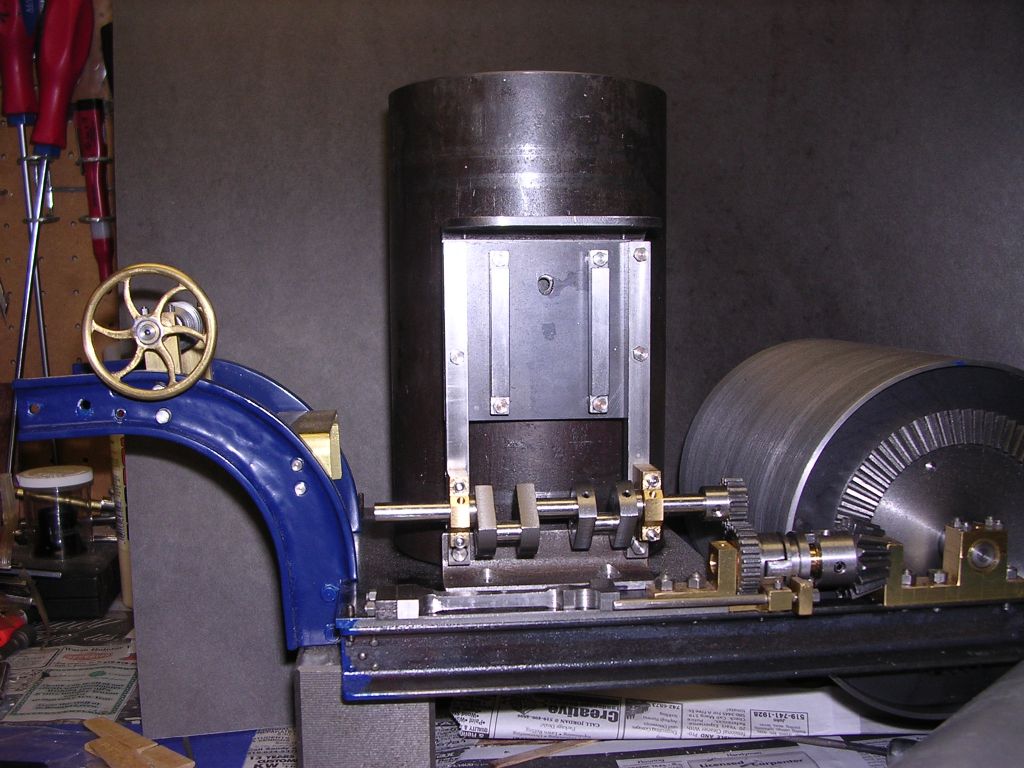

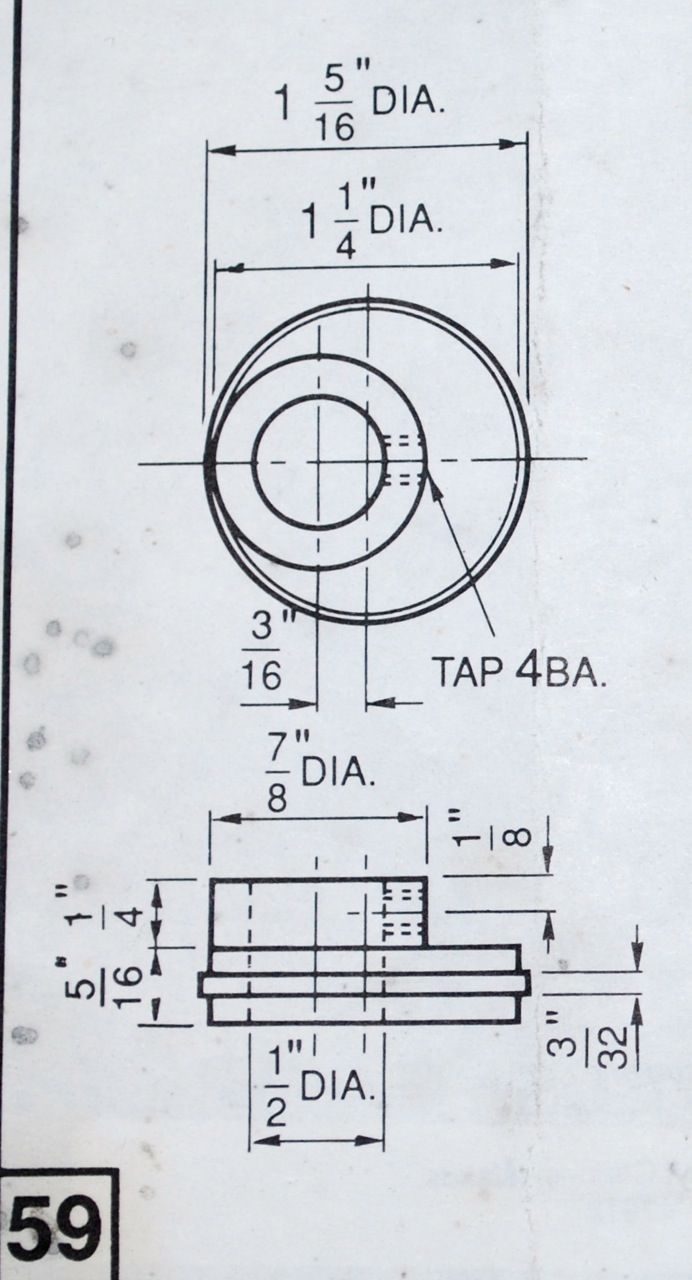

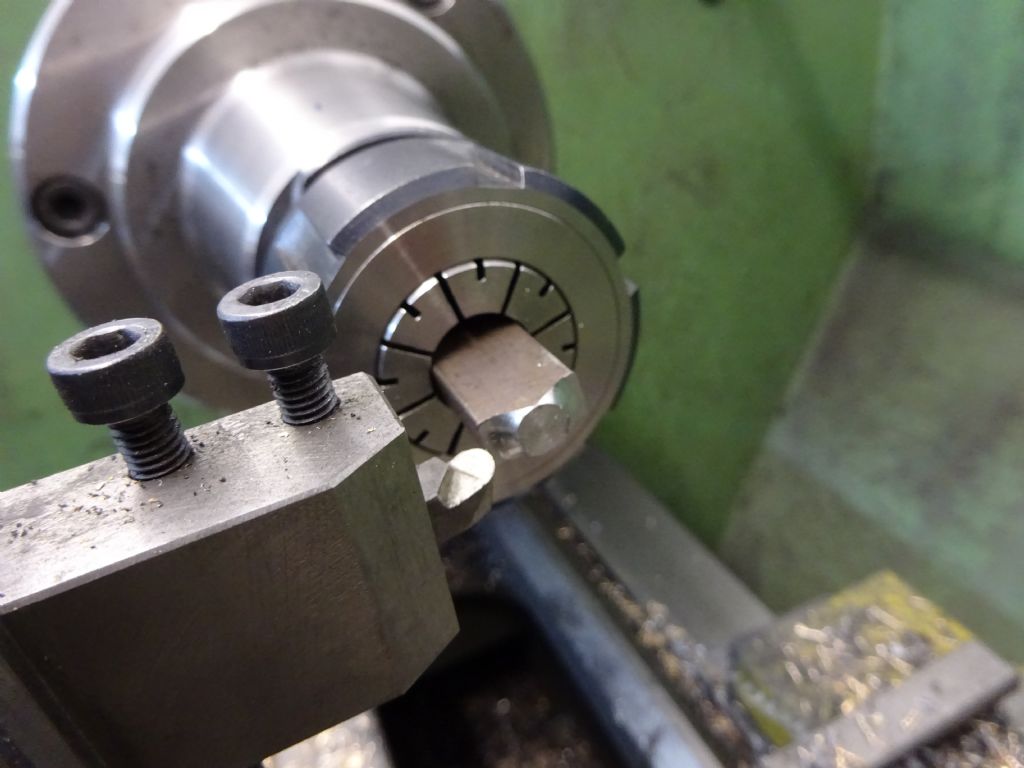

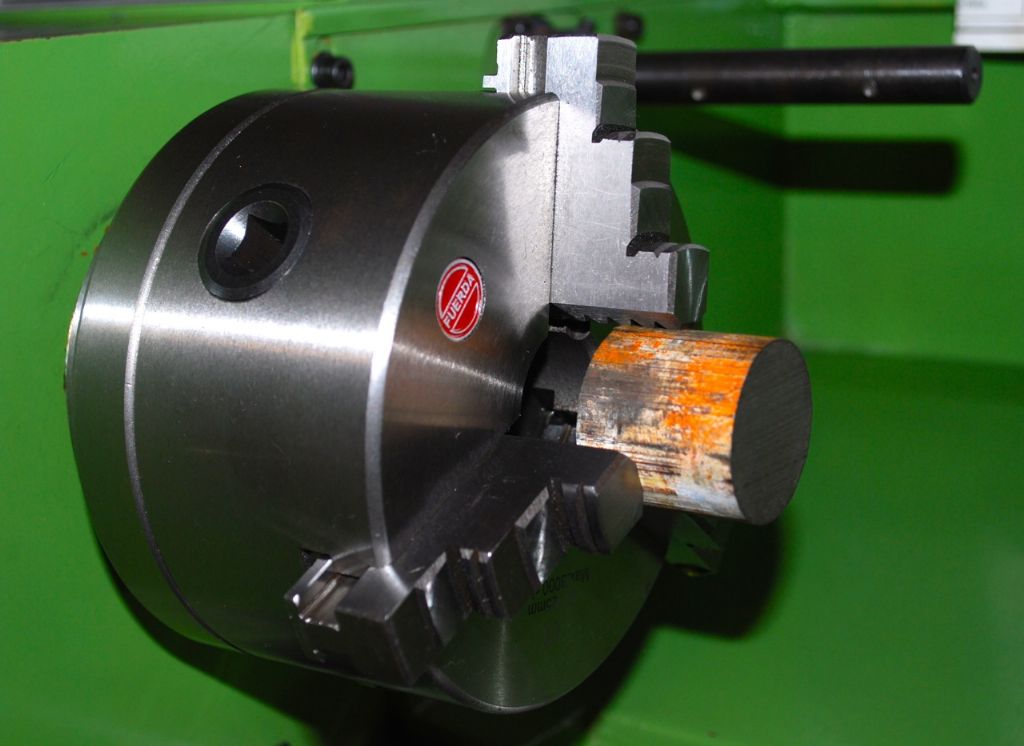

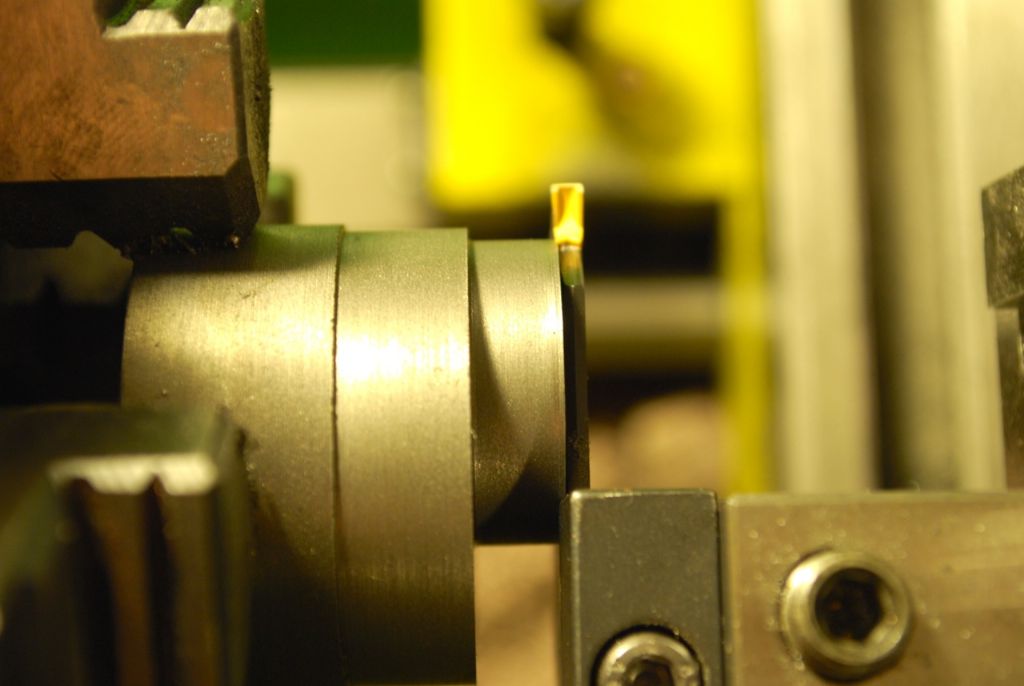

This is more me marking a bit of a milestone than a build update