Started the Big End Bearing this morning, not much progress yet..

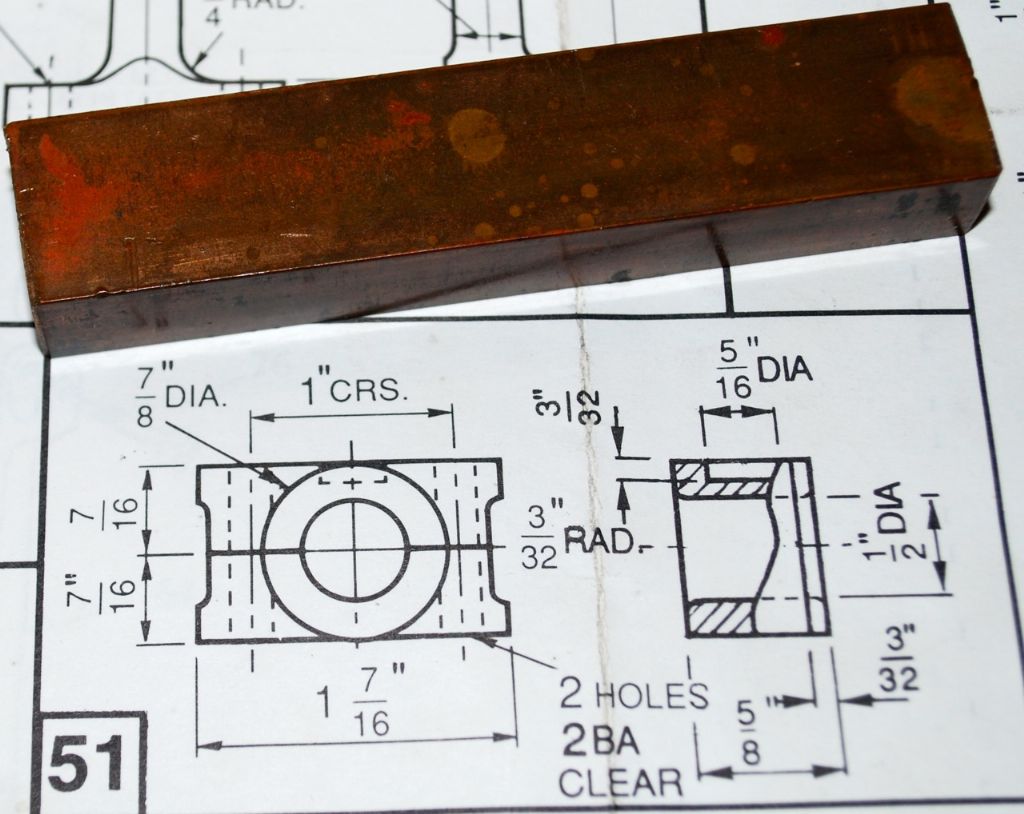

The Big End Bearing Drawing and the Phosphor bronze Bar supplied.

