Been making slow progress with the Crankshaft but finding it very interesting as a first attempt. I've made lots of mistakes that I may as well include here in case its of interest to anyone else first time around.

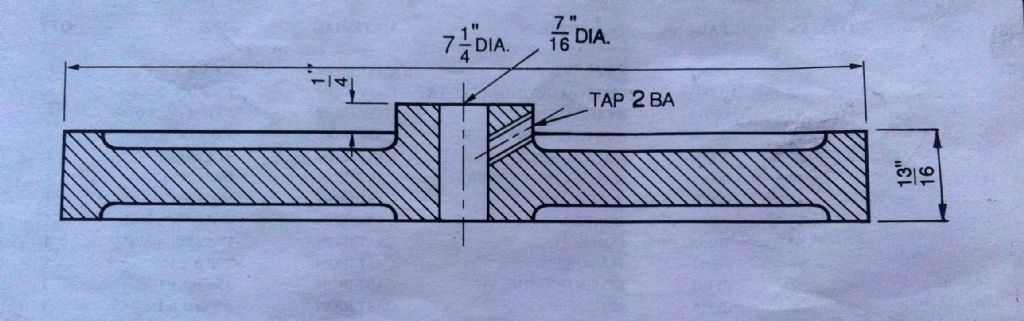

First off as I had already used the supplied bar I tried to turn one from my own stock (larger diameter) which turned out to be PGMS – I don't know why but I had problems getting any kind of finish. As soon as I changed to black mild steel I was able to make a start. Next up was on perhaps the easiest bit in cutting away the excess shaft between the webs – I tried to hacksaw off flush with the webs and ended up marking them quite badly. They have ended up slightly undersize between the webs by the time I had cleaned them up. Hopefully I can allow for this later. Next time around I would leave excess to clean up with a file before skimming. I also hadn't realised that the thread in the throw plates only needed to go through halfway to the slit and that the rest of the hole need to be drilled out oversize for the clamping action to work. Last was me leaving too much for the radius cut of the webs – not recognising the significance of the interrupted cut. I have left the webs slightly long to cut down on the number of cuts on the Lathe, means they won't look quite so pretty but I can live with that or if not I can always take them down more later. Guess that all sounds like a disaster!

