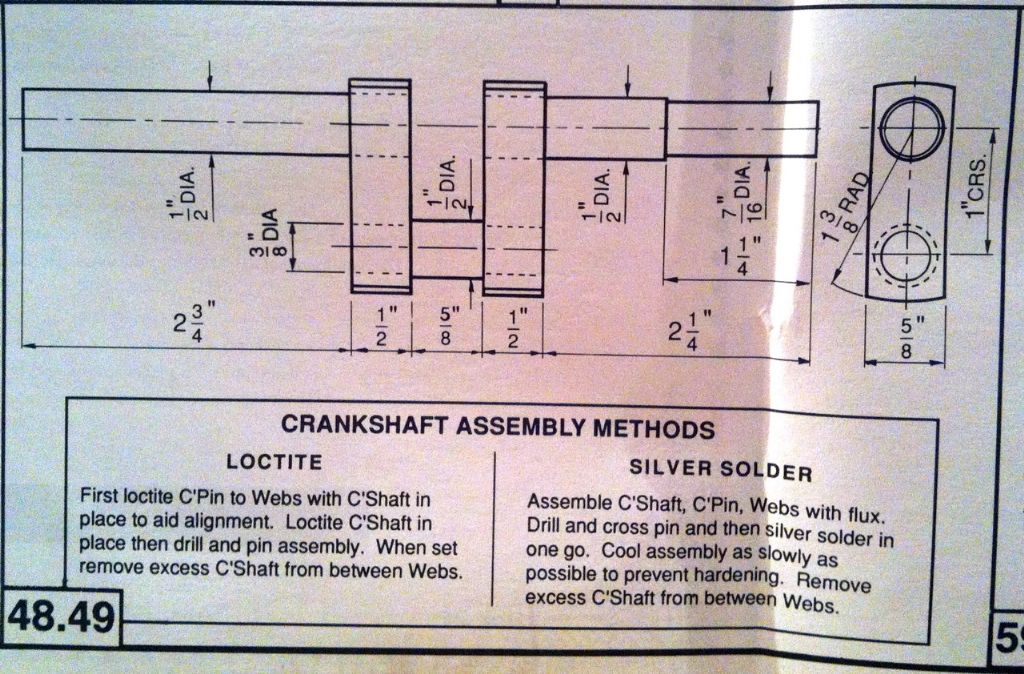

Starting to look at doing the Crankshaft now. As usual another first for me (from scratch) and a bit of a look at setting things up accurately. For a Lathe that cost half the price of the TV I can't expect anything great here but I thought it might be interesting to look back at some figures in the future when using different equipment.

I have no idea at the moment as to wether the following figures are good, bad or indifferent…

