So with us all on lock down I thought it would be a good time to get a set of drawings together and write up the build if anyone wants a small project to pass the hours. This time rather than separate drawings I have put all 10 sheets into one pdf which should make it easier when looking over them on the computer as you can scroll up and down rather than having to open multiple files. I have also done a Bill of materials for those that like to have one, note that sizes are generally of the finished part so make your own allowances for holding, parting etc.

In most cases materials can be substituted as well as methods, anyone with queries please ask. Also if you find anything wrong or missing on the drawings please let me know and I will update as needed.

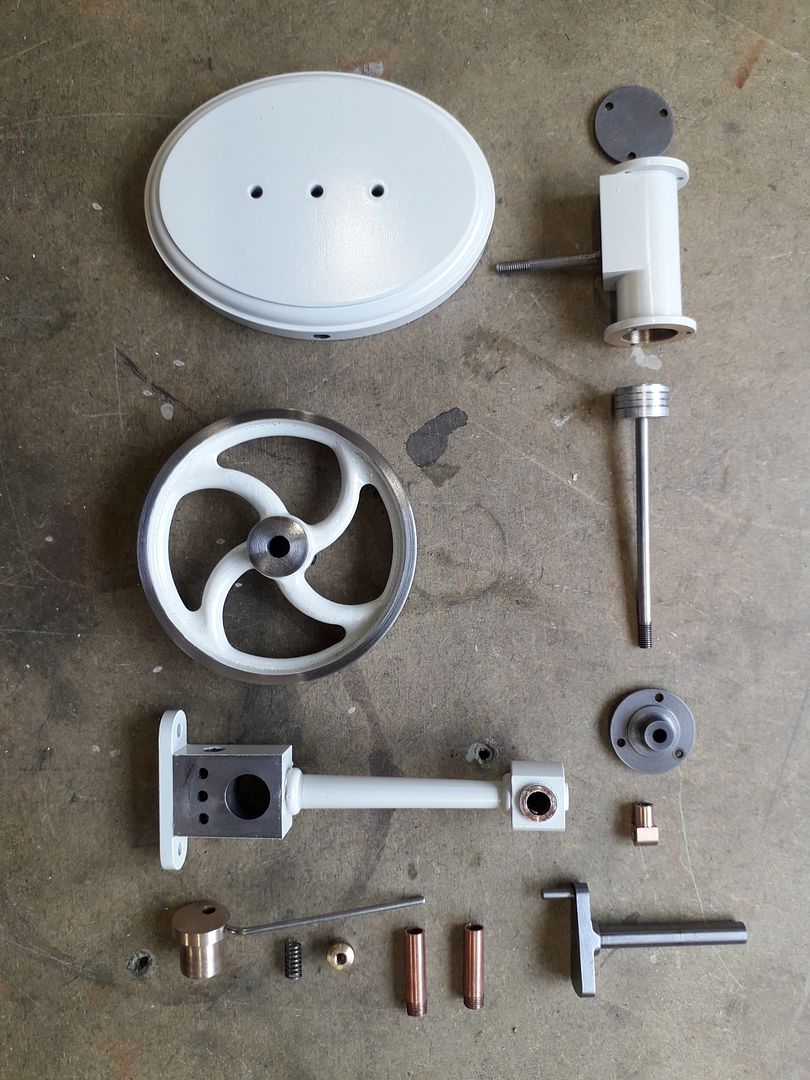

Column

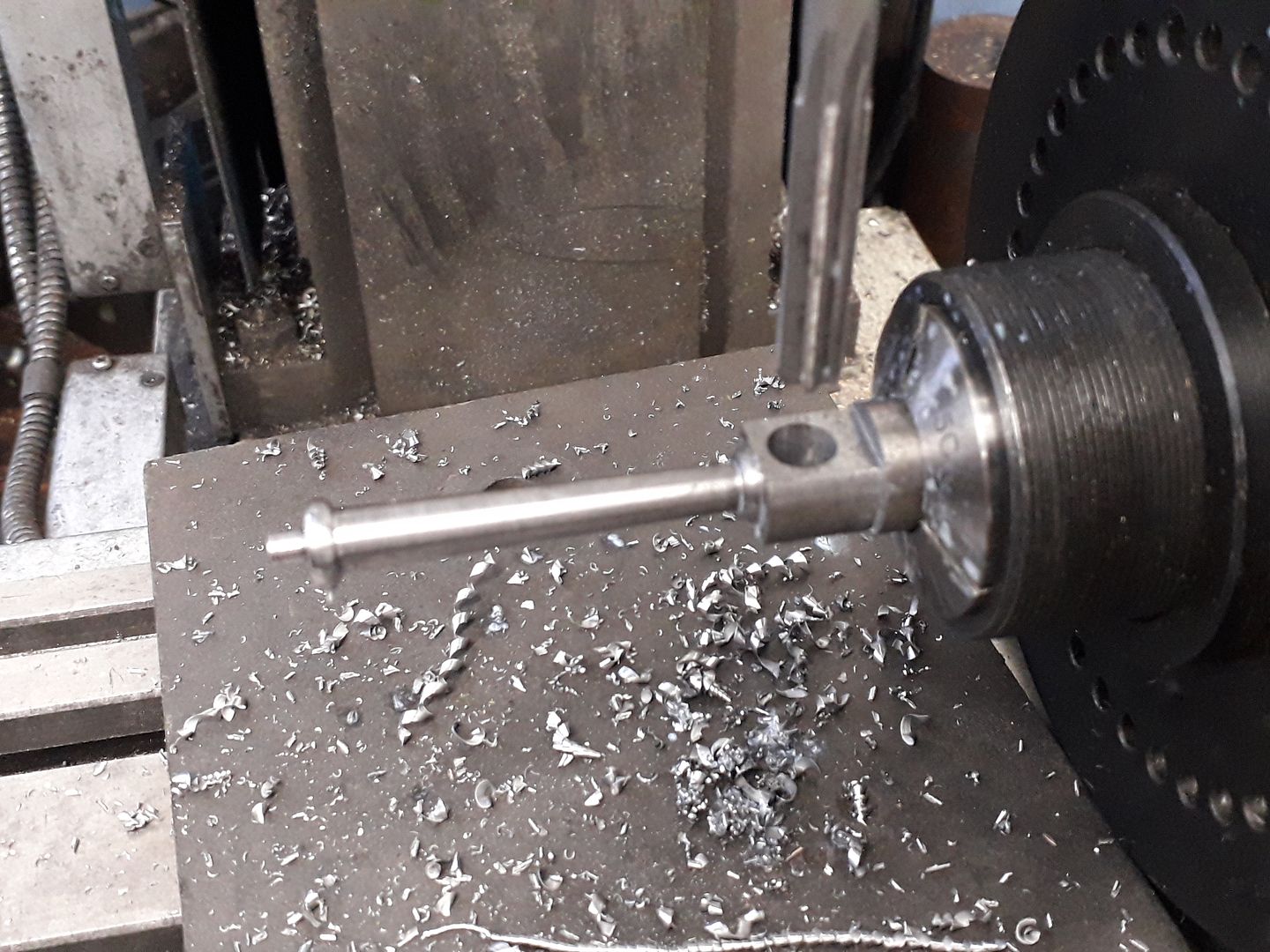

Start by facing the end of your 15 or 16mm stock and then form the spigot on the end followed by a small ctr drilled hole. The material can then be pulled further out of the chuck and tailstock support used while the tapered section and decorative beads are turned.

