Anyhoo, got to the end of the Evaporust treatment today and all is good. The main spindle came up beautiful, ditto the index plate, the vertical slide table and all other bits. Very impressed. A light wire brushing (hand, not wheel) and it looks good. There is some etching visible on the overarm but the rust is gone and the parent metal preserved so functionally it will be all good, sitting on the original OD. If I had emery clothed it down in the lathe, the bar would have come down to the diamter of the bottoms of the pits. This way the original OD is preserved.

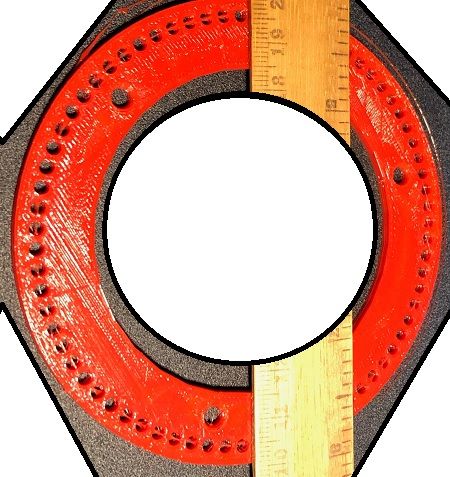

Compare and contrast that last image with this "before" shot:

Pretty much says it all. Very pleased with that result. Very pleased indeed.

Now for the part of restoration I enjoy the least: painting. In 32C with 85pc humidity it can be a real challenge, as I am sure it is for you guys in mid-winter. Paint will sit there and just look at you and refuse to dry for day after day after day. But I have my secret weapon now: air conditioning in the shed which knocks humidity down to a sensible, paint-drying 50pc. I have some leftover grey machinery paint from when I did the ML7 so will brush a bit of that on all these fiddly bits. Should dress it up nicely to match the shiny new metal finish.

Onward through the fog!

PS: ONe thing I did learn is that as you use the Evaporust overnight etc, it turns black from the particles of converted (or whatever) rust floating around in it. This tends to leave black stains on the pristine new surface of the job. particularly around the waterline on partly submerged parts. They can be removed with a wire brush, but much easier to wash down with fresh Evaporust and it gets rid of it. A final brush down with fresh Evaporust gives a nice final finish, a matt surface that brightens up with a quick manual wire brushing. Very nice. I used about three quarters of my 1 litre of Evaporust on this job. For anything thing bigger I would buy the 5 litre pack and use it in a lidded container to stop evaporation.

Edited By Hopper on 22/01/2023 10:35:40

Edited By Hopper on 22/01/2023 10:41:09

Edited By Hopper on 22/01/2023 10:42:03

Edited By Hopper on 22/01/2023 10:42:23

Bazyle.

Bazyle.