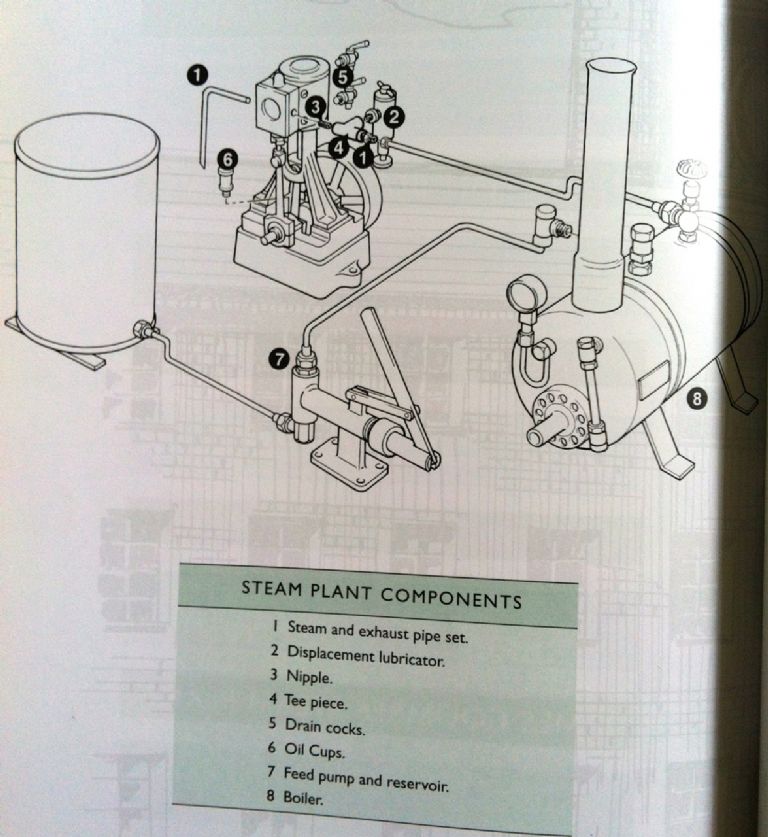

Just a little update to start work on the Steam Chest and Cover..

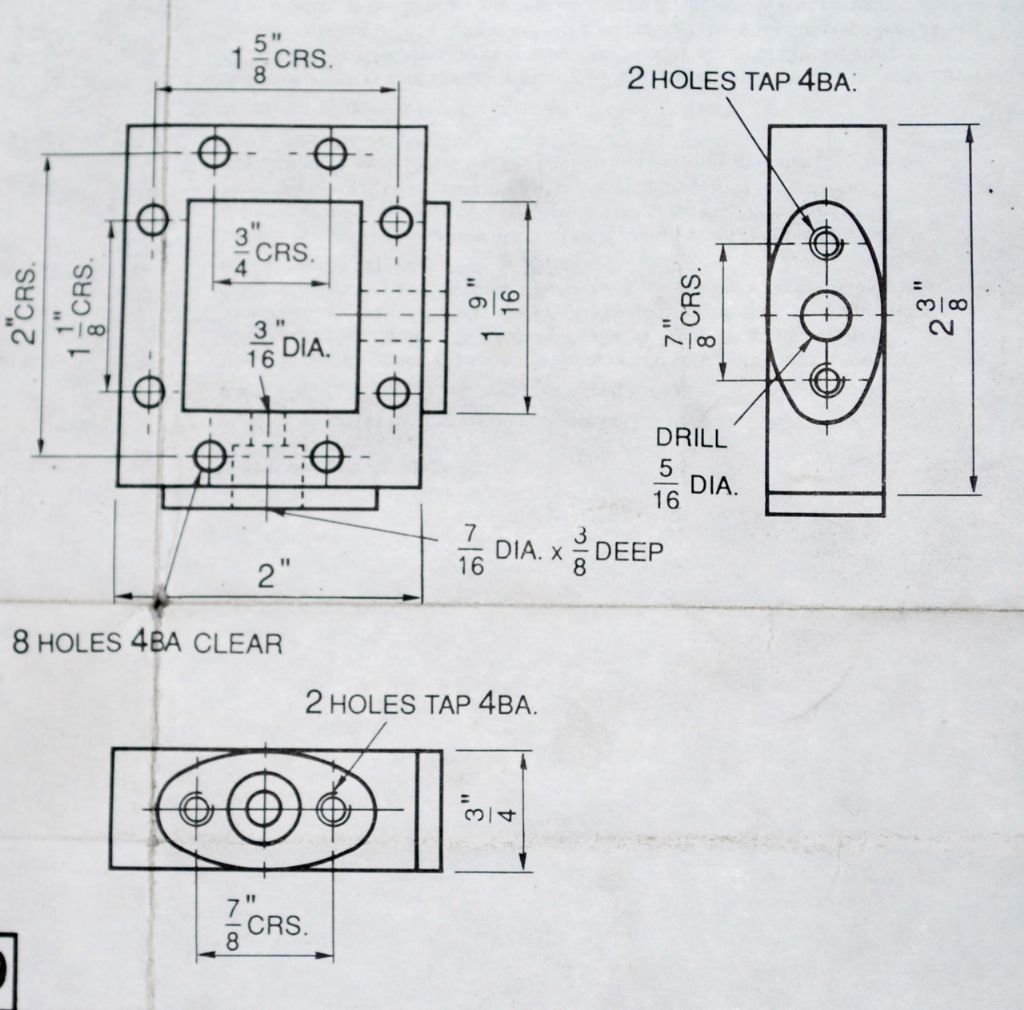

The Steam Chest Drawing.

