Posted by Morty on 18/04/2020 00:11:24:

Hi there!

Sorry for the lack of updates, stripping the cabinet etc. at the moment not a lot to see, raising blocks responded well to paint stripper and wire brush, but on the tray and cabinet the stripper had no effect! ( thinking of something a bit more invasive, such as a small tactical nuclear weapon!!

Seriously, I've sent for a stripping disc which should arrive during next week!

Werner – It is nice to hear of the service that You received at Myford, good to hear that customers were looked after!

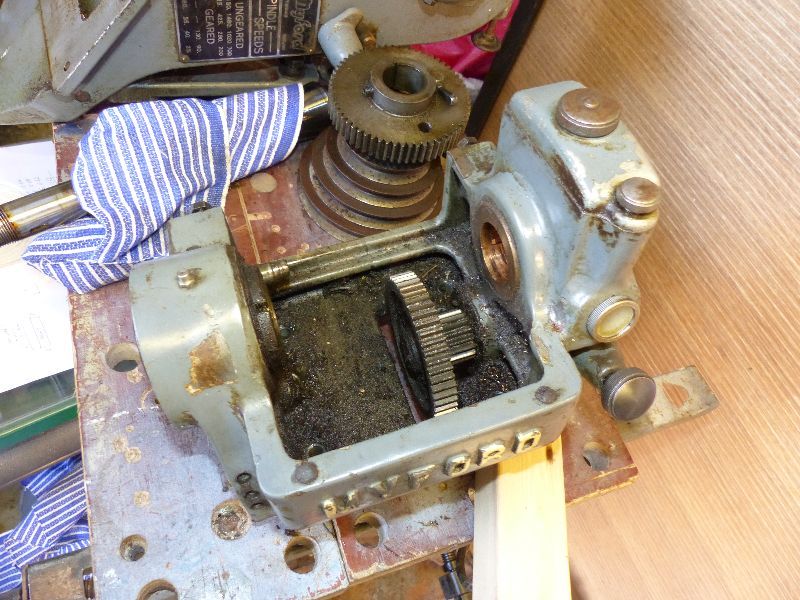

Looking at ideas at the moment to improve the bed (see below )

Dave – I will search out the articles You mentioned, well worth a look.

Steve – I had a look at Sven's videos before, He does go into the details really well!

I think I am going to clean up the bed for now and get it going again, what I was looking at was changing over to a wide guide set up as detailed in this thread:-

https://www.model-engineer.co.uk/forums/postings.asp?th=110700&p=1

This would be something I could do by just removing the saddle, but would need a miller (J.A. Radford's method),

so It would have to wait until the workshop is completely set up.I

Thanks for.the replies, I will put some progress pics up on the next posting.

Cheers, Pete

Edited By Morty on 18/04/2020 00:12:47

Hi Pete

If you search the MEW index for the series of articles by Pete Barker over the past year or so, you will find a lot more information on Myford bed wear, wide guide, bearings etc etc if you can get back issues or a digital sub.

In a nutshell, old Myford literature on their former reconditioning service recommends a bed regrind if wear exceeds .003" (note, inches not mm) measured in the horizontal plane (ie measuring wear on the vertical surface of the shear) and .005" in the vertical plane. But you could probably get away with a bit more if you are not doing micron-level work.

There is an easier alternative to the Radford and Ganderton methods that does not require a milling machine. It is outlined in the MEW articles. Basically add a strip of gauge plate to the rear carriage surface so it contacts the bed's unworn rear shear. Then just leave the old narrow guide surface as is, sitting a good 20 or 30 thou away from contacting the shear. No need to do the Radford thing and have two contacting surfaces. The factory never did that. They just went (in 1972) to using the rear surface only.

The surface of the carriage that runs on the top of the bed ways can then be touched up with a file and a small scraper made from a file. All detailed in the MEW articles. No need for a milling machine at all.

Looks like you have a lot of wear on the inner vertical shear surfaces. This can also be remedied as outlined in the articles by adding a cutting tool to a vertical slide mounted on the carriage and running it back and forth like a hand-powered shaper. Sounds crude but it has produced an excellent result and a lathe that turns dead true between centres, where the tailstock relies on these surfaces for alignment. So is is well worth doing.

Your measurements posted earlier seemed a little odd in that the vertical depth of the front shear varied so much from front to back. Not sure what is going on there? Depends where the wear is. Could be tailstock caused wear, or if it is in the usual high wear patch about six inches from the left end of the bed ways, it's from the carriage. Could be a bit excessive for fine work if that is the case. Might pay to measure carefully again and do an assessment.

Have fun with your rebuild. It's very satisfying to be able to do precision work on a machine you have rebuilt yourself.

Pete B.

Grindstone Cowboy.

Grindstone Cowboy.