really – I don't recommend that anyone watches the video as it goes on a bit and then some more – (I've probably got the settings wrong as well and was just an experiment until I get some more practice). Its the first time I've tried parting off under power and I thought that the eccentric sheave with its offset diameter and the offset bore would be as good a test as I'm likely to find (the bar is about 1 3/4" cast iron). (I don't have a pump coolant system).

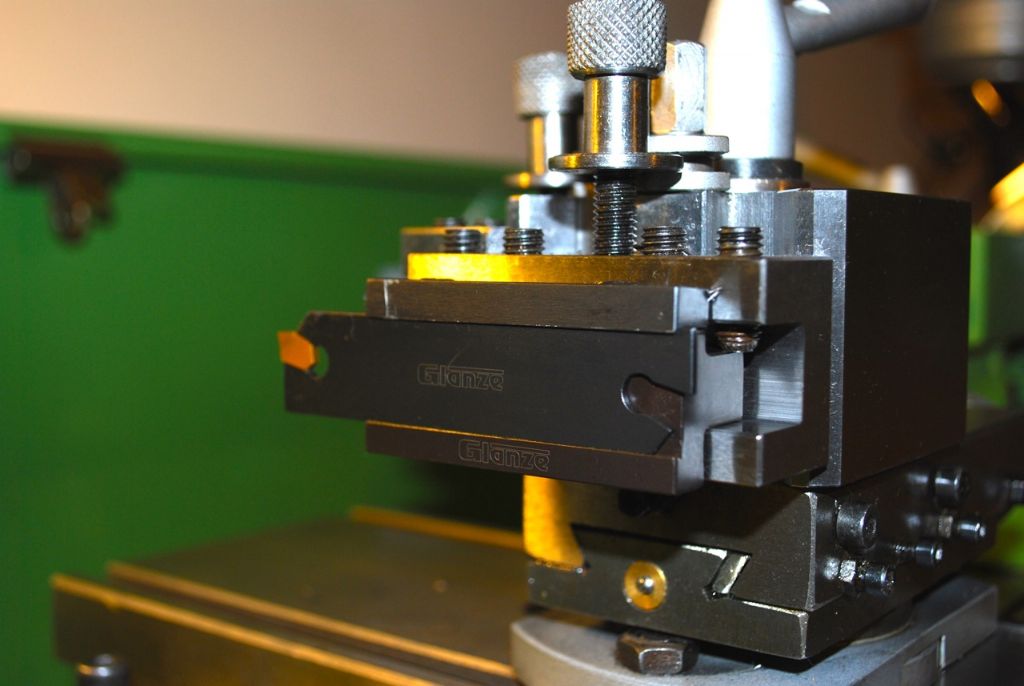

I wouldn't have even thought to try this with one of my 'standard' parting tools, but the Glanze I've always found to be superb when hand feeding and have been wanting to try under power for ages, also wasn't sure if the lathe was too small to even try it given some of the horror 'parting off stories' I've seen..