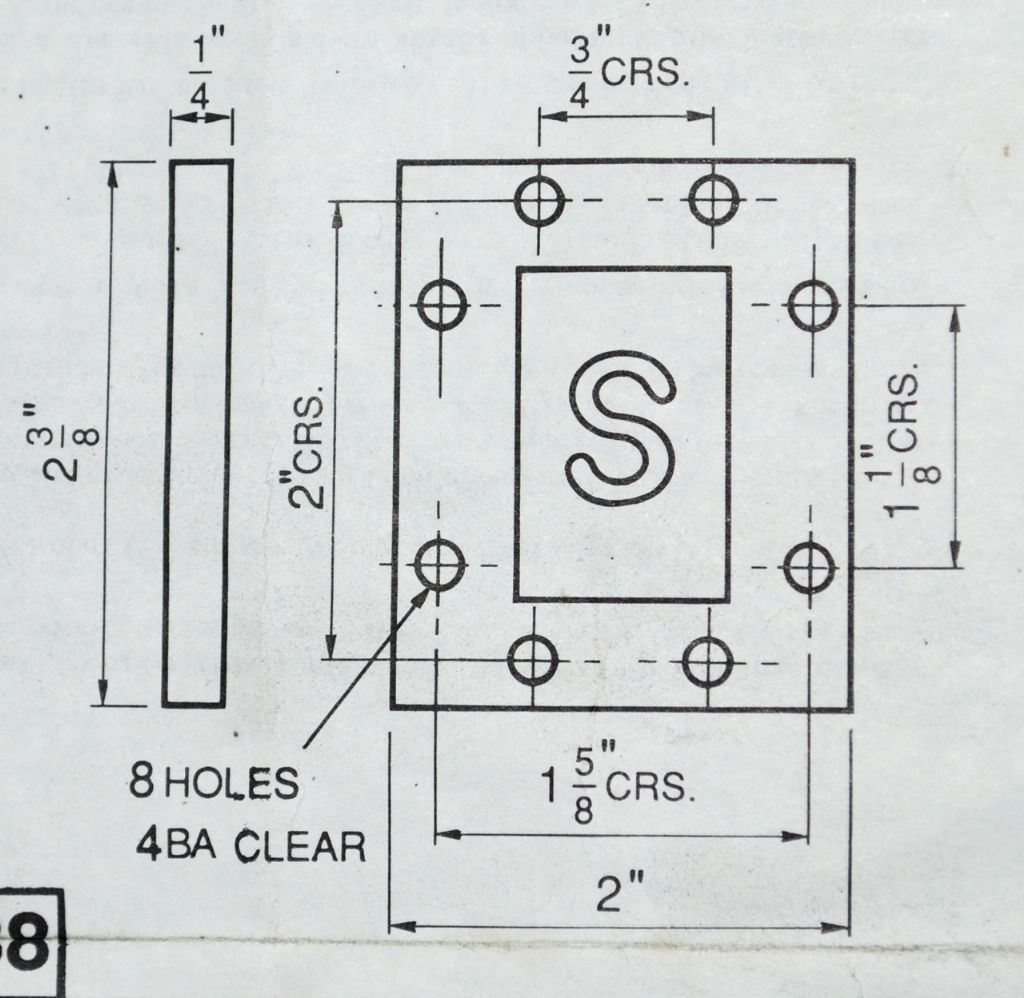

The Steam Chest Cover Drawing.