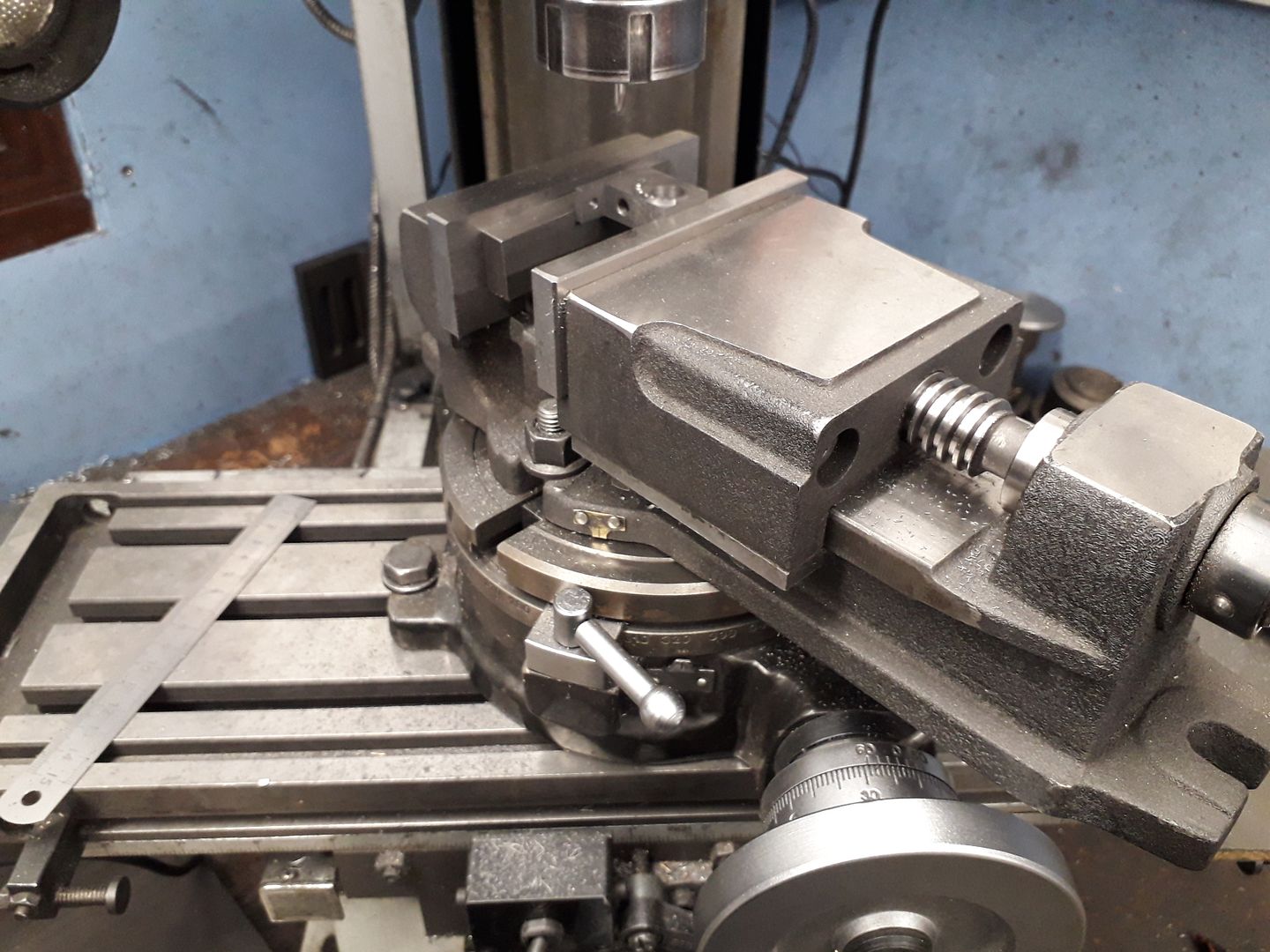

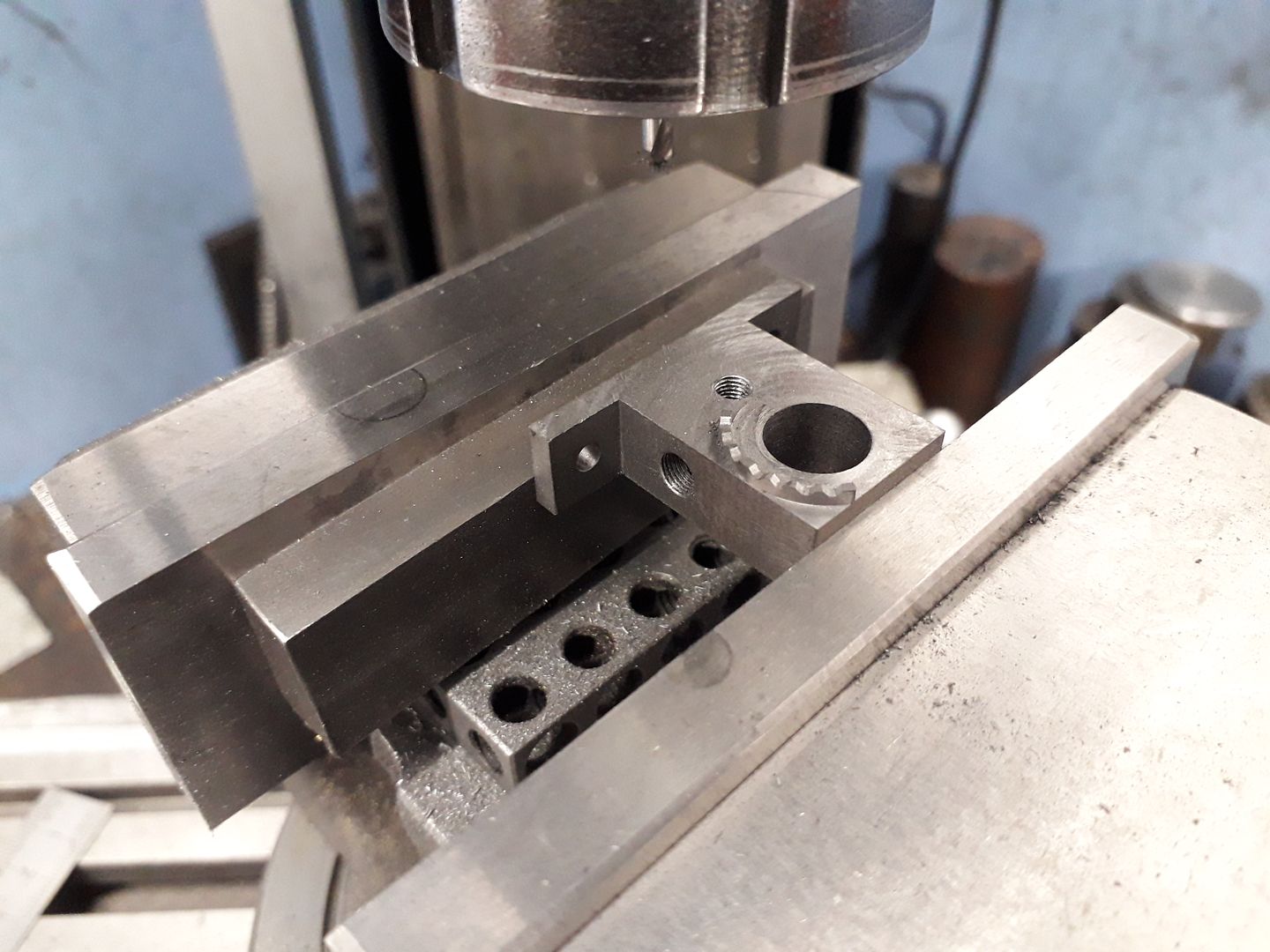

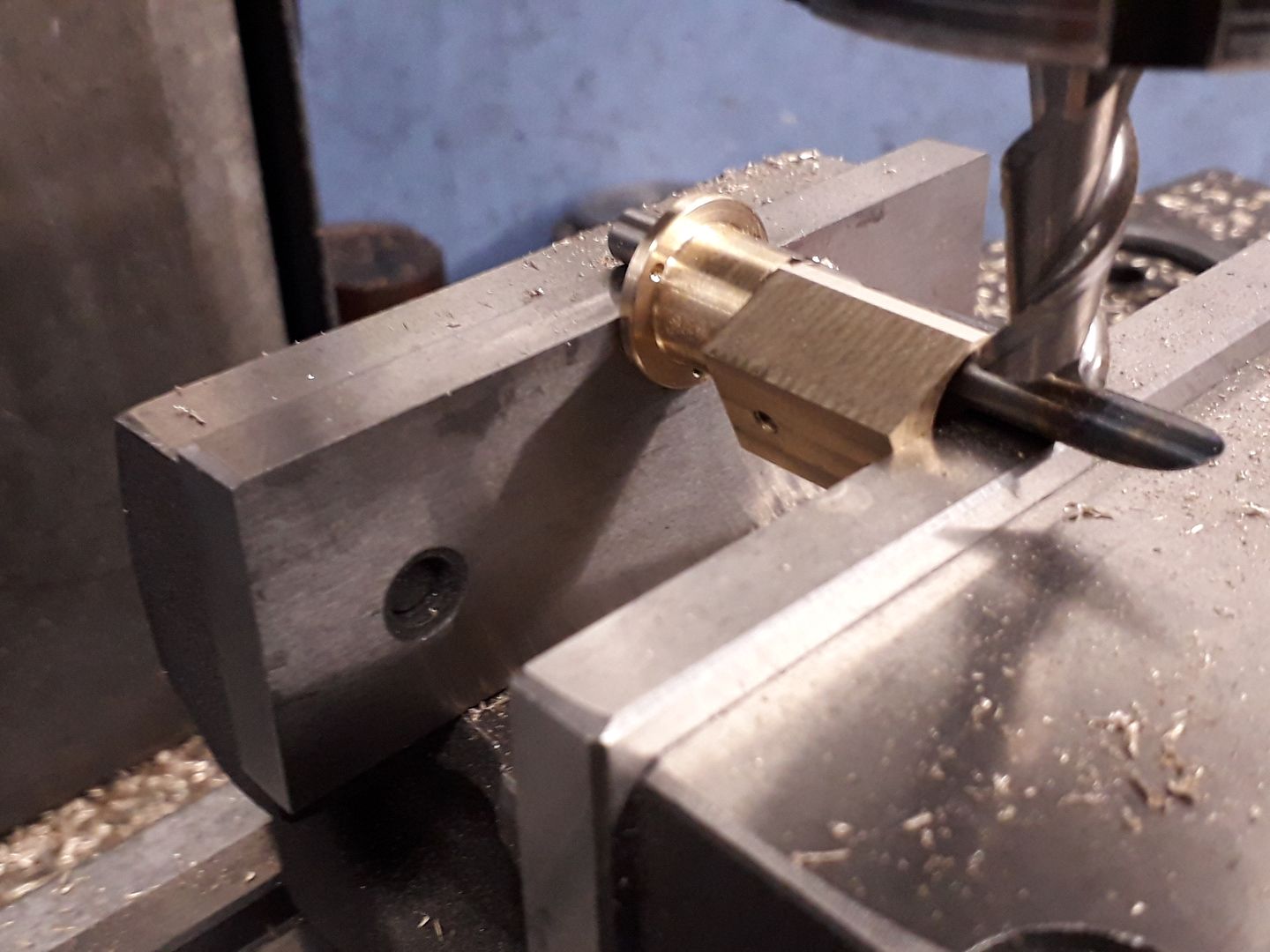

Transfer the part to the mill and hold by the remaining bar in a collet block or indexer to mill the two flats at the top followed by drilling and reaming for the bearing.

With the work back in the lathe form the small boss for the oil hole before parting off. The oil hole can be drilled while lightly holding the top of the column in a collet or in the 4-jaw, you could even leave it until later and just use the bench drill.