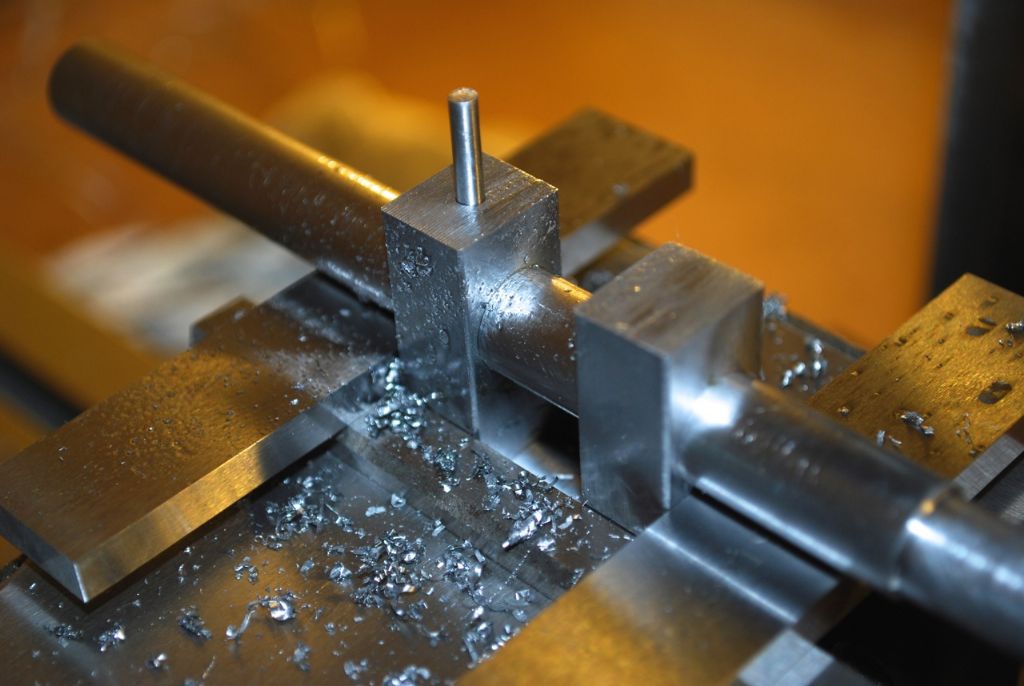

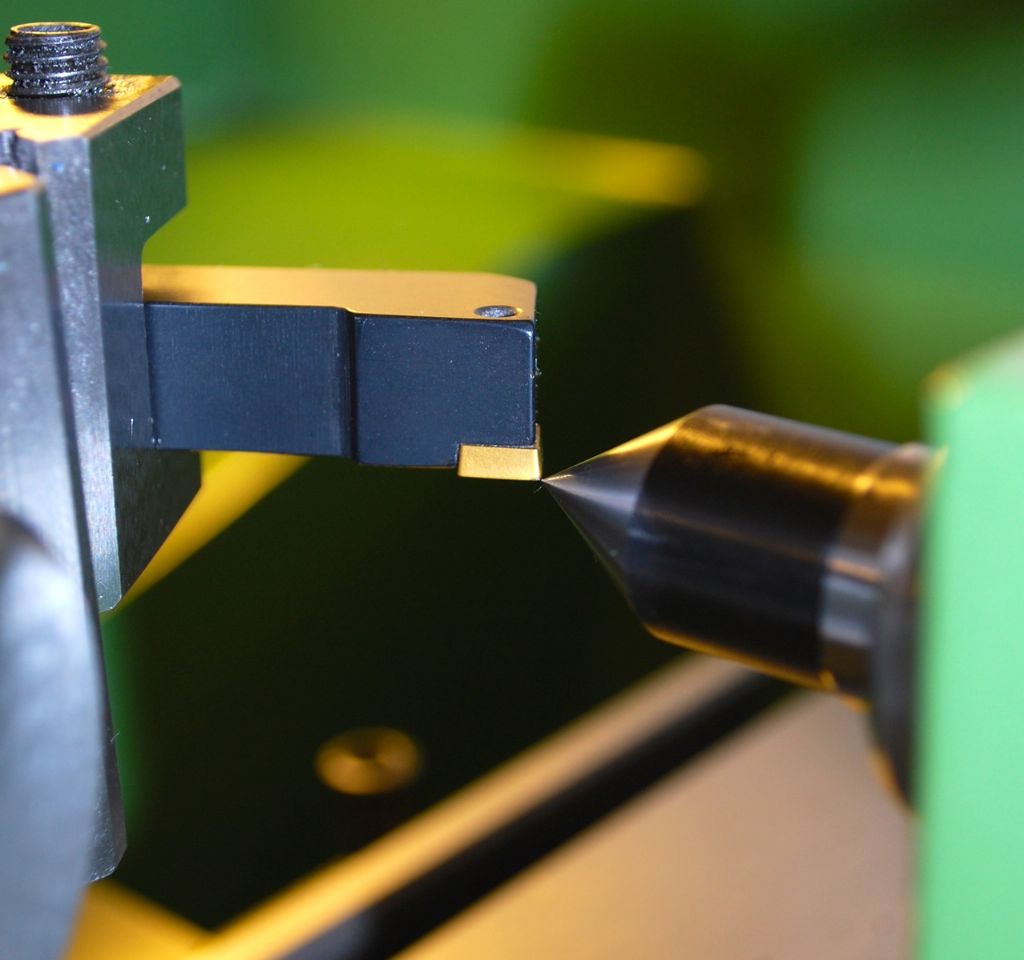

I was stumped for a while in how to reach between the webs to skim the Crankpin when assembled between centres – in the end I ground a round nose on a piece of approx 1/8" tool steel and put into the tool holder on top of an existing tool, to my surprise it worked a treat and gave a great finish..

Anyway some pics of progress along the way..

