I've done some more with the Steam Chest today. Its taken a while as there is a lot of checking that everything is square every time it needs to be moved for a new setup – and you can perhaps see from the photos above (last post) that the 'valve Boss' as cast is well off centre, making things a bit more awkward – so things look a bit off below until I can hopefully tidy around the bosses and glands when they are done – with a file..

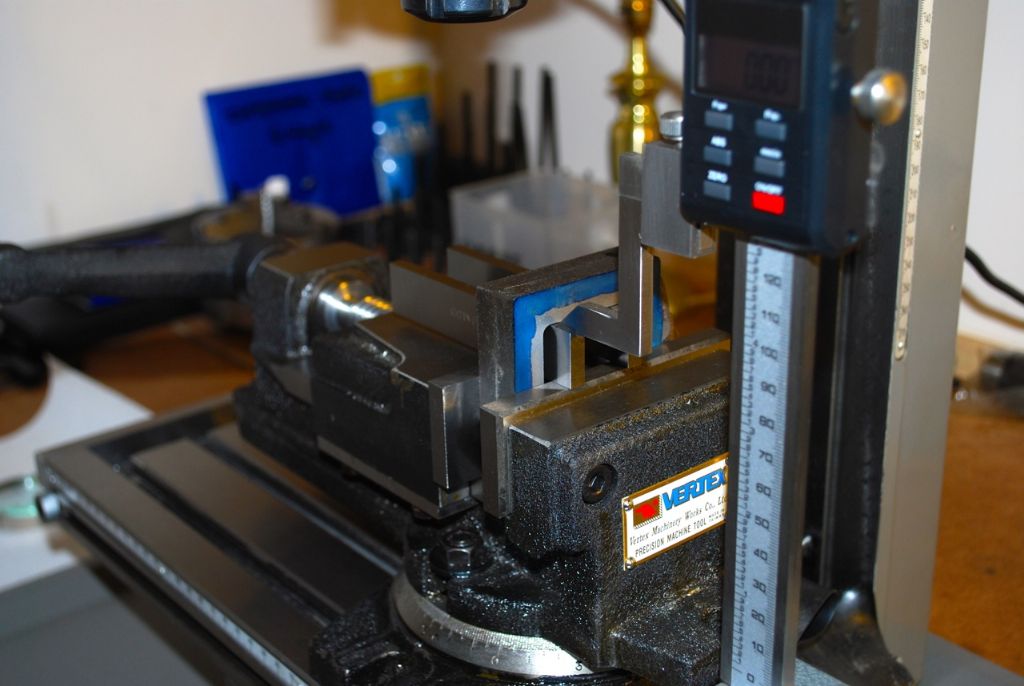