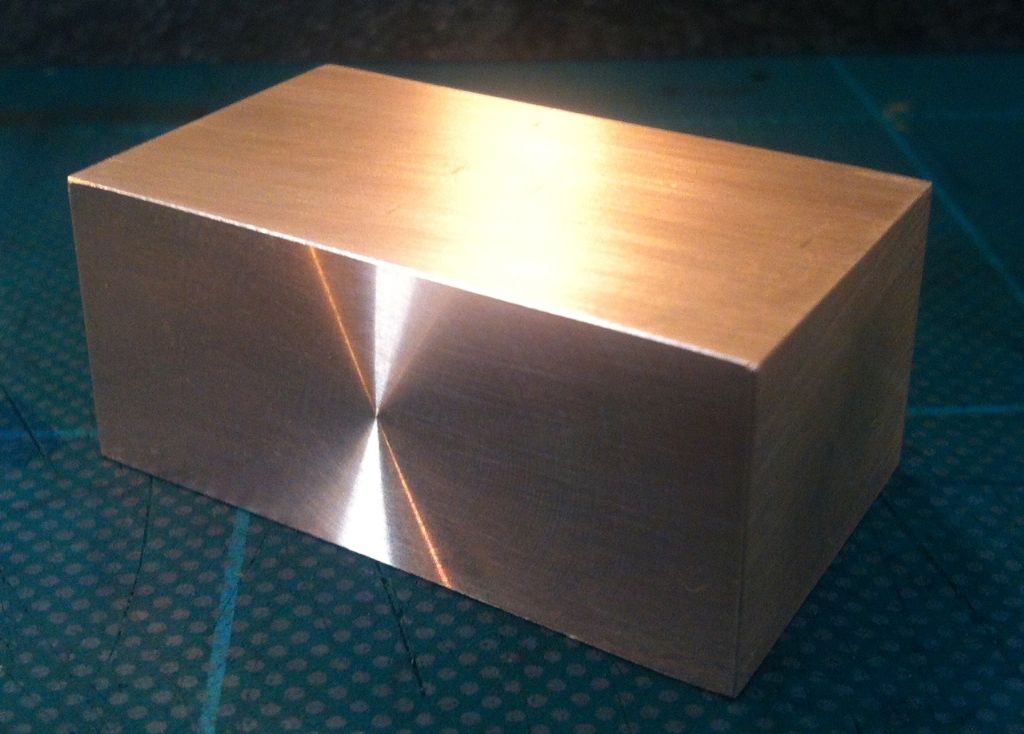

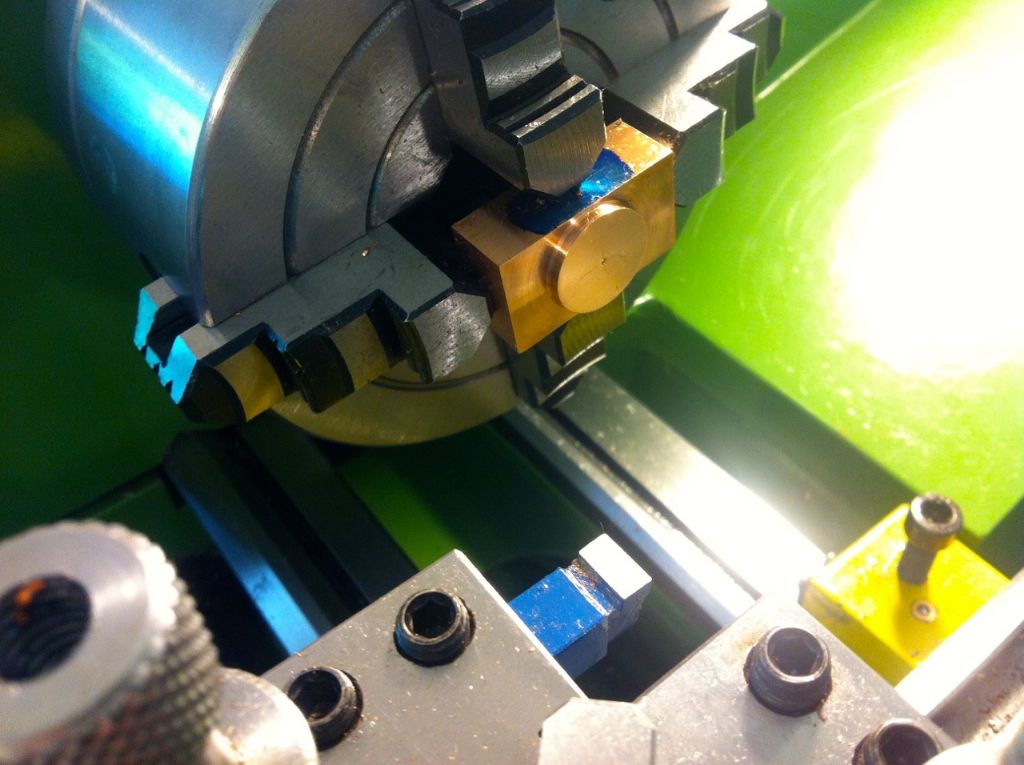

The bar cut to a close approx size to minimise the interrupted cut later – the foot is still slightly oversize here and the little end is not to any size or symmetrical yet….