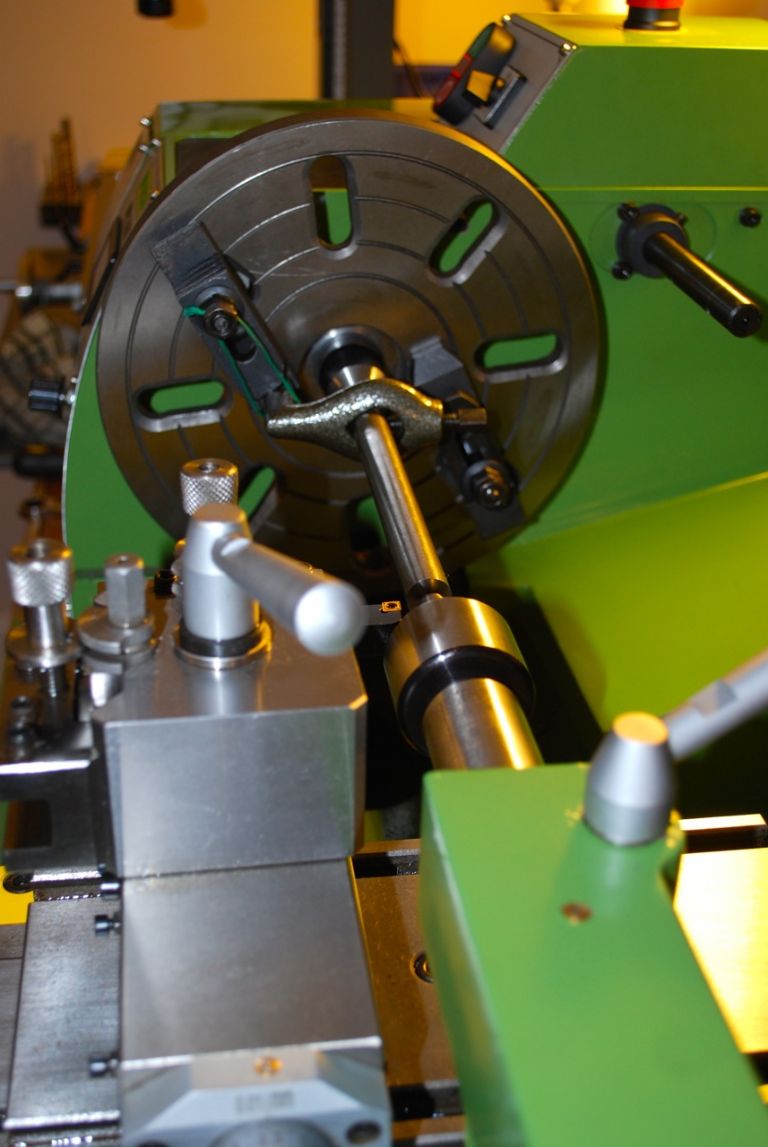

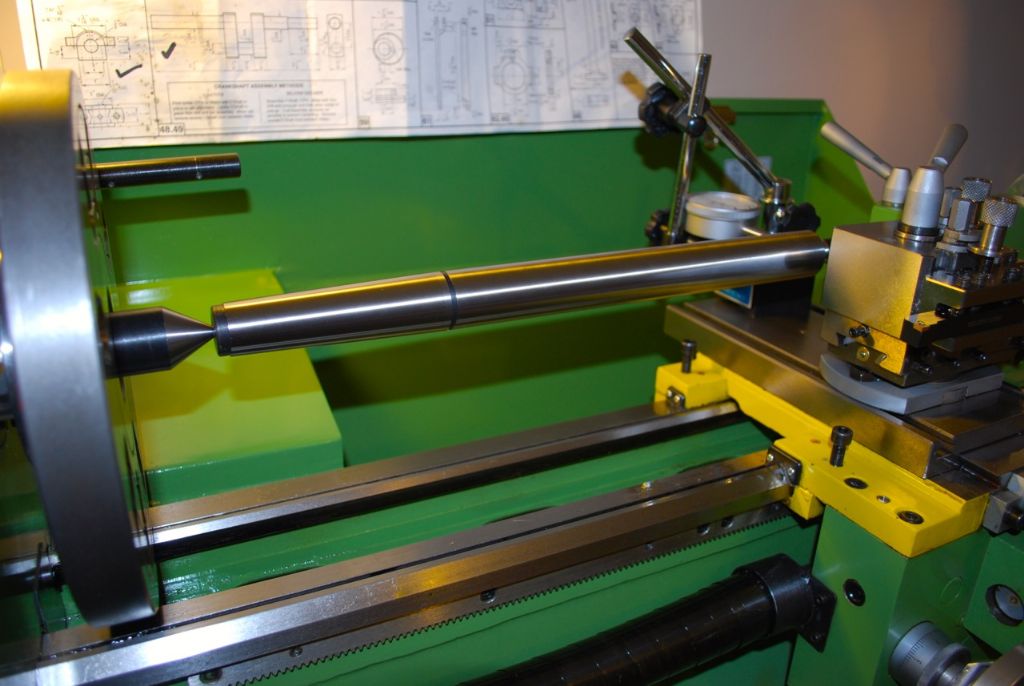

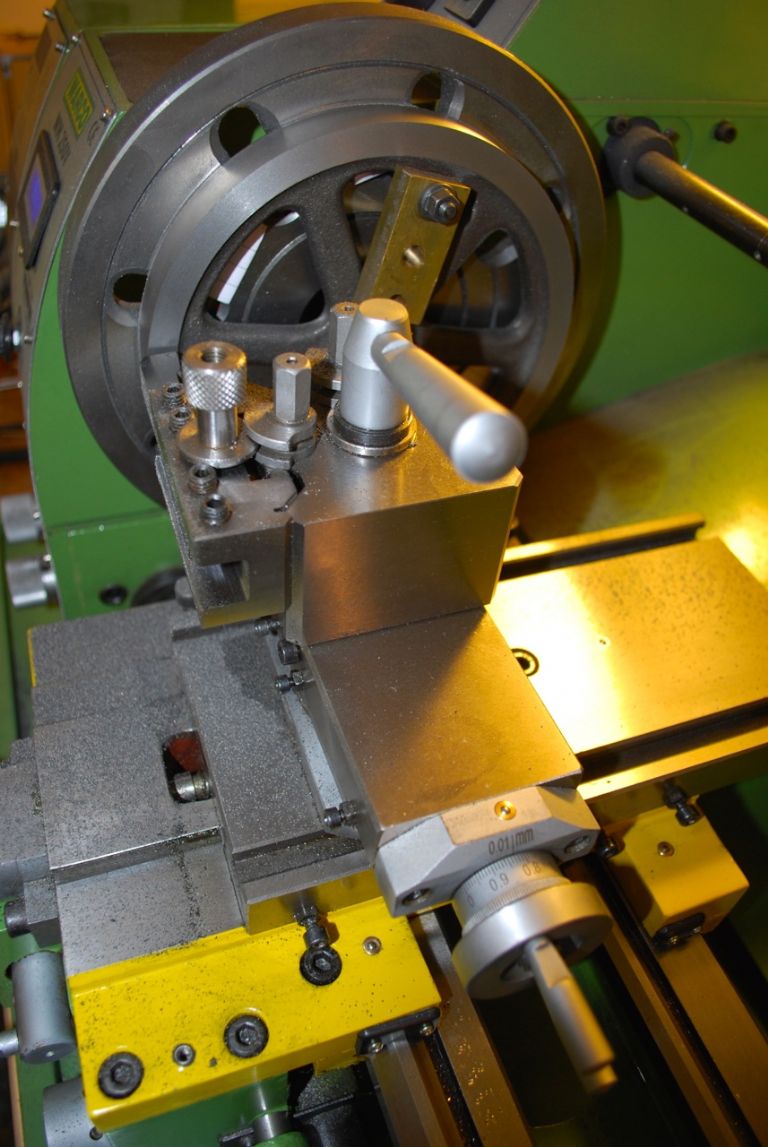

Ready to start turning