Recently, I built my first wobbler, which wobbles very nicely thank you. I was very excited by this but many of my friends said, 'yes, but what is it for?'.

Needless to say I don't need to justify that in this forum! However, this made be determine that my next model would be a steam engine which could actually do something useful – I started the process in another post where (as usual) I received a lot of help and corrections.

But (for reasons devoid of logic, though in part due to the sheer cost of kits) I want to do my own design from scratch.

My main design parameters are:- bore 2 inches, stroke 3 inches, double action, d valve, vertical (though I'm not tied to that) and single direction. (at least to start with – valve gear adds too much complexity). So pretty simple.

At the moment I'm struggling with the valve design. Most of the posts and articles I've come across assume that you have a design already and want to add a bit of lap and lead.

I gather that what I need to aim for is for the inlet to be open for the first 25 – 30% of the stroke and then closed until near the end. The outlet should be open from as early as possible until just near the end of the exhaust stroke.

I'm struggling to find any approach other than trial and error to get something which matches these settings.

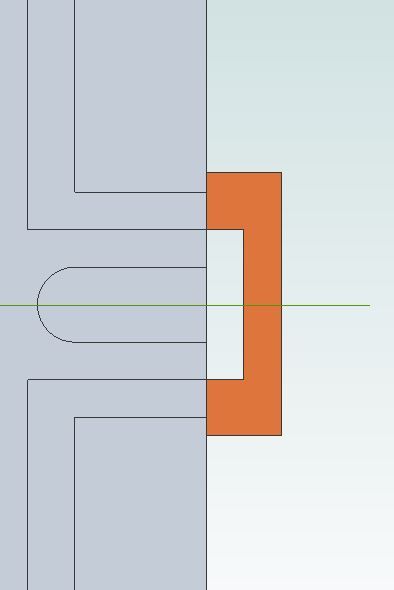

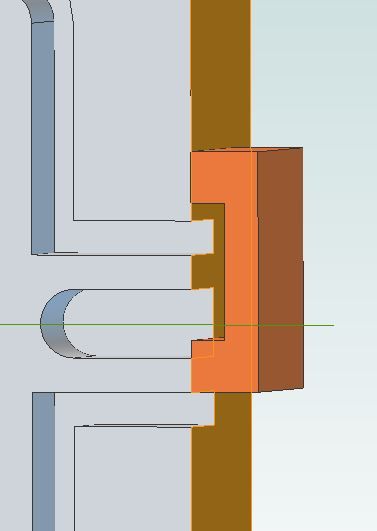

Being of a geeky background, I've tried to do this by creating an interactive graphical simulator which you can find here.

The default settings there are about the closest I've come to what I think is reasonable. However, I have only managed that by reducing the D travel to less than the valve width which doesn't seem right.

I'd be obliged if someone who understands this stuff would have a look and suggest some more appropriate settings.

I have the impression that the connecting rod has to be long compared to the stroke (the shorter the con rod the further the motion is from a sine wave). Is 2x about right or 3x?

Finally (for now), what is a good material for the crank? I don't expect this to be particularly stressed so I would think that most hobby steels would do?

Cylinder and valve will be cast iron.

Thanks in anticipation…

Iain

Iain

Iain Downs.