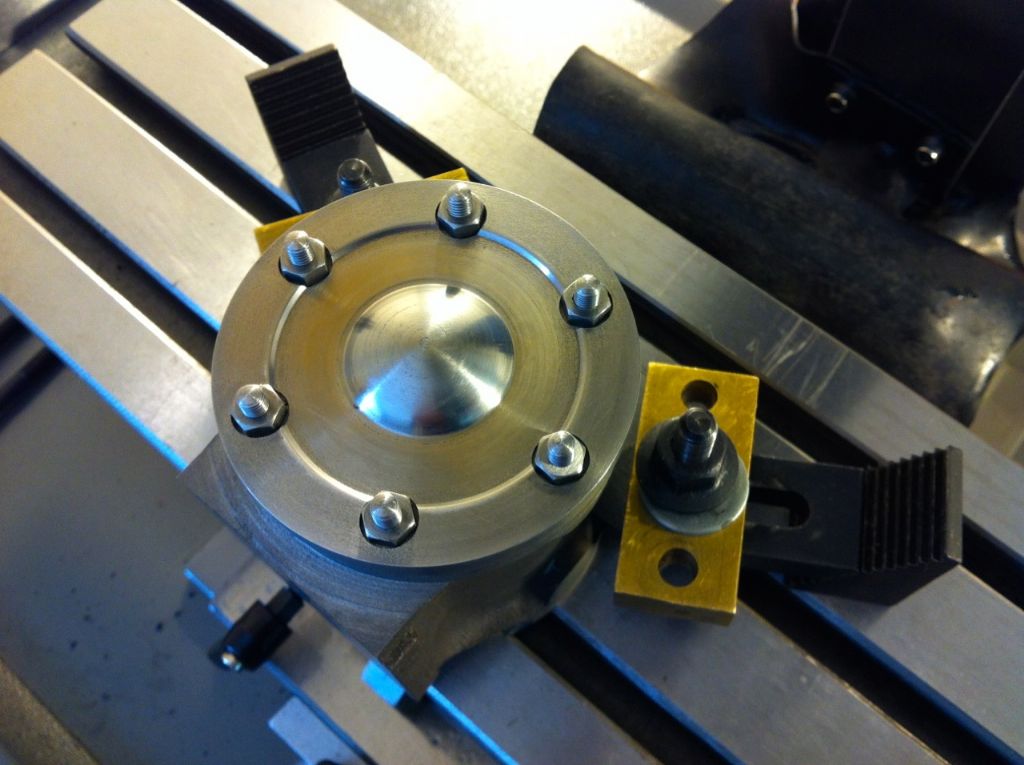

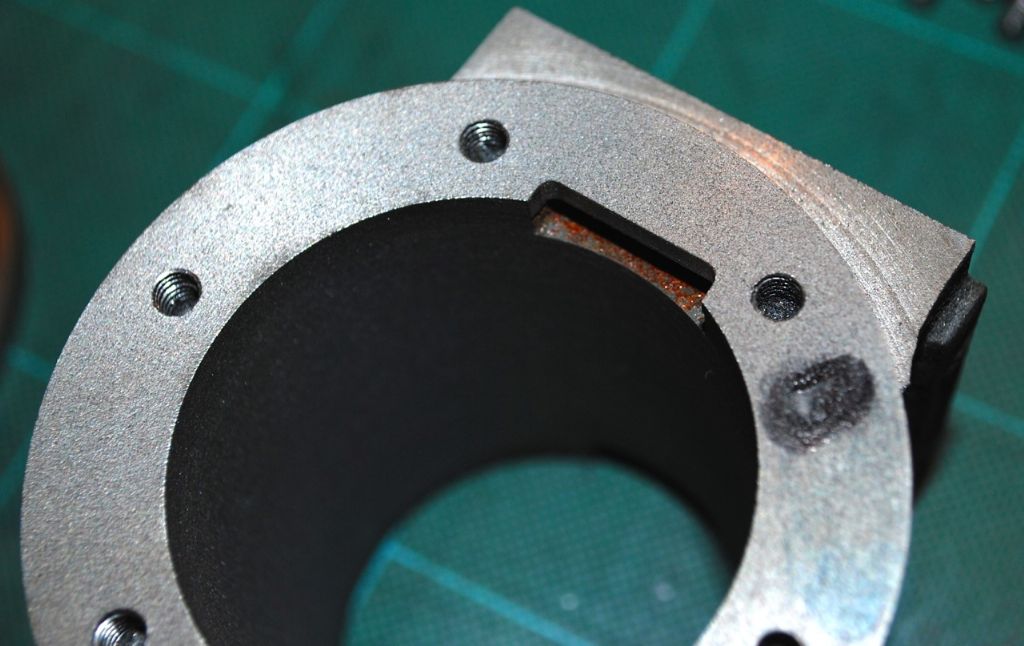