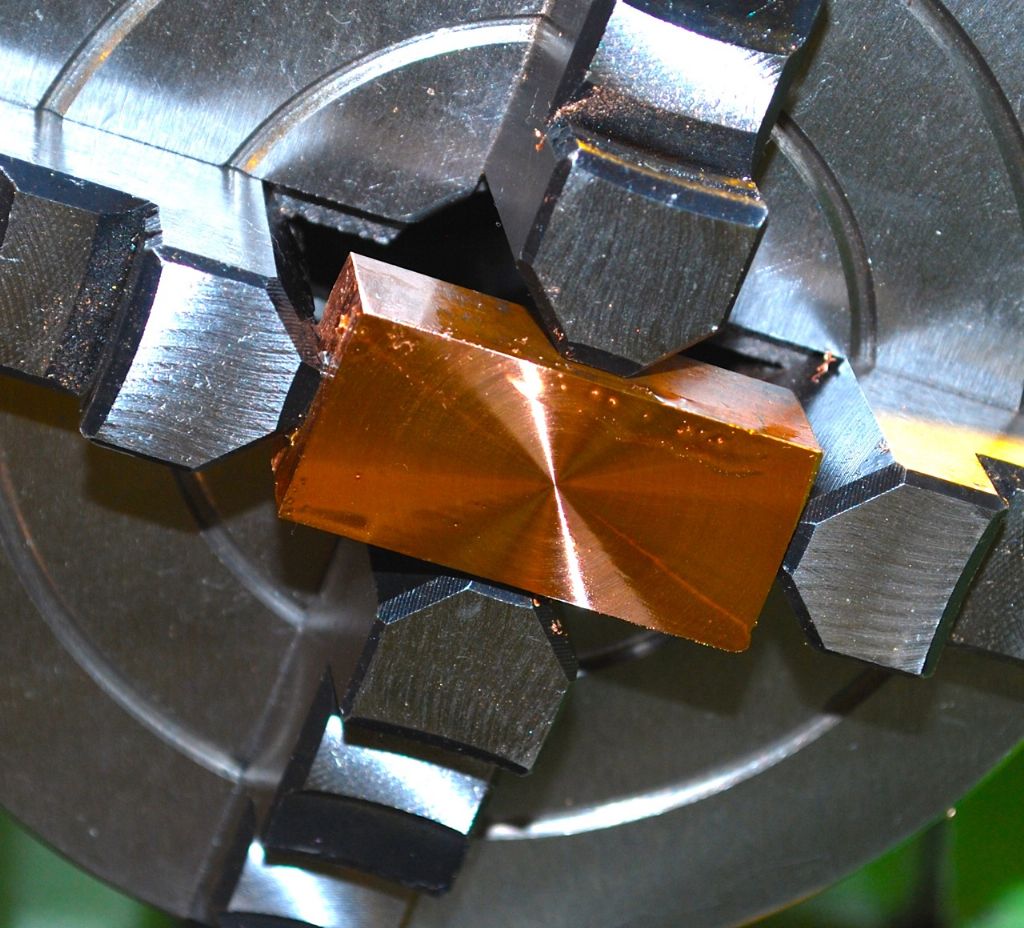

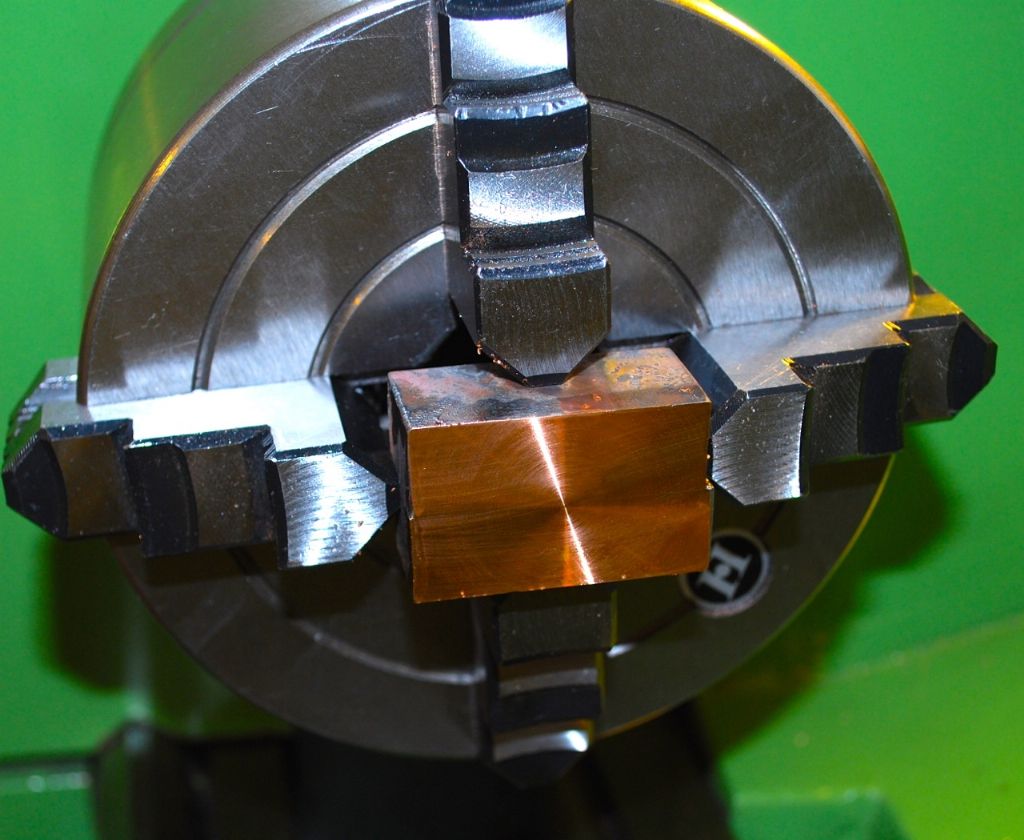

The mating surfaces of the Bearing are skimmed ready for sweating together. When I first started I had a problem – my formula that I use for cutting speeds said rpm 800 and I used a slow feed – I assumed the phosphor bronze was a brass type material – but the surface finish was terrible and felt like a file to the touch, I've never had anything like that before and thought at first it was because of holes in the material it was that bad – but dropping the speed to 300rpm and all was then immediately very good..

