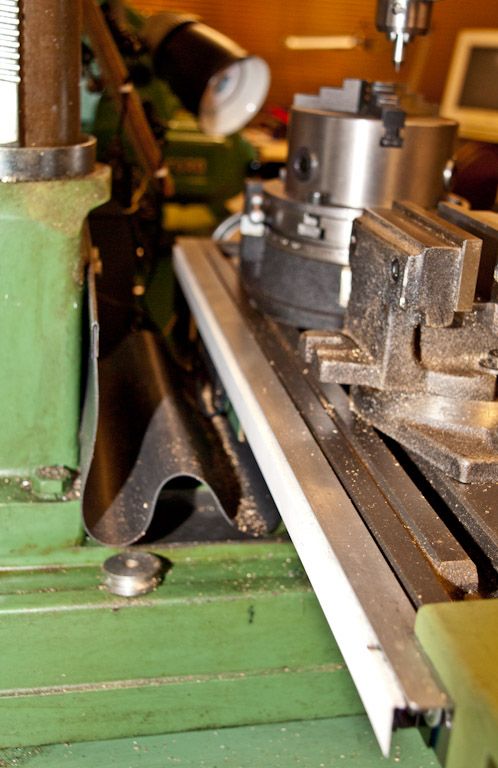

I recently fitted economy DRO scales (igaging) to my Emco milling machine. These work on the same system as the cheap Chinese calipers but have the digital display at the end of a 1m cable.

I have only done the X and Y axis (mounting both took about 2 hours) and I then mounted the displays on the head of the machine. facing the front.

Whilst the DRO works as expected, when I used them in ernest on the first job I found the machining less instinctive and slightly more 'stressfull' than normal. When I analysed the problem I realised that when turning a handwheel to approach a particular reading my gaze was at the display and I had no sight of the job, or probably more especially, my hand on the handwheel.

I think visual feedback from the graduated collars and being able to see my own hand movement combine to made the non electronic process ergonomic. With the DRO display well away from the table the procedure feels far from natural.

My solution was simply to position the individual diplays adjacent to the X and Y handwheels. Now when working I can see the job, the digital display and what my hands are doing.

This set me thinking, a combined, 2 or 3 axis display can only be in one location, setups I have seen tend to have the display above and to the side of the machine. I suppose that someone with good eyesight just gets used to concentrating on the job or the display but only seeing one of the two with their peripheral vision.

Am I alone in finding the display location critical to easy working.

Ian P

Jon.