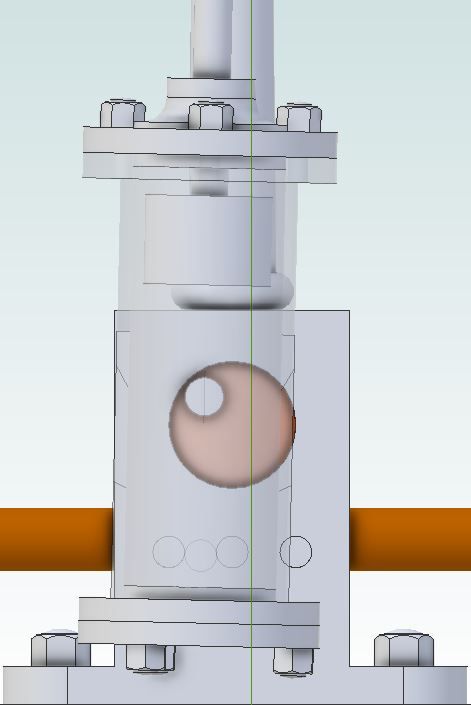

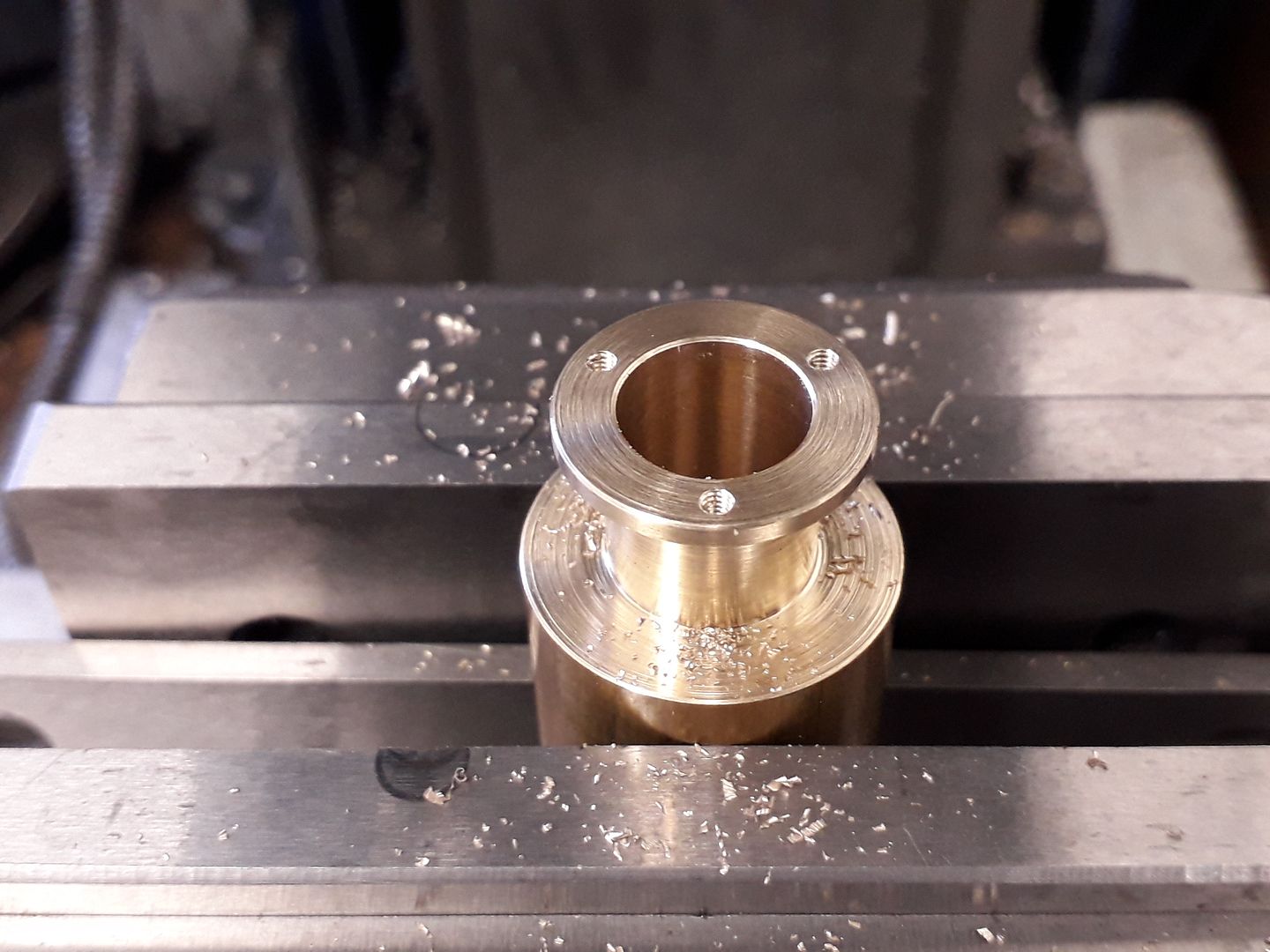

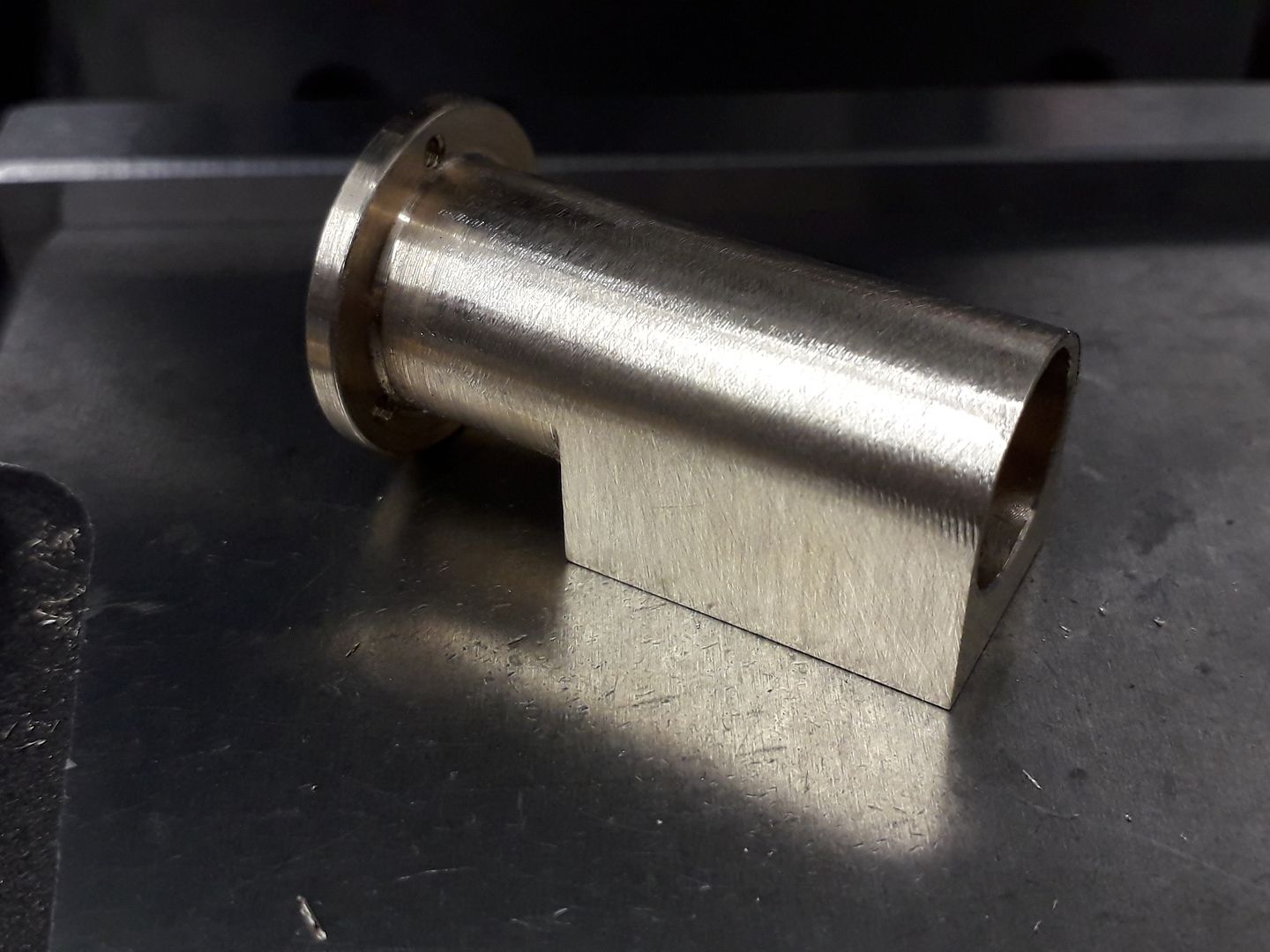

Bearing

This is a straight forward turning job, the column can be used to gauge the outside diameter and the 5mm hole is best reamed. The bearing is Loctited into place with 1mm protruding on the cylinder side and then the oil hole drilled through but don't do either of these things yet.

Crankshaft

A very easy part to make from either Precision Ground Mild Steel or Silver Steel (Drill Rod) but leave it say 1.0mm over length for now.