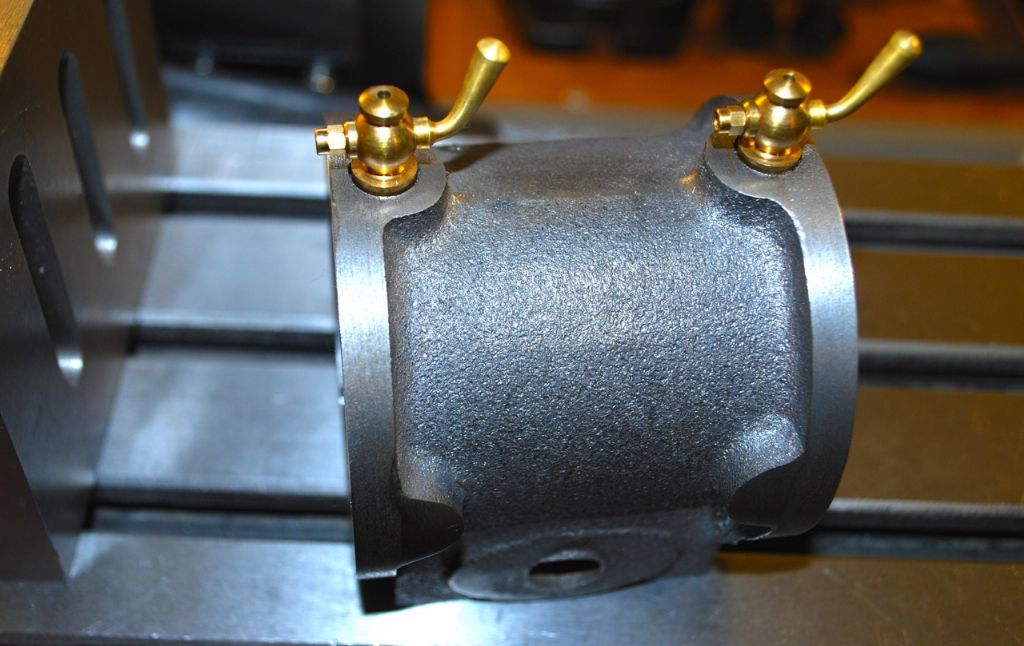

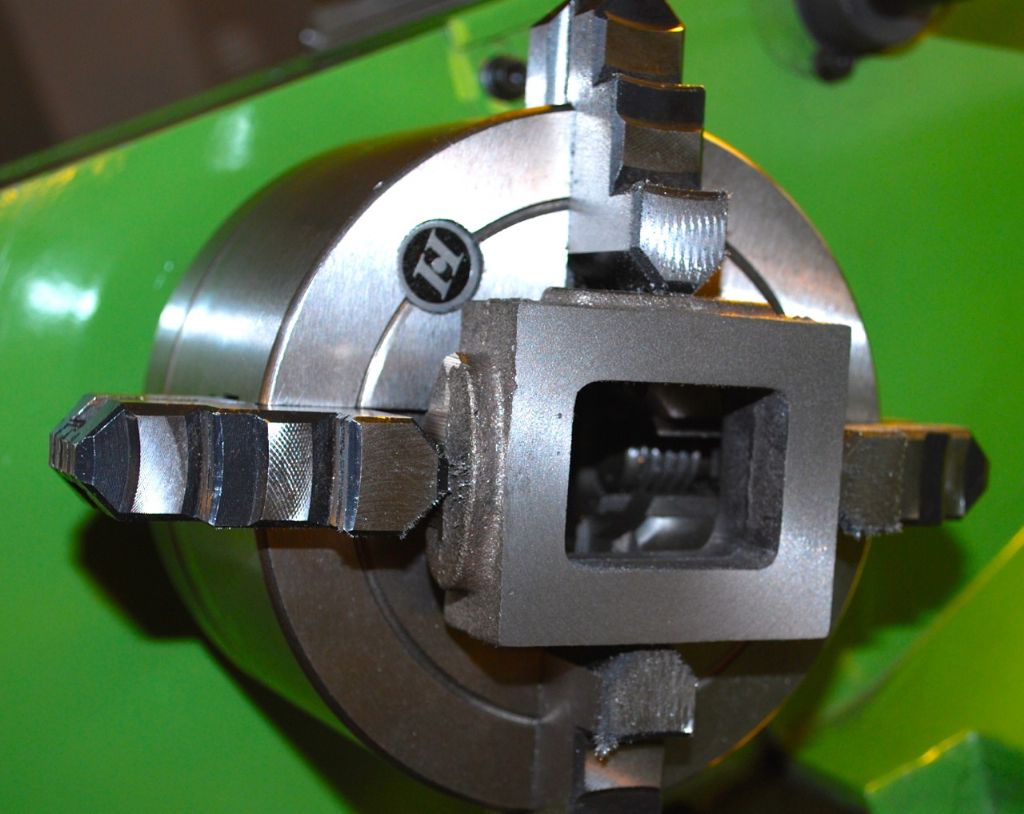

The Steam Chest & Cover castings.