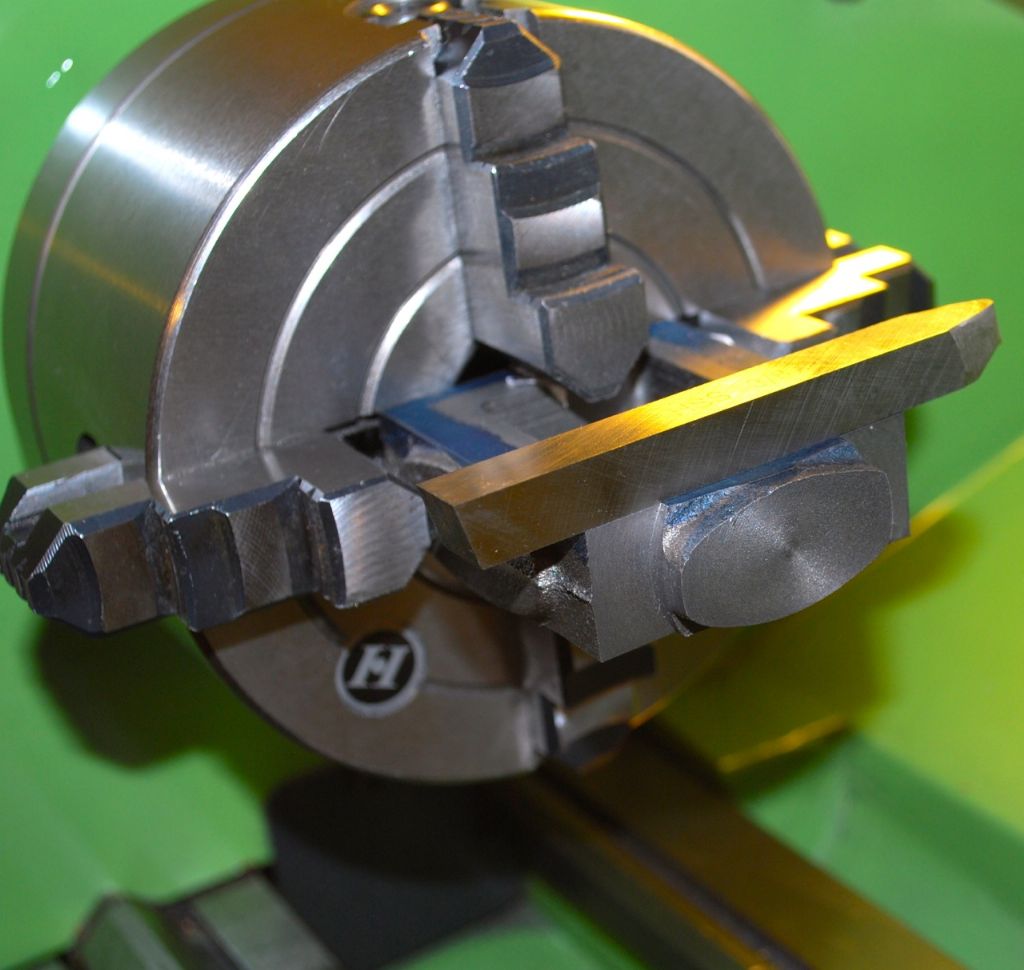

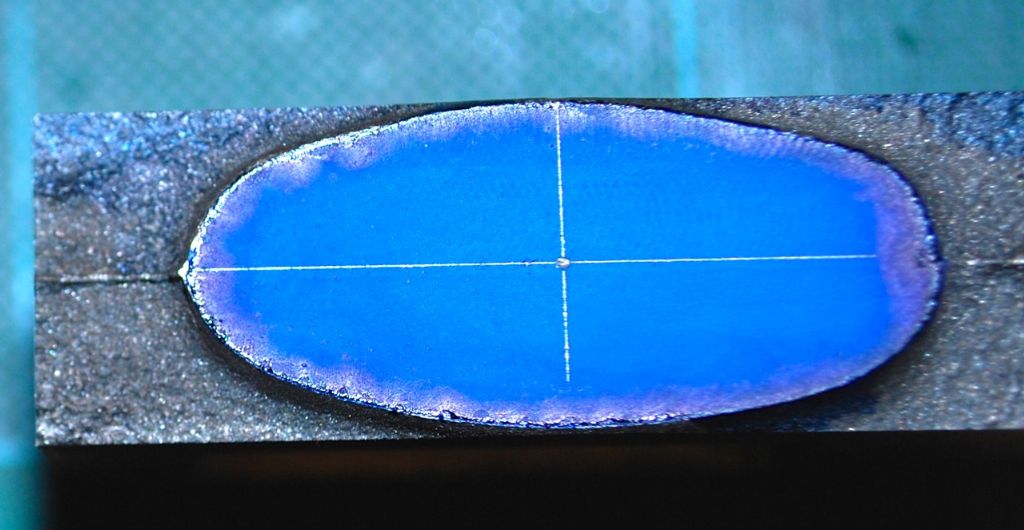

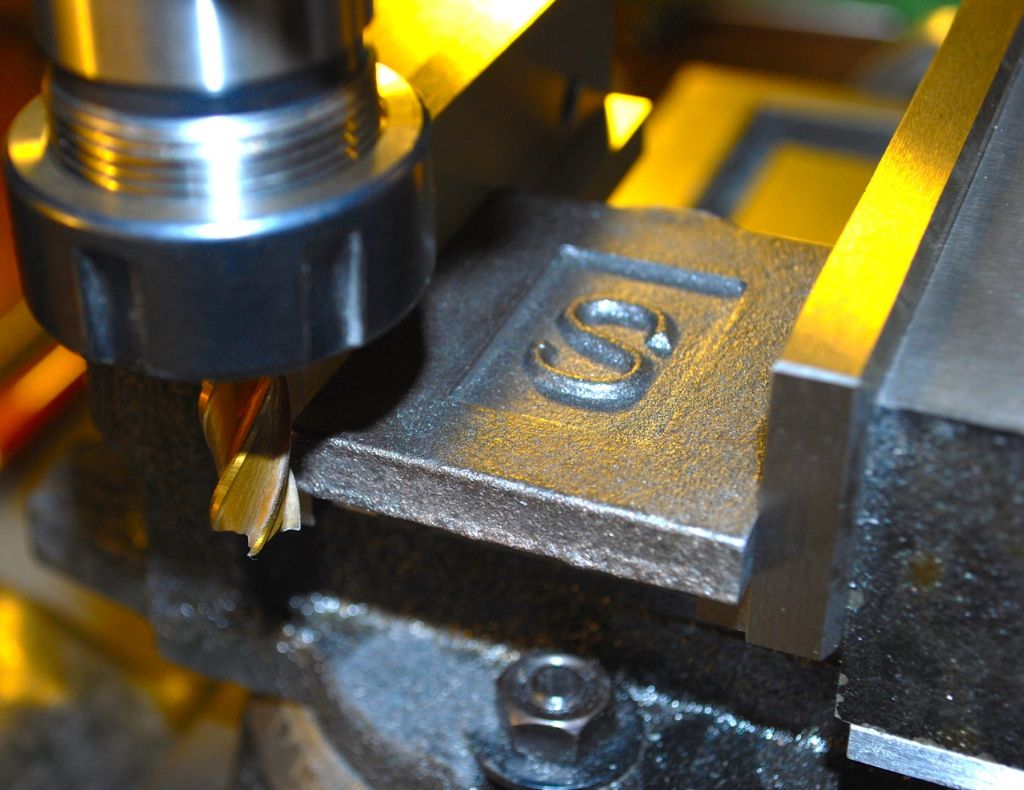

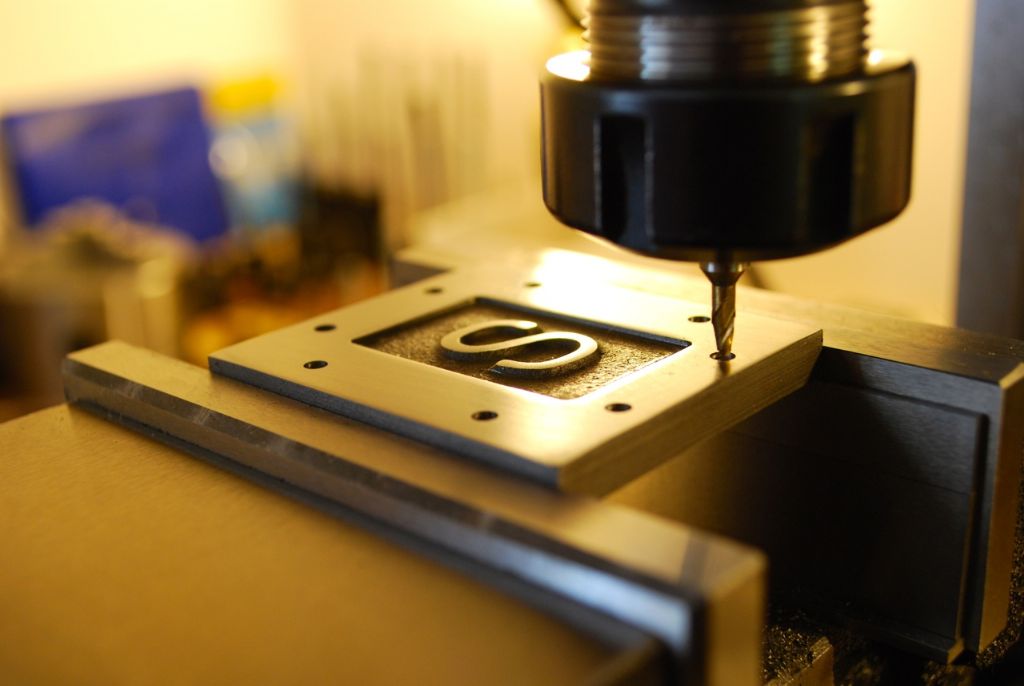

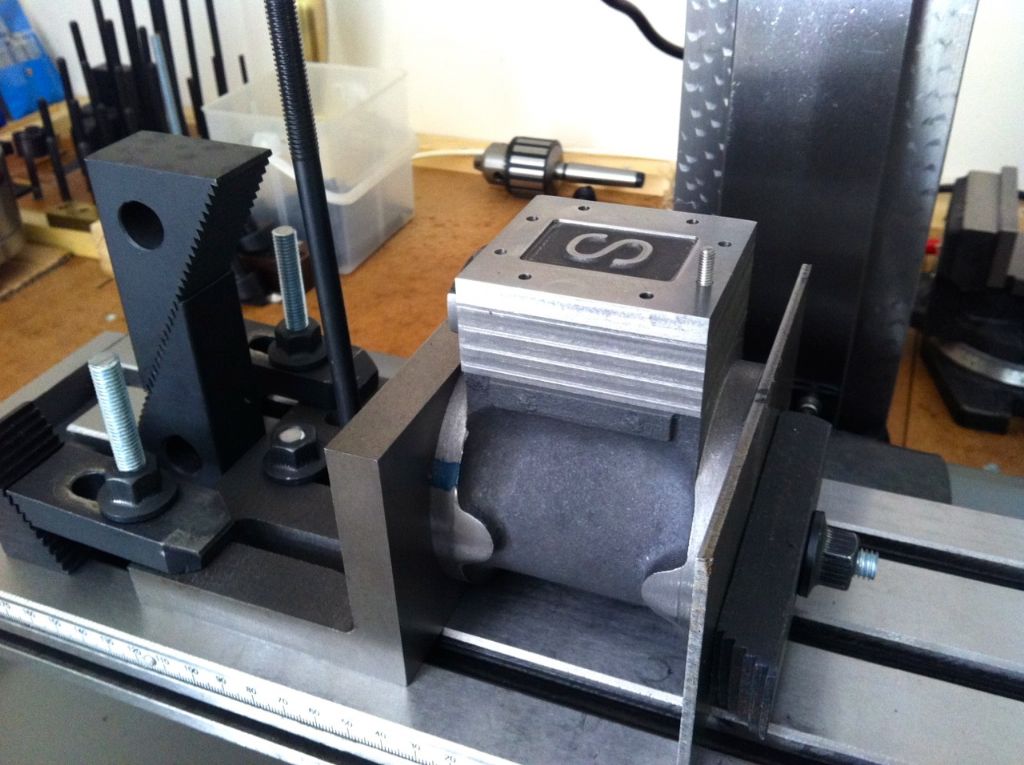

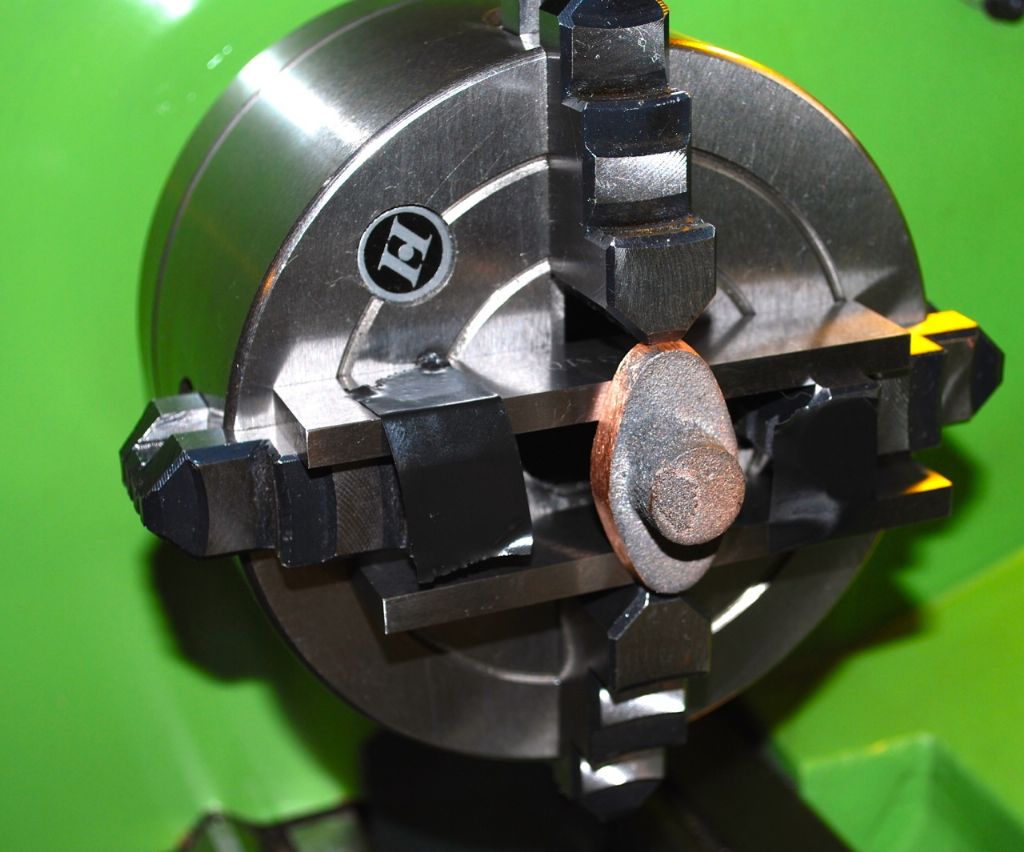

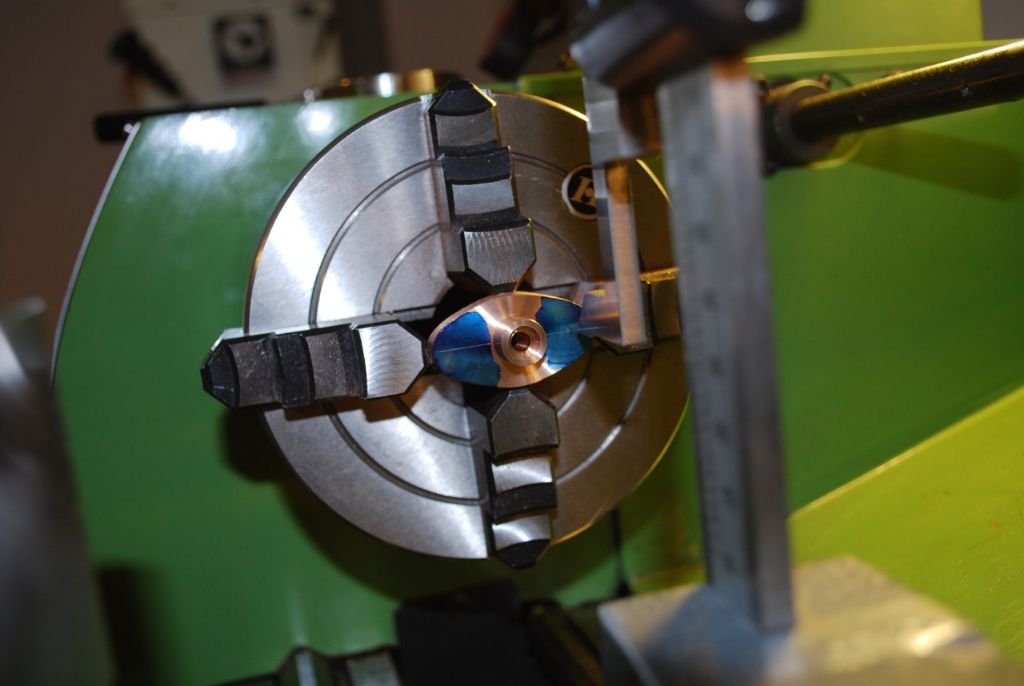

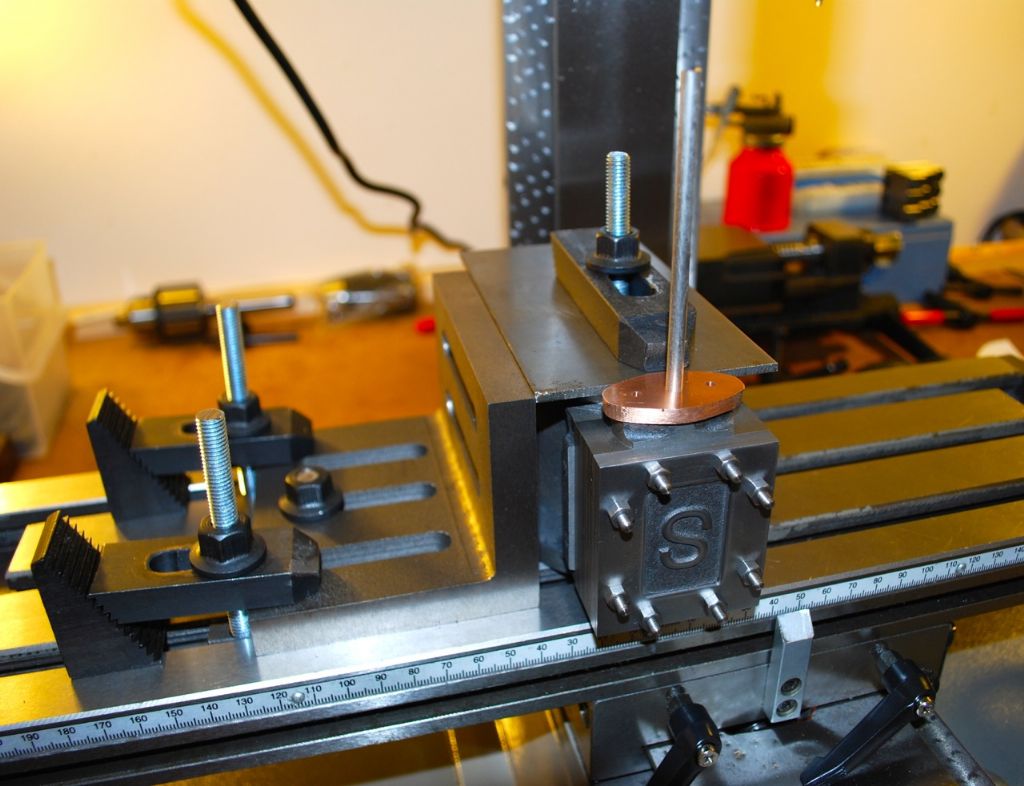

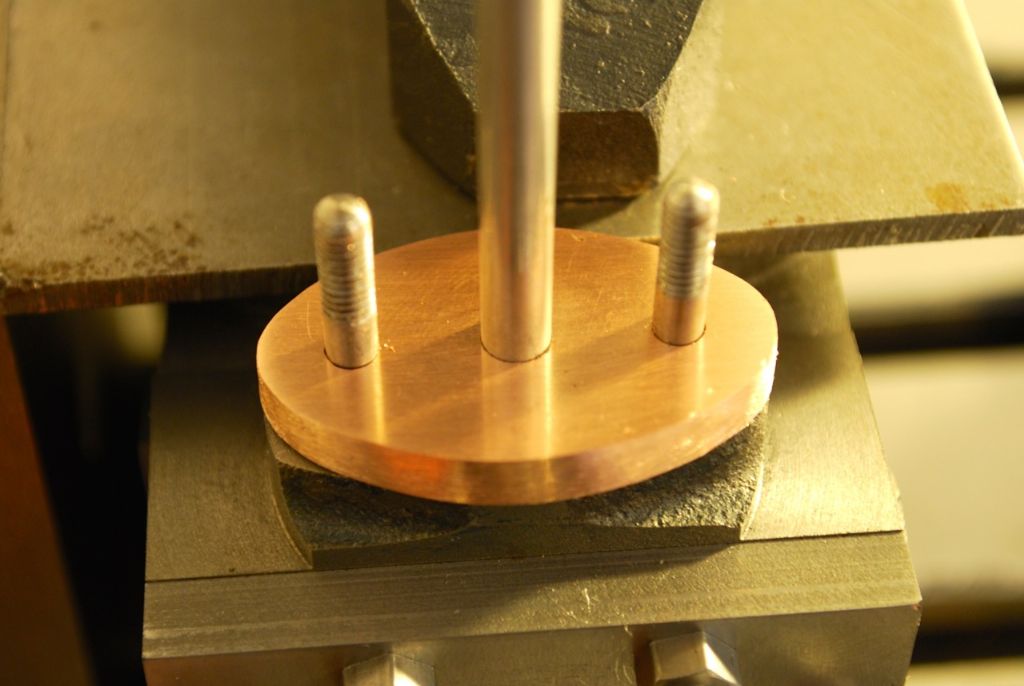

Starting to machine the Valve Boss end with the 'inside centre' of the steam chest running true.