Crankpin

Another simple part from Silver steel

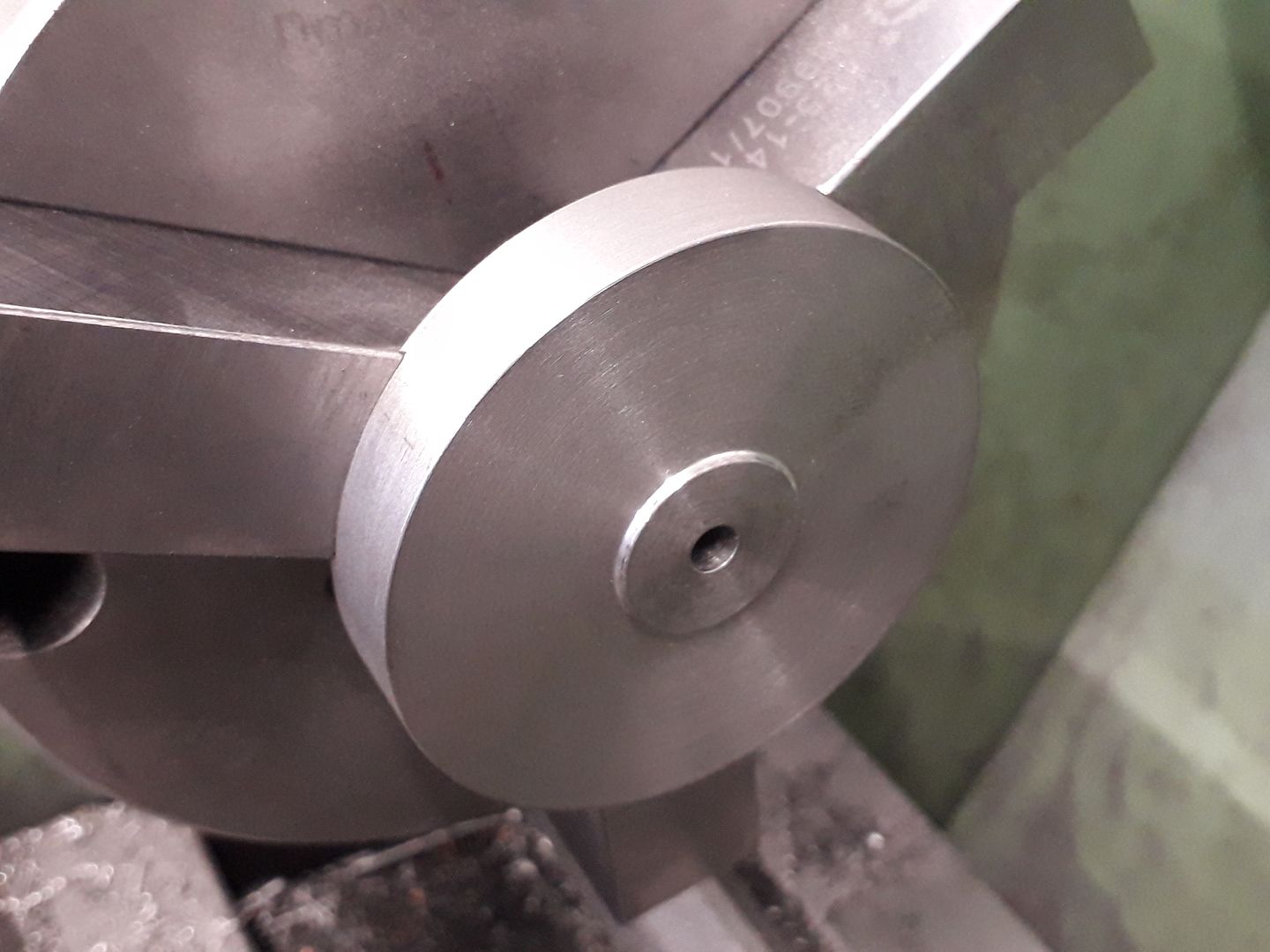

Crank Web

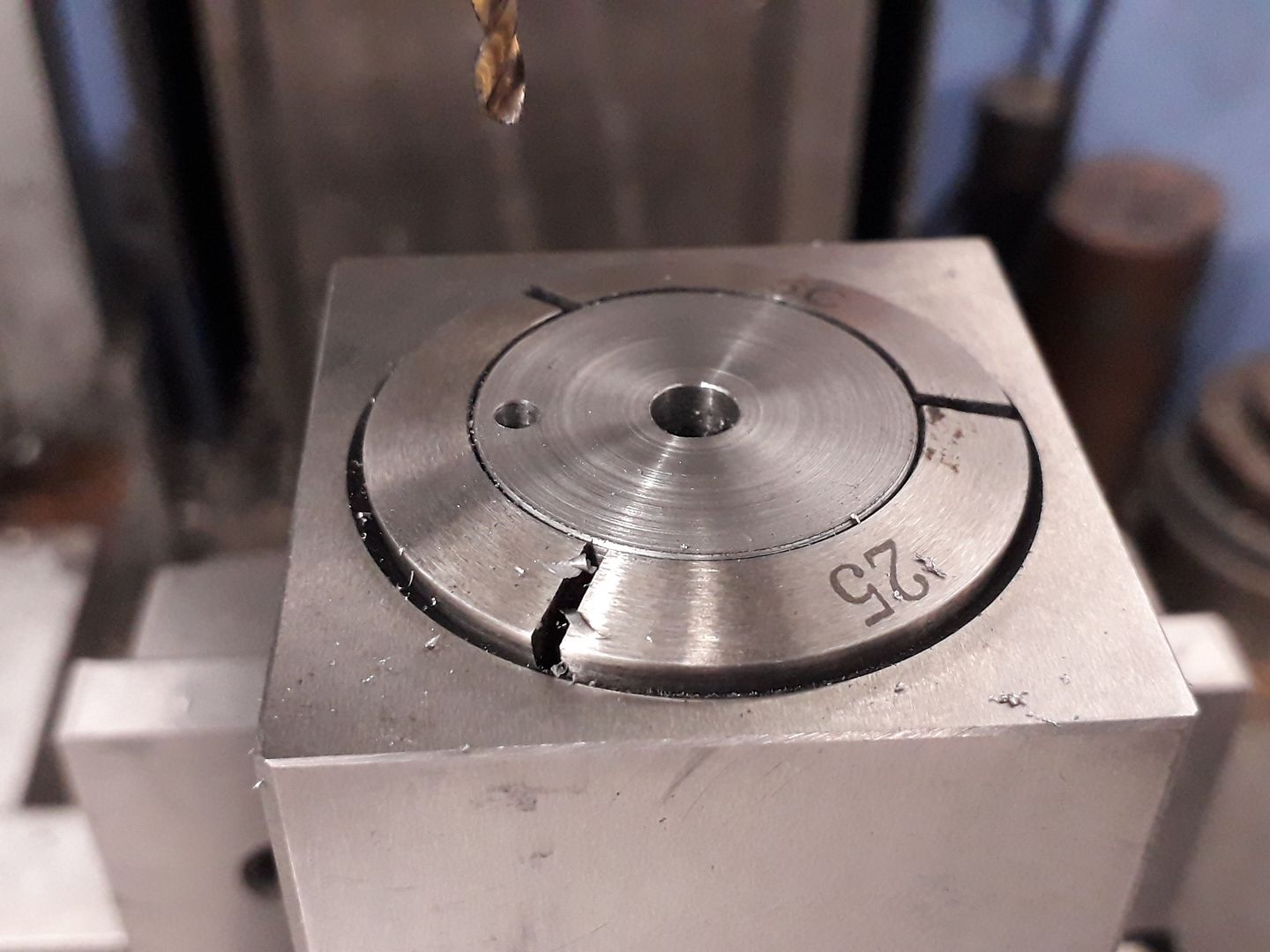

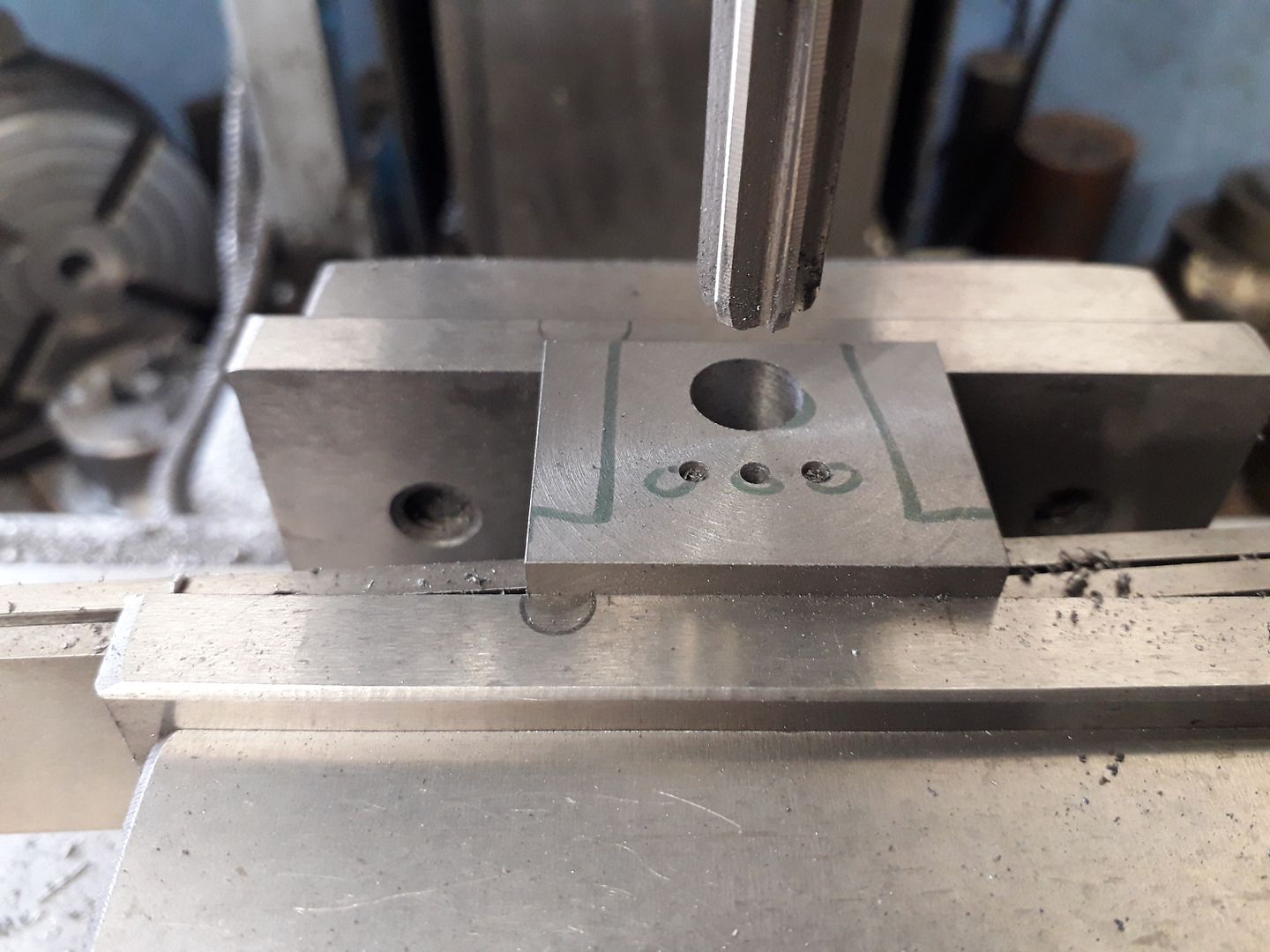

