GHT's 4 Tool Turrets have served me well over the years.

The one I had on my Maximat Super 11 was also fitted with a self indexing attachment.

It was fitted with two additional face cams which returned the turret to the 90 degree position. This did not mean the Turret could not be set for any angle in between.

The addition of a one way clutch in the underside of the lever meant the turret started to index as soon as the lever was undone.

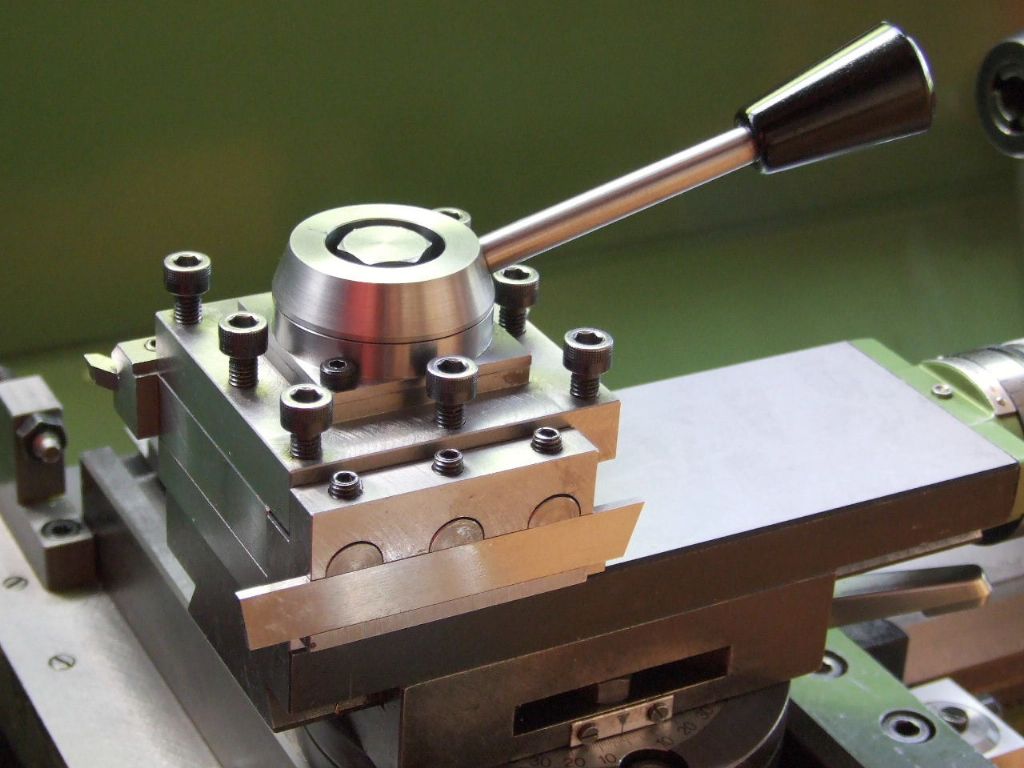

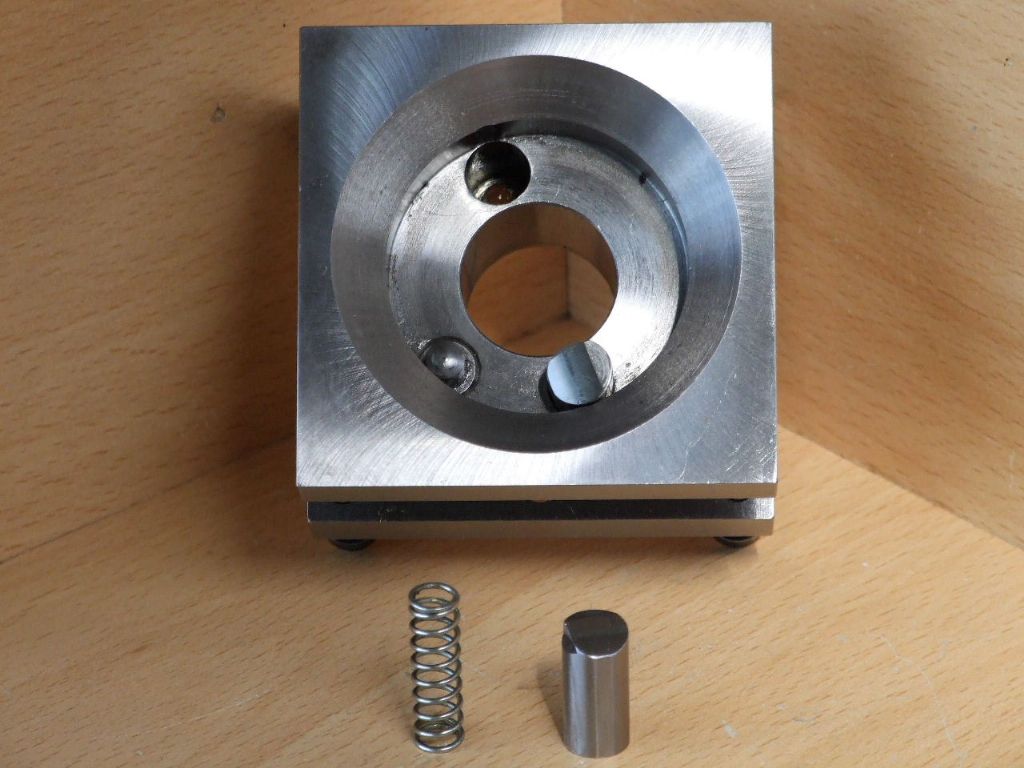

This a non-self indexing version I have fitted to my current lathe the Emco Compact 5. Repeatability is very good even in this small version.

Because of the inbuilt rake angle on the Tool holders there is no need for any packing. The underside step on the Tool holder means each Tool holder can be removed and replaced at will, with no loss of position. All the benefits of QC but the advantage of 4 tools at my disposal before I need to change.

The Parting blade and Boring tool holders are automatically on Centre height.

Regards

Gray,

Martin Kyte.