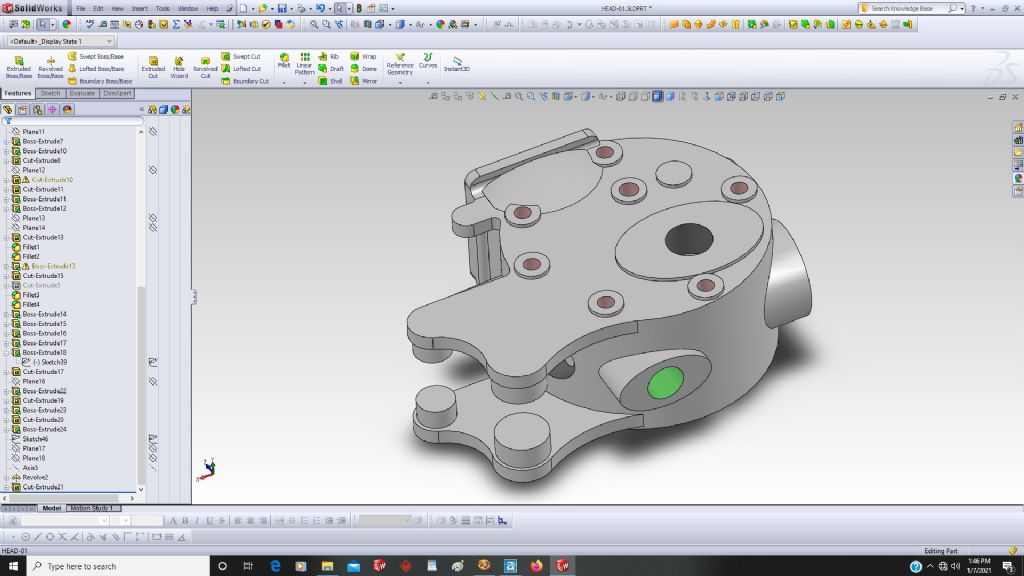

New burner design, poor furnace lid lifter design.