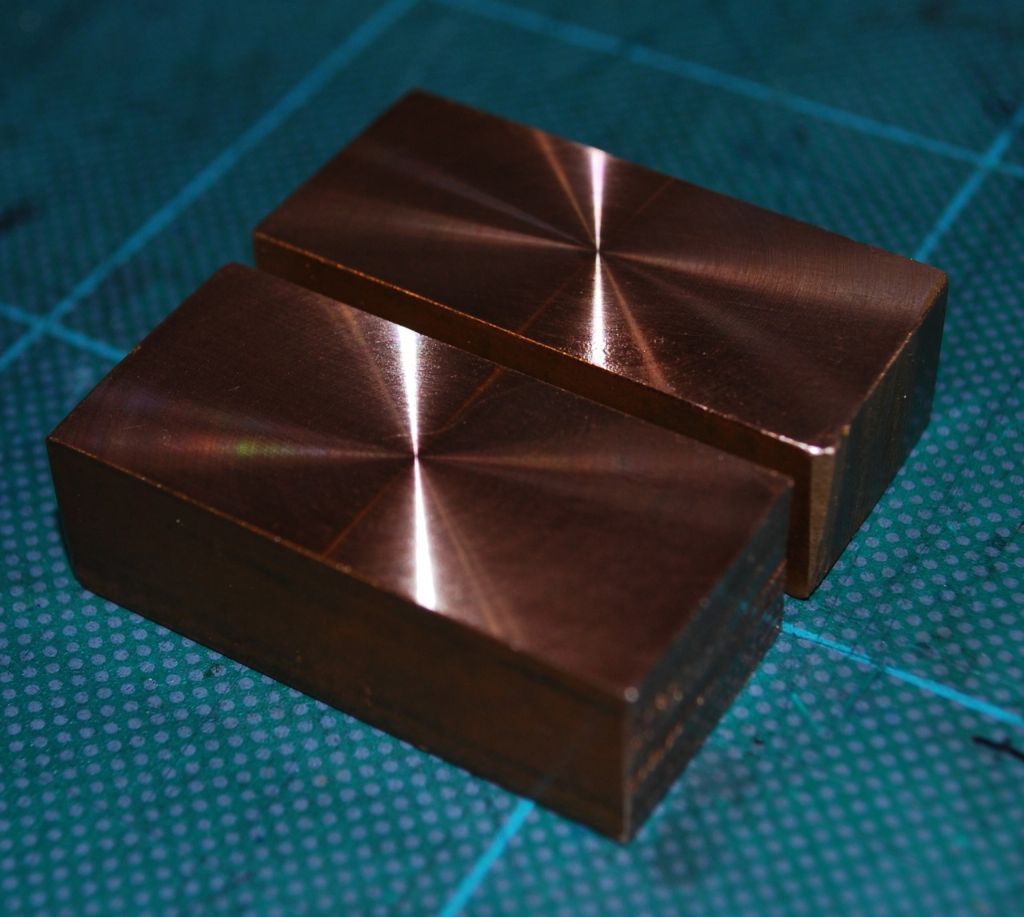

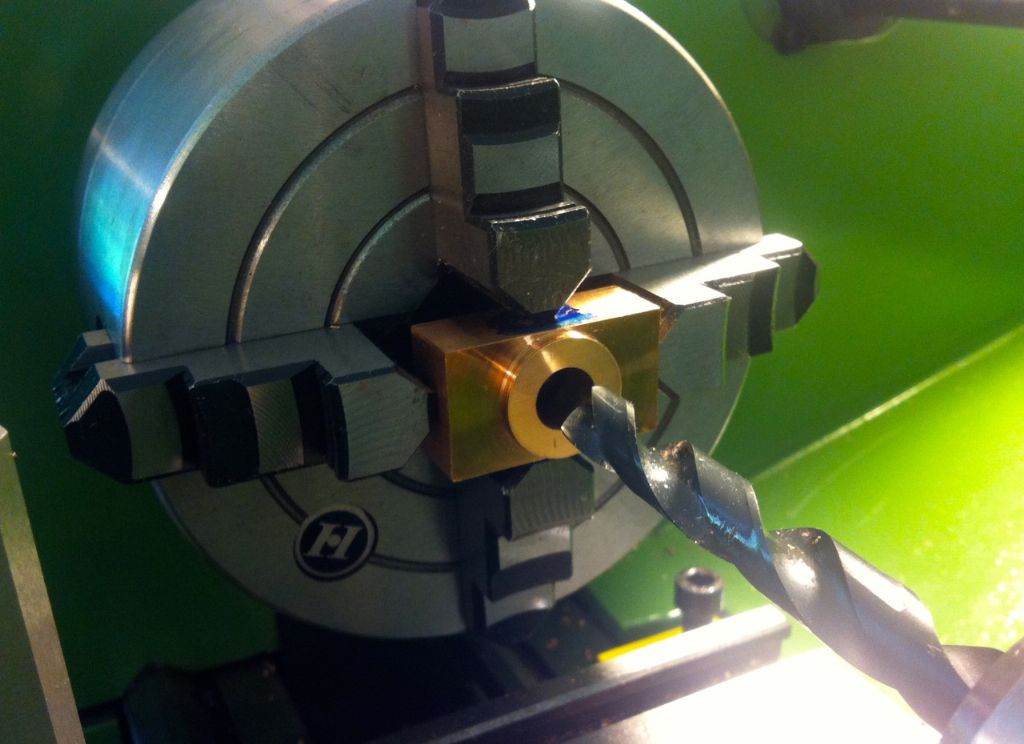

Both surfaces skimmed ready to be sweated together and machined as one.