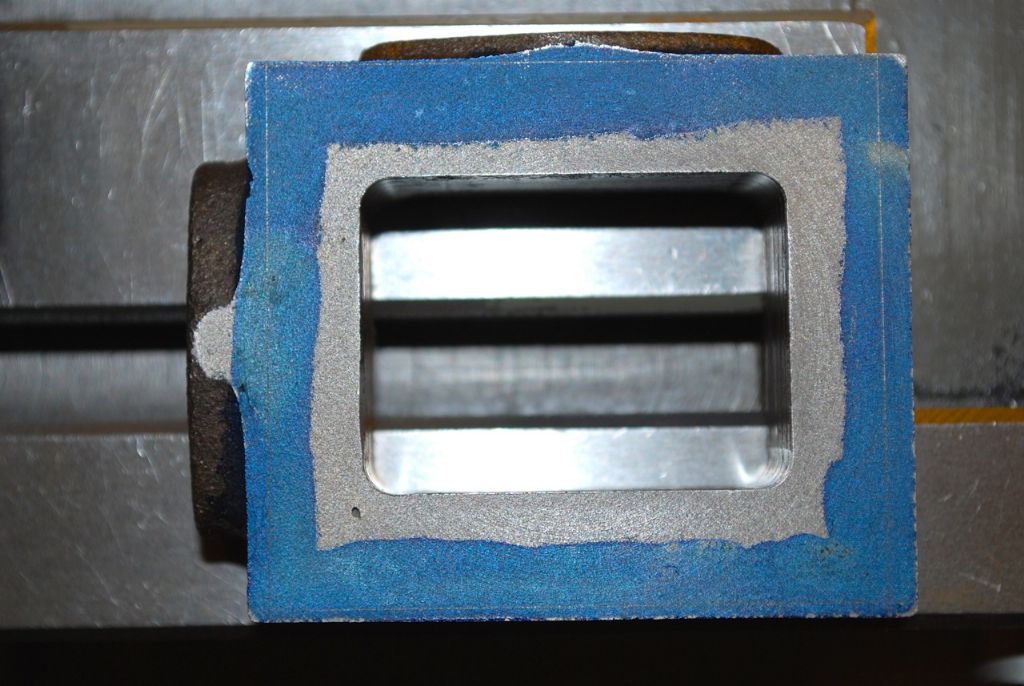

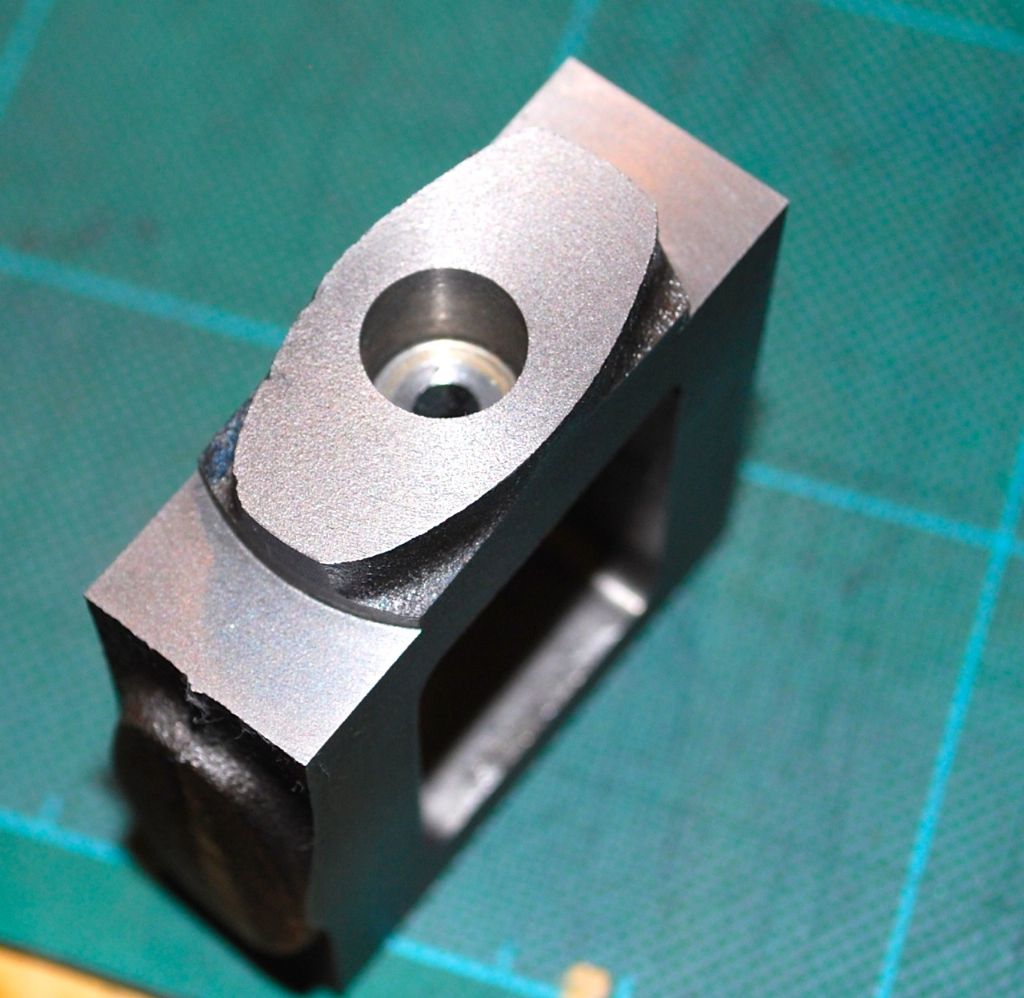

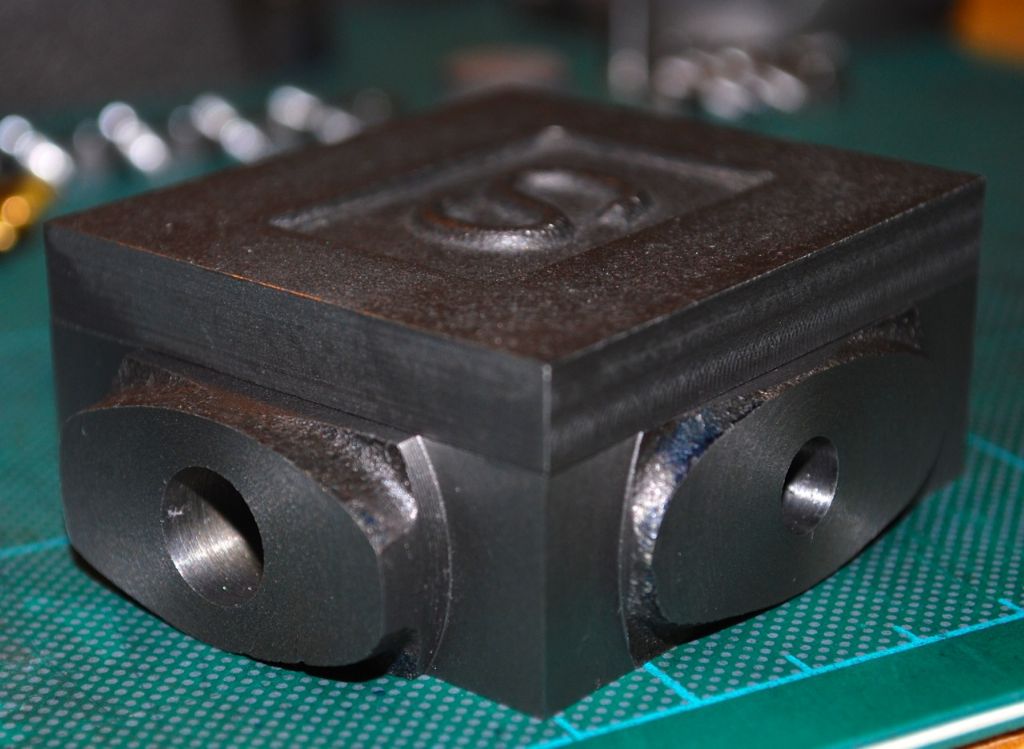

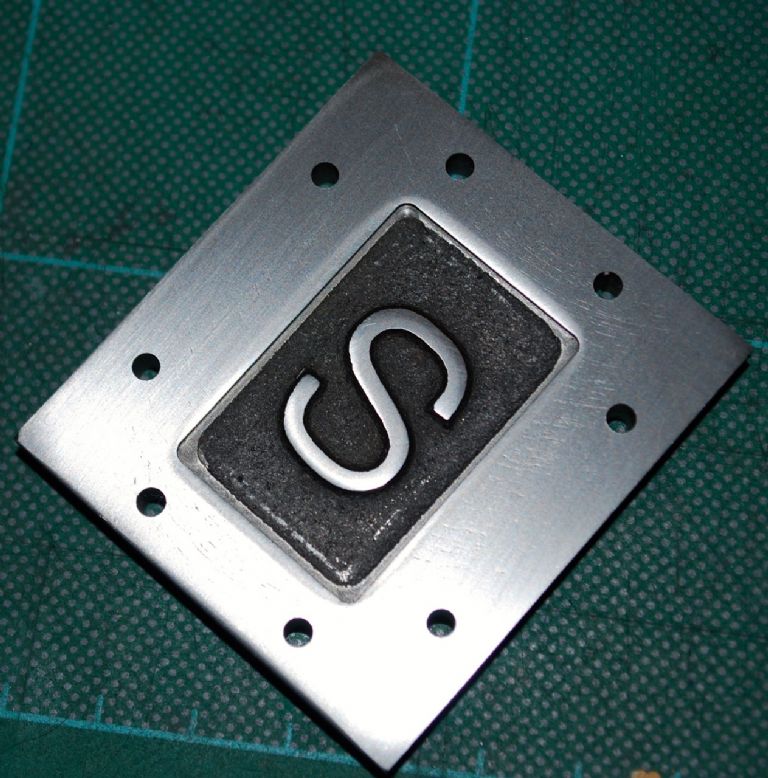

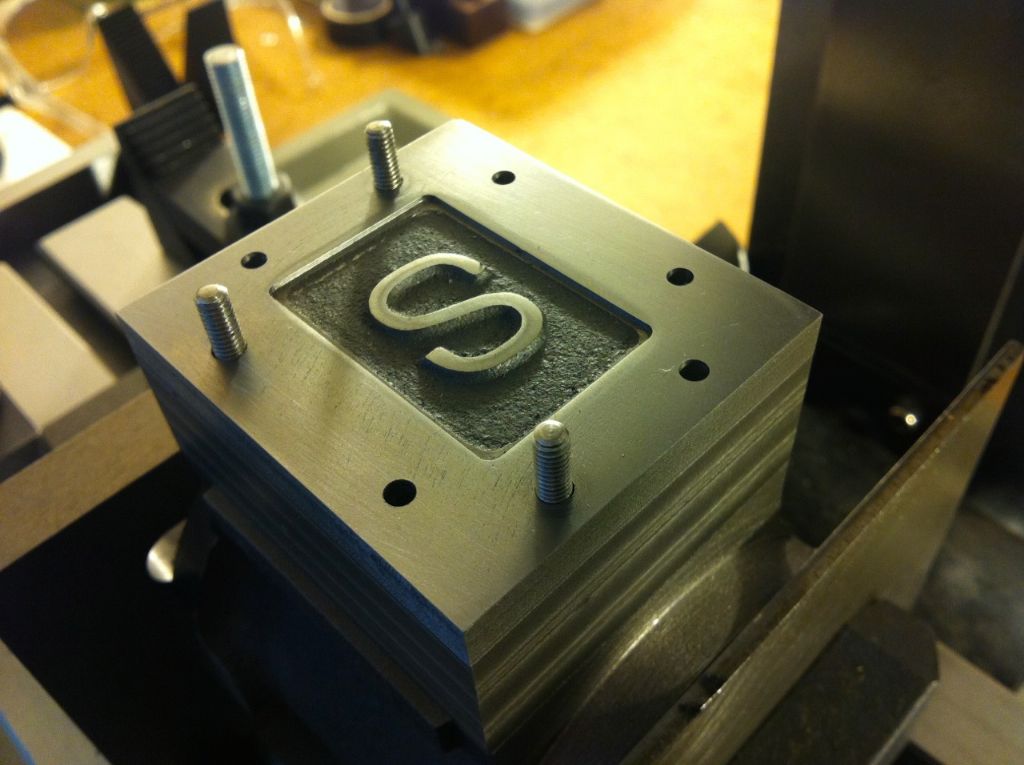

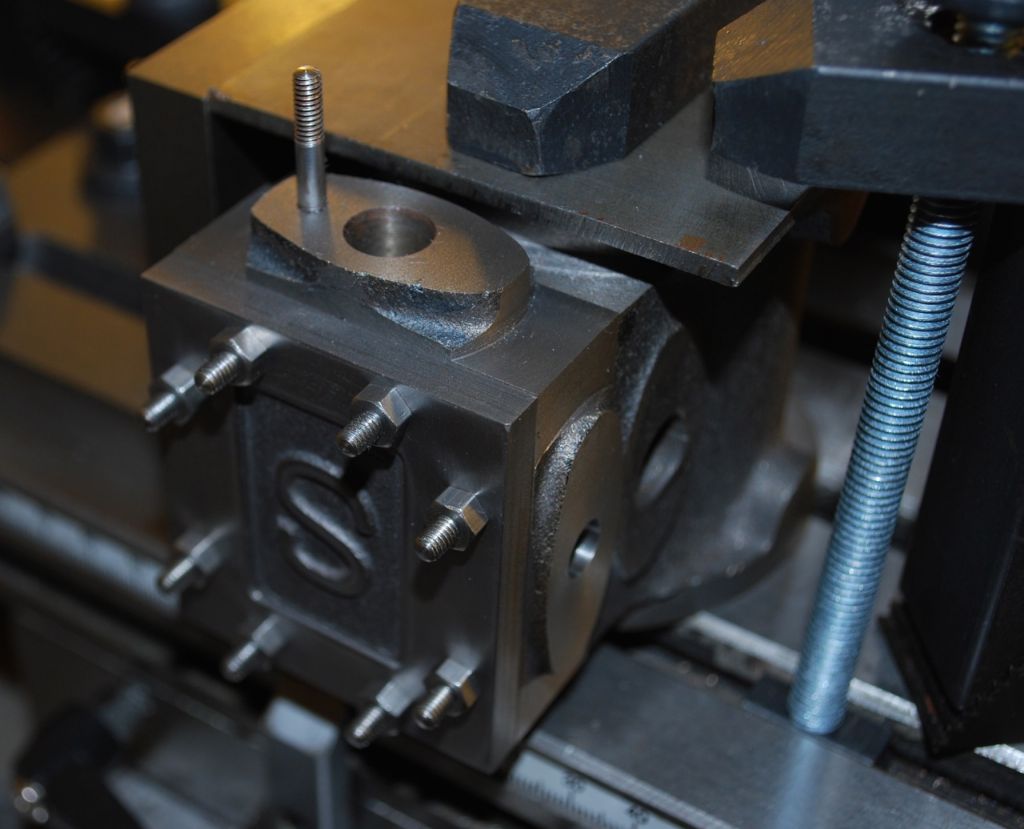

The 'Valve Boss' now looking a bit more central, but its going to take some careful filing later to get it looking right.

I'm thinking I'll try and clamp a piece of tool steel across the ends to help with some of the filing when the time comes.. The outside edges of the Steam Chest are being machined to the size of the Steam Cylinder Port face and so I'm getting left with little steps to remove later – I dare say it's not helping because I've taken too much from the Steam Cylinder Port Face when I did that earlier..