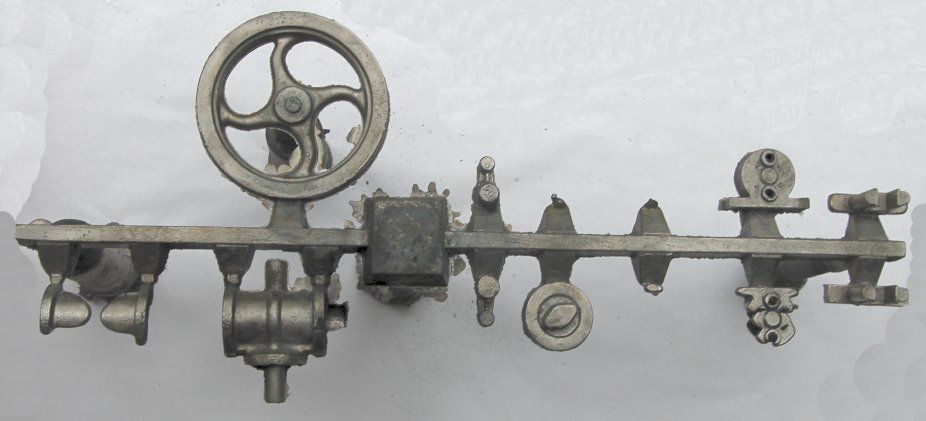

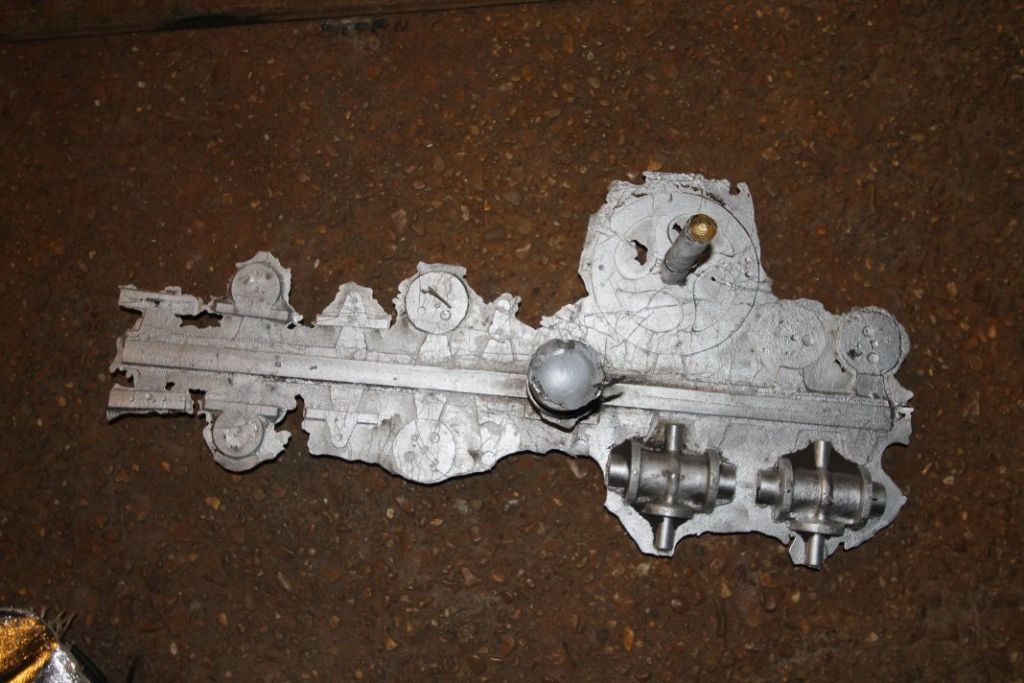

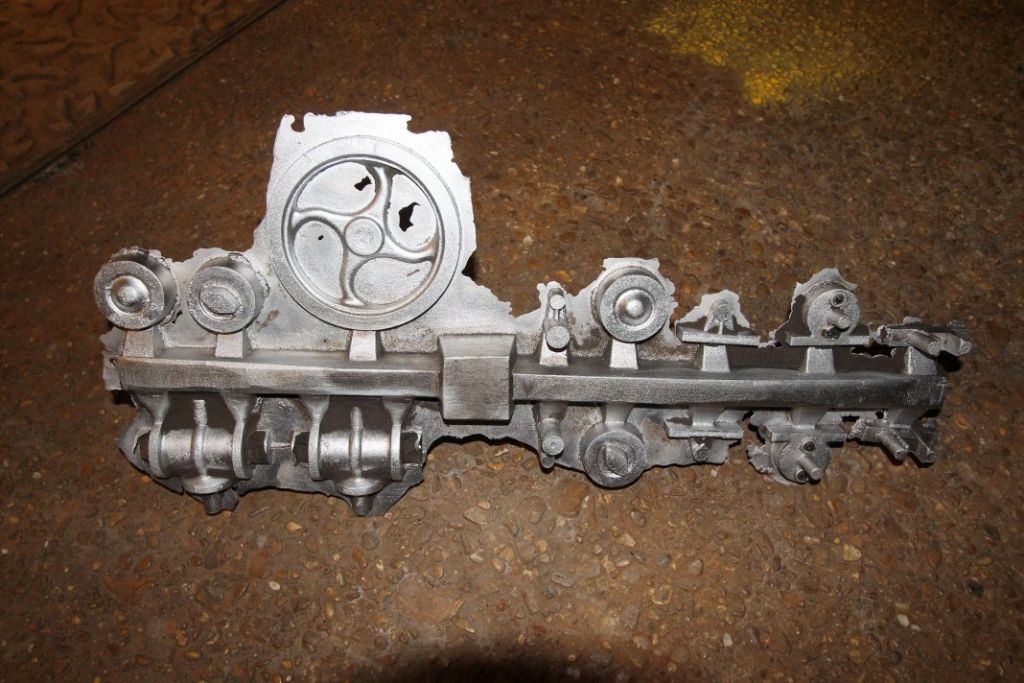

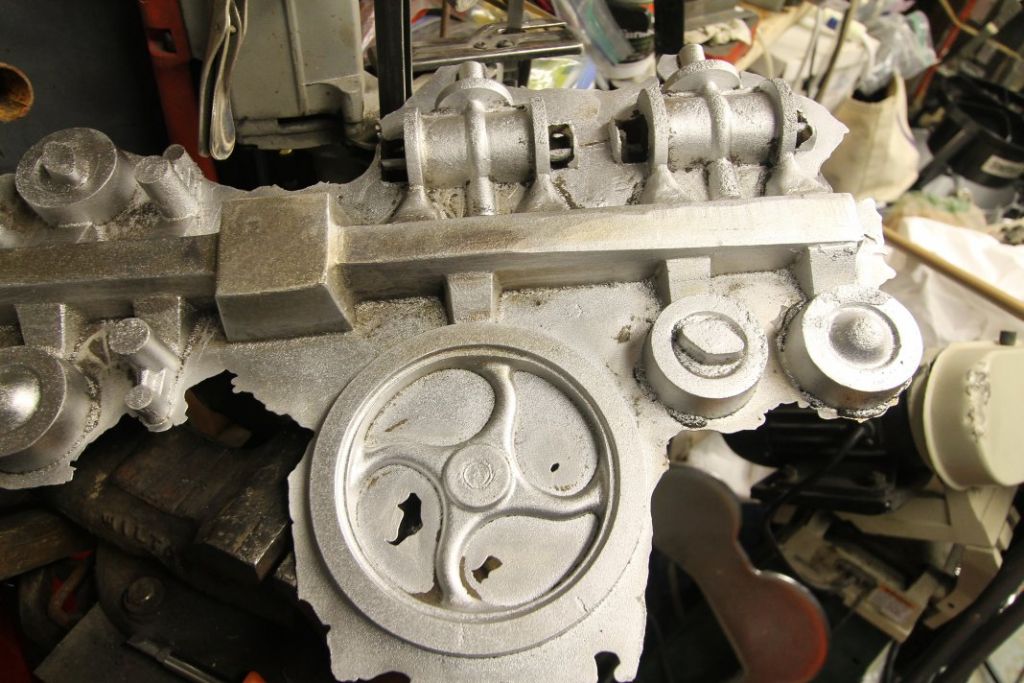

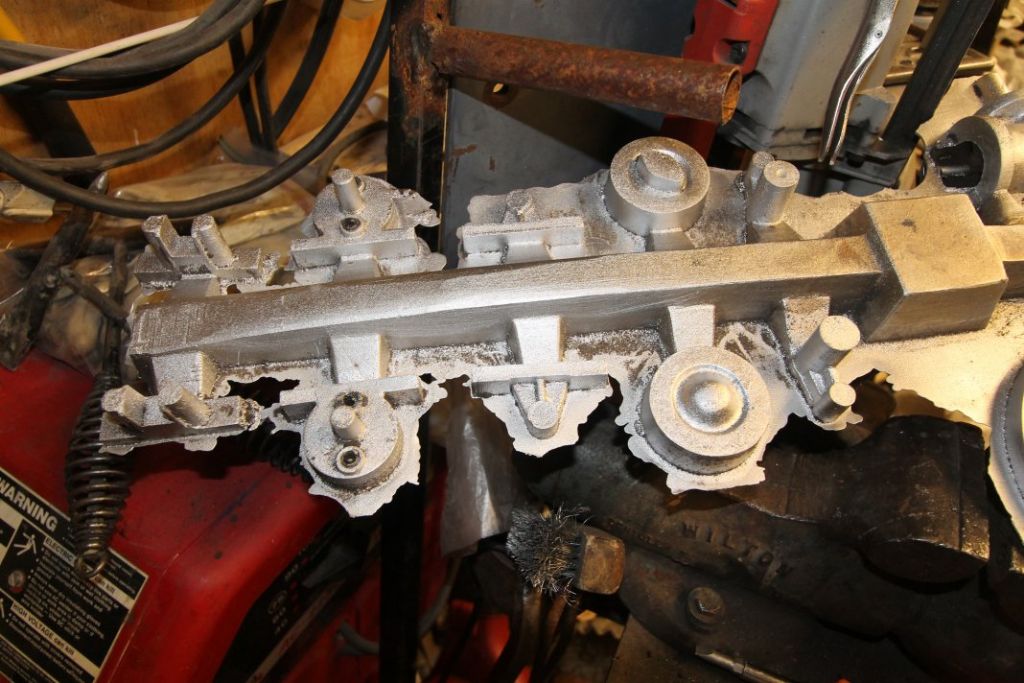

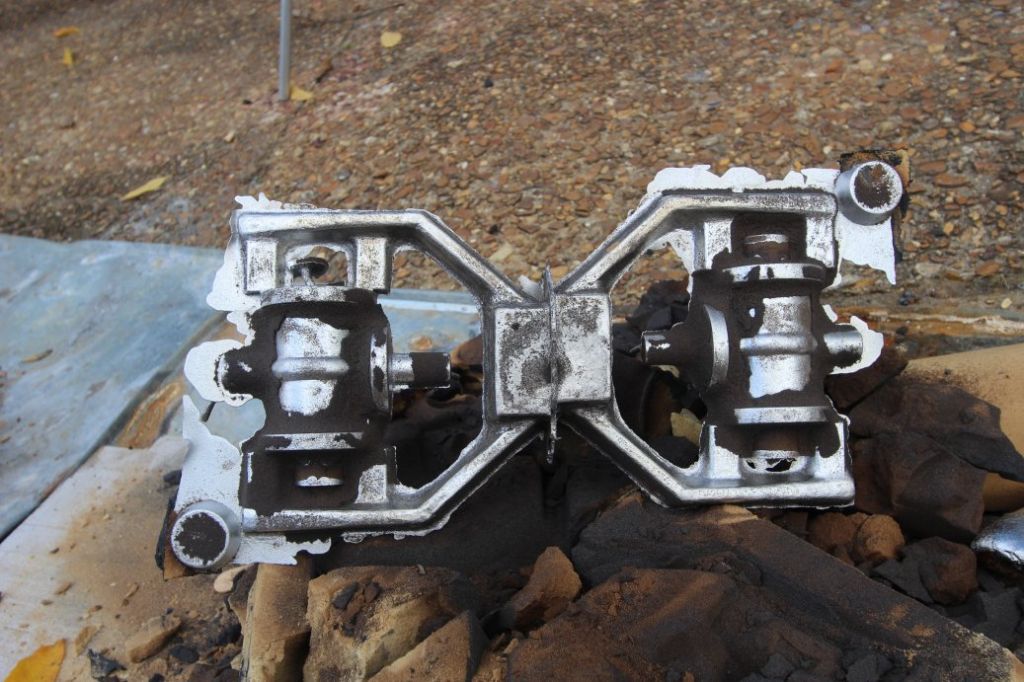

