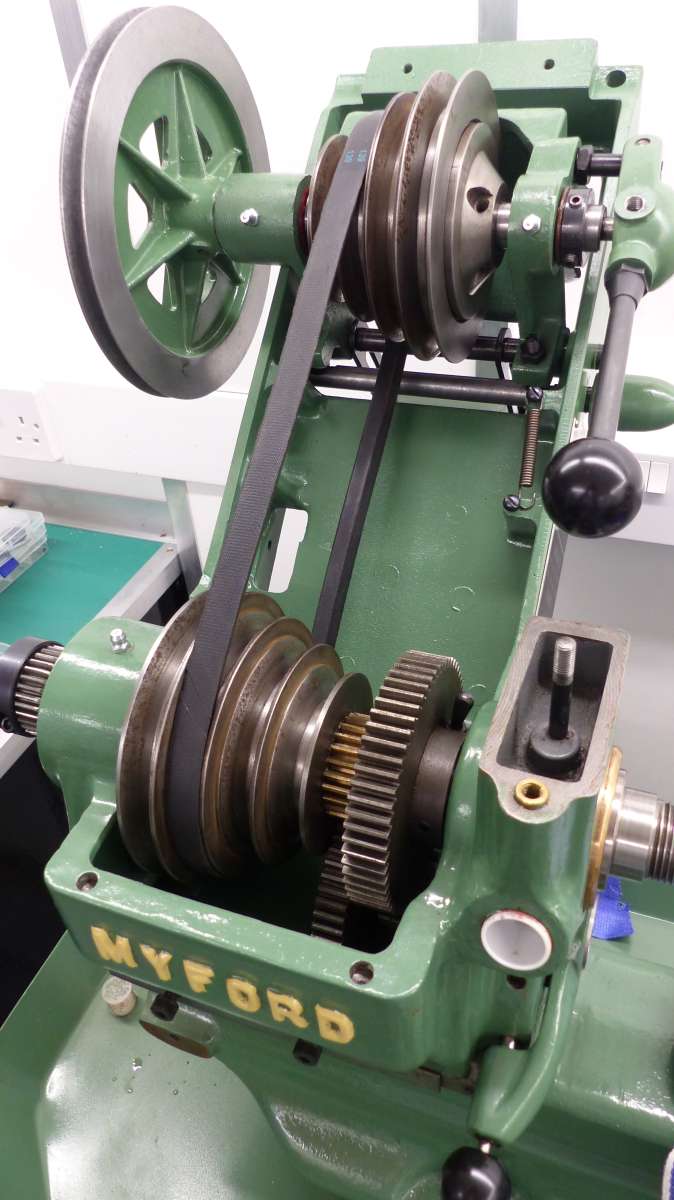

New belts fitted and tension set on countershaft cradle Adjustment bolts.

Headstock bearings set up by following instructions in Myford Manual.

Phillips Gun Blueing used to re-finish parts when cleaned up.

Drip feed oiler works well and can be adjusted to keep a fine flow to keep reservoir constant.

Will post more pics tomorrow, thanks for looking in!

Cheers, Morty

Grindstone Cowboy.

Grindstone Cowboy.