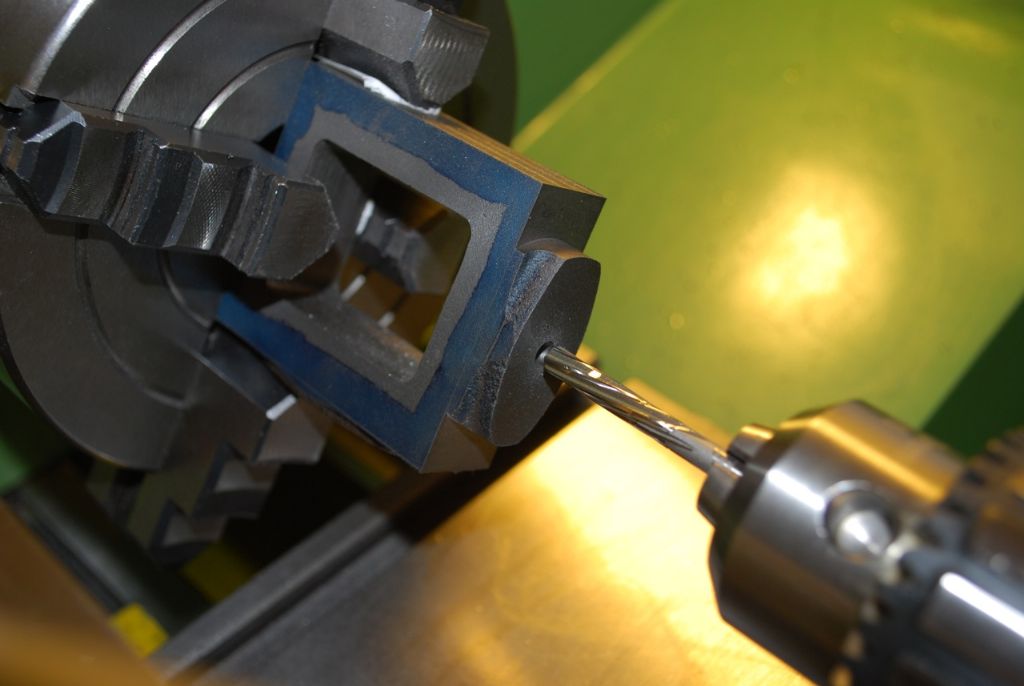

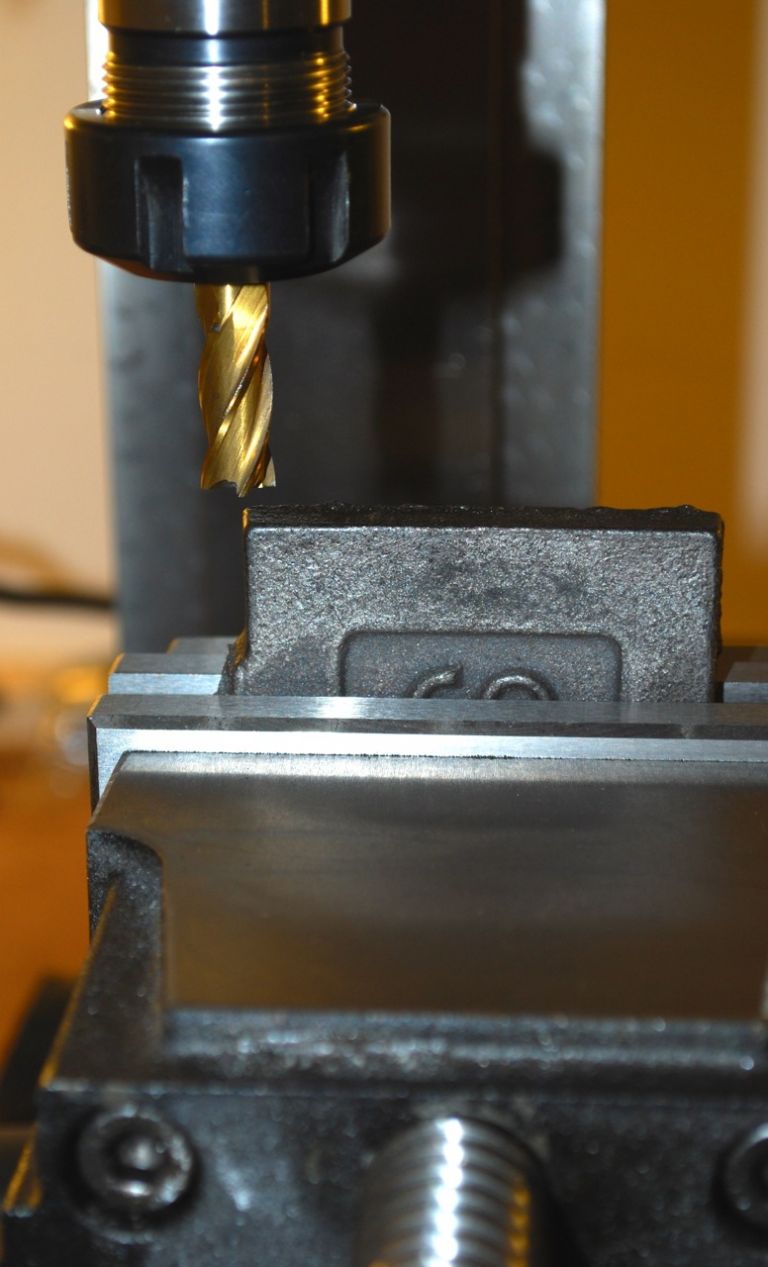

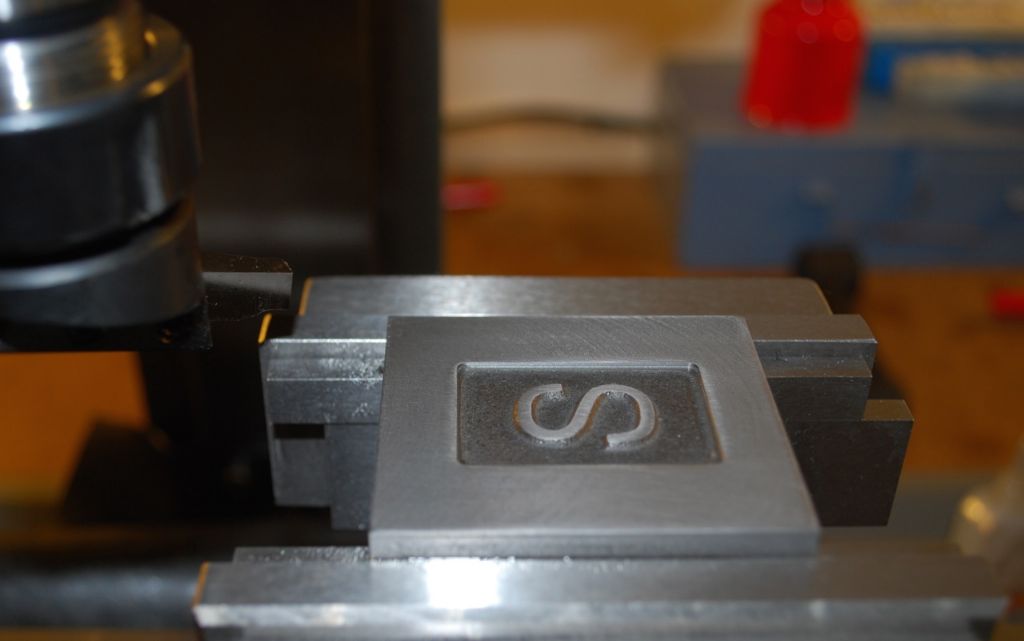

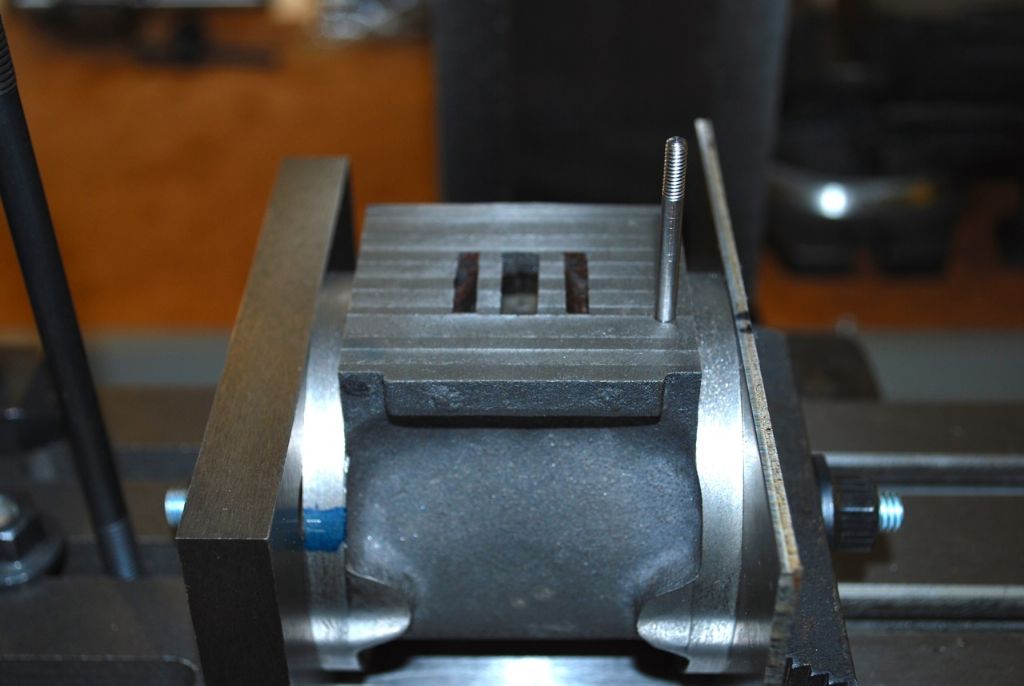

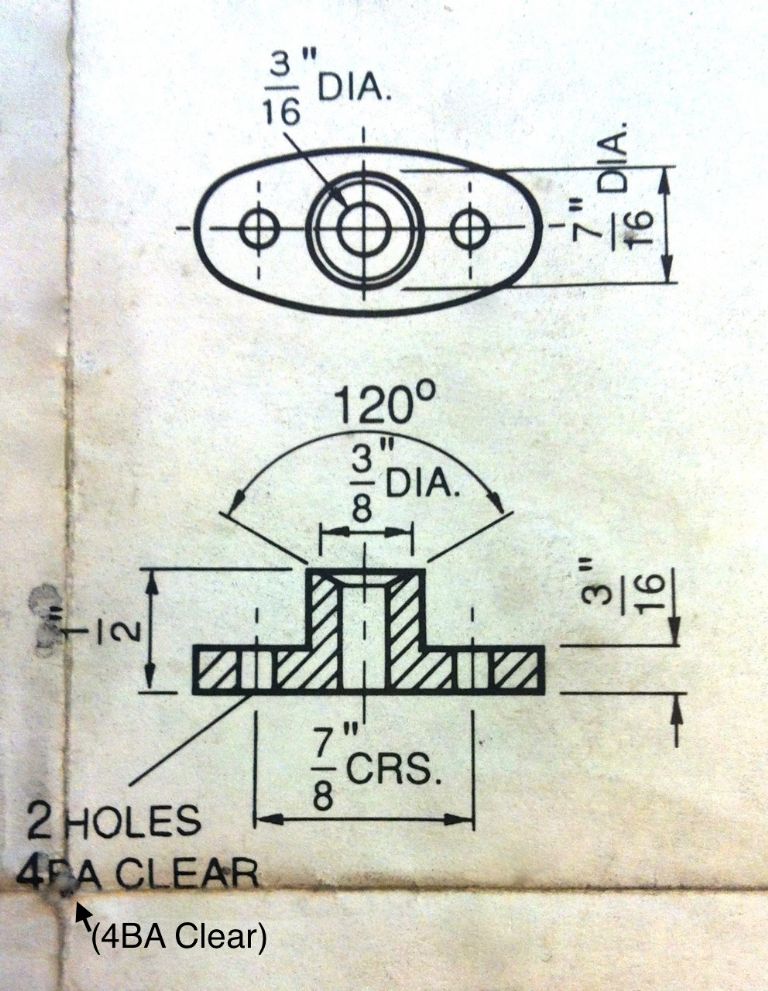

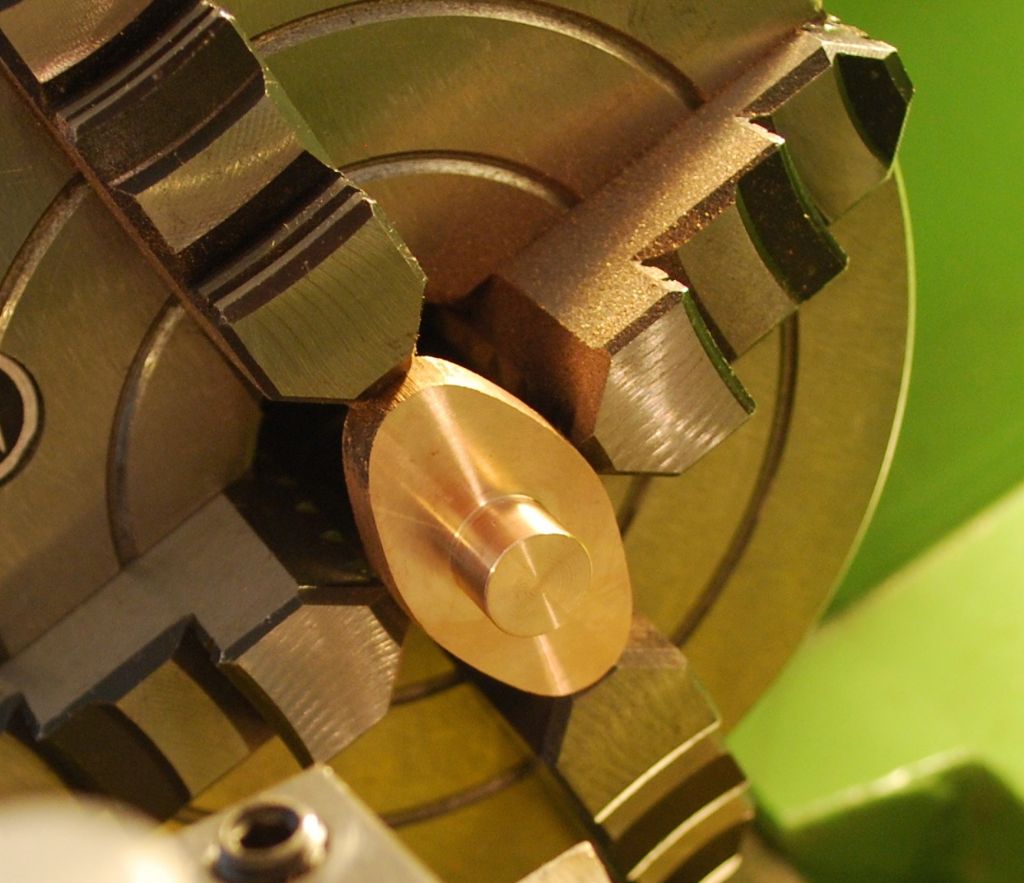

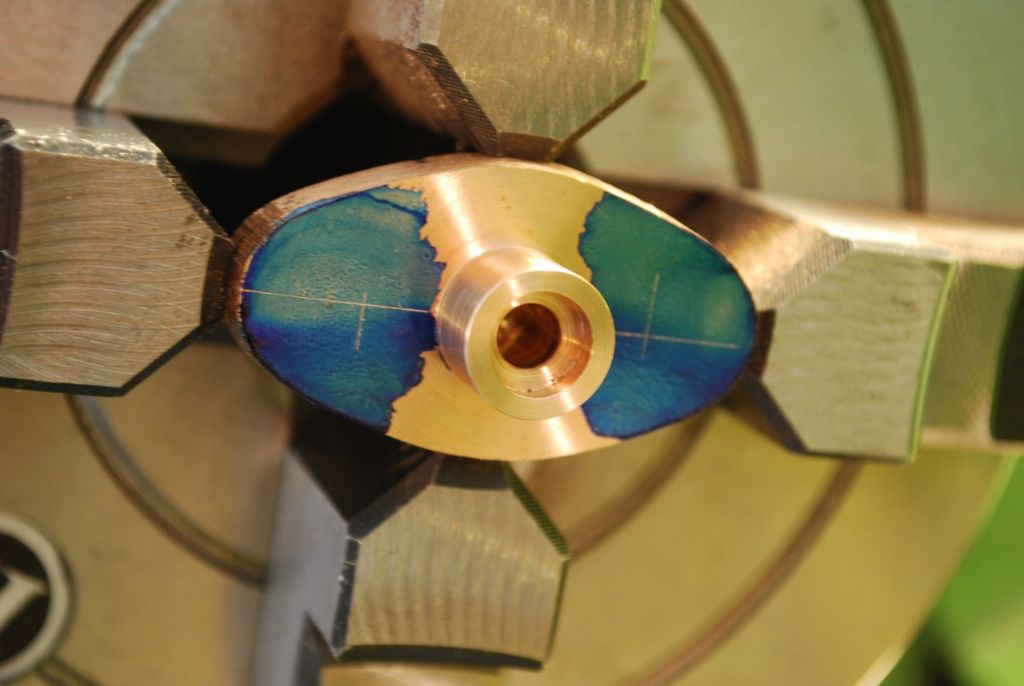

The 3/16" hole for the 'Valve Rod' was drilled and reamed first..