the larger diameter of the main shaft.

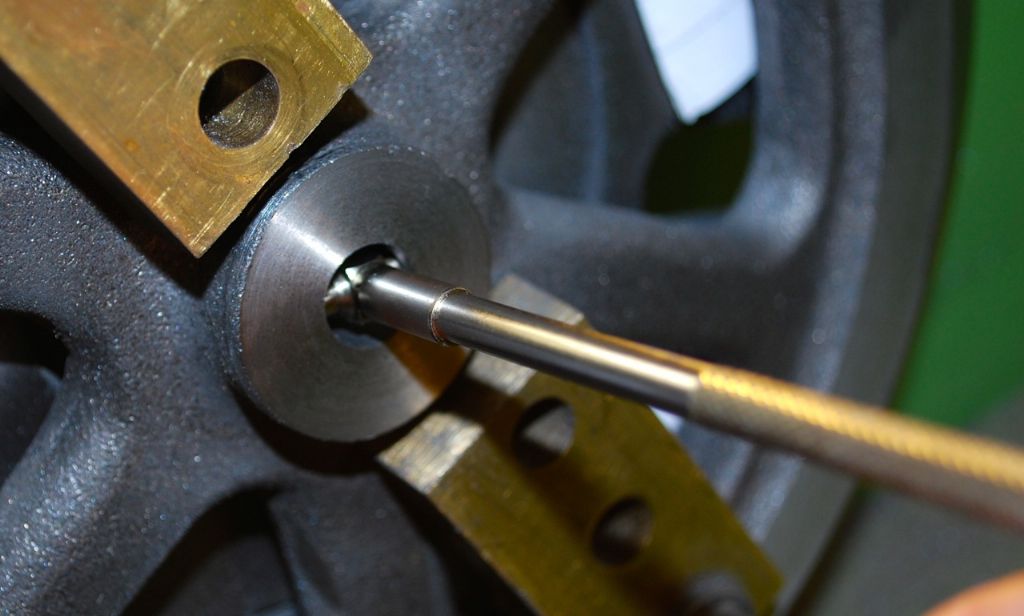

The shaft reversed between centres to turn the smaller diameter.