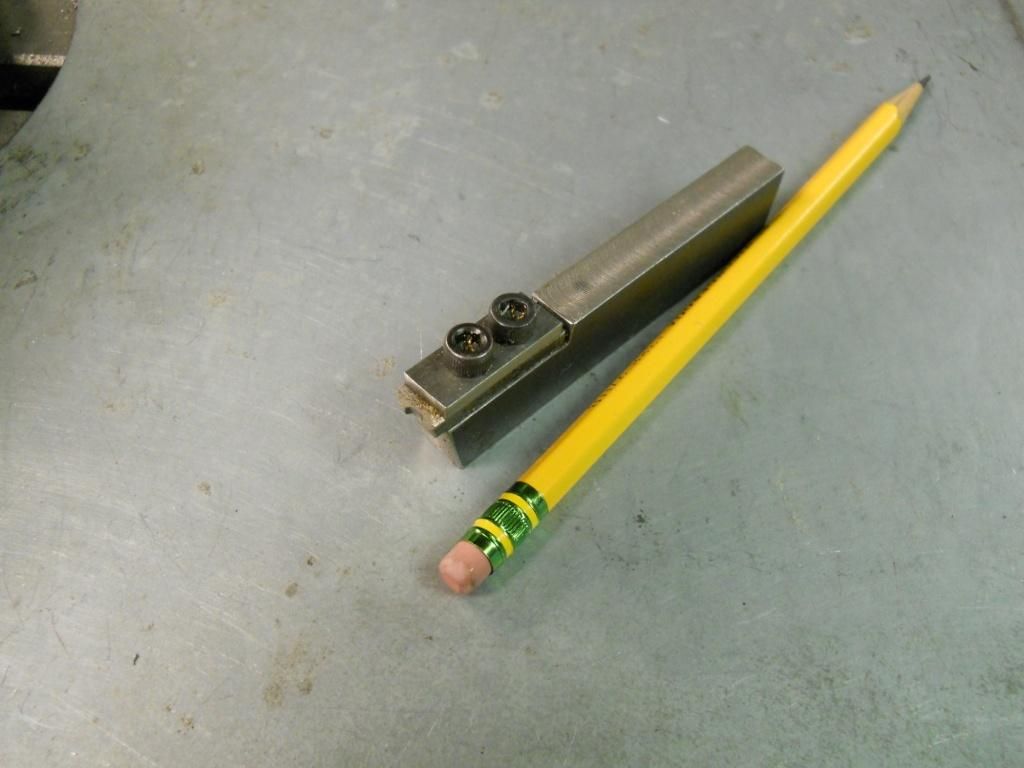

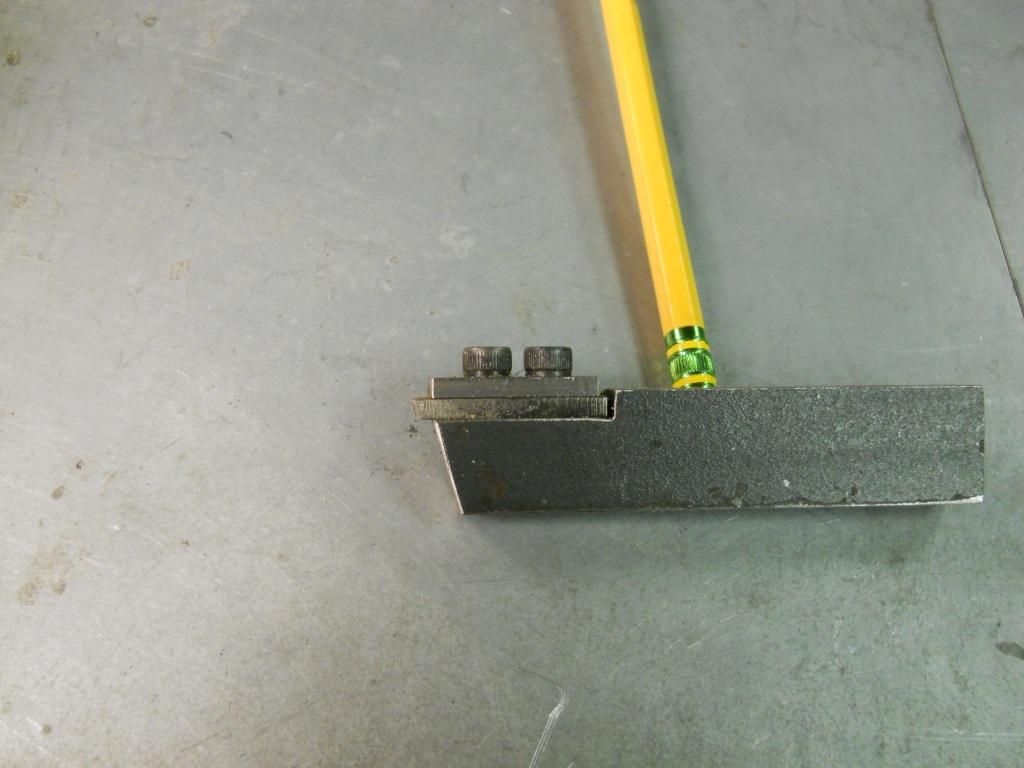

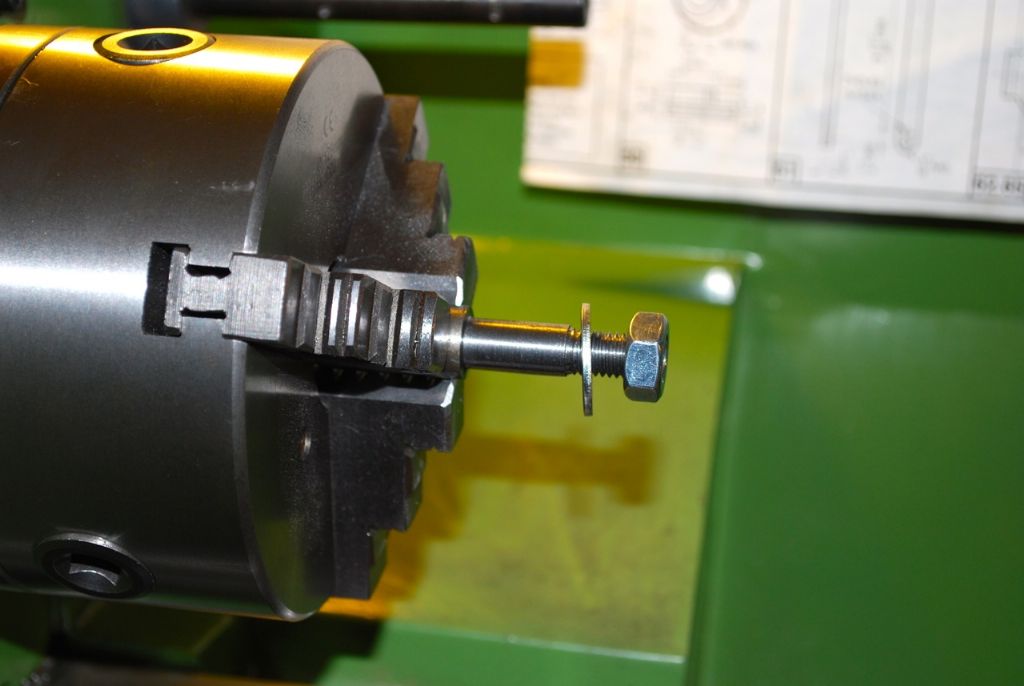

Setting the tool position before starting..

This is just something to maybe look back on as another first (for me) – don't watch its way too long..!