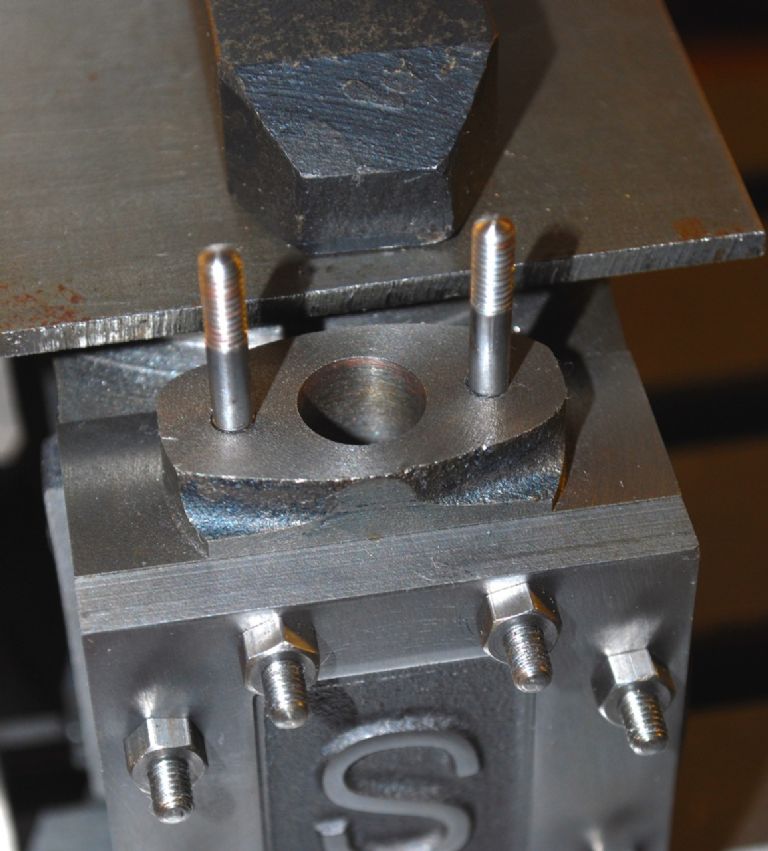

and then opened out with a drill bit and bored to size. The face edge is a bit rough but that will be filed away, (I though I'd better not take any more off the face to get rid of it that way as the boss would be getting too thin..)