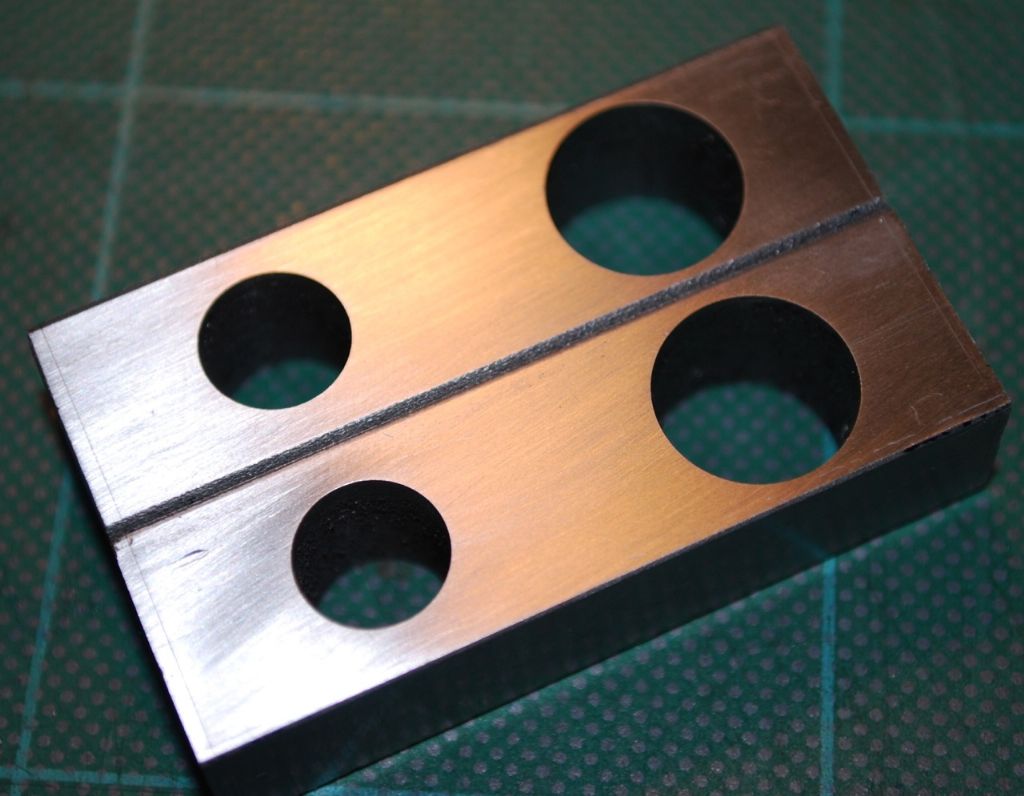

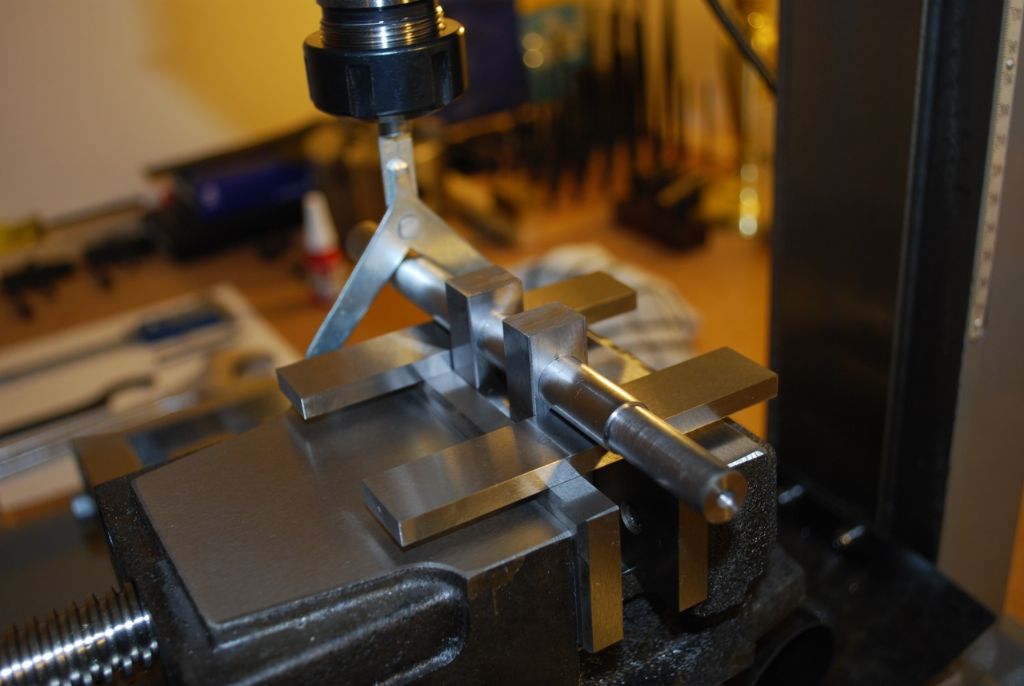