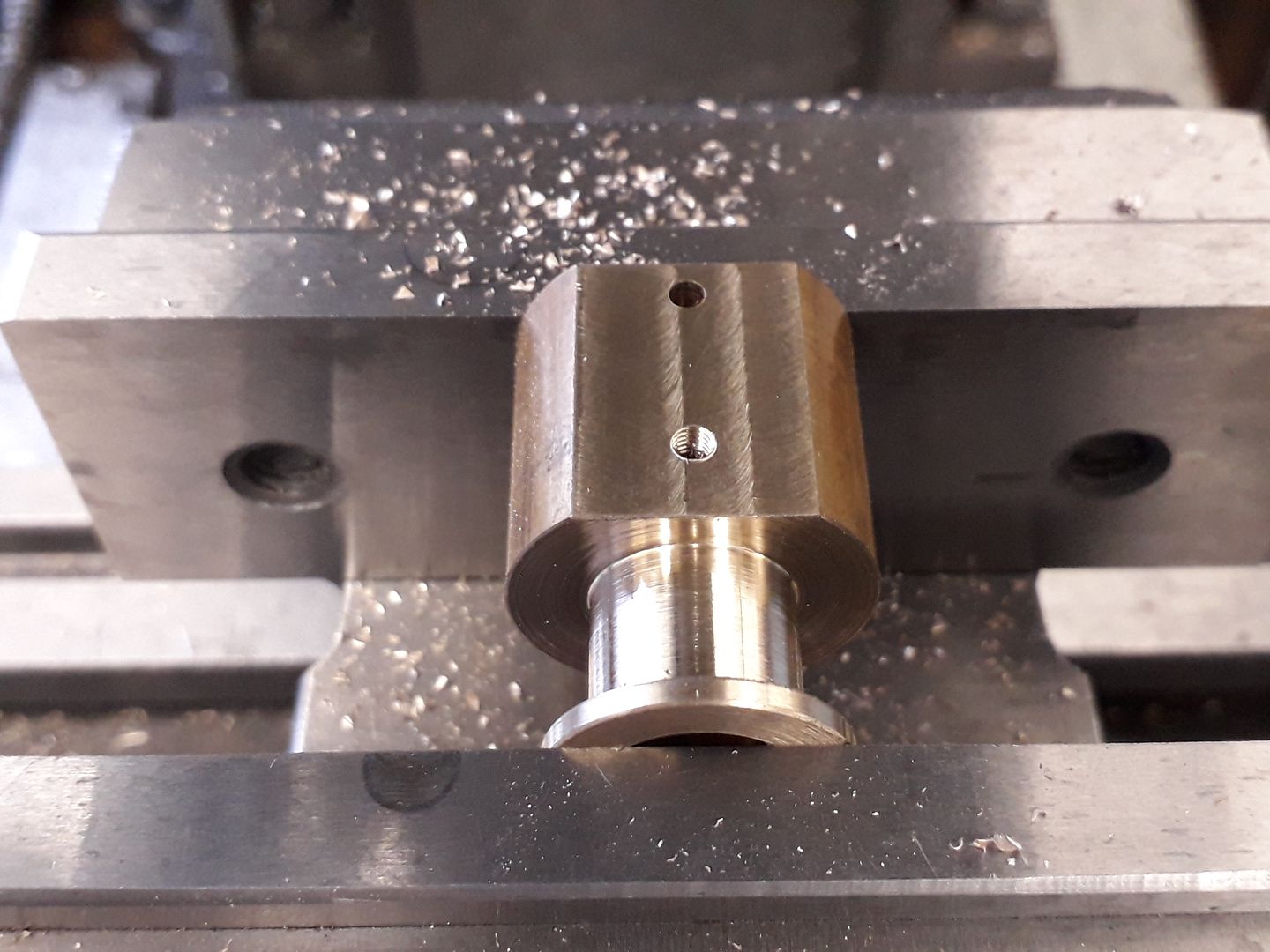

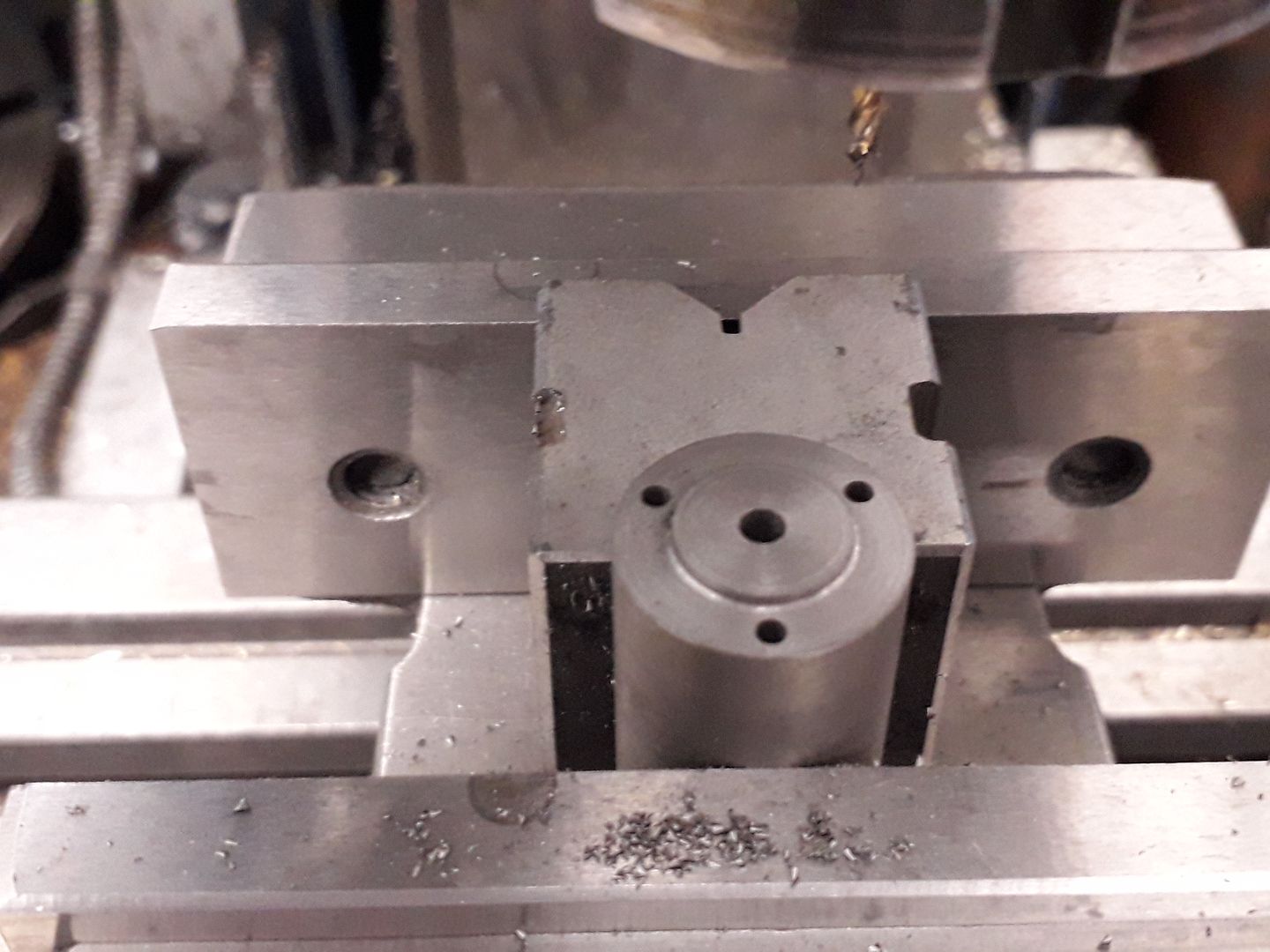

Start by forming the 8mm dia boss on the end of a piece of 25mm dia steel then drill and ream 5mm. Part or saw off leaving the web 1mm over thickness.

Transfer to the mill, locate the ctr and then move 10mm to one side to drill for the crankpin.