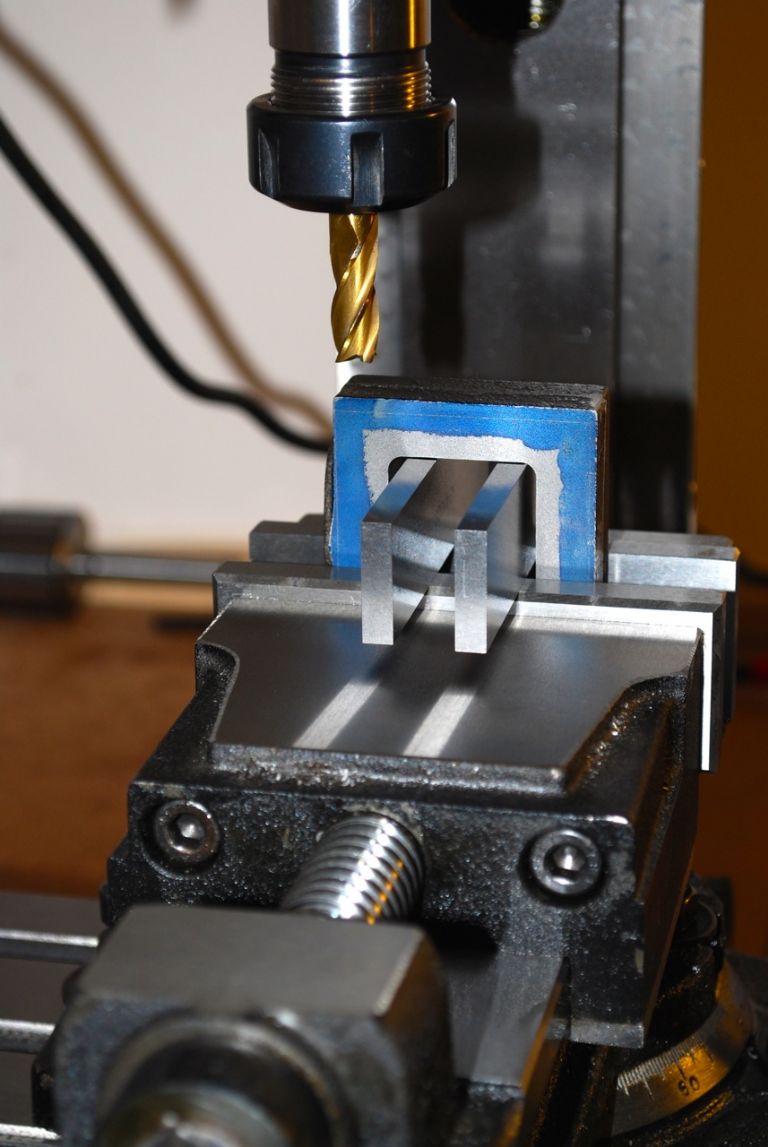

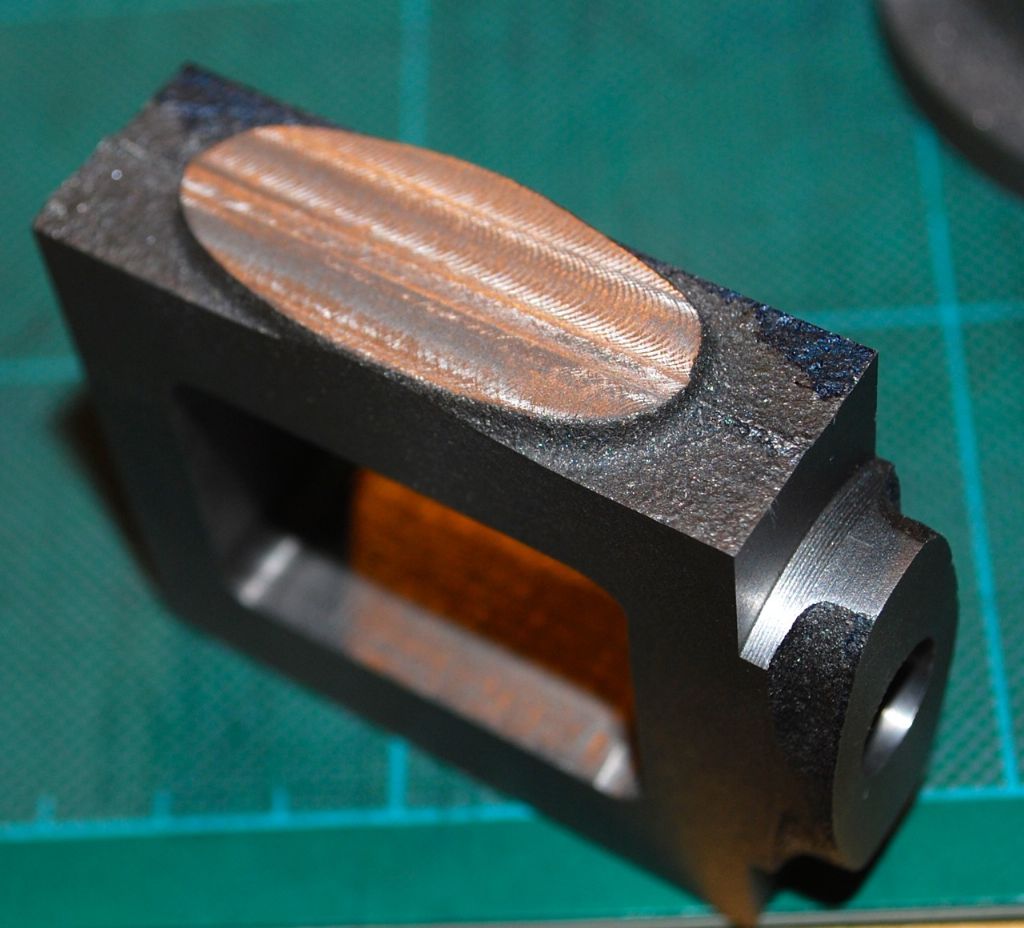

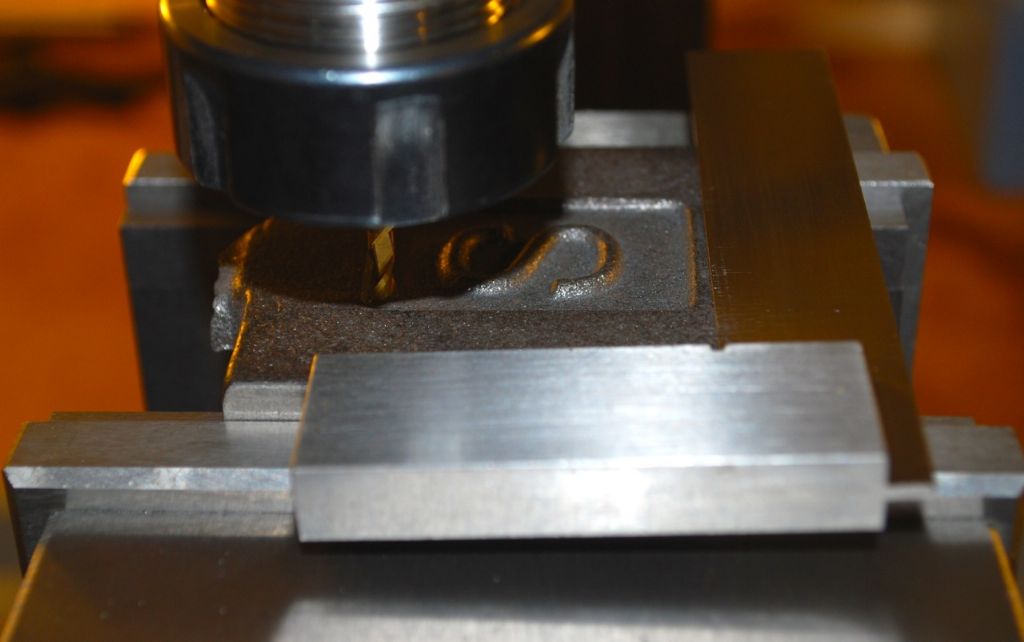

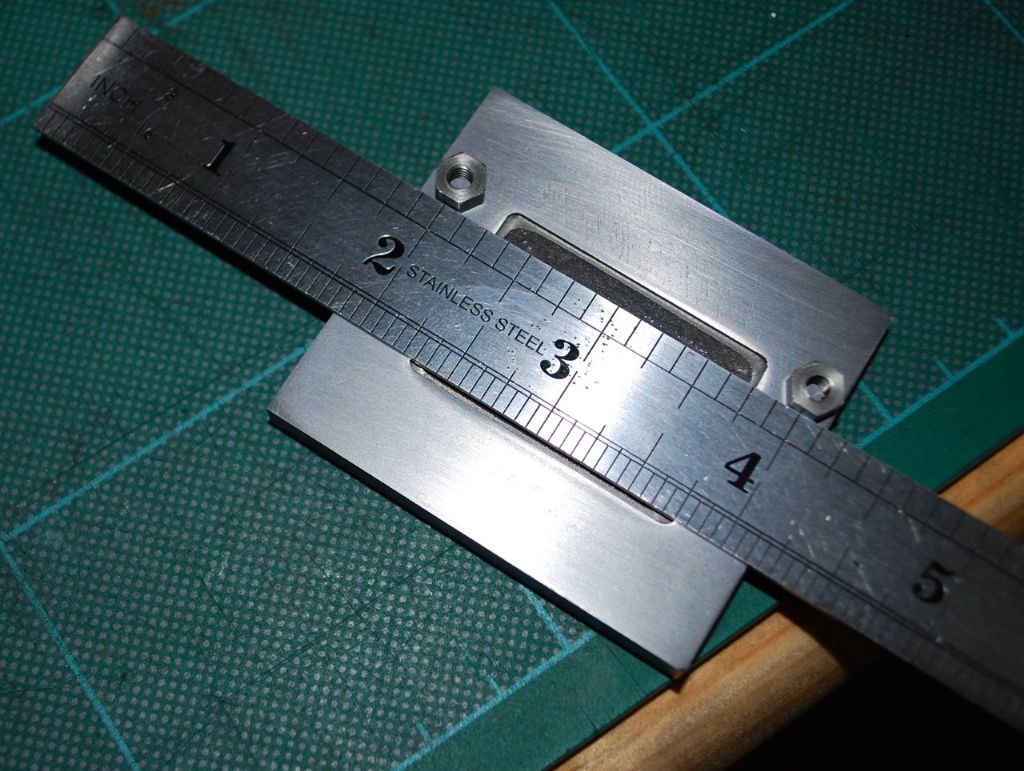

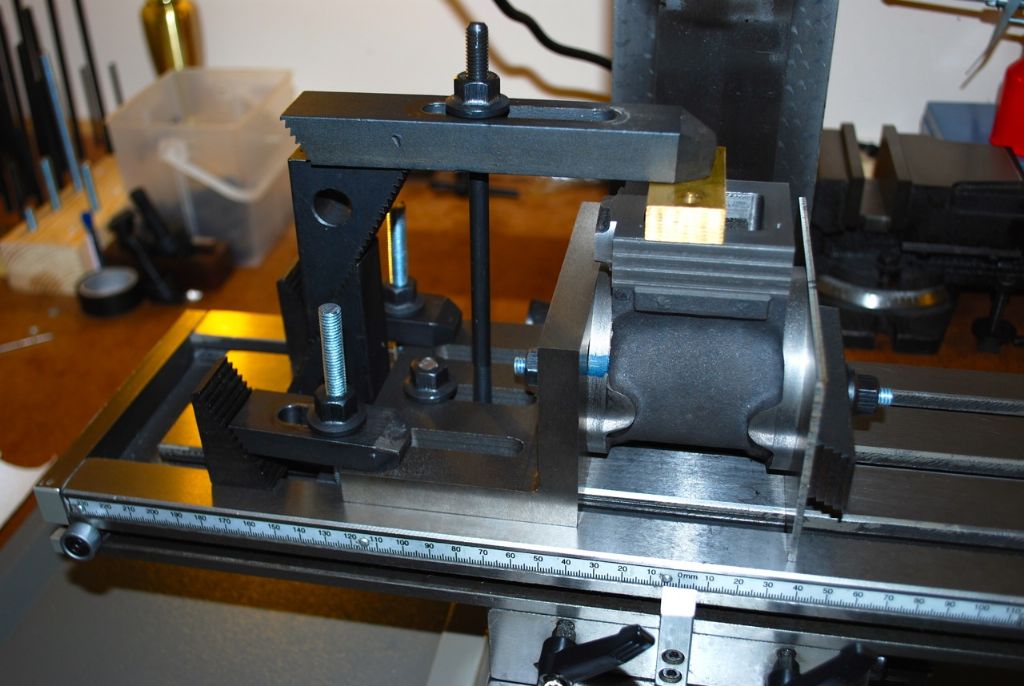

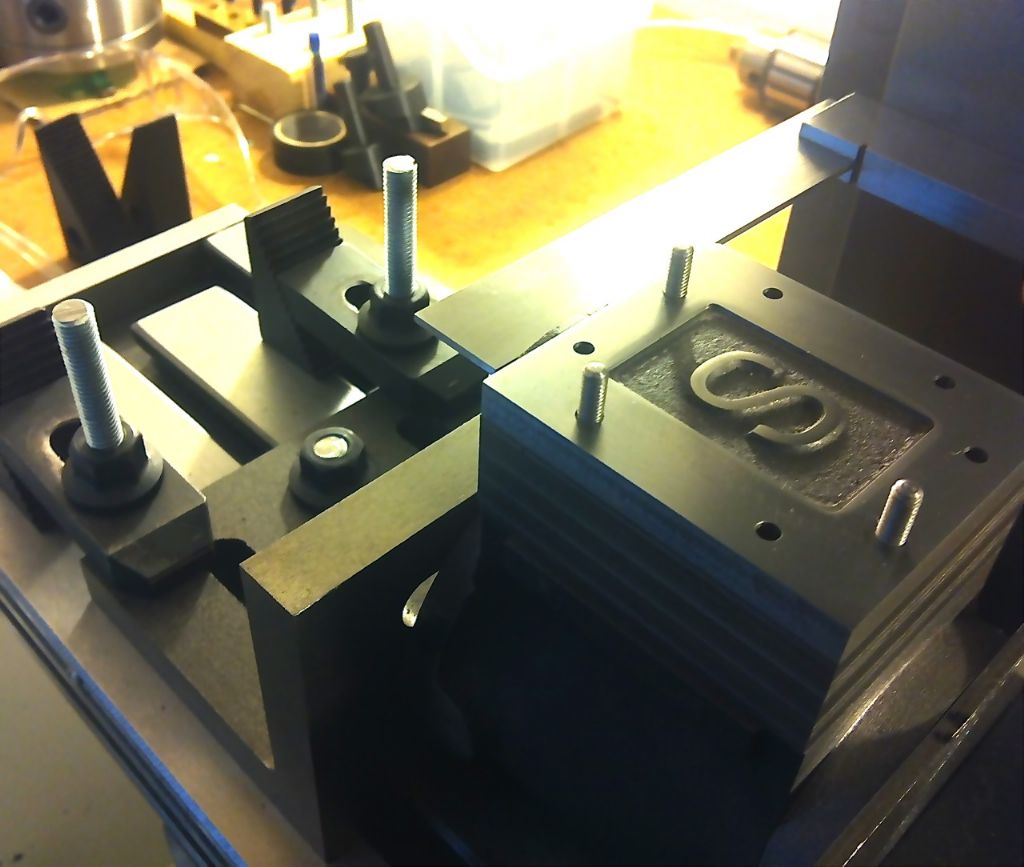

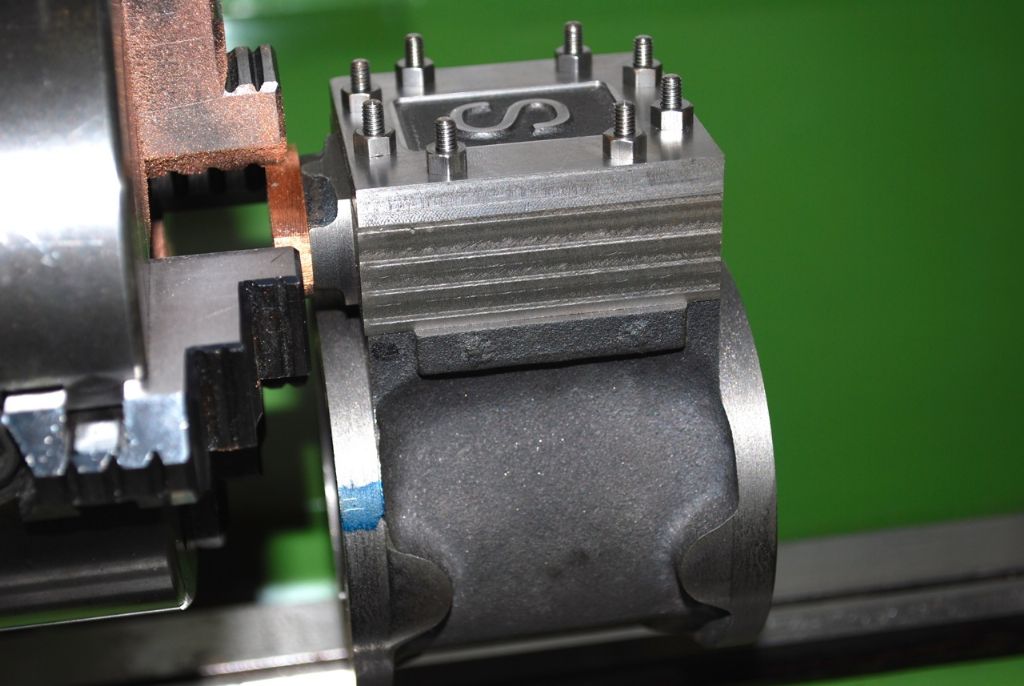

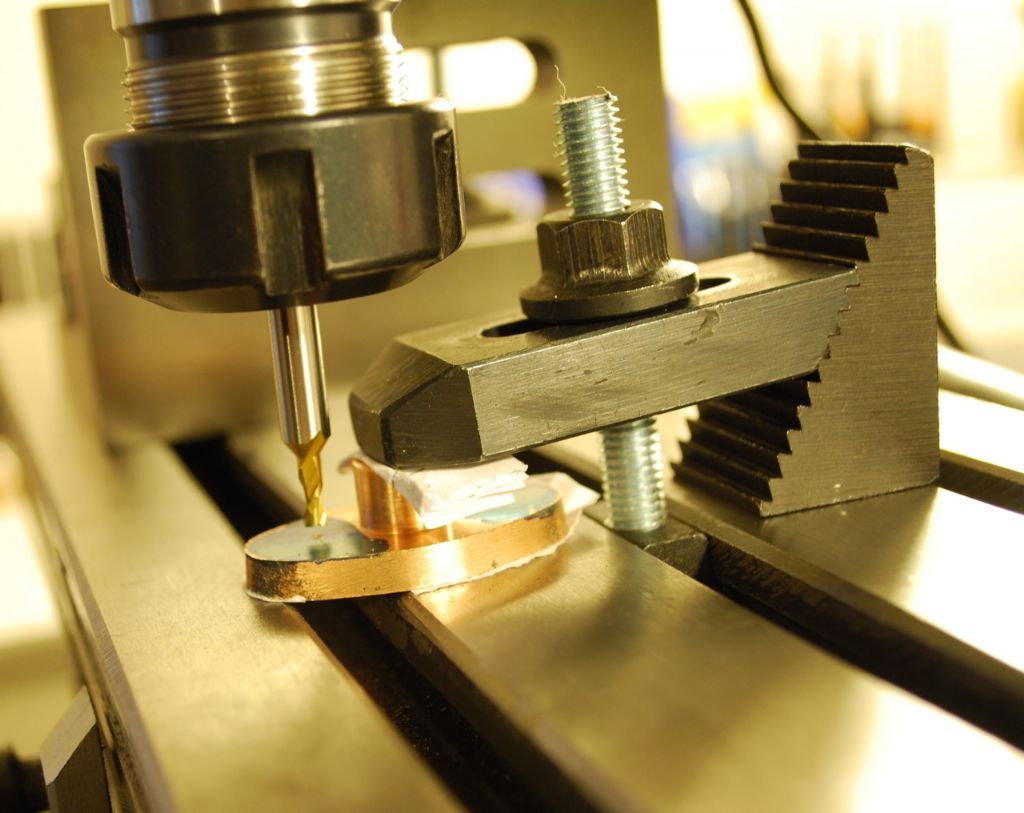