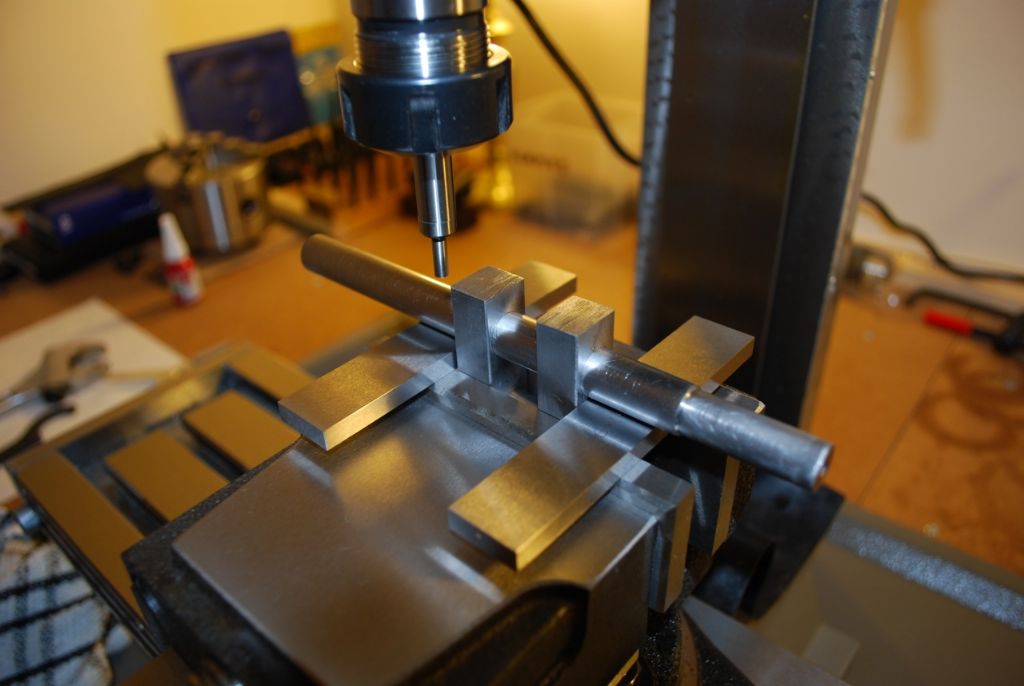

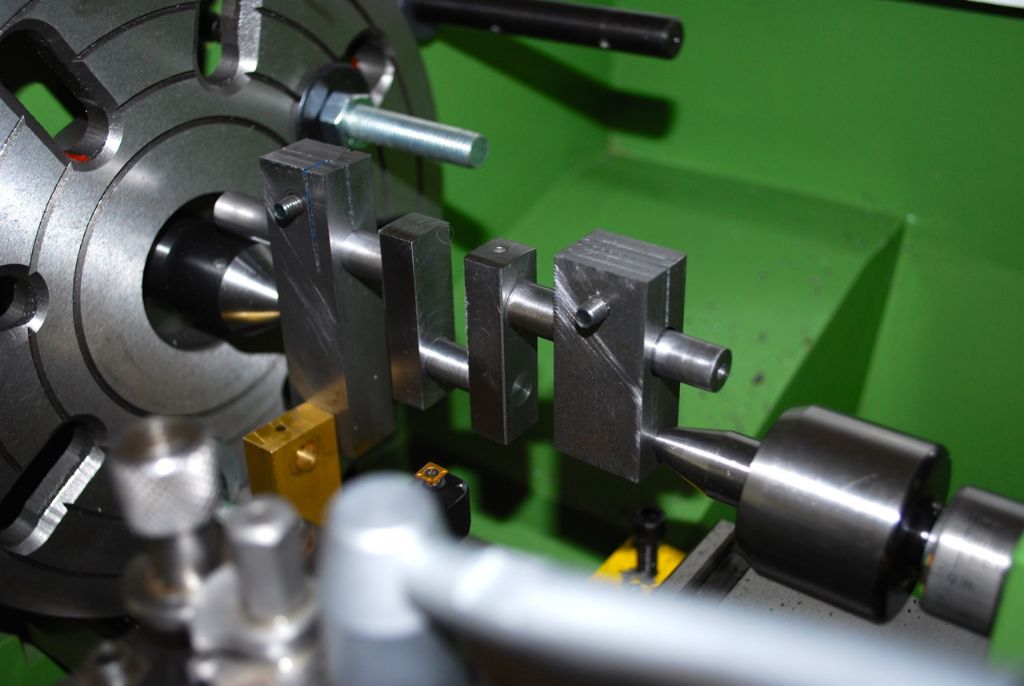

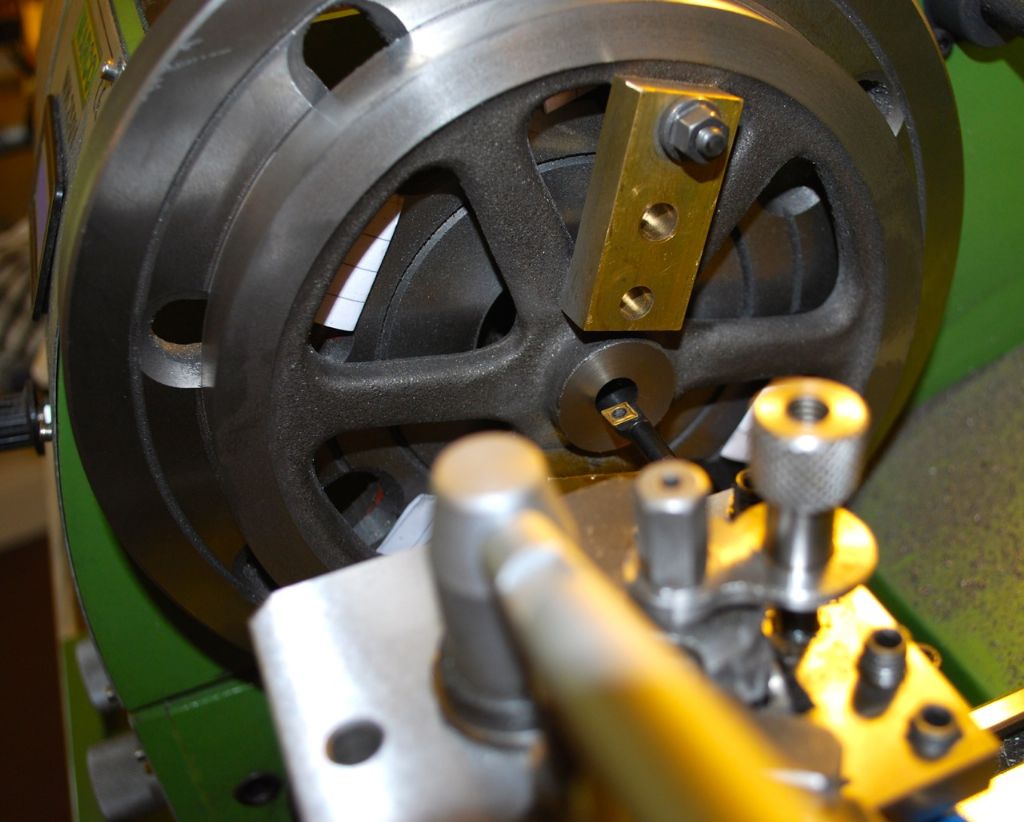