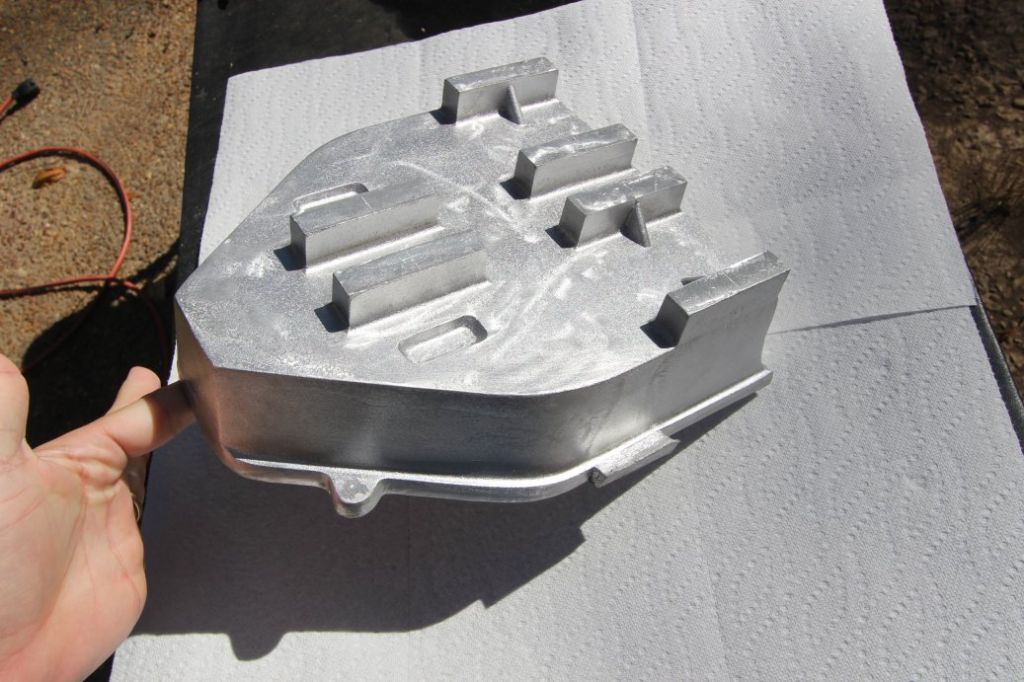

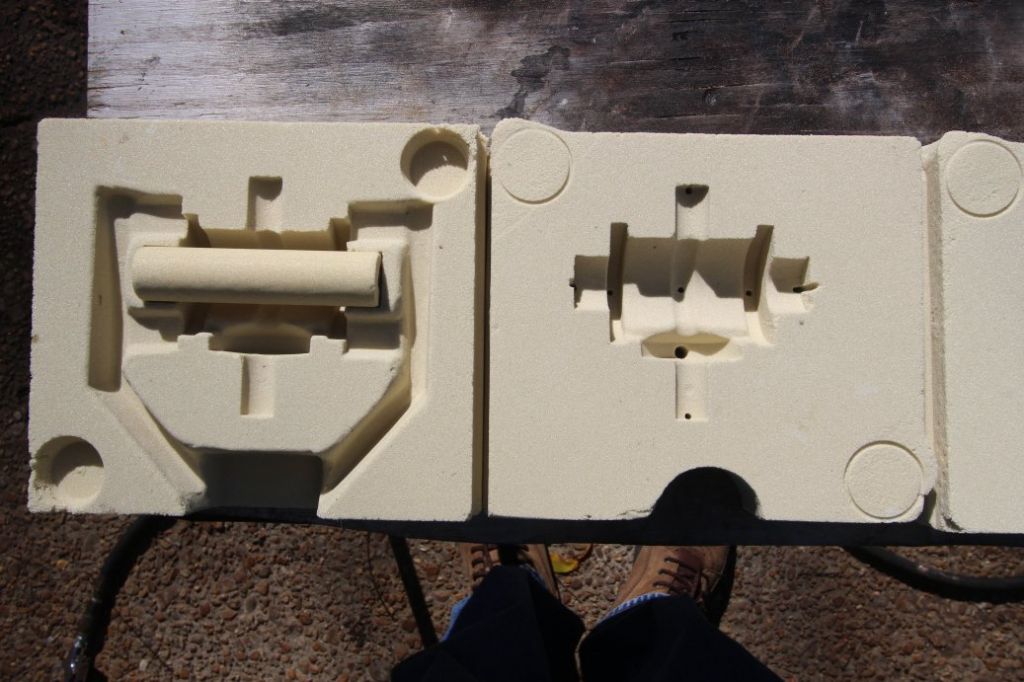

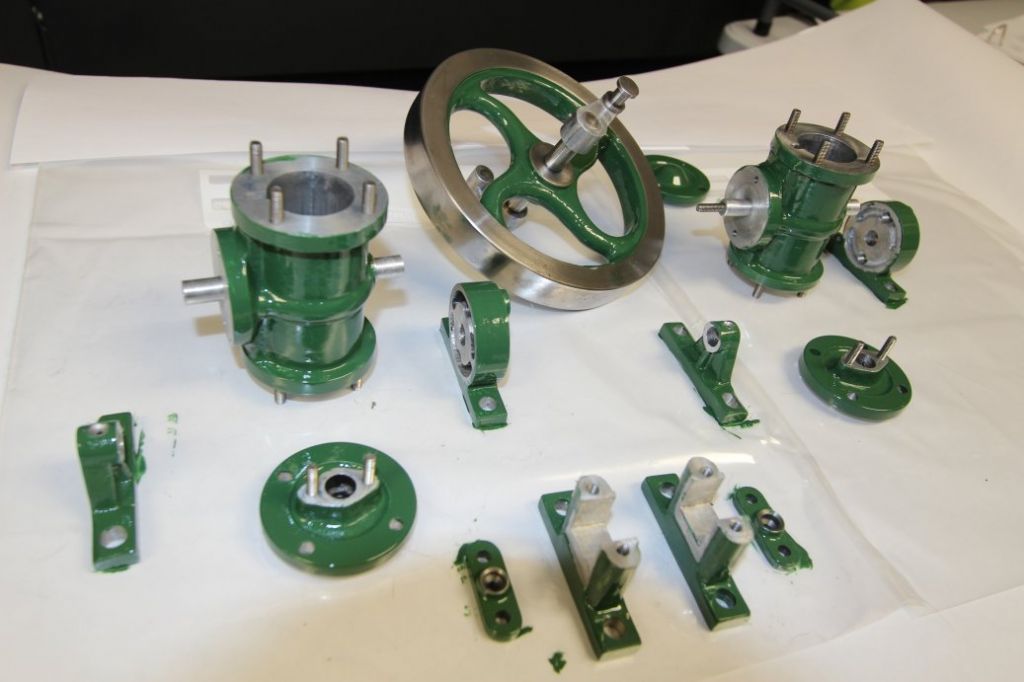

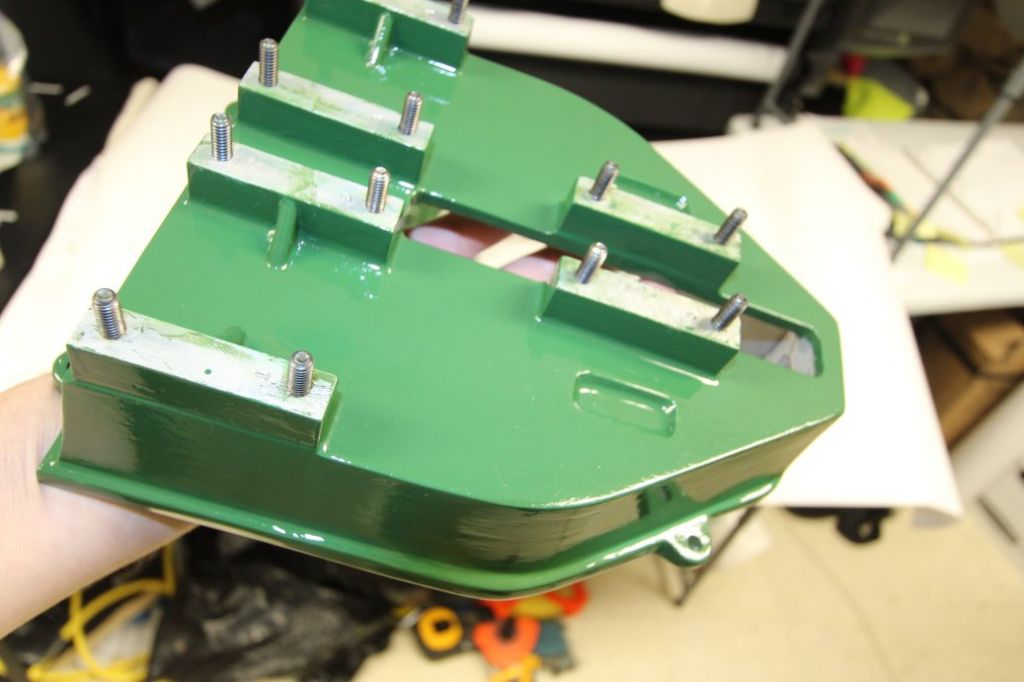

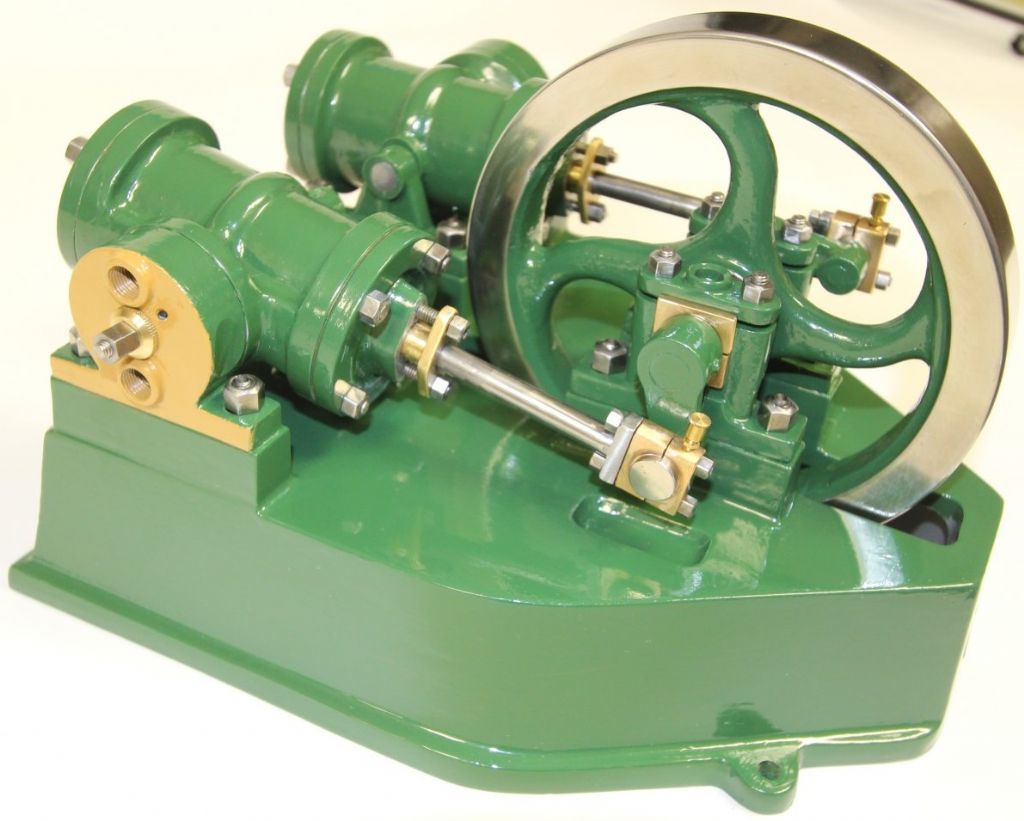

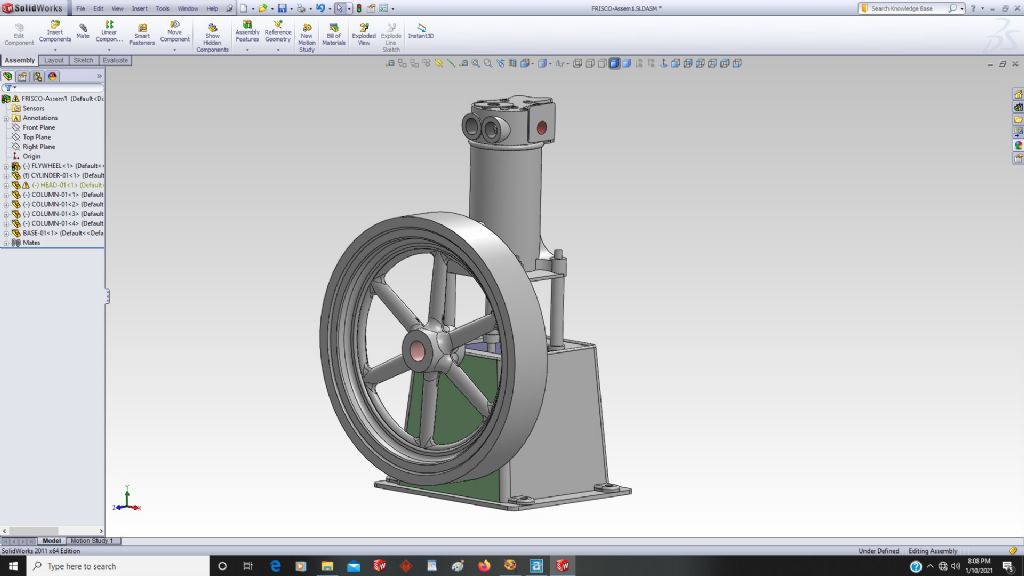