Next the Steam Inlet boss was then lightly tidied up square on the mill so that it could be marked and a square used on the Lathe to help with checking the setup..

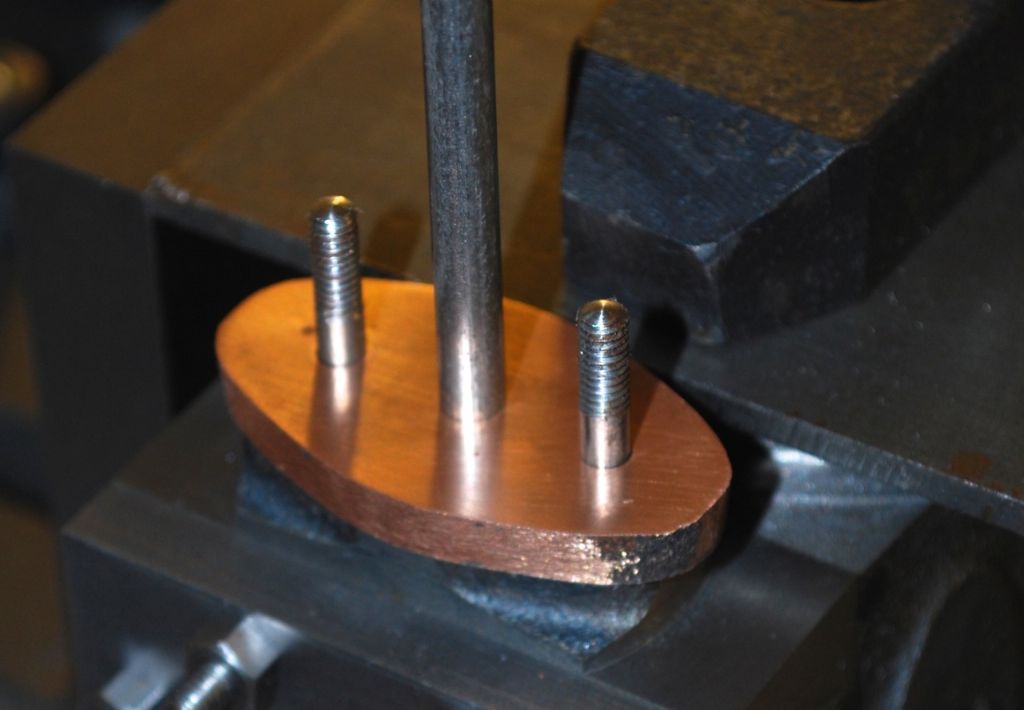

and then the Steam Inlet marked – again on a centre line of the inside of the Steam Chest. This Boss seemed pretty central as cast – unlike the Valve Boss.