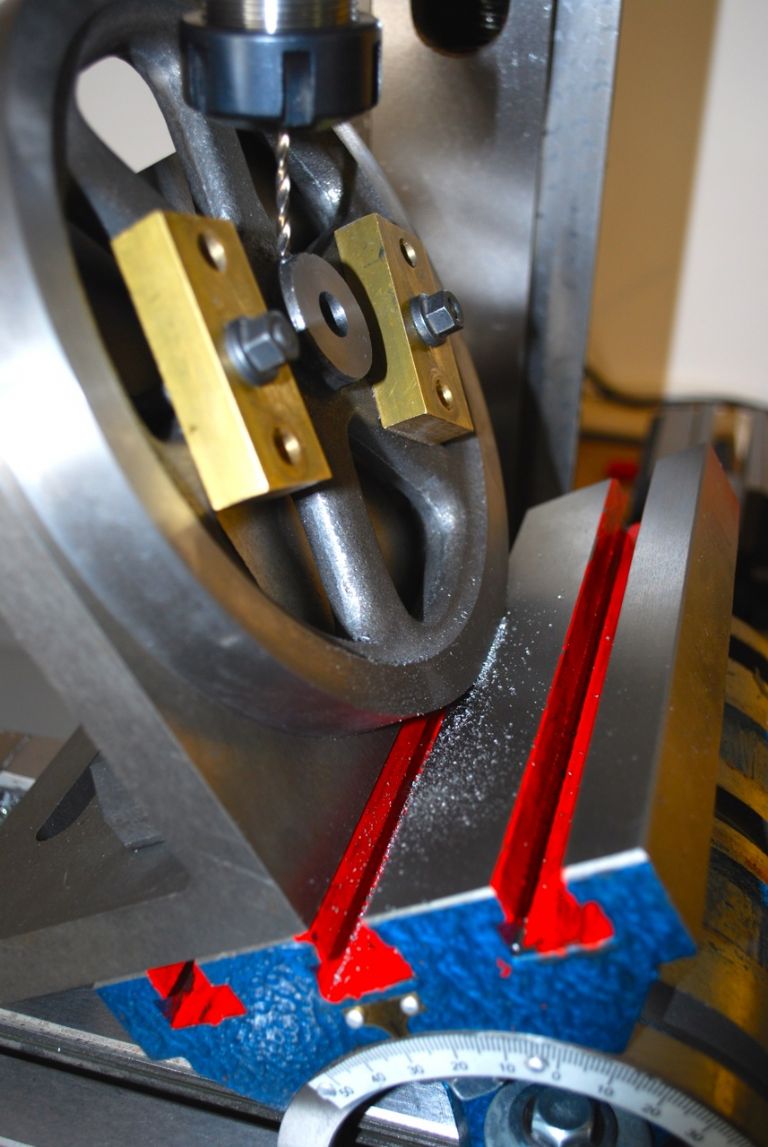

Setting up to drill the Crankshaft Webs.