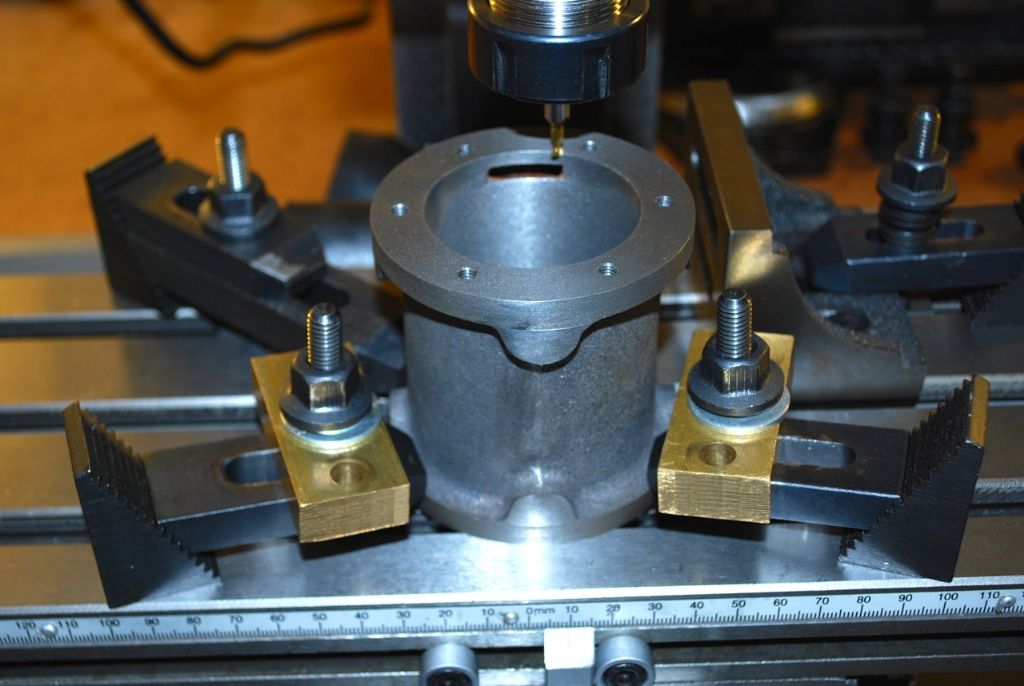

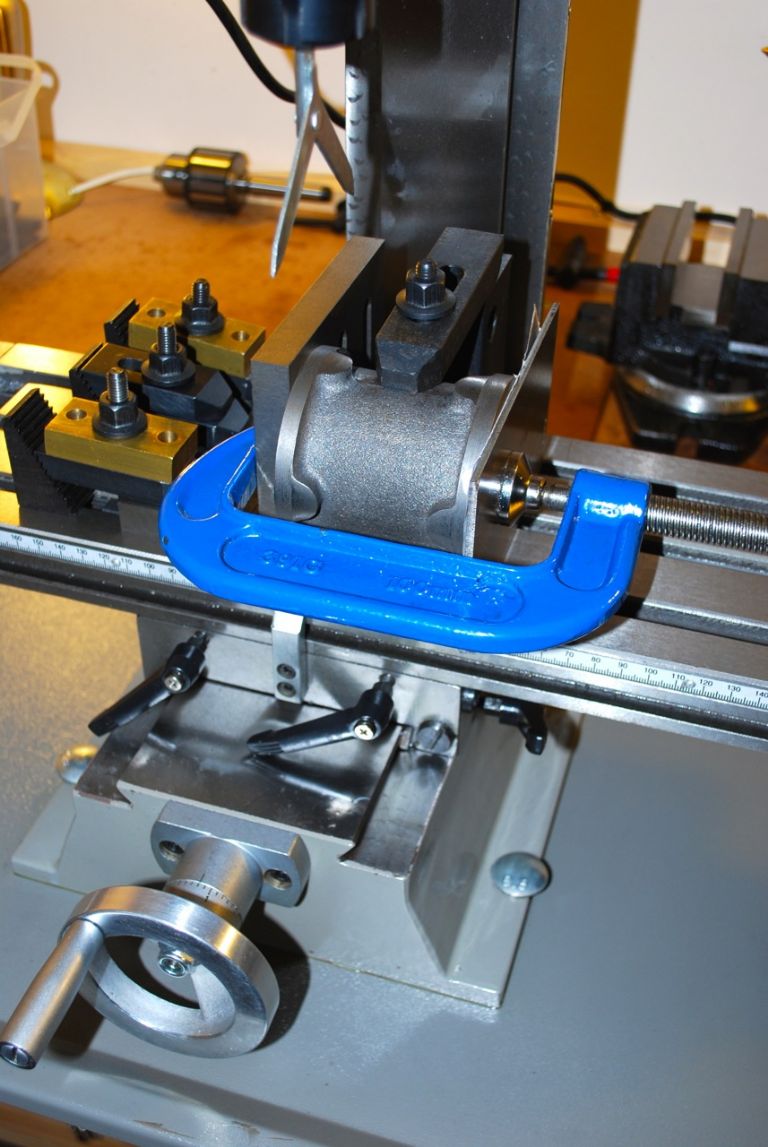

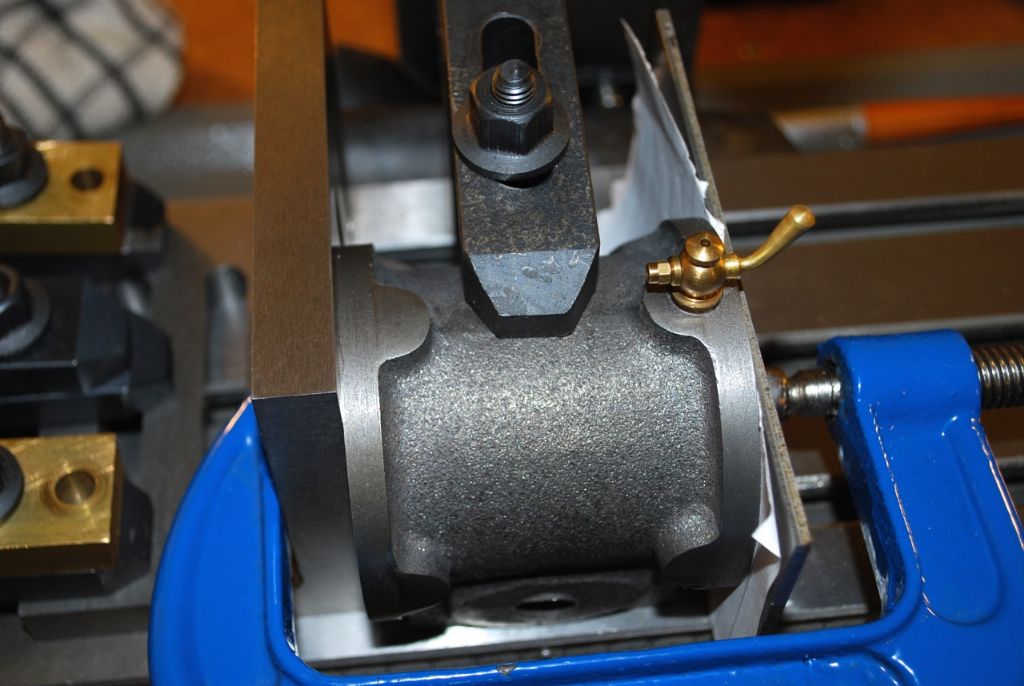

Starting to face both sides to the 3/4" thickness.. You can better see here I think the sides of the centre of the casting are quite 'bowed' and rough..

Sorry this one is a bit blurry – I wasn't quite sure what to about the inside, I seem to remember from Victoria that it was important not to take away too much material to clean and square it up..