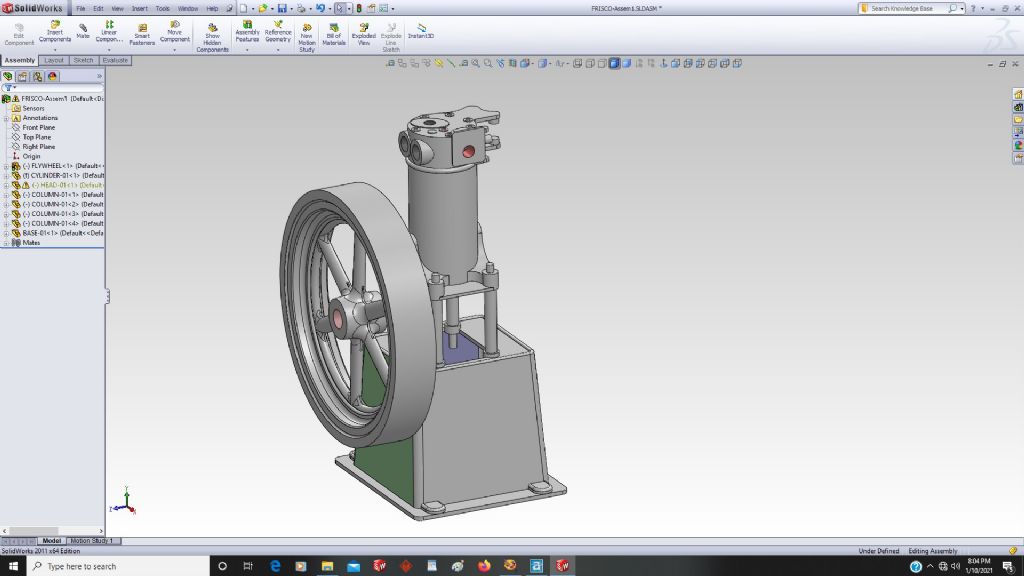

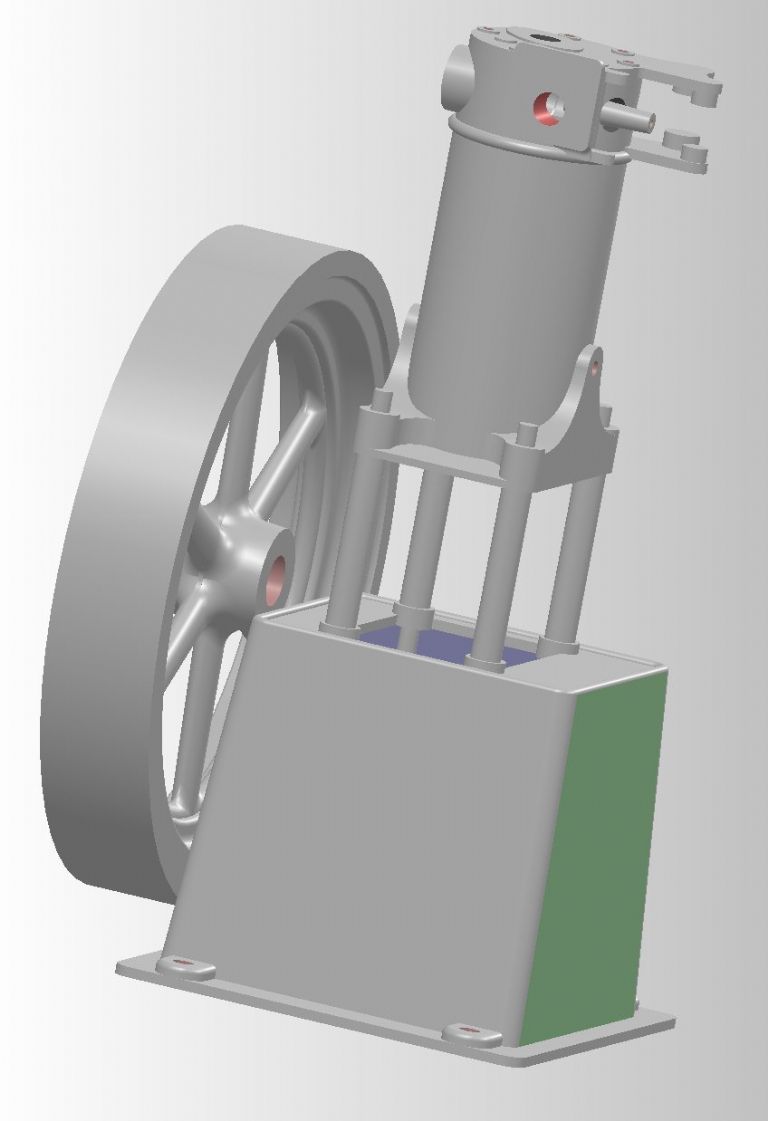

I attempted to cast the green twin base in iron on this attempt.

I was under the impression that if a medium-sized oil burner was good, then a BIG oil burner must be much better.