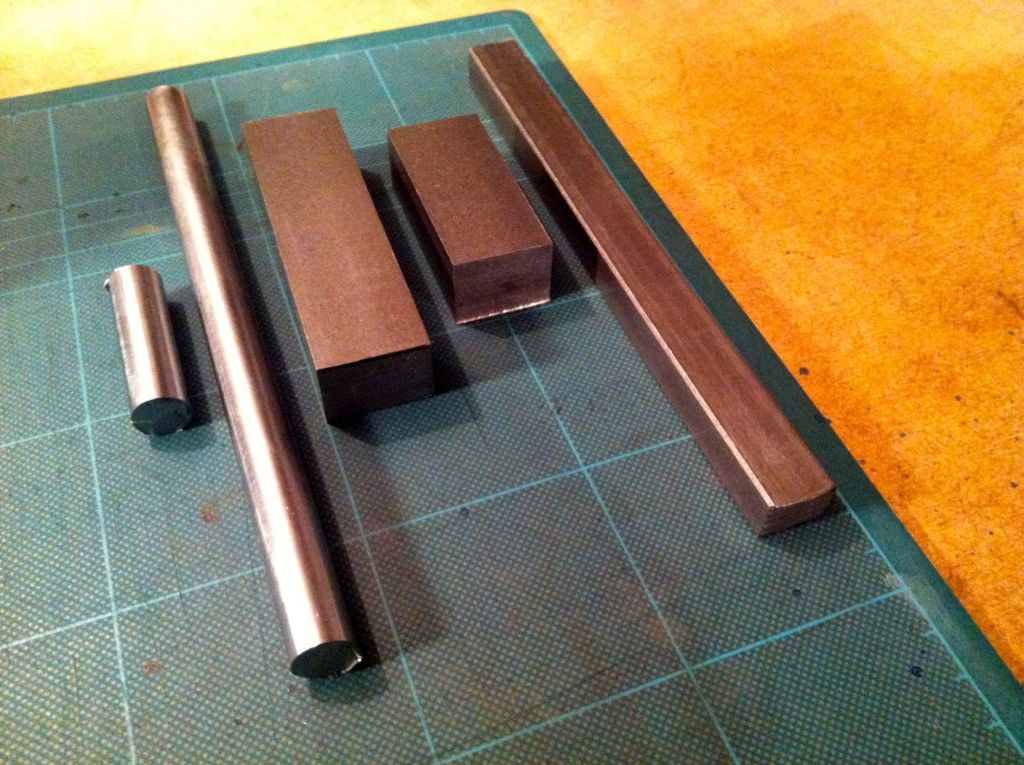

Likewise, I won't know whether I'm going about this the right way until i work my way through it… The first thing I wanted to do was to get the Crankshaft Axle a good fit through the reamed bearings – not least so that I can use the reamer for all the other Crankshaft bits… I decided to order a 1/2 inch PGMS Bar.

My 1/2 inch reamed bearings came out at 12.701mm. – measured with a bore gauge.

The PGMS Bar after polishing came out at 12.666mm – and it feels a lovely fit, no play at all. I'm guessing though that 1.5 thou undersize won't be considered good on here.

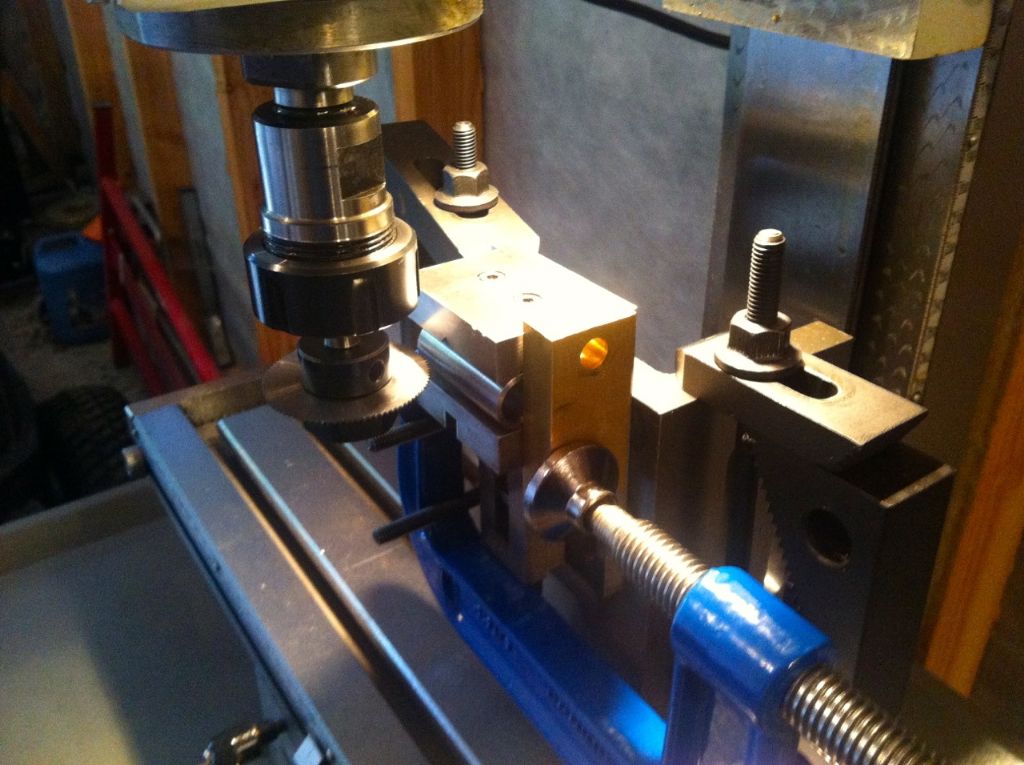

I was interested to see what my Chucks were like.

My 3 Jaw Runout figures with the PGMS 1/2" x 12" bar.

Next to chuck – less than 1 thou

Middel of the bar – 4.5 thou

End of the bar – 15 thou.

That didn't seem too good to say the least although when I took the chuck off there was some tiny bits of swarf on the 'back' fitting surface which may have made a difference.

The 4 Jaw setup with the same bar using the dial test indicator and same 12" length bar.

Next to the chuck – about 1 thou – my digital iphone converter won't convert to less than 1 thou..

Middle of the Bar – 0 thou.

Edited By JasonB on 03/06/2014 17:02:32

GarryC.