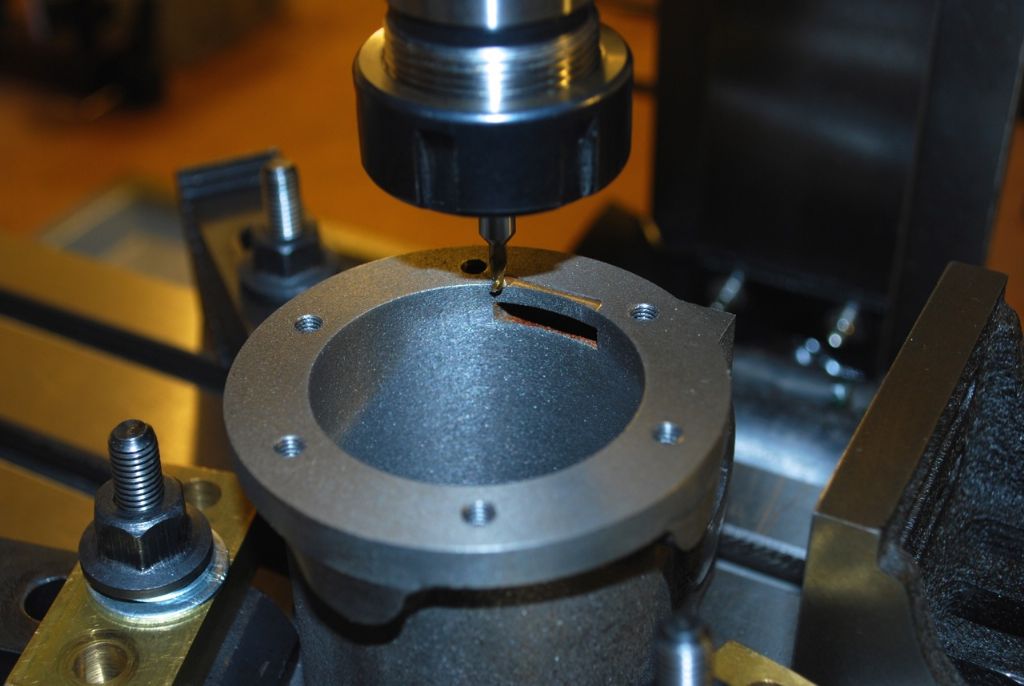

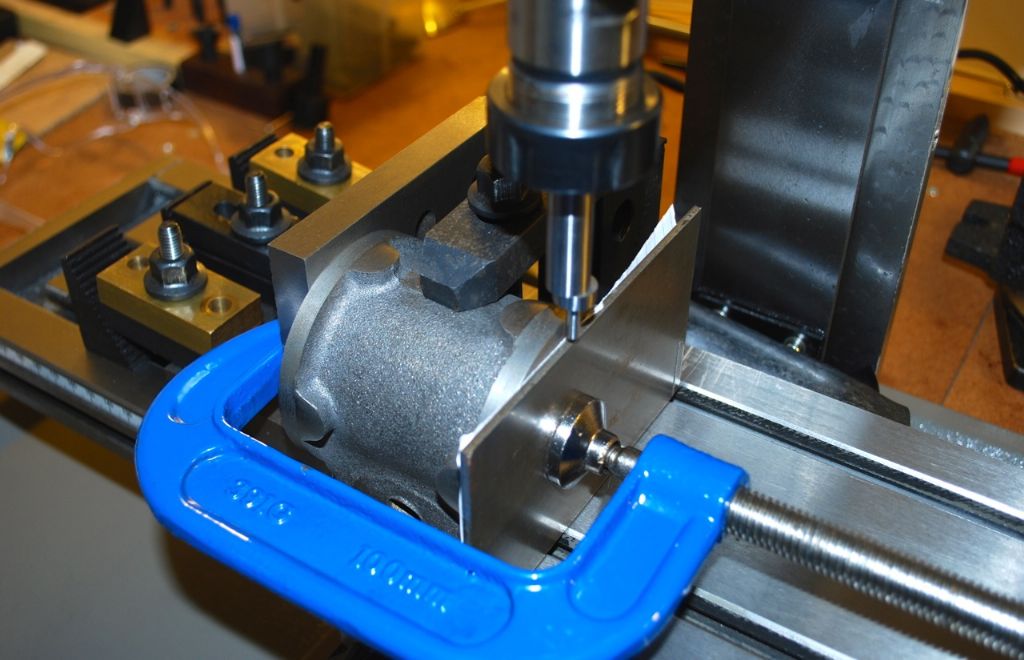

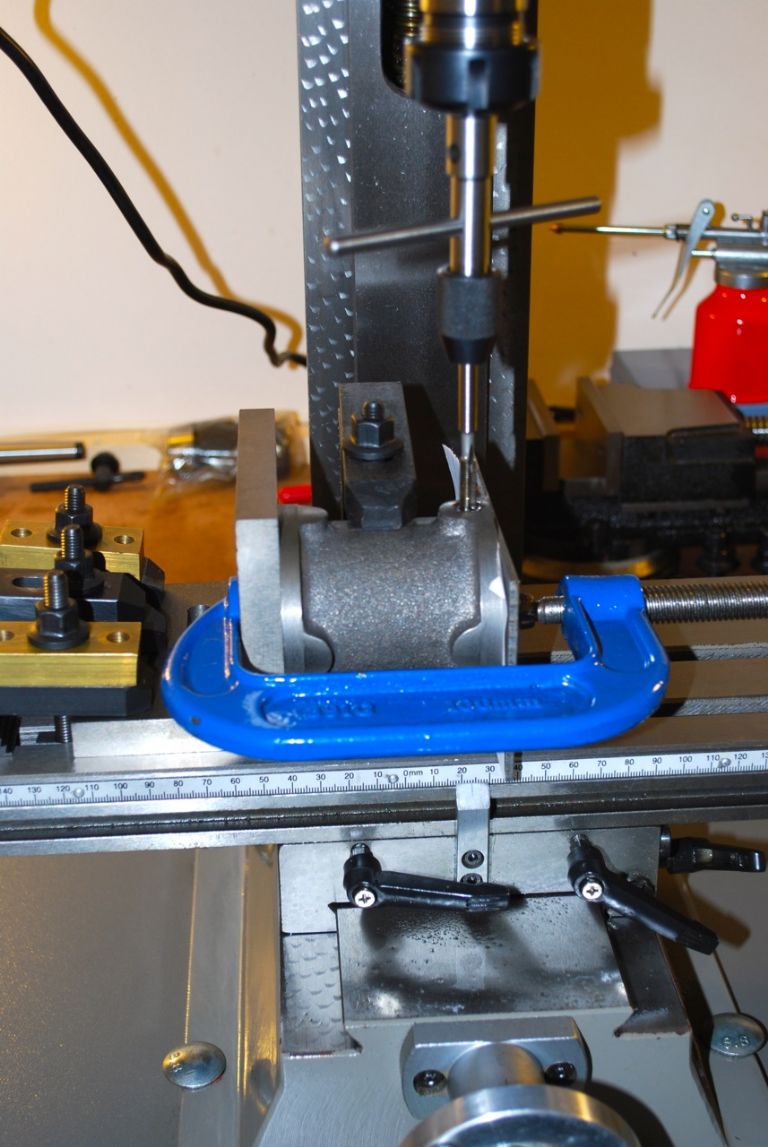

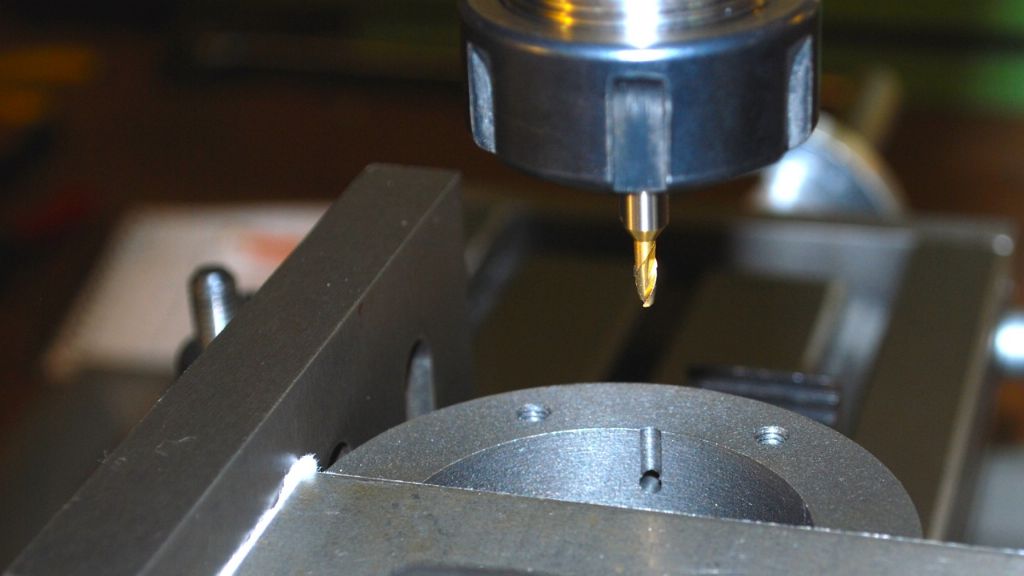

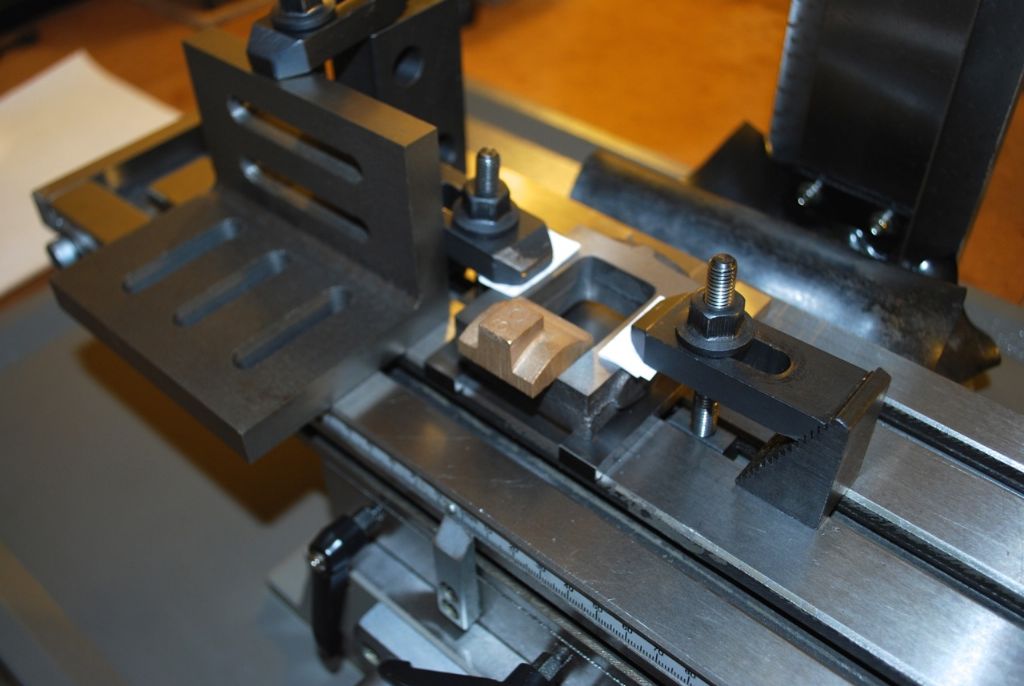

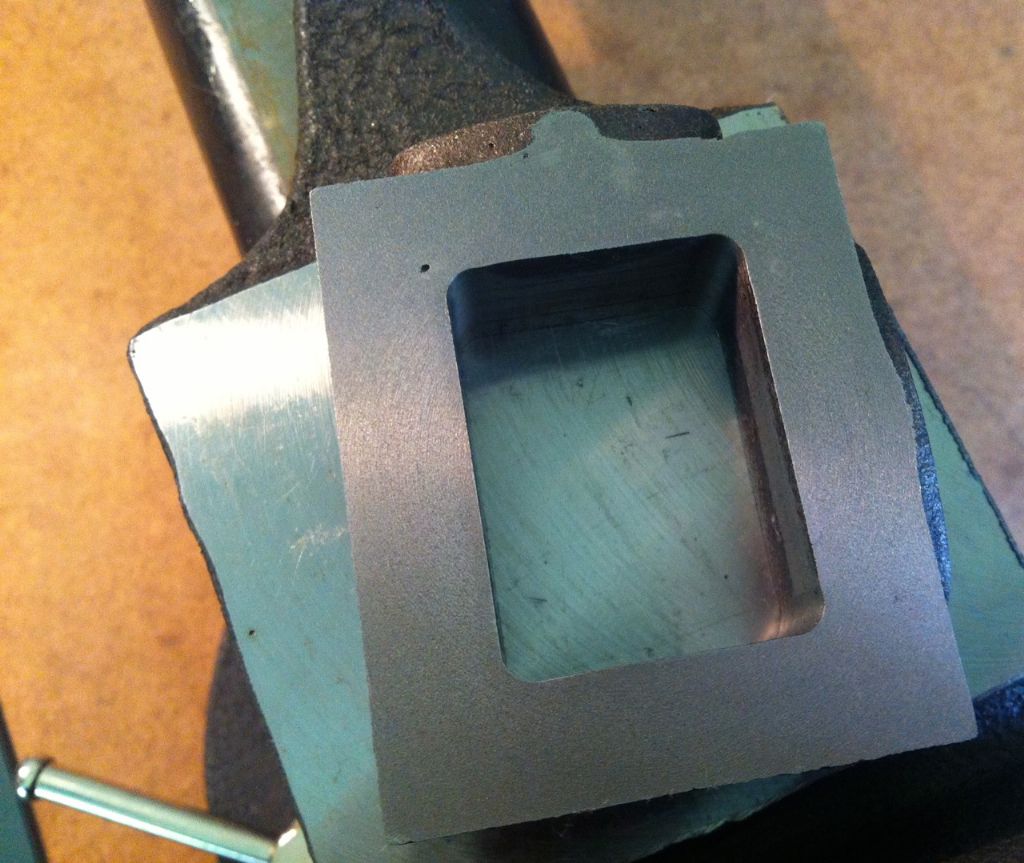

This photo showing the setup used – 6mm End Mill as the cutter.

