The guides are indeed cut from solid.

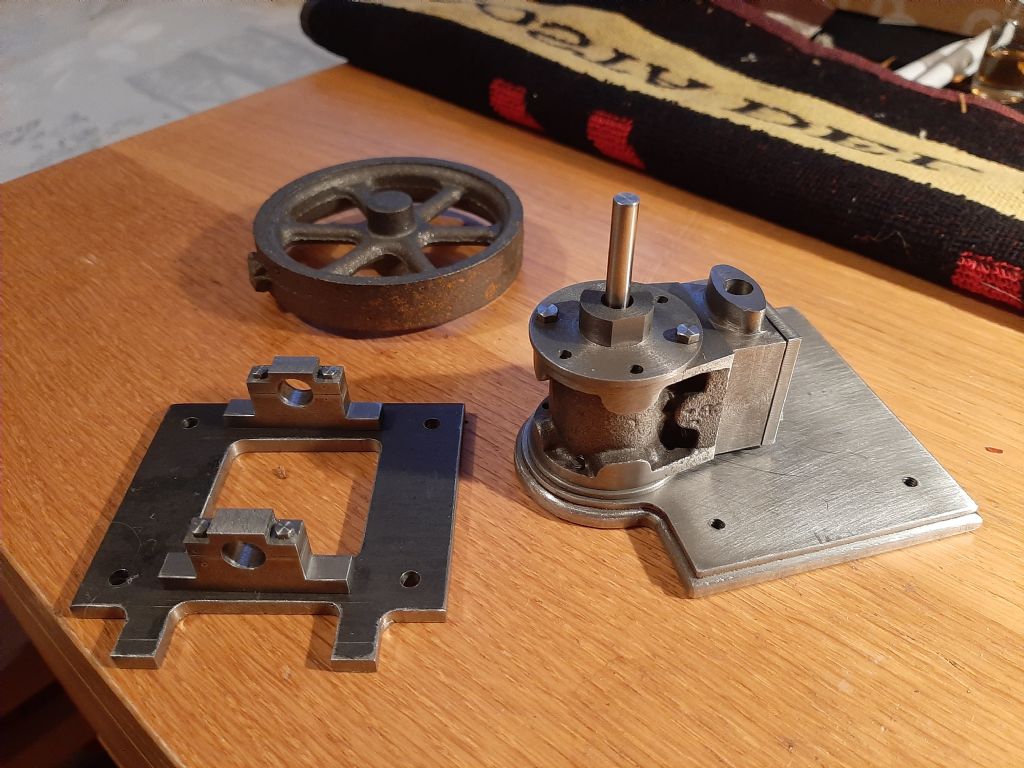

This is basically as described in the text but photos will be a bit bigger:

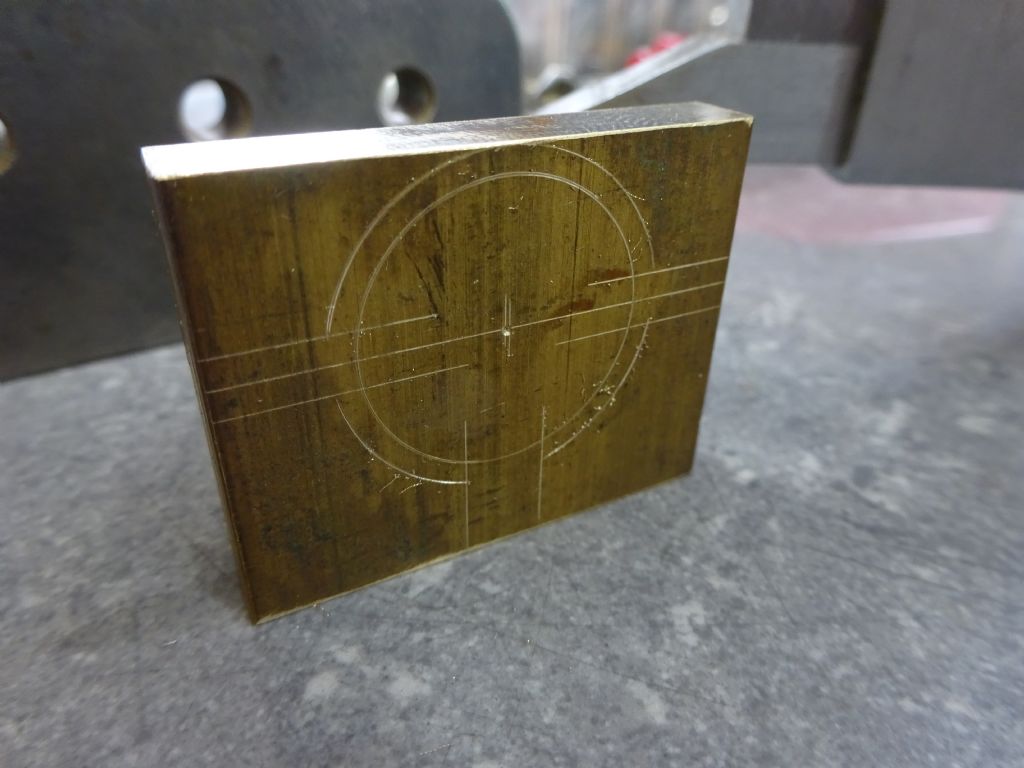

First machine your two pieces of 6mm thick material to the overall 79.5mm x 20.0mm, then mark out so you can saw away most of the waste.