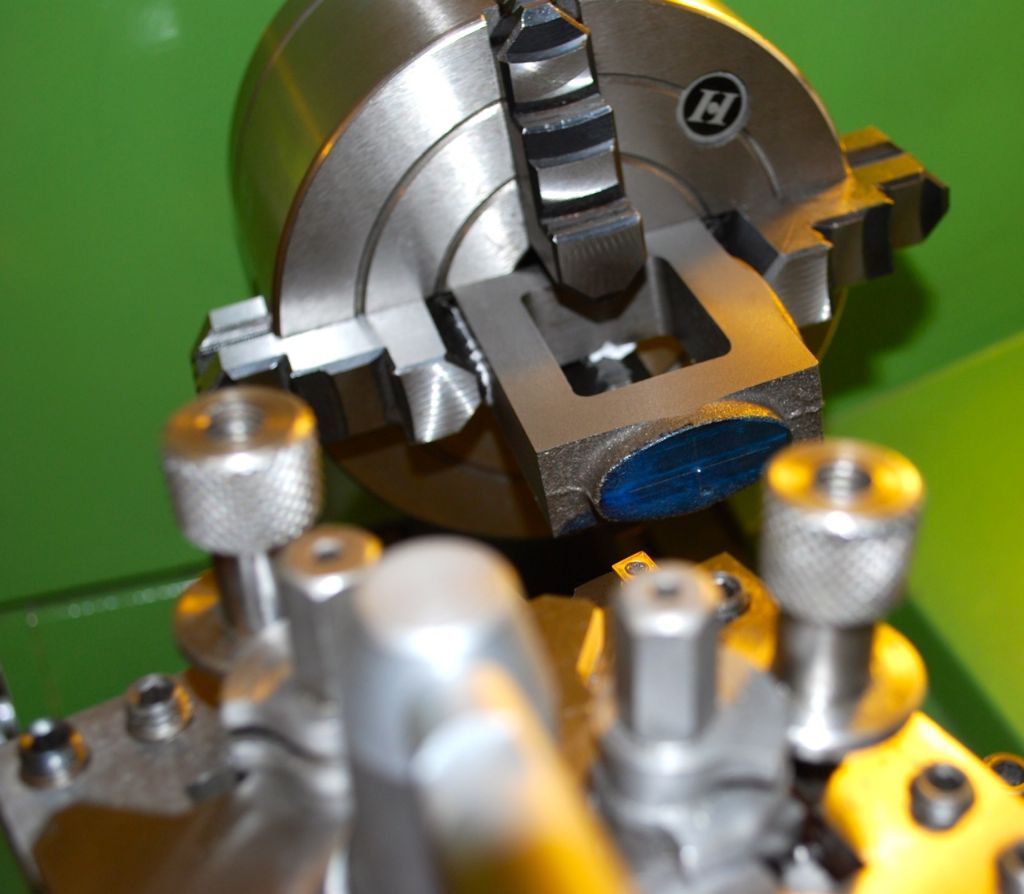

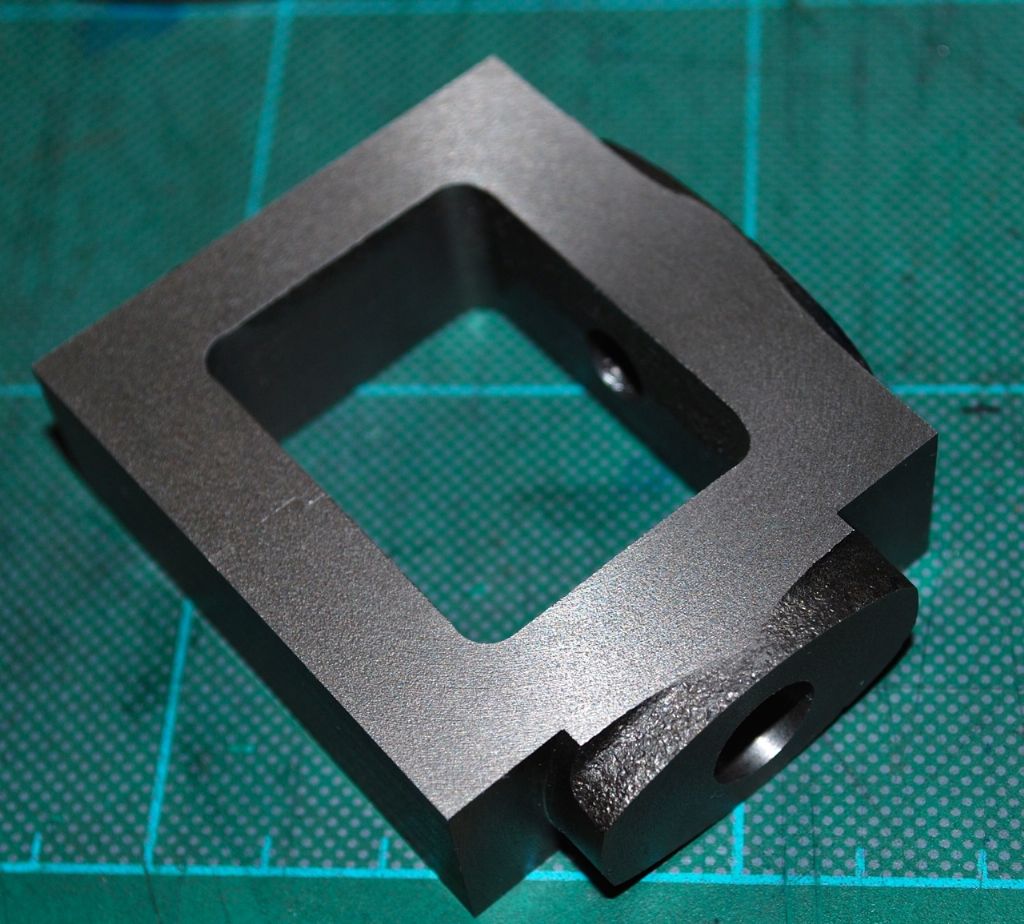

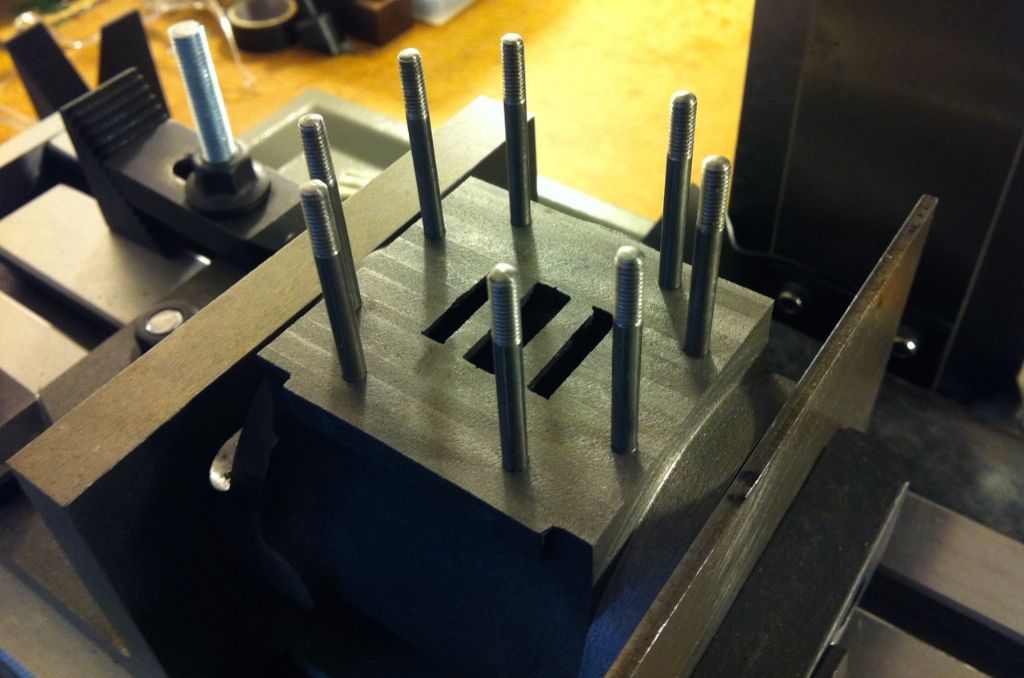

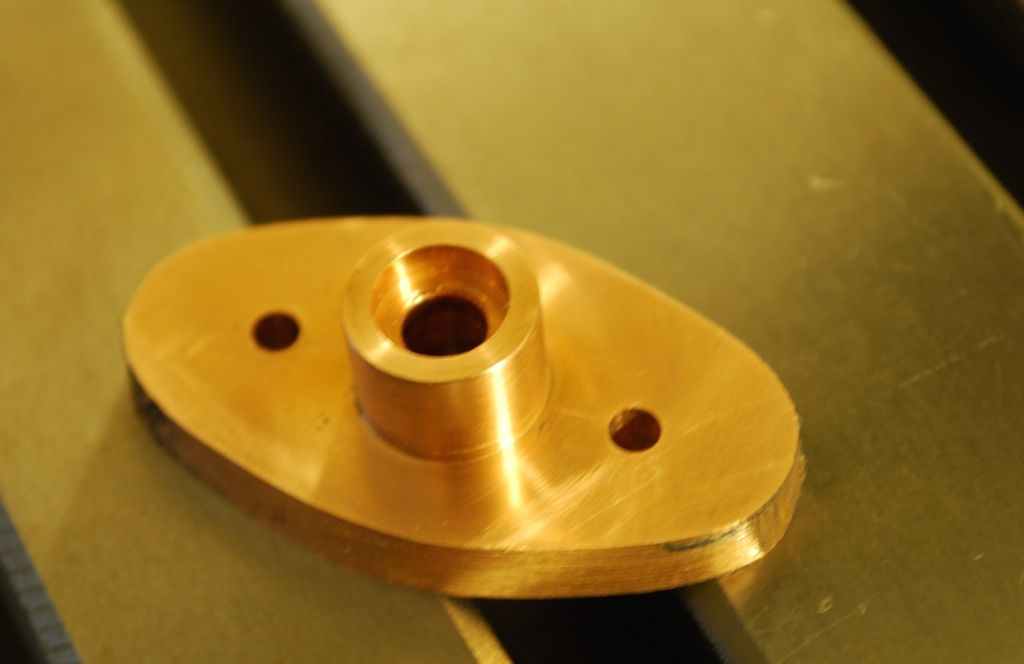

The Steam Chest so far – ready now to do the Steam Chest Cover so that the fixing holes can be spotted through to the Steam Chest and then on to the steam Cylinder..

Its far from perfect but should hopefully be ok..

Cheers

Garry

Edited By Garry_C on 30/08/2015 13:56:51

Edited By Garry_C on 30/08/2015 13:59:13

JasonB.

JasonB.

'

'