This was a very bad assumption.

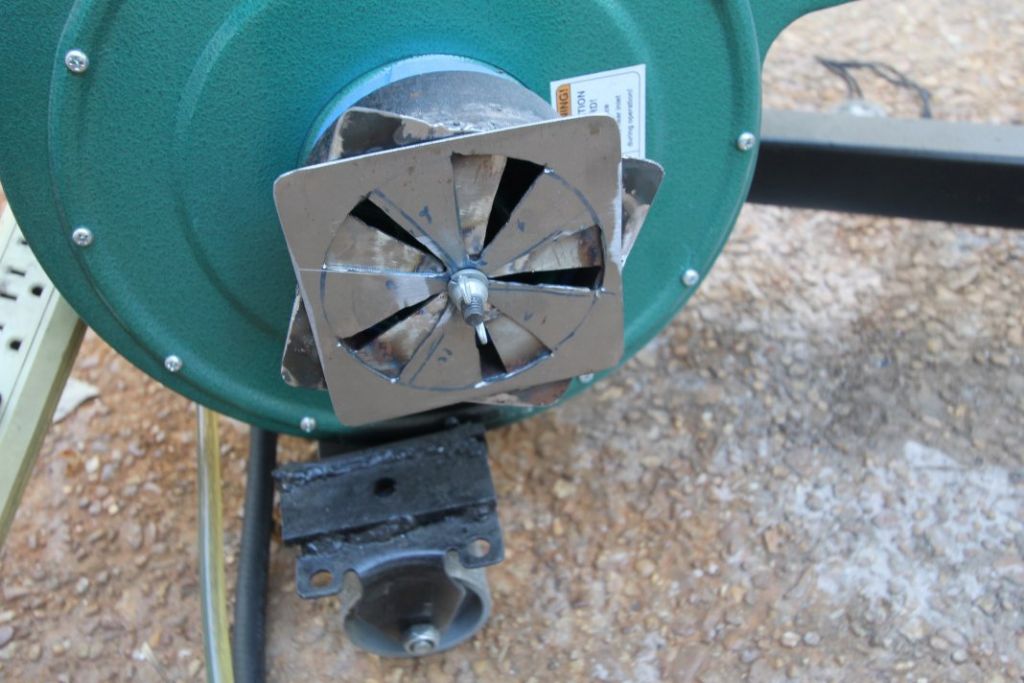

The combustion air blower was a sawdust collector blower, and the burner nozzle was a 4" diameter steel pipe with two siphon nozzles inside of it. The design was experimental, and so I used some PVC pipe for some of the burner tube. For a permanent burner design, one would not want to use any PVC.

As usual, I stumbled blindly ahead, still being totally ignorant of combustion dynamics as related to a foundry furnace.