[also showing the Slide Valve casting – thats to come as I've not done anything with that yet.]

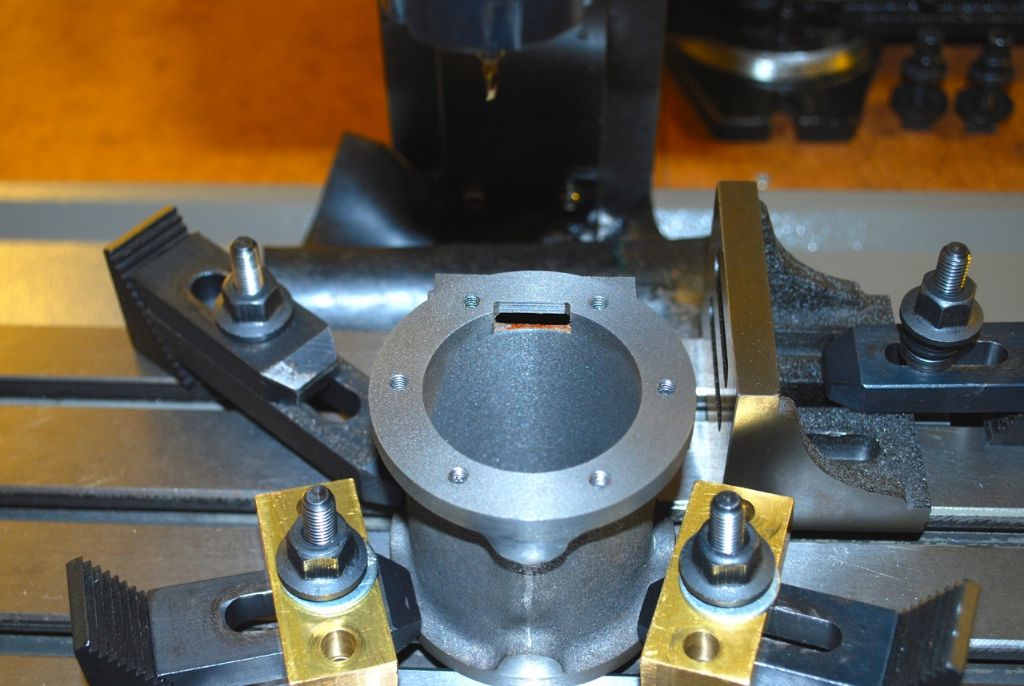

So I've really only just barely taken away the skin and not all of that – 0.05 cut around each length – but its nice and square now and I can always do more to it later if need be – although I was a little bit out in one corner. I only have 'stops' on one axis on my Mill – maybe that's normal I don't know. I went out I think from 'once' not locking the table when going 'down' to start a new cut around the rectangle – sorry thats not very well explained..

But I now have clean lines around the rectangle to be able to measure outwards from to mark the sides to size..

Cheers

Garry

JasonB.

JasonB.