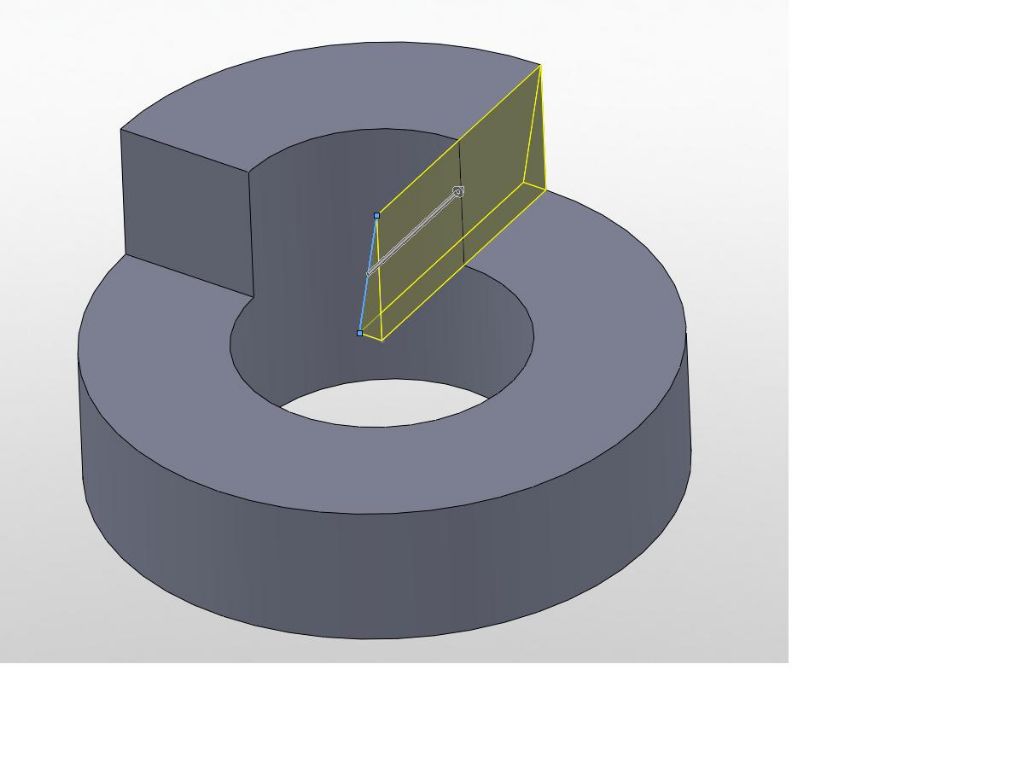

Cant see you'd need a spiral to make one like in Speedy Builder's picture. Appears a flat plane he has cut rather than a spiral. That should do the job. It is only clearance for when the motor starts, and does not affect the "grip" of the dog's driving face.

What is critical is the flat driving face of the dog. When making similar ratchet drive mechanisms for old motorbike kickstarter drives, we undercut that face on both halves by a few degrees, maybe two or three. This ensure positive engagement and is pretty standard on drive dogs in motorcycle gearboxes that use the same principle for main power transmission.

Two flat faces bearing squarely together can tend to half engage and then slip out of mesh, Two slightly undercut faces will tend to slide into full engagement under pressure and motion. Highly critical when your entire body weight is perched on the kickstarter lever and your knee will turn inside out if the drive ratchet lets go mid kick. Guys have ended up in hospital from it with what the doctors call hyper-extended knee. Usually on older model Harley Sportsters which are notorious for it.

If you have already machined your part, and have the matching part on the end of the crankshaft already, some careful work with a thin disc in a Dremel can put the slight undercut on each surface. A check with bearing blue to make sure both faces on both pieces are engaging evenly will make an even better job.

The pic shows the principle where the driving face is cut a few degrees past square so it kind of "hooks in" under drive load, yet lets go when the engine starts, or when you pull the clutch in to shift gear on a transmission gear.. Google "gear dog undercutting" for more info.

Edited By Hopper on 21/03/2021 06:45:00

Edited By Hopper on 21/03/2021 06:59:28

Edited By Hopper on 21/03/2021 07:01:40

Edited By Hopper on 21/03/2021 07:04:11

martyn nutland.