I haven't been on here for a while. Lots has been going on but we're through the worst of it! I hope everybody is keeping well.

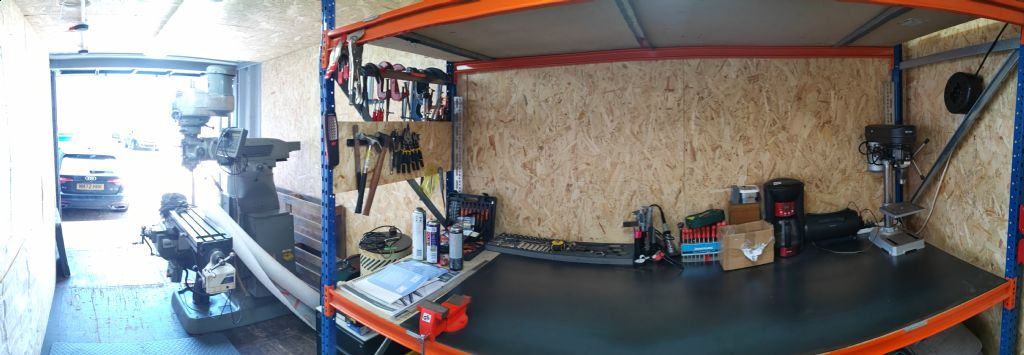

While I've been offline, I've been pottering about at the workshop getting little jobs done where I can. I scored a free, very rusty metal cabinet that I wheeled back from another mechanic shop 50 yards away, cleaned up the worst of the rust with an angle grinder and then treated it to a bit of Hammerite. Another thing thats been happening is I've been collecting the louvre style parts boxes for storage, and as luck would have it, a few days after the cabinet score, they were chucking out a decent looking metal louvre panel, needless to say I have recycled that and it is now on the wall at the end of my lathe holding all my chuck jaws, cutting tools, jacobs & live center. I have also used some scrap blocks of pine and chipboard to make some nifty stacking shelves for my chuck keys and QCTP spanners.

Yes, I mentioned 'lathe'….

I am now the proud owner (finally) of a (I think) 1963 Colchester master Mk1.5 6.5"

I have created a youtube channel and will be making further videos but here is one regarding my workshop progress…..

Please do like and subscribe so you can follow my progress and all that!!

Rooossone.