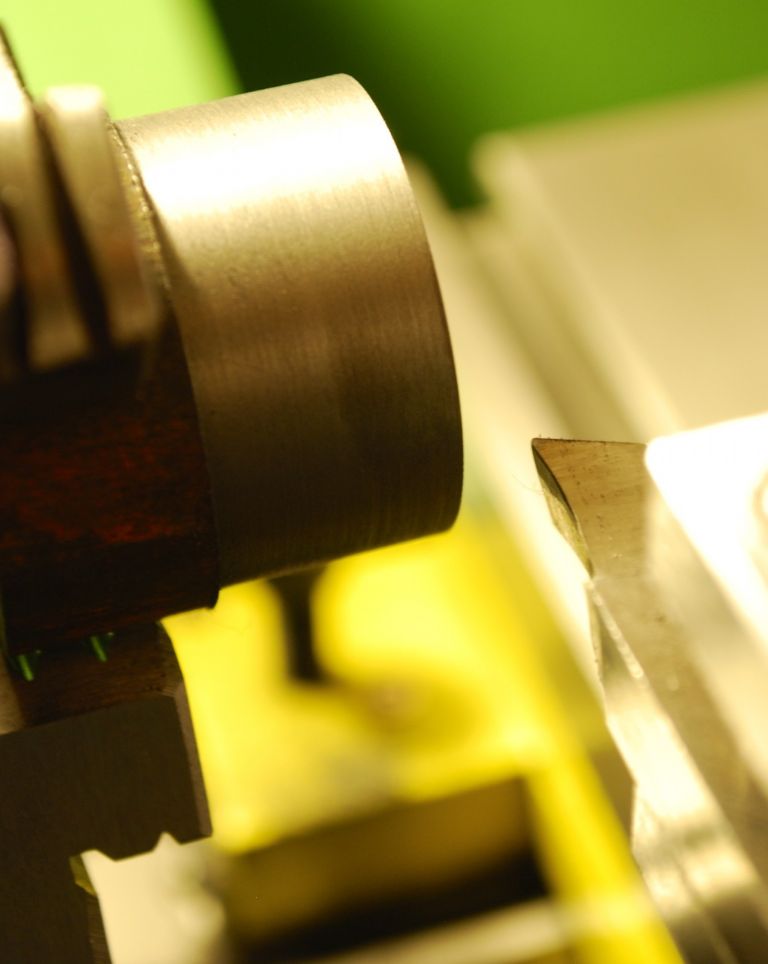

The cut I thought was great, I always seem to get a burr at the end sometimes quite big when I've been hand feeding but not here under power – there was a slight wafer thin coil left around the hole and which came away in one piece with my fingers. I may be converted to this way now.. I used the slowest feed rate on the lathe, I'm sure on a true running diameter I could have gone faster – not that matters anyways…