Now hold in the vice with the inner face resting on parallels and mill down the 6.2mm leaving 3mm which forms the horizontal leg.

Hold the part again with the inner face resting on a parallel but use a thicker one this time and mill the outerface for a length of 55.3mm from the bottom of the part and again leave 3mm thickness of material to form the vertical leg.

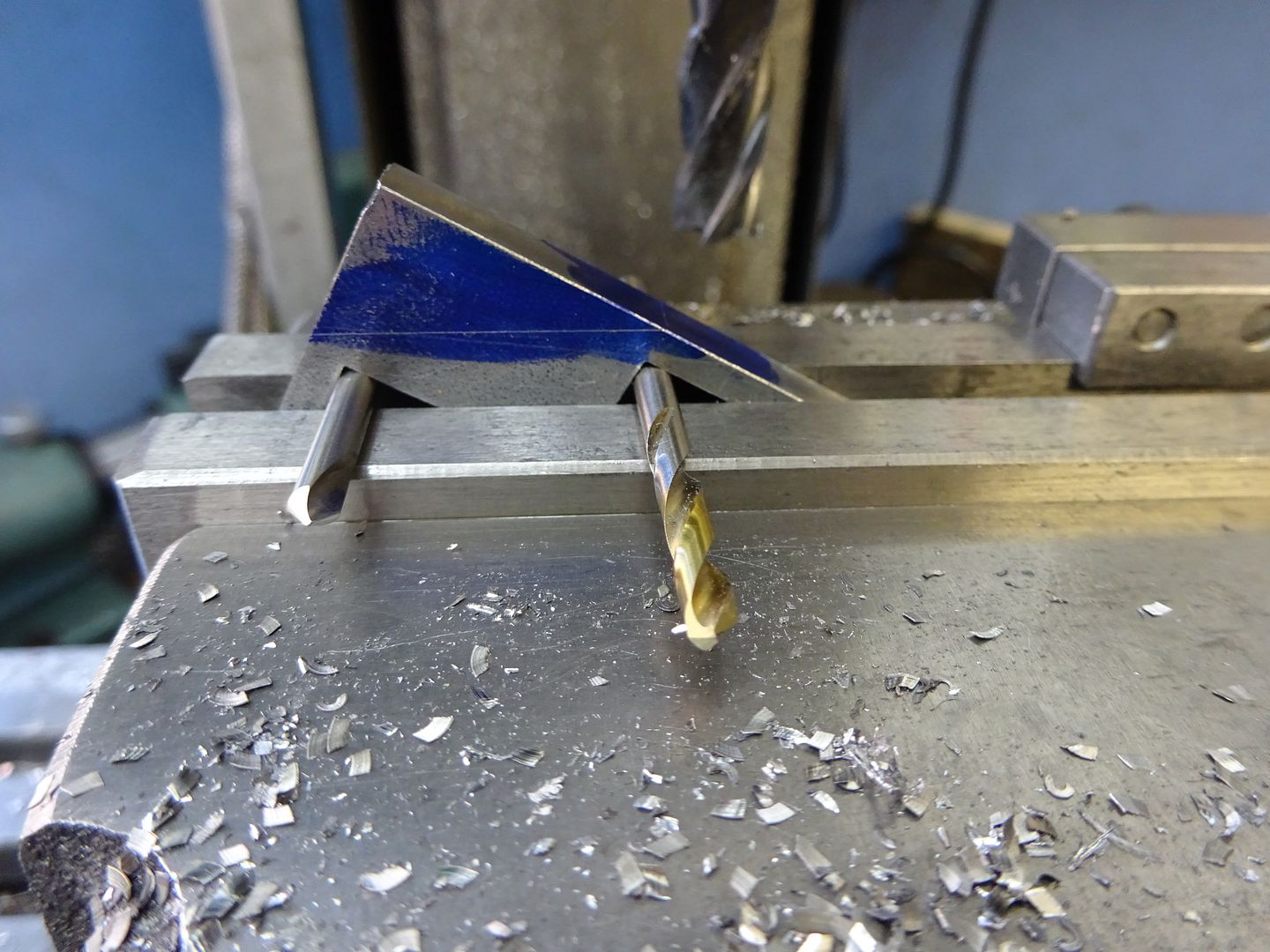

You can now blue the inner edge of the part and mark a line 23.5mm down which is just visible in the photo and I also carried a line around from that to show where the metal will be removed to but that is optional. Slip two matching diameter rods or drill bits onto the vice and use them to support the two internal corners machined in the earlier steps. This will hold the work at the correct angle so no measuring required, just machine down until the cutter is at the marked line on the side.

The final operation is to turn the part the other way up so the sloping face you just machined is resting on a parallel and mill out the remaining material to leave a 3mm finished thickness. No pic of that.

