How I plan to make the spindle-

Cut a piece of 10mm EN8 to slightly over total length. Face and centre drill one end.

Hold the last 10mm of the unfaced end in centred 4-jaw with live centre at the other end.

Turn the plain shank at tail end of the spindle. I will make it a bit longer than the drawing as it has to be held in a collet later.

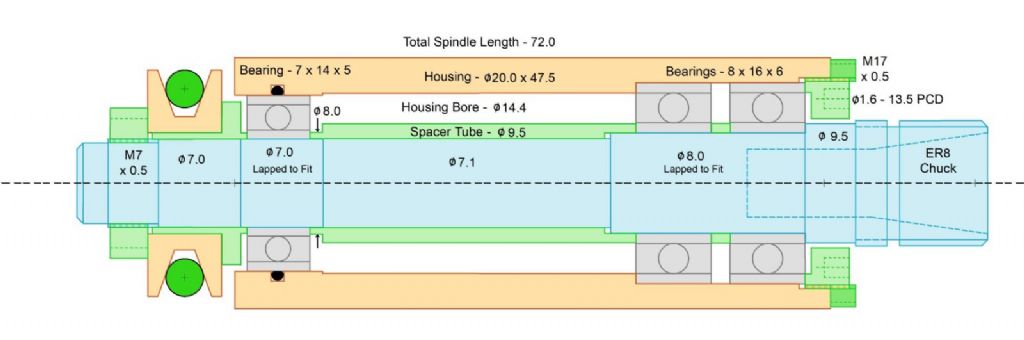

Turn the 7mm pulley section to 6.98 then the bearing journal to 7.01. Continue along the spindle, one diameter at a time (leaving the journals 0.01 oversize), until the 9.5mm section is done.

The idea is to leave as much meat and stiffness in the spindle as possible while turning. A fixed steady might help but I think I'll get away with it.

When the turning is done, single point the thread and do any chamfering. Then lap journals to suit bearings.

Remove from chuck, reverse and hold 9.5mm diameter in a collet. Then drill, bore, taper bore, thread etc. Basically complete the ER8 chuck.

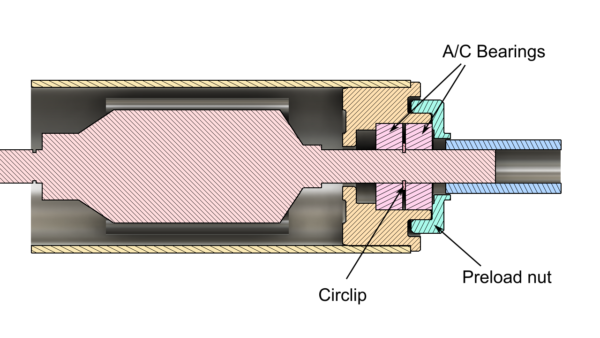

Before the next stage, you will have needed to make the spacers and rear lock nut assembly.

Assemble spindle, bearings, spacers nuts etc. and nip everything up.

Hold the tail end plain shank in a good collet or well centred 4-jaw. Support front bearings in a fixed steady and adjust so the 9.5mm diameter is as true as you can get.

Move clock to the collet taper bore and check run-out. Its only going to be as good as your 9.5mm collet during the last process.

If its good enough, your done! If not, take a light skim along the taper until it is.

This last idea was adapted from the Swindles Spindles book that started the thread.

I'll describe the housing machining later.

Steve

Steve Crow.

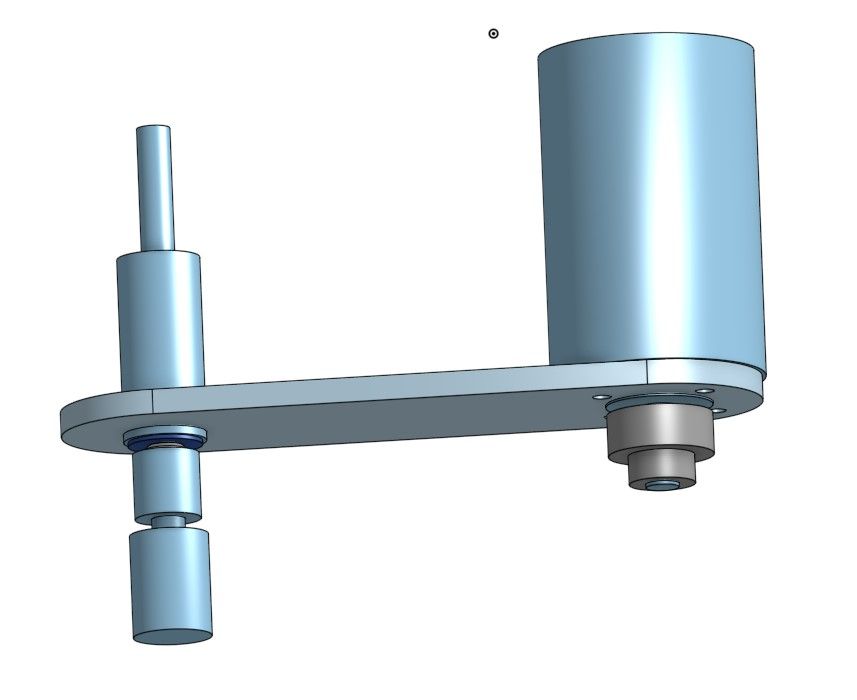

which runs in a 'cartridge' (some imagination is required to see the bottom part as an ER11 collet and above that a timing pulley). Attached to the bottom of the cartridge is a bracket that holds the motor (in my case a 200W Chinese thing). Again imagine the timing belt between the two,

which runs in a 'cartridge' (some imagination is required to see the bottom part as an ER11 collet and above that a timing pulley). Attached to the bottom of the cartridge is a bracket that holds the motor (in my case a 200W Chinese thing). Again imagine the timing belt between the two,