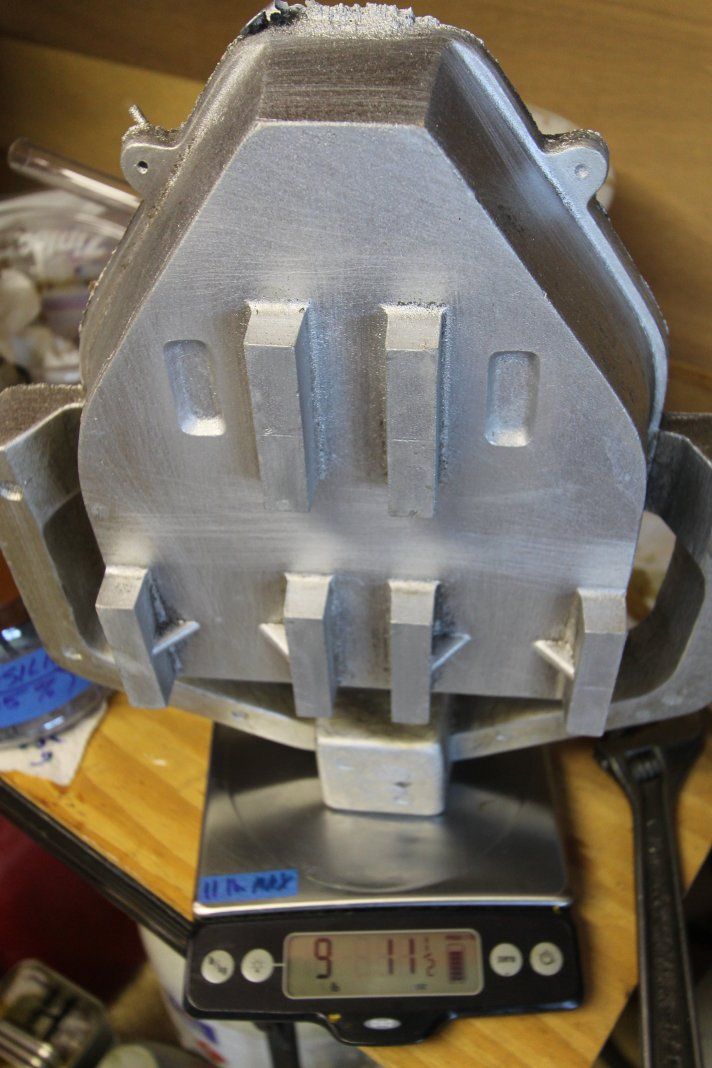

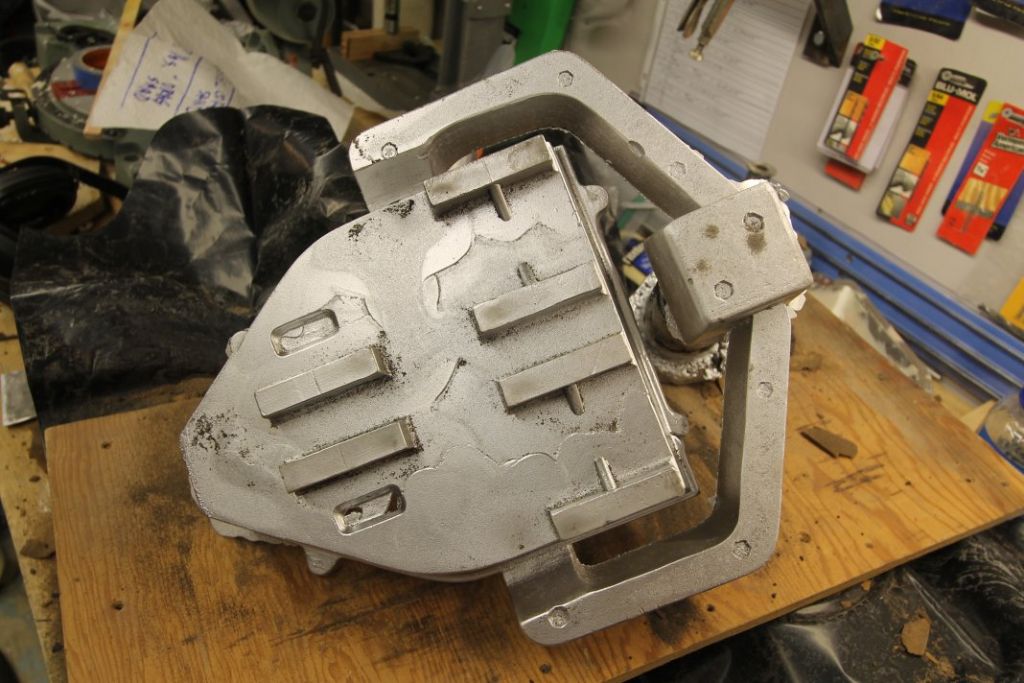

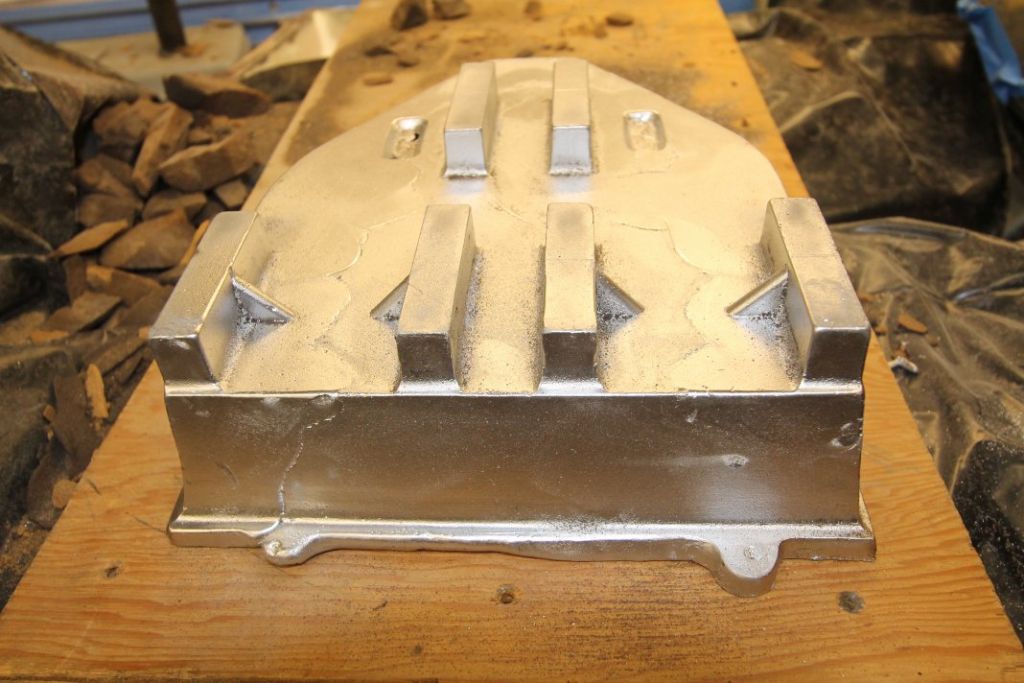

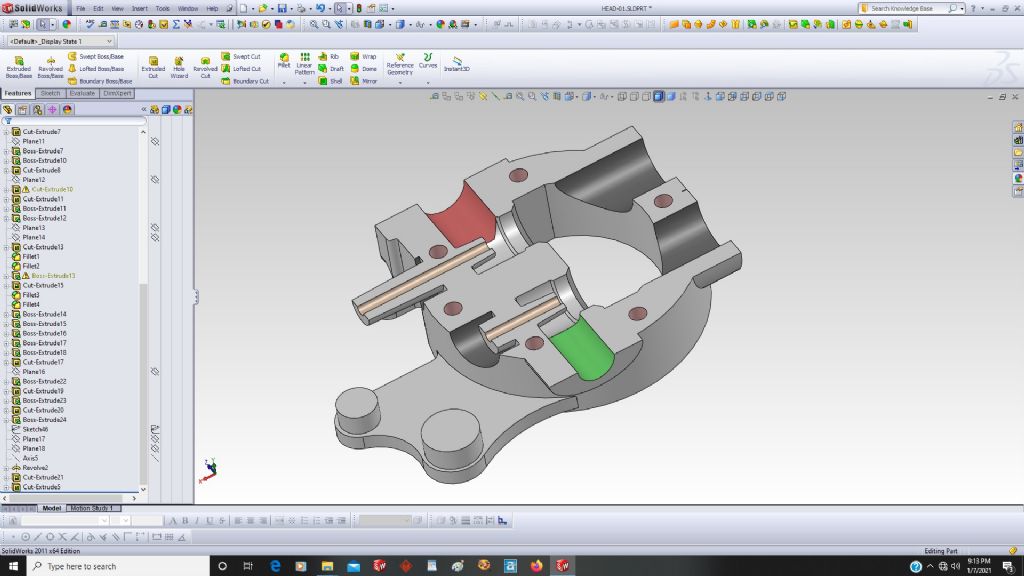

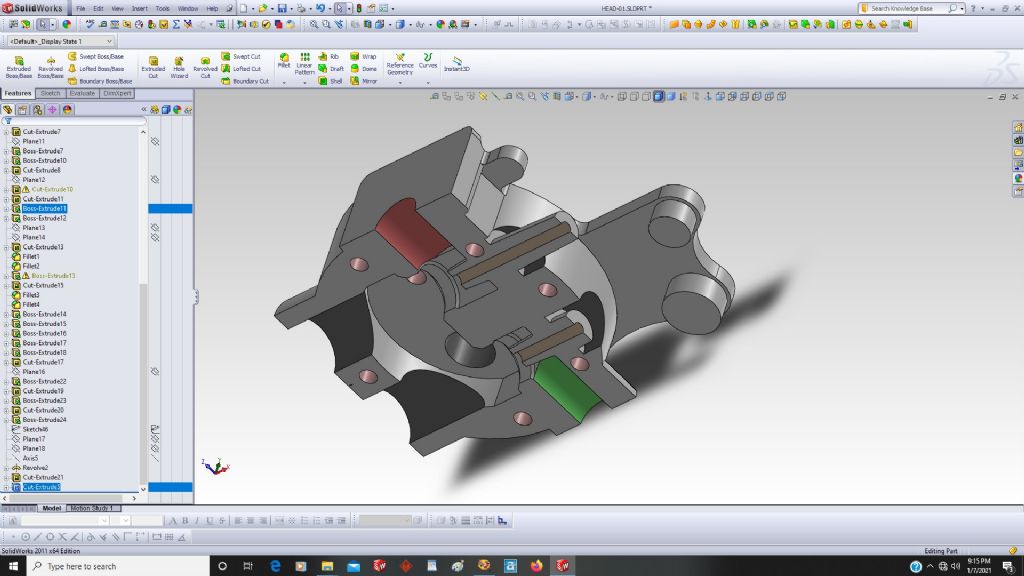

My first iron furnace was also a bumbling affair, with an extremely high mass, a lid that was 5 times too thick, and a lid lifter vertical shaft that was supported by a band around the top of the refractory.

Multiple blunders.

The refractory expanded when it got hot, causing the band to slip and rotate, binding the lid lifter, and jamming the lid open just enough to prevent removing the crucible.

This was a miserable and bitter failure for me, and I lost a good Morgan B30 crucible as a result.

Good thing I was determined to learn iron or die trying, else this experience would have finished my desire to learn how to cast gray iron.

Luckily the mold was untouched, and so could be reused.

