Right. 'Tis done – more or less. I might make oil cups for the main bearings and eccentric strap, and I'll probably paint the frame, cylinder and the flywheel except its rim, but it runs from a big bicycle pump – though my 12V tyre inflator doesn't seem to shift enough air. Unsurprising as the cylinder swept volume's much bigger than my Sturat Beam, which it can just operate.

Took me several tries to get it running.

First I tried a Nylon 66 piston ring. Maybe that would've worked if I'd worked up a mirror-smooth bore, but as it was I couldn't get an air seal without a tight frictiony fit. So I took some cotton kitchen string and smeared it with LM3, and that finally gave a smooth-fitting seal.

There was a few thou shimmy on the eccentric because I'd started it from a bit of CI that was pretty much exact length, and that was just fouling the protruding tip of one of the bearing support bolts once per rev, till I found a way to chop the tip off without dismantling the whole thing.

The Loctite 271'd interference fit of the mainshaft to the crank throw wasn't up to the torque, and shifted – so I drilled 3/32 through both and pinned it with silver steel. Meant I had to fiddle the valve chest cover with its 11 x 8BA studs and nut off and on again so as to reset the lost valve timing. Growled away half a morning on that.

But the stupidest issue was my inlet assembly. I had a hollow hex tube feeding the valve chest, and a plain inlet pipe screwed in at a right angle to that. Screwed it in so far that it completely occluded the 'ole into the hex tube, didn't I? So the compressed air wasn't even reaching the valve, never mind the cylinder. I really don't wanna say how long it took me to find that. Duh.

There are two weird-shaped tie-rods from cylinder to stator ring. Only the Michigan original has these, and I can't really see the point of them in the model as the four 5BA bolts holding cylinder to frame should easily be adquate. The drawing's not completely dimensioned and there's no obvious easy way to calculate the compound angle, so I fabricated them from steel components screwed together, which took quite a while as suck-it-and-see seemed the only method.

So. I've got a nice new model now.

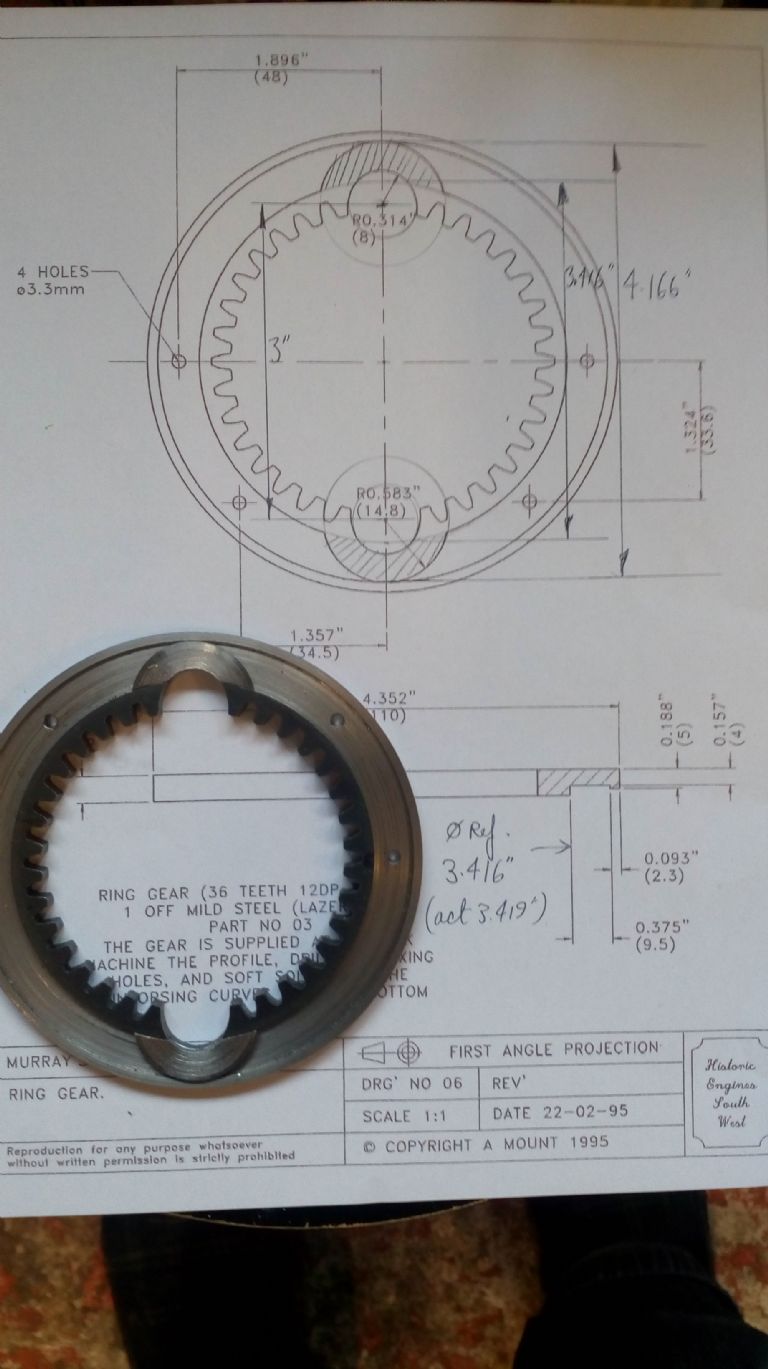

Is it because of the laser pre-cut frames and gears that I now feel a bit of a cheat? I strongly doubt that I'd ever've worked up the commitment to build such a thing without – dunno how I'd've done the gears at all with the kit I have.

Thanks to all who've answered questions and provided advice, even if I haven't always followed it.

Jon Lawes.

Jon Lawes.