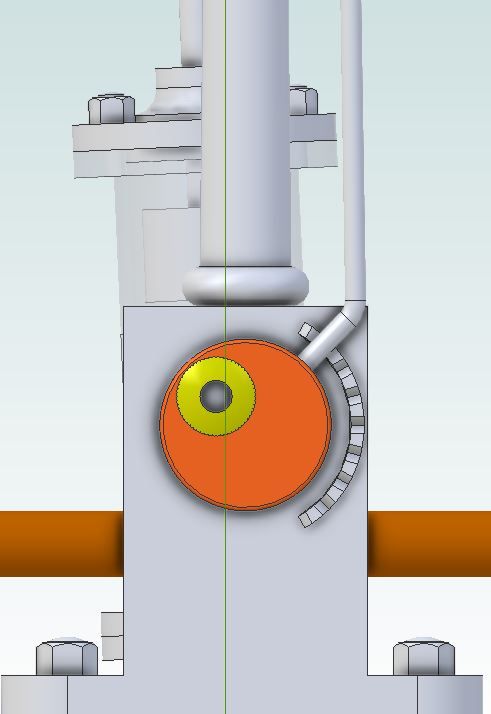

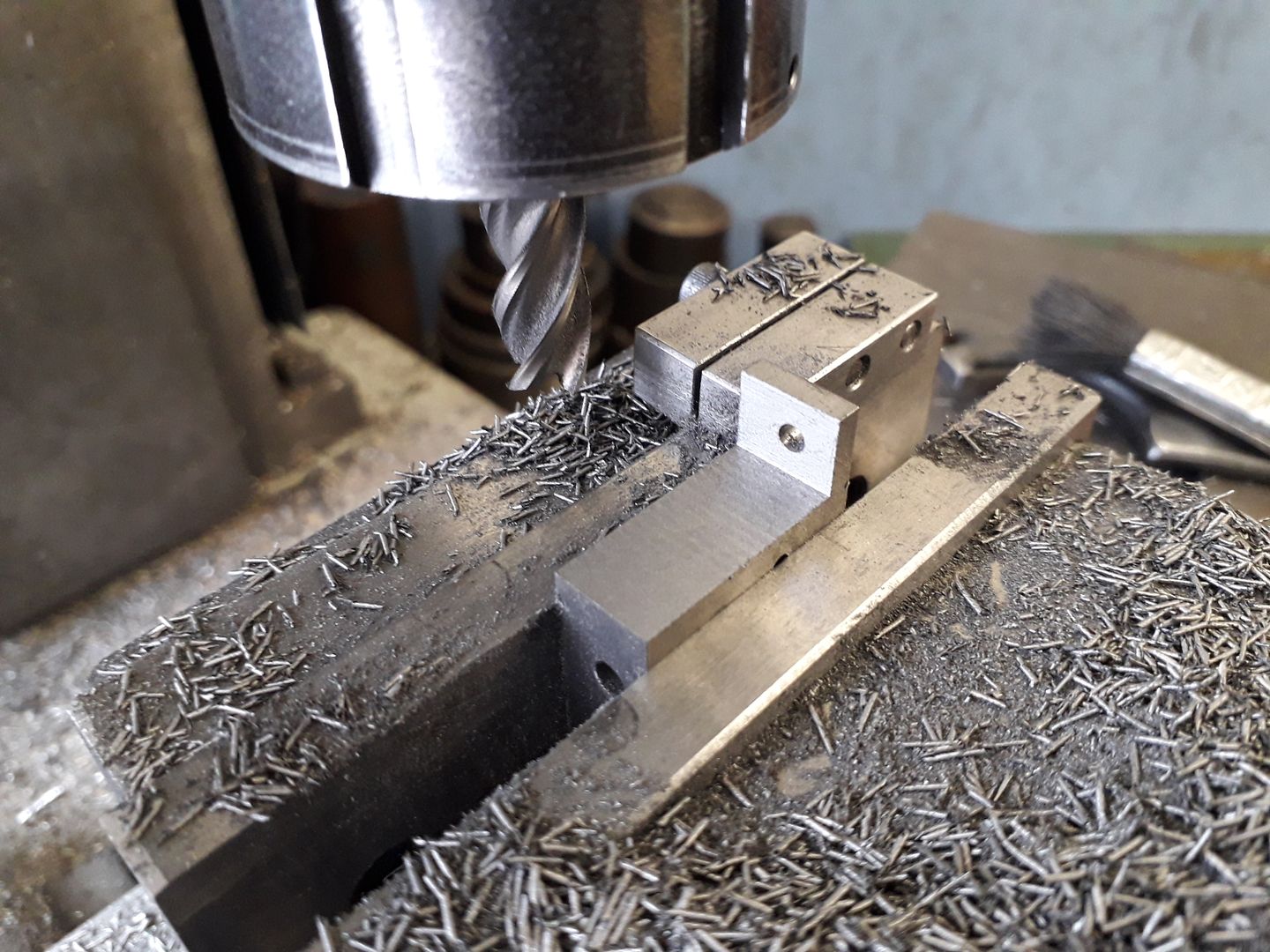

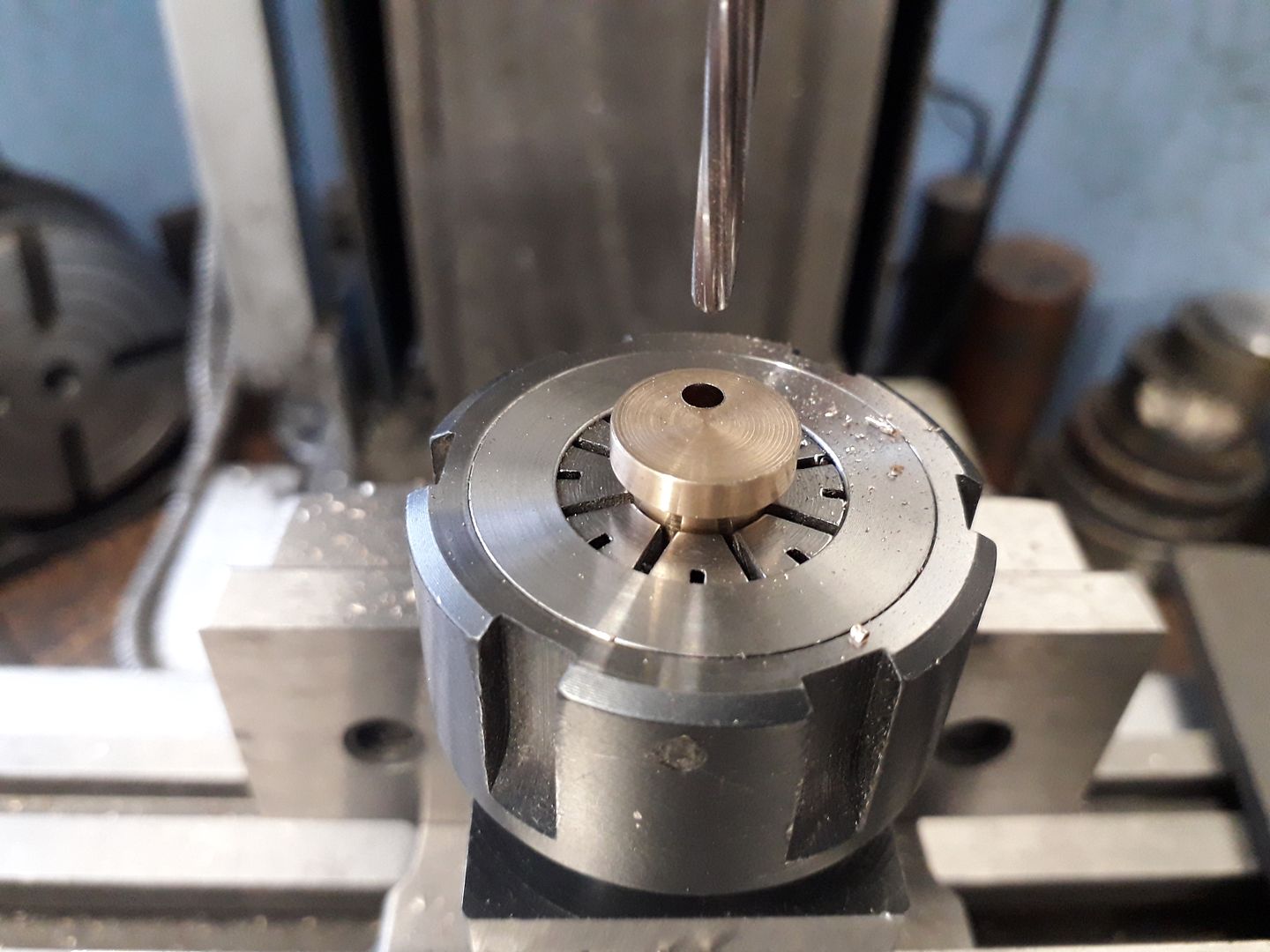

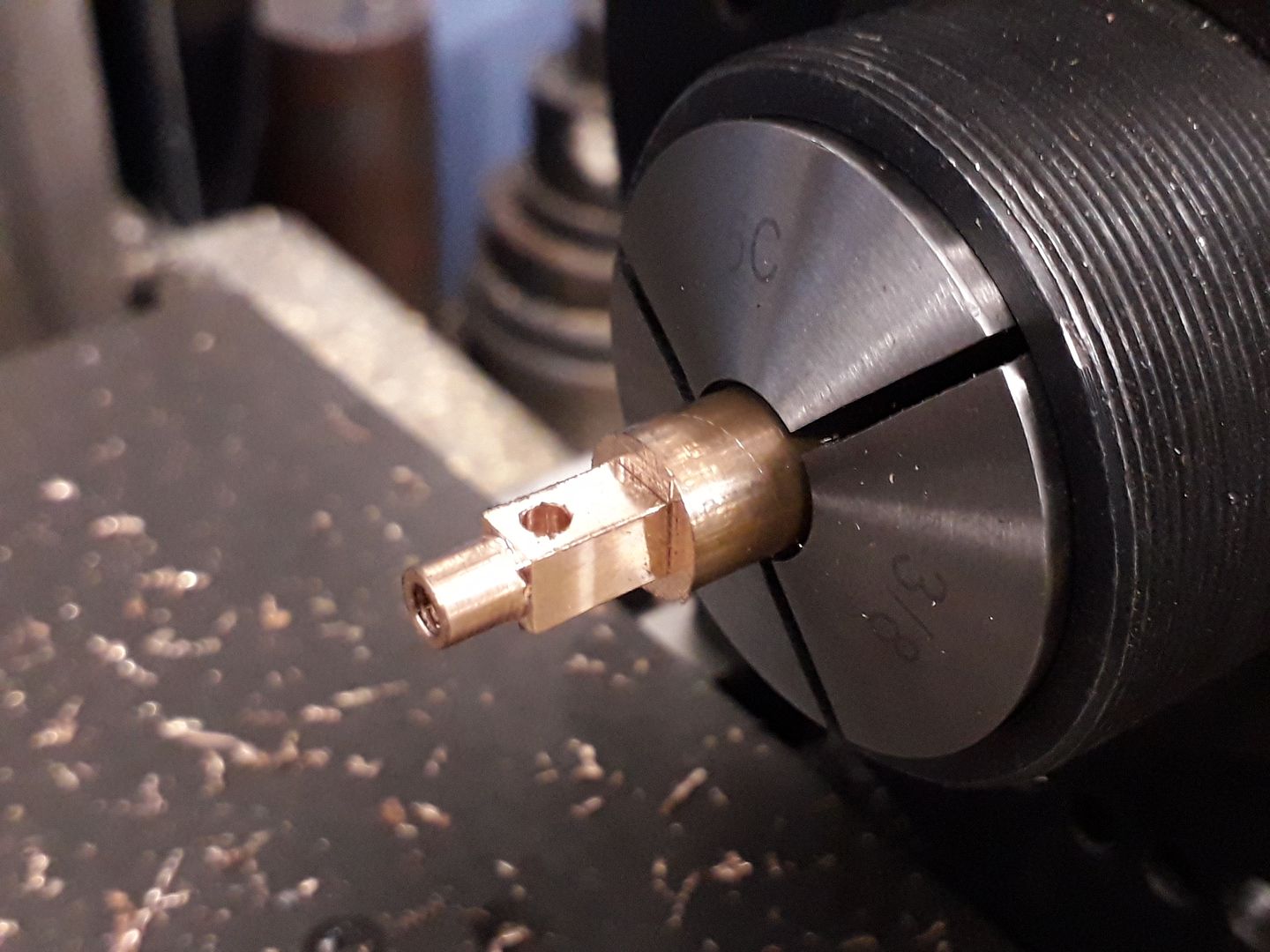

To mill the tapered sides slip the crankshaft material into the 5mm hole letting it rest on the vice jaws and the 2.5mm drill into the pin's hole but raise this up 2.75, you can see the black 2.8mm drill shank I used for this and then mill one side before repeating for the other though there is not so much to hold this time around so light cuts after sawing off most of the waste.

After rounding the corners to the final profile with a file the web can be Loctited to the crankshaft with 638 or 648 and set aside to dry. Then holding the shaft preferably in a collet a couple of cuts can be taken across the end of the web & shaft to bring them both to final size. deburr and then Loctite the pin into place.

Drawings to download

Bill of materials to Download

JasonB.

JasonB.