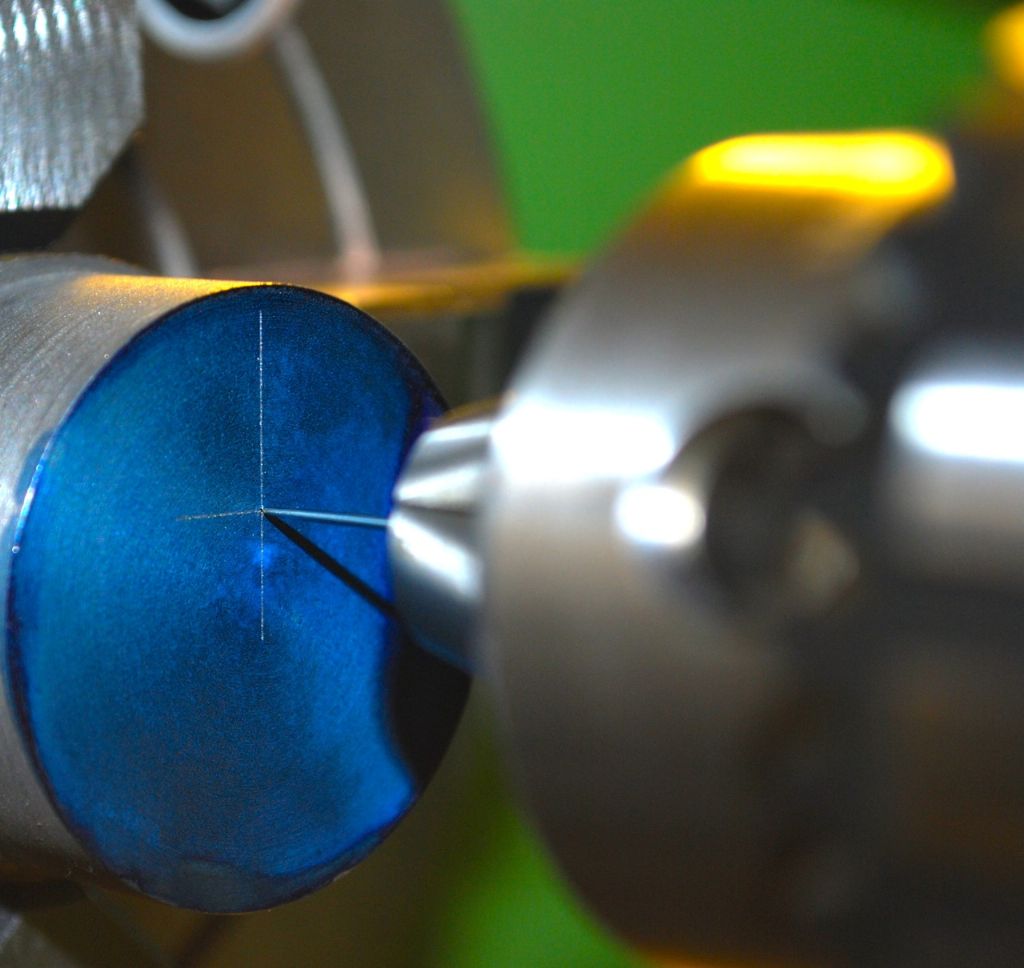

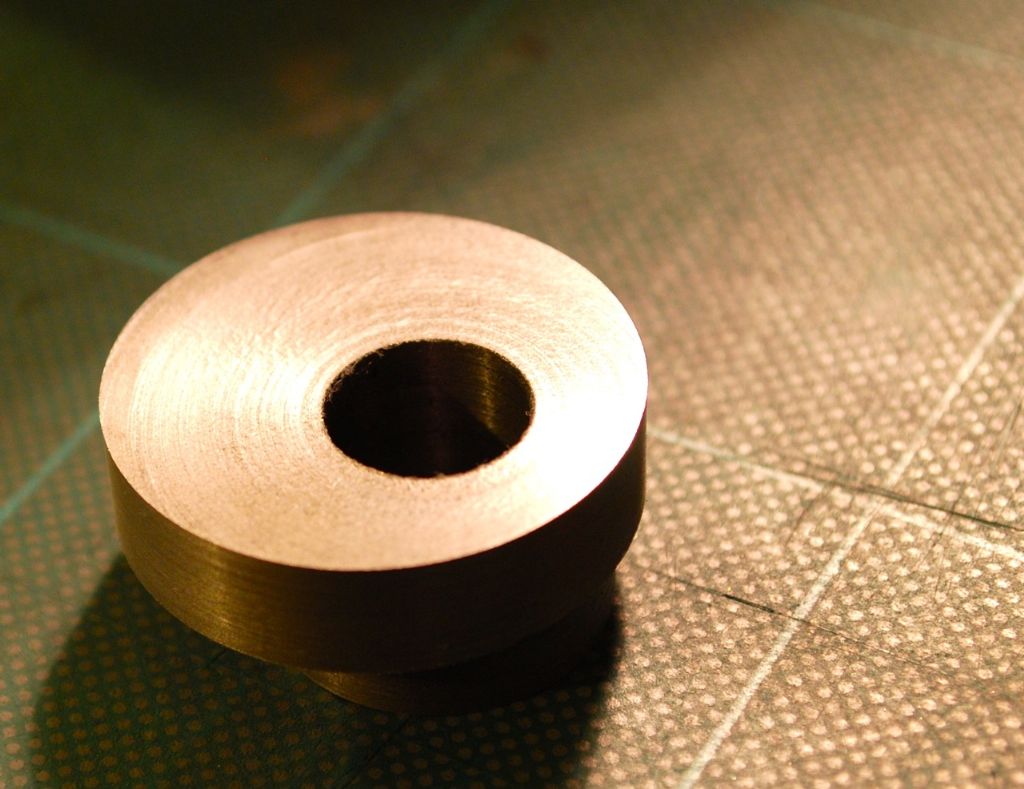

This was straight after the cut had finished, just the thin 'coil' removed around the bore and cleaned with a rag – no other cleaning up at all yet…. I did nothing except position the tool and engage the cross feed – and a bit of sweating I guess. I have an idea now that with the offsets involved this was a much better and easier way than hand feeding would have been..

Cheers

Garry

JasonB.

JasonB.