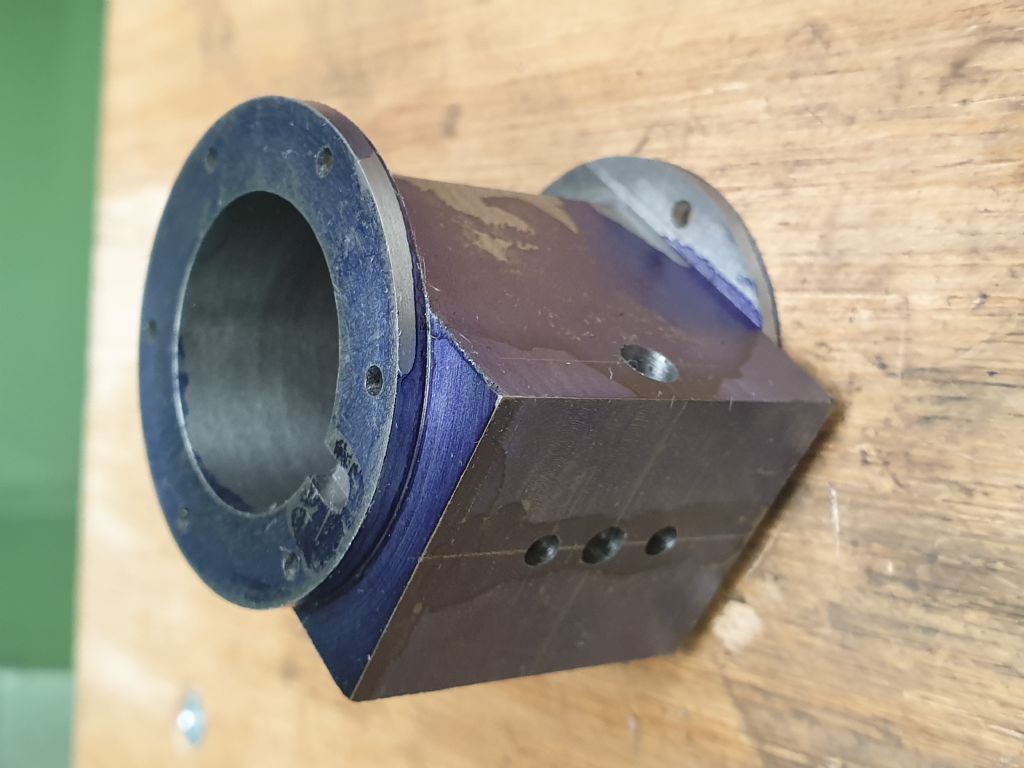

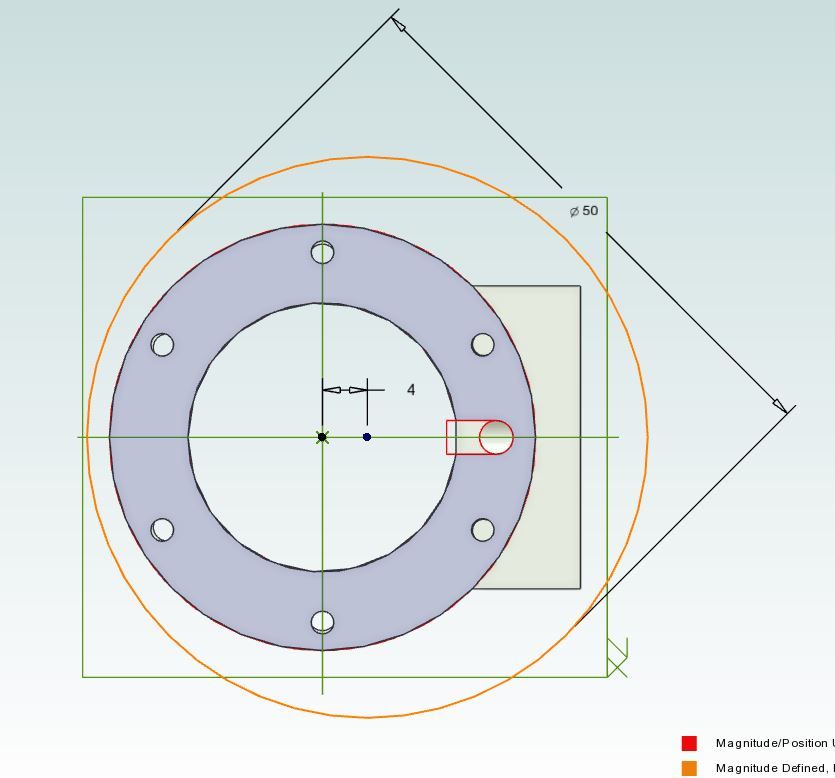

As for the cylinder that will indeed come out of 50mm stock as per the article, just offset the bore of teh cylinder, something like 4mm will do nicely and leave plenty to spare all round

John, I'm also just about to send you a message so look at the green bar along the top of the page and your "inbox" will be flashing, click that.

JasonB.

JasonB.