Gentlemen ! In the context of high temperature,ie 1150/1200c, been there ! There are 2 types that will work well and not cost the earth, 1 is ceramic fibre and 2 is K23 fire brick. The latter is very easy to work with or form. Intended for pottery kilns Etc it comes in numerous shapes and sizes and can be glued into position with air setting cement. How well does it work = I would run up the furnace to white heat for 20mins and be able to pick it up put it in the back of the car afterwards, the wall is a single brick thick, was made 30 years ago and still has the paint on the outside. The whole furnace weighed about 17Kg. When thinking about the cost of building DO NOT forget the cost of running, a cheaper lining will cost more fuel ! The traditional fire cement lined furnace would use 4 times as much gas as the K23lining did. I costed the bricks a few years ago at about £3 each and 20 would make a furnace to take an A6 crucible. In passing, the body was the casing of a Creda spin drier !

Ceramic fiber is good but needs to be treated carefully, it is fragile even if rigidizer is used.

For electric elements one can use old stock electric fire elements if you can find them to make a small heat treatment oven and for Fulmen and ally it will work but it is important to heat the metal as fast as possible so gas is better.

For smelting to prove the point I set 8 bricks on end in a circle (bit like stonehenge) and used a sievert 2943 (I think) burner in at a tangent and melted the brass to do a casting – you don’t need a furnace per se !

I’ll help if I can, Good Luck. Noel.

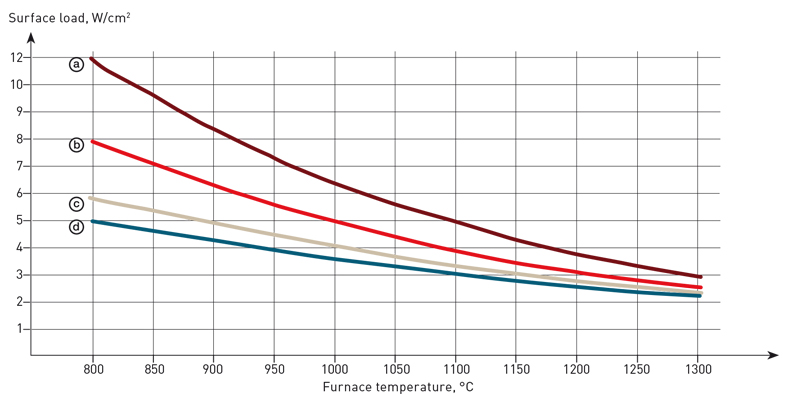

I’m not sure what is K23 fire brick. Here we have JM23 bricks. It might be a similar thing. JM23 works up to 1260ºC. There are available up to JM30 that work above 1500ºC. The higher the temperature, the higher the density and thermal conductivity.

Meanwhile I bought this calcium silicate board. It is interesting. Very light and it can be machined easily. The only thing I don’t like is that is covered in a very fine dust. I suppose if I’ll try to make a groove for resistor I’ll make a big mess. I got also a 1500ºC glue. It works very well with the silicate board. I think I’ll make a combination of bricks and silicate plate.

I was thinking a lot about what resistors to use. I would like to avoid mounting them in the wall. So ideally must be some self supporting type. I found some MoSi2 Heating Elements.

The nice thing is that only two holes are required. The active part the is the smaller diameter. But they came with serious issues. They have very large variation of resistance with temperature. They require low voltage at the beginning. And are expensive. Even on Aliexpress a 2kW one can jump above 200$.

Then there are SiC heaters. Again, very easy to mount. And are much cheaper and available locally in many shops. But they have ridiculously low resistance, I’ll need a transformer. And can’t be connected in series because the resistance is changing a lot during lifetime. I think the only advantage of SiC and MoSi2 is the much higher working temperature, up to 1800ºC

In the end I think I’ll just buy some 400W Ni80Cr20 ceramic elements. The cost is ridiculous, 1.5euro each!!! I suppose they will die quickly. I could rewind them with kanthal wire. Or simply buy more 🙂

After the initial enthusiasm I dropped the idea to write a PID control software. While it would be interesting realistically I just don’t have enough time. Instead I’ll order this PID controller. It has ramp & soak with multiple segments, just what I wanted. It can also drive a SSR with PWM with programmable period.

Sonic Escape.

Sonic Escape.