The two bearing halts being sweated together after the solder paint had been applied to the surfaces – the flame was not held on constantly but moved to and from across – I've no idea really how much to heat and so just waited for the solder to start bubbling out of the joint and then a bit more..Hoping it will be ok

After sweating together and the Solder Paint used.

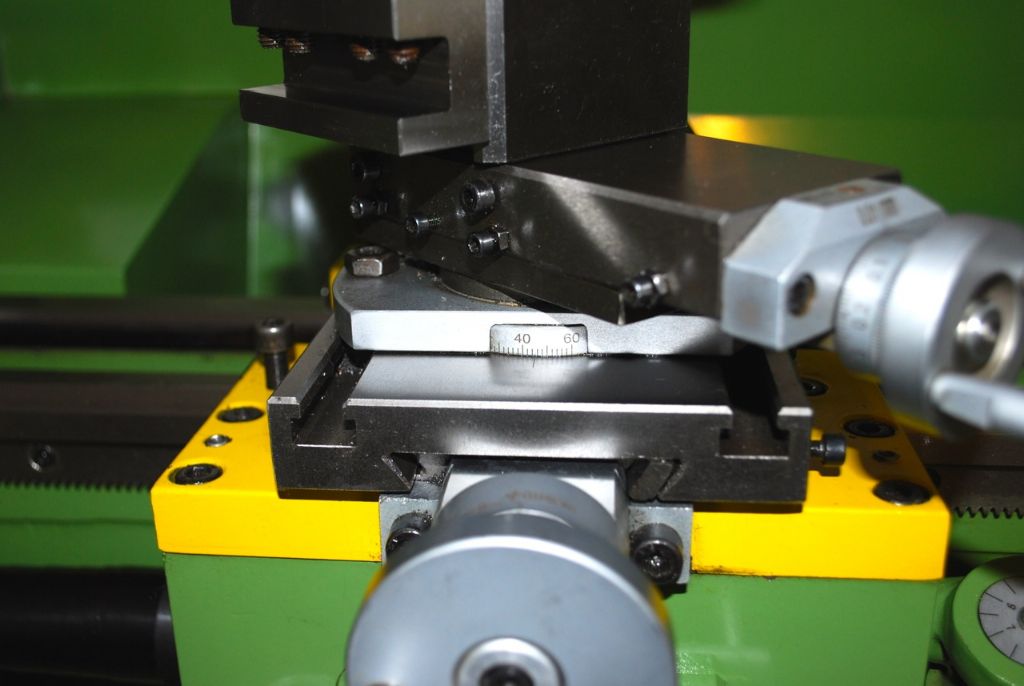

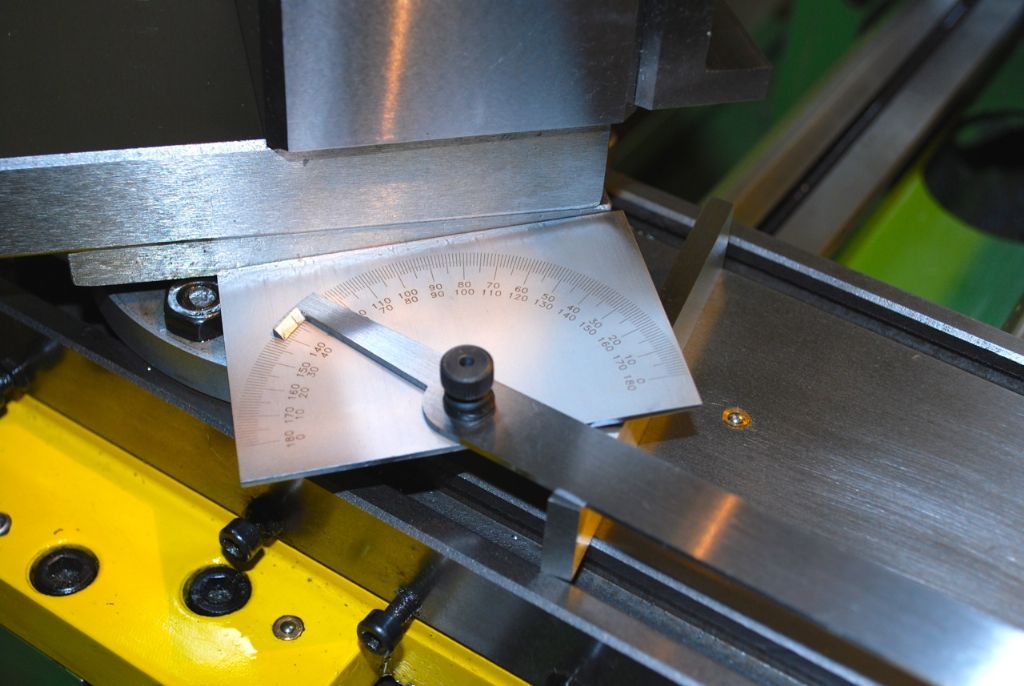

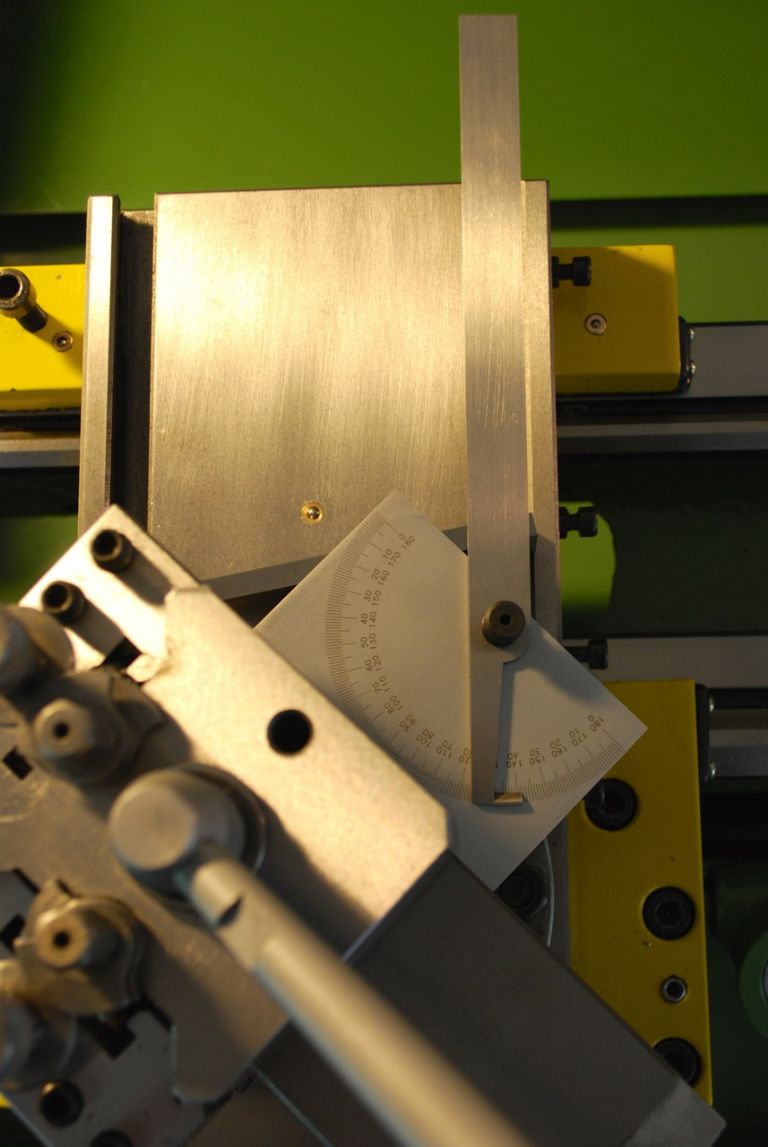

Then the two halts starting to be machined as one to size ready fro marking out..

Cheers.

Garry

Edited By Gary on 03/06/2015 10:36:14

Edited By Gary on 03/06/2015 10:37:54

Edited By Gary on 03/06/2015 10:38:58

JasonB.

JasonB.