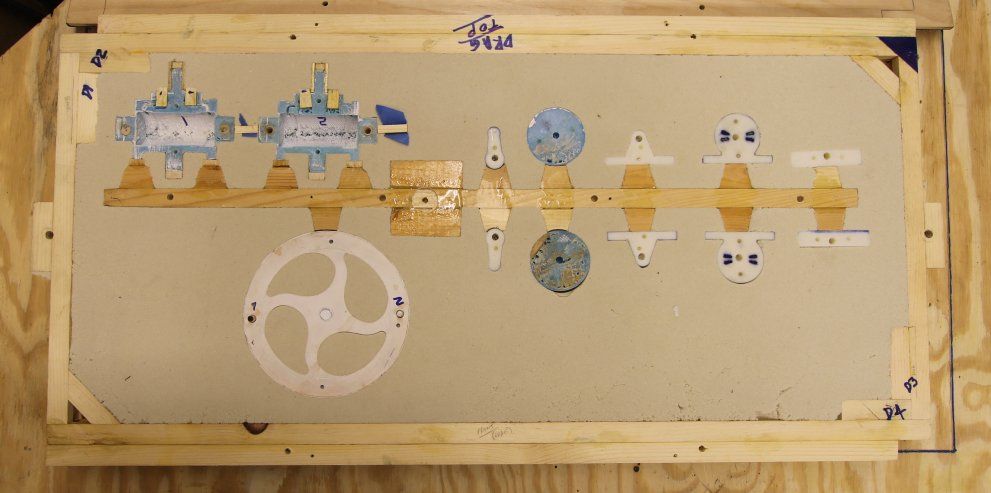

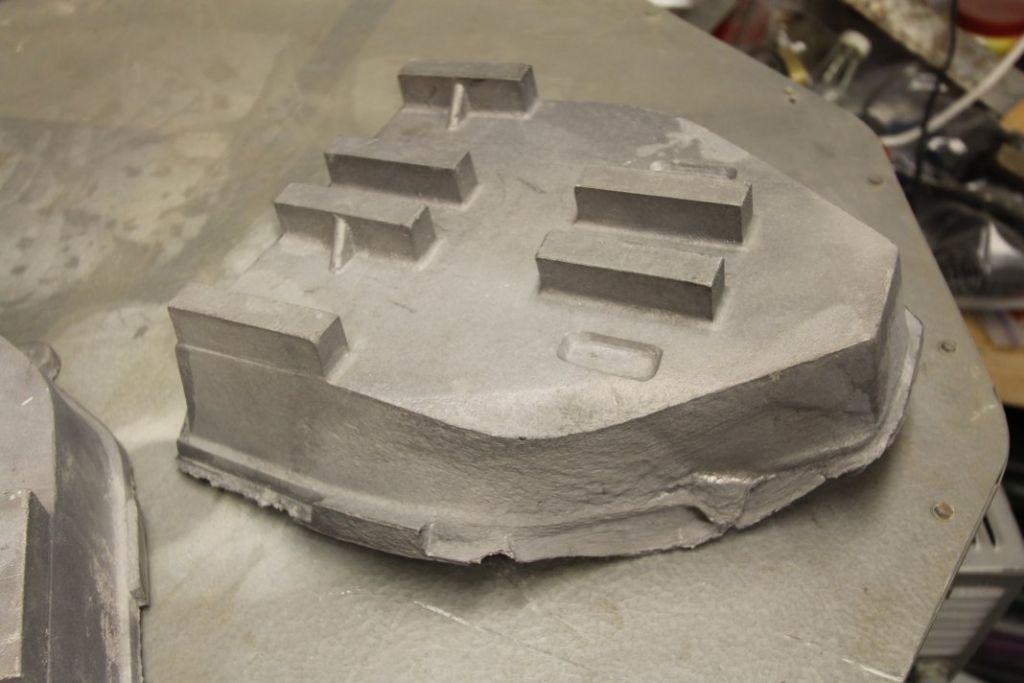

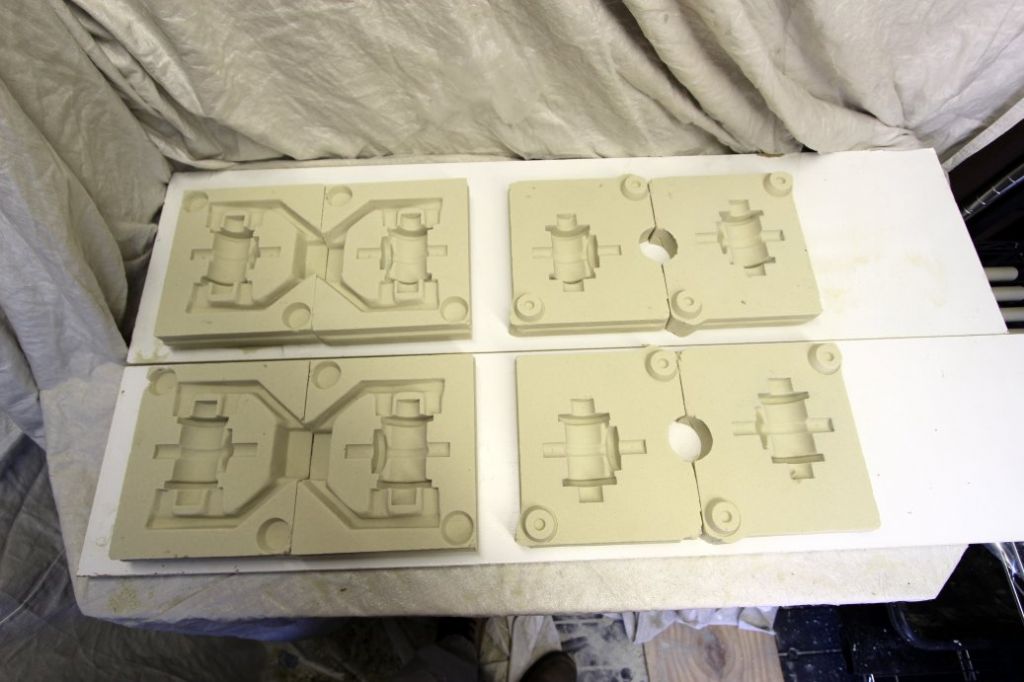

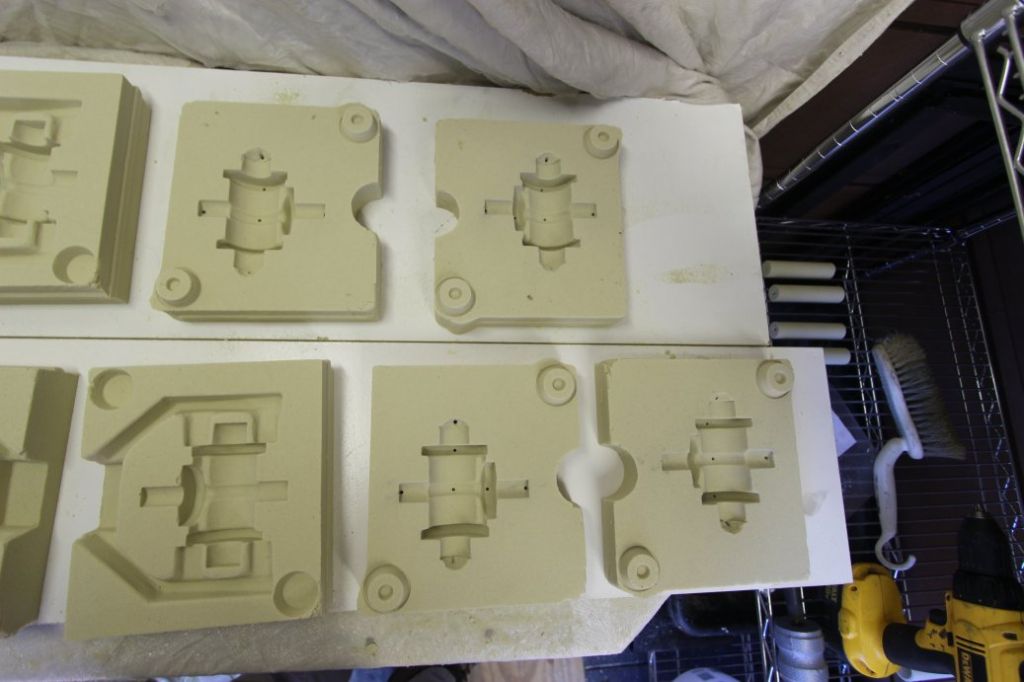

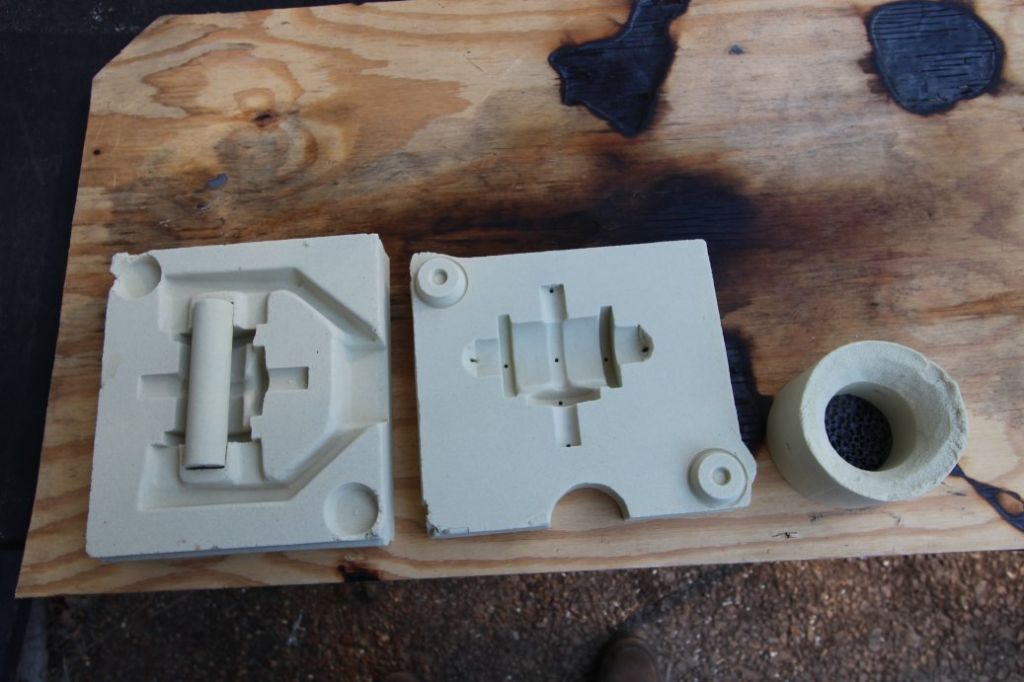

I was making progress though, and the resin-bound mold was a very nice design.

You can see a pouring cart that I made by adding wheels to a pouring shank.

I have gotten a lot of comments about how the wheels should have rubber tires on them, not bare metal rims, but if you have ever run a foundry, you would understand why you don't want rubber or plastic anywhere near a hot furnace or crucible.

Lessons Learned:

A small well tuned oil burner operates much hotter than an oil burner and combustion blower that is sized too large for a given furnace, such as the burner used during this melt. This huge burner ran much cooler than my much smaller first oil burner.

I also notice that I had discovered ceramic filters, and was trying one of those with this melt.

Since I did not know how to tune my oil burner at the time, my iron was not hot enough to flow through a filter like this. I have since redesigned my runner system so that I do not need a filter (more on that later).

Edited By PatJ on 03/07/2022 17:29:08

PatJ.

PatJ.