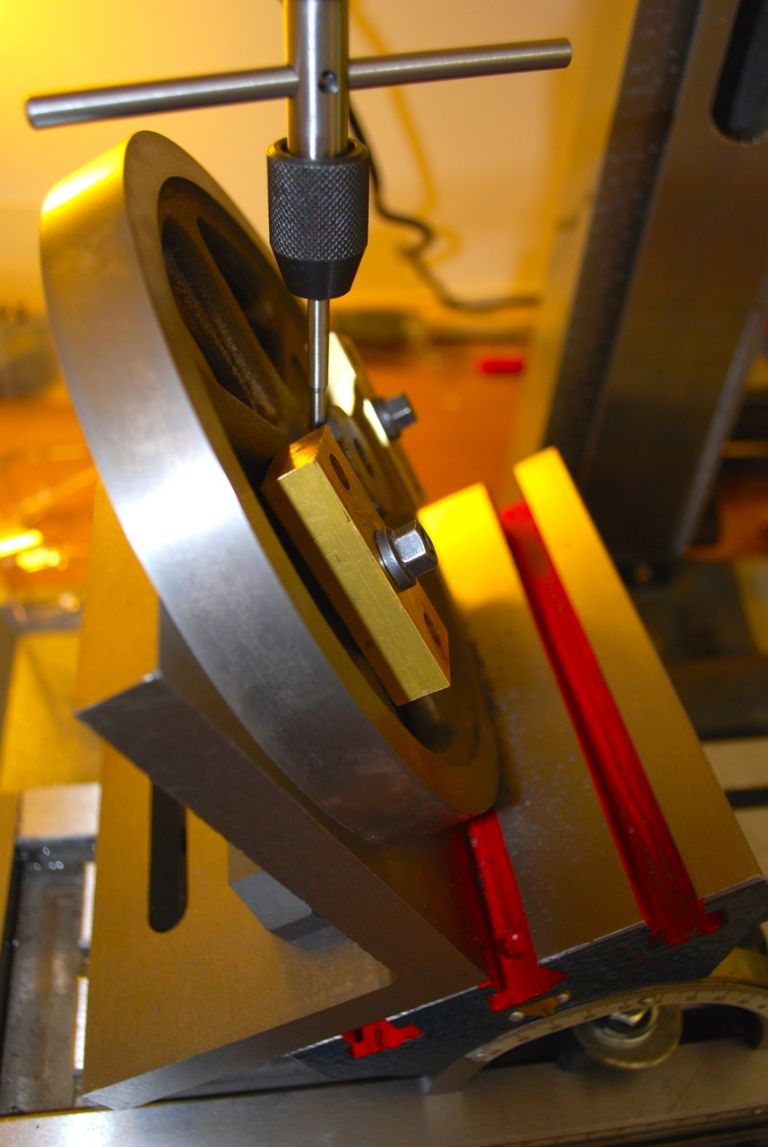

Setting up to drill the Crankshaft Webs 2 with an edge finder. First time for me using this and was great.

The first of the 4 pins. I used 1/8" Silver Steel.

Ready to start turning the Crankshaft Assembly.

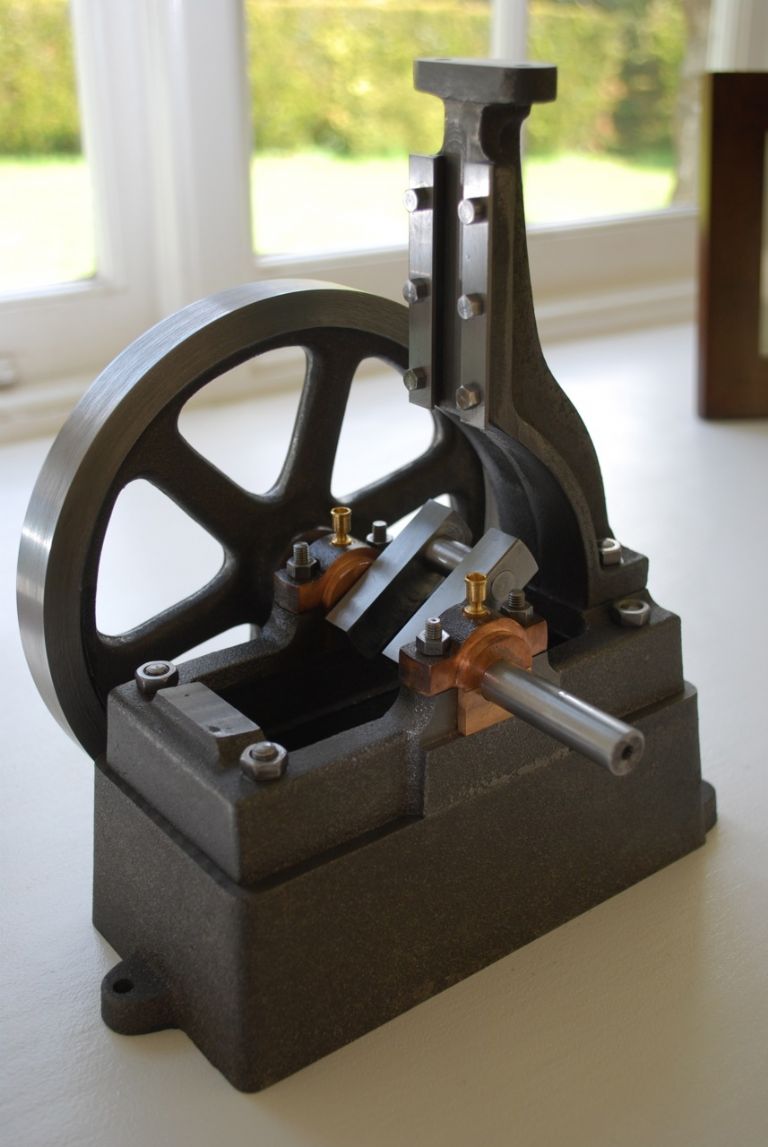

The finished Crankshaft.

Test fitting the Crankshaft in place. As a first attempt I'm quite pleased with it – and I've learned lots again through all the mistakes.. The fit seems very nice and it spins very nice and smooth..

Cheers.

Allan.

Edited By Allan. on 31/03/2015 17:05:45

Edited By Allan. on 31/03/2015 17:10